Minimizing Building Heat Loss: Insulation & Passive Design

advertisement

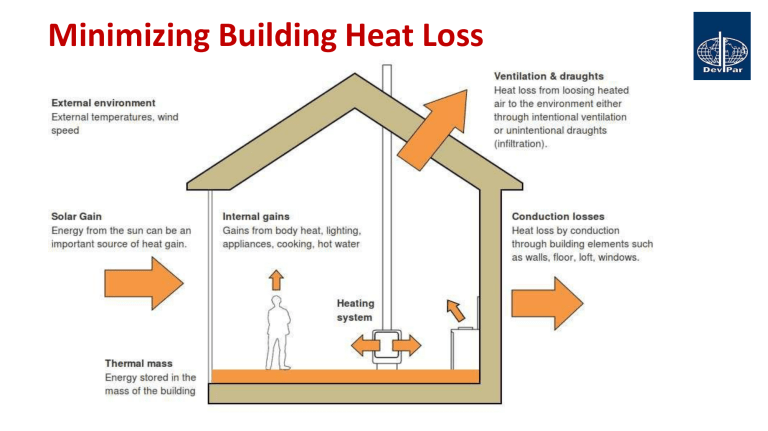

Minimizing Building Heat Loss Introduction • Today we introduce the concept of heat loss and how to prevent it, ways of increasing building efficiency • Heat loss mechanisms: 1. Conduction (heat flow on a molecular scale. Medium at rest or moving) 2. Convection (heat conveyed as internal thermal energy of mass that is displaced by mean or turbulent motion) 3. Radiation (heat transfer by electromagnetic waves such as infrared or visible light) Thermal radiation 1. The transmission of electromagnetic waves through the oven is also known as the microwave oven. 2. The heat energy emitted by the radiator. 3. The solar radiations. 4. The light energy radiated by incandescent lamps. 5. The emission of gamma rays. Conduction • Conduction is the movement of heat energy directly through solid materials from molecule to molecule. • Thermal Conductivity (k) is the term used to indicate the amount of heat that will pass through a unit of area of a material at a temperature difference of one degree. • The lower the “k” value, the better the insulation qualities of the material. Units; US: (Btu.in) / (h.ft2.oF), Metric: W / (m.oC) • Conductance (c) indicates the amount of heat that passes through a given thickness of material. • Conductance= thermal conductivity / thickness. Units; US: Btu / (h.ft2.oF) Metric: W/ (m2.oC) Determination of Thermal Conductivity Coefficient for Different Wall Systems (TS EN ISO 8990): Example Thermal Resistance (RSI for metric unit, R for US units) It is that property of a material that resist the flow of heat through the material. It is the reciprocal of conductance; R= 1/c Thermal Transmittance (U) It is the amount of heat that passes through all the materials in a system. It is the reciprocal of the total resistance; U= 1/Rt TABLE THERMAL PROPERTİES OF SOME MATERİALS (examples) Convection • While still air is a good insulator, moving air can carry heat from a warm surface to a cooler one. • A warmed fluid, such as air, will expand as it warms, becoming less dense and rising as a result, creating a fluid flow known as convection. • This is one of the principal modes of heat transfer through windows. It occurs between the air and the glass on the inside and outside surfaces, and, in double-glazing, in the gas trapped between the panes. • The rate of heat transfer in convection depends on three factors: • temperature difference (difference in temperature of the medium at the warmer and cooler points) • the rate of movement of the carrying medium in terms of kg/s or m3/s • the specific heat of the carrying medium in J/kg degC or J/m3 degC Radiation • Heat energy can be radiated, in the same manner as it is radiated from the sun to the earth. • The quantity of radiation is highly dependent on the temperature difference between the radiating body and its surroundings. • The amount of radiation also depends on the surface’s emissivity. • Most materials used in buildings have high emissivity of approximately 0.9, that is, they radiate 90% of the theoretical maximum for a given temperature. • Other surfaces can be produced that have low emissivity. • ‘Low-e’ coatings are now normally used inside double-glazing to cut radiated heat losses from the inner pane to the outer one across the air gap. • There are two basic types. ‘Hard coat’ uses a thin layer of tin oxide, giving an emissivity of 0.15–0.2. ‘Soft coat’ uses very thin layers of optically transparent silver sandwiched between layers of metal oxide and gives an emissivity of 0.05 or better. Strategies of climate control 6 Steps for Calculating Heat Loss 1. Determine Design Temperature 2. Calculate Surface Area 3. Calculate R-Value and U-Value 4. Calculate Surface Heat Loss 5. Calculate Air Infiltration Heat Loss 6. Calculate Total Heat Loss What is Thermal Insulation? • Thermal insulation is the reduction of heat transfer between objects in thermal contact or in range of radiative influence. • In simple terms, we can say thermal insulation of buildings means creating a shield around your home to maintain your rooms temperature according to your requirement. • Thermal insulation by adding material mean adding thermal insulators within walls, roofs or floor can make your house thermally insulated. • There are different type of material available in the market to add to buildings and make them thermally insulated. How can heat loss be reduced through insulation? 1. Windows and doors 2. Cavity wall insulation 3. Solid wall insulation 4. Floor insulation 5. Roof and loft insulation 6. Draught-proofing 7. Insulating tanks and radiators Doors and windows Types of Thermal Insulation Materials • Fiberglass • Mineral wool • Cellulose • Polyurethane foam Fiberglass • Fiber glass insulating material made up of fine glass fibers. • A reinforced plastic material composed of glass fibers embedded in a resin matrix. • Because of how it is made, by effectively weaving fine strands of glass into an insulation material, fiberglass is able to minimize heat transfer. • Advantages • It can be easily moulded into any shape and has mechanical strength that is so strong and stiff. It lasts for long time. No maintenance required . It is anti-magnetic, fire resistant, good electrical Insulator, fireproof. • Disadvantage • It needs to be re-gel coated every 5 years. It may not work if it is wet or damp during installation. • Installing it requires safety precautions. Examples of Installation Mineral wool • Mineral wool is a fibrous material drawn from molten mineral or rock mineral. • Mineral wool is a general name for fiber materials that are formed by spinning or drawing molten minerals (or "synthetic minerals" such as slag and ceramics) • Advantages • It is installed as sheet into walls. • It is fire resistant, Noise resistant. • Disadvantage • it is very expensive material. Examples of Installation Cellulose • Cellulose insulation is plant fiber used in wall and roof cavities to insulate, draught proof and reduce free noise. It is often made by hammer milling waste newspaper. The newspaper is treated with chemicals, such as boric acid, to retard the spread of fire. • Four major types of loose-fill cellulose products have been developed: dry cellulose, spray applied cellulose, stabilized cellulose, and low dust cellulose. • Advantages • Cellulose insulation is treated with boric acid which makes them fire resistant and makes them unpalatable. • Have long term thermal insulating properties. • Are cheaper than fiberglass. Normally health risk is less. • Disadvantages • Creates enormous amount of dust when installed. • Cellulose insulation absorbs moisture easily and decreases the long-term insulating properties . Examples of Installation Polyurethane foam • Polyurethane foam insulation is made up by reacting polyols and diisocyanates, both products derived from crude oil. • These foam insulation are spread on walls and roofs and then it solidifies to make an insulating material. • It has good thermal insulating properties, low moisturevapor permeability, high resistance to water absorption, relatively high mechanical strength and low density. • Reduces HVAC capacity requirements and have stable insulation over time. • Reduces air and moisture Infiltration resulting in a more consistent temperature. Examples of Installation POLYSTYRENE (Styrofoam) • Styrofoam is a good insulator because the plastic foam contains billions of trapped gas bubbles. • Gases hinder heat conduction because their molecules are very far apart making it difficult for other molecules to collide with them. • Insulation foam – are used for a variety of applications because of its excellent set of properties including good thermal insulation, good damping properties and being extremely light weight. • From being used as building materials to white foam packaging, expanded polystyrene has a wide range of end use applications. • foam is durable, strong as well as lightweight and can be used as insulated panel systems for facades, walls, roofs and floors in buildings Examples of Installation Other options for heat Insulation of roofs • False ceilings with an air gap can be built internally. • Water sprinkling on roof . • White-washing the roof before summer. • Applying reflecting materials on the roof. Heat insulation of exposed walls • Construct wall of sufficient thickness. A brick wall of 23 cm thickness is adequate. • Thermal performance can further be improved by providing cavity walls (gap between two walls) and hollow bricks. • Constructing a wall with suitable lightweight materials. • Applying a light colour on the external surface. What is Passive Design strategy? • It is based upon climate considerations • Attempts to control comfort (heating and cooling) without consuming fuels • Uses the orientation of the building to control heat gain and heat • Uses the shape of the building (plan, section) to control air flow • Uses materials to control heat • Maximizes use of free solar energy for heating and lighting • Maximizes use of free ventilation for cooling • Uses shade (natural or architectural) to control heat gain Differentiating Passive vs. Active Design Passive design results when • building is created and simply works “on its own” • The plan, section, materials selections and siting create a positive energy flow through the building and “save energy”. Active design uses equipment to modify the state of the building, create energy and comfort; ie. Fans, pumps, etc. • Passive buildings require active users (to open and shut windows and blinds...) What is the Solar Geometry ? Why Solar Geometry for passive design? Advantage of studying Solar Geometry for passive design Solar geometry works for us because the sun is naturally HIGH in the summer, making it easy to block the sun with shading devices. And it is naturally LOW in Winter, allowing the sun to penetrate below our shading devices and enter the building - with FREE SOLAR HEAT. This space is using classic Direct Gain for heat. The sun shines through the windows. Strikes the exposed concrete floor. Heat is absorbed into the concrete as it is an excellent thermal mass. When the space cools off, the heat is radiated into the space making it warm.