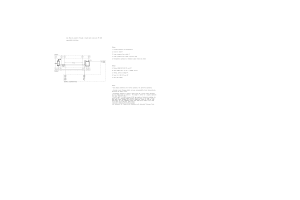

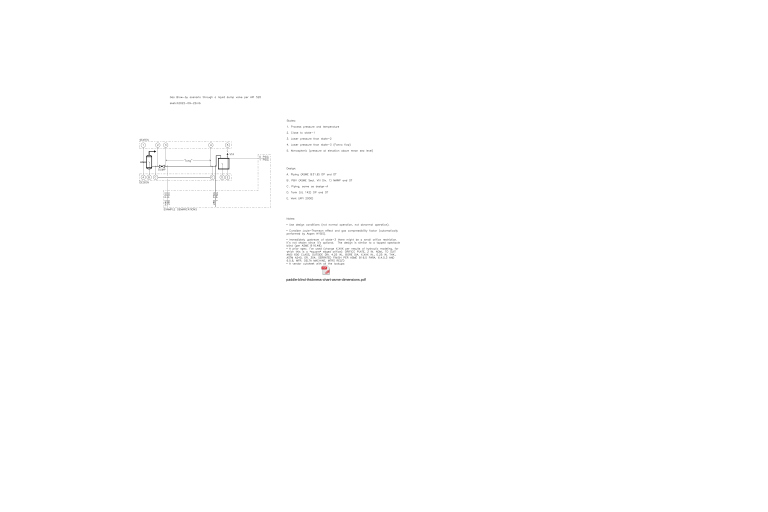

Gas Blow-by scenario through a liquid dump valve per API 520 sketch2022-09-22nrb States: 1. Process pressure and temperature 2. Close to state-1 3. Lower pressure than state-2 STATES 1 2 3 4. Lower pressure than state-3 (Fanno flow) 5 4 5. Atmospheric (pressure at elevation above mean sea level) VTA "long" 0 PSIG 1 PSIG Design: DUMP A. Piping (ASME B31.8) DP and DT A B C C D E B. PBV (ASME Sect. VIII Div. 1) MAWP and DT DESIGN 285 PSIG 1 PSIG 1440 PSIG 285 PSIG C. Piping, same as design-A D. Tank (UL 142) DP and DT E. Vent (API 2000) EXAMPLE DEMARCATIONS Notes: • Use design conditions (not normal operation, not abnormal operation). • Consider Joule-Thomson effect and gas compressibility factor (automatically performed by Aspen HYSIS). • Immediately upstream of state-3 there might be a small orifice restriction. It's not shown since it's optional. The design is similar to a tapped spectacle blind (per ASME B16.48). • A prior spec. I've used (change X.XXX per results of hydraulic modeling, for which this is a *square* edged orifice): ORIFICE PLATE, 2 IN. NOM., TO SUIT ANSI 600 CLASS, OUTSIDE DIA. 4.25 IN., BORE DIA. X.XXX IN., 0.25 IN. THK., ASTM A240, GR. 304, SERRATED FINISH PER ASME B16.5 PARA. 6.4.5.3 AND 6.5.6, MFR. DELTA MACHINE, MTRS REQ'D • A vendor cutsheet with all the lookups: paddle-blind-thickness-chart-asme-dimensions.pdf