0506

SOLUTIONS MANUAL

to

INTRODUCTION TO

MICROELECTRONIC

FABRICATION

SECOND EDITION

by

RICHARD C. JAEGER

-1-

© 2002 Prentice Hall

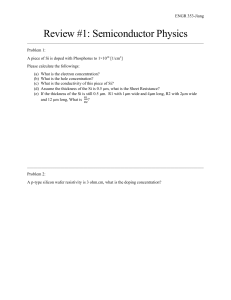

CHAPTER 1

1.1

Answering machine

Alarm clock

Automatic door

Automatic lights

ATM

Automobile:

Engine controller

Temp. control

ABS

Electronic dash

Automotive tune-up equip.

Bar code scanner

Battery charger

Calculator

Camcorder

Carbon monoxide detector

Cash register

Cellular phone

Copier

Cordless phone

Depth finder

Digital watch

Digital scale

Digital thermometer

Digital Thermostat

Electric guitar

Electronic door bell

Electronic gas pump

Exercise machine

Fax machine

Fish finder

Garage door opener

GPS

Hearing aid

Inkjet & Laser Printers

Light dimmer

Musical greeting cards

Keyboard synthesizer

Keyless entry system

Laboratory instruments

Model airplanes

Microwave oven

Musical tuner

Pagers

Personal computer

Personal planner/organizer

Radar detector

Radio

Satellite receiver/decoder

Security systems

Smoke detector

Stereo system

Amplifier

CD player

Receiver

Tape player

Stud sensor

Telephone

Traffic light controller

TV & remote control

Variable speed appliances

Blender

Drill

Mixer

Food processor

Fan

Vending machines

Video games

Workstations

Electromechanical Appliances*

Air conditioning

Clothes washer

Clothes dryer

Dish washer

Electrical timer

Thermostat

Iron

Oven

Refrigerator

Stove

Toaster

Vacuum cleaner

*These appliances are historically based only

upon on-off (bang-bang) control. However,

many of the high-end versions of these

appliances have now added sophisticated

electronic control.

-2-

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

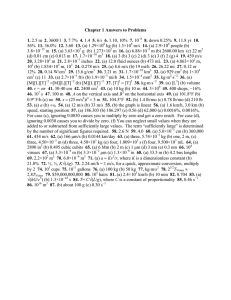

1.2

(a) A = π d2/4

d (mm)

A

(mm2)

25

49

1

50

196

0

75

442

0

100

785

0

125

1230

0

150

1770

0

(b) n = π (450)2/(4)(12) = 159043

1.3

200

3140

0

300

7070

0

450

159000

(b) n = π (450)2/(4)(252) = 254

(a) n = π (300)2/(4)(202) = 177

(b) n = 148

0.1977( 2020−1960)

13

1.4

B = 19.97 x 10

1.5

N = 1 0 2 7 x 1 00.1505( 2020−1970) = 3 4.4 x 1 09 tr a n s is tor

s

1.6

= 1.45 x 10 bits

lo g B2

B1

0.1977( Y −1960)

B = 1 9.9 7 x 1 0

Y2 − Y1 =

0.1 9 7 7

lo g2

( ) = 1.5 2 y e a r s b Y − Y = lo g1

( 0) = 5.0 6 y e a r s

(a ) Y2 − Y1 =

( ) 2 1

0.1 9 7 7

0.1 9 7 7

1.7

-3-

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

lo g N2

N1

0.1505( Y−1970)

N = 1027 x 10

Y2 − Y1 =

0.1505

lo g2

( ) = 2.00 years b Y − Y = lo g10

( ) = 6.65 years

(a ) Y2 − Y1 =

( ) 2 1

0.1505

0.1505

-4-

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

−0.06079 ( 2020 −1970 )

1.8

Using 5 Å for the

diameter of an atom, this feature size is only 15 atoms wide. However, this narrow

width can probably can be achieved.

1.9

(3 x 108 tubes)(0.5 W/tube) = 150 MW!

1.10

(a) L = (25mm)(18mm/0.5mm) = 0.90 m !

F = 8.214 x 10

µm = 7.50 x 10

−3

µm = 75 Å.

IRMS = (150 MW)/(220 VRMS) = 685 kA

(b) L = (25mm)(18mm/0.2mm) = 2.25 m !!

1.11

Two Possibilities

276 Dice

1.12

277 Dice

(a) From Fig. 1.1b , a 75 mm wafer has 130 total dice. The cost per good die is $400/

(0.35 x 130) = $8.79 for each good die. (b) The 150 mm wafer has a total of 600 dice

yielding a cost of $400/(0.35 x 600) = $1.90 per good die.

1.13

-5-

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

(a) N = 5000

2

25 (12 ) = 1 million transistors

(b) N = 5000

2

25 (0.25 2 )= 16 million transistors

(c) N = 5000

2

2

25 (0.1

) = 100

million transistors

-6-

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

1.14

Thermal oxidation

n+ diffusion mask

Oxide etch

n+ diffusion and oxidation

Contact opening mask

Oxide etch

Metal deposition

Metal etch mask

Metallization etch

Mask 1

Mask 2

Mask 3

1.15

p

n+

E

C

n+

B

-7-

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

CHAPTER 2

2.1

(a) If Y is the yield at each step, then Y25 = 0.3 or Y = 95.3 %.

(b) Y25 = 0.7 or Y = 98.6 %.

2.2

(a) Three of many possibilities

(b) Three of many possibilities

2.3

SiO2

SiO2

(a)

3 µm

(b)

-8-

3 µm

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

2.4

1) Negative resist – n+ mask

2) Negative resist – Contact mask

3) Positive resist – Metallization mask

n+ Mask

2.5

Contact

Mask

Metal

Mask

1 λ 1 193n m

=

= 0.536

2 F 2 180n m

(a )

NA=

(b )

DF = 0.6

(a )

NA =

2

λ

4F 2

4(180n m)

=

0.6

= 0.6

= 0.403 µm

2

NA

λ

193n m

2.6

1λ

2F

1=

1

λ

2 0.25µm

λ = 0.5 µm = 500 nm

λ

0.5µm

= 0.6

= 0.3 µm

2

NA

12

1λ

1

λ

NA =

0.5 =

λ = 250 nm

2F

2 0.25µm

DF = 0.6

(b )

DF = 0.6

2.7

Fmin ≅

λ

0.25µm

= 0.6

= 0.6 µm

2

NA

0.5 2

λ 193nm

=

= 96.5 nm or Fm in ≅ 0.1 µm

2

2

-9-

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

2.8

Fmin ≅

λ 13nm

=

= 6.5 nm or Fm in ≅ 0.0065 µm

2

2

- 10 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

CHAPTER 3

3.1

Using Fig. 3.6 with 100 nm = 0.1 µ m: (a) Wet O2 yields 0.15 hours or approximately

9 minutes. (b) Dry O2 yields 2.3 hours. Nine minutes is too short for good control, so

the dry oxidation cycle would be preferred.

3.2

Using Figure 3.6: The first 0.4 µ m takes 0.45 hours or 27 minutes. The second 0.4

µ m takes (1.5-0.45) hours or 63 minutes. The third 0.4 µ m takes (3.2-1.5) hours or

102 minutes.

3.3

d Xo D No

1

X o + D d Xo = D No t

=

or

dt M X + D

ks

M

o

ks

Integrating and rearranging where α is an integration constant yields:

M

+ X o M + Mα

t = X 2o

2DN o

No k s DN o

B=

Assuming τ = 0 at Xo = Xi:

2D No

M

A=

2D

ks

τ=

Mα

D No

X 2i

Xi

+

=τ

B ( B/ A )

Problems 3.4 through 3.10 evaluate the following equations with spreadsheets.

4B

X o = 0.5 A 1 + 2 (t + τ) − 1

A

2

τ = X i B + X i (B A )

2

t = Xo B + X o (B A ) − τ

3.4

T

1150

1150

1150

3.5

B/A

5.322

5.322

5.322

<100> Silicon - Wet Oxygen

B

Xi

tau

0.667

0

0.000

0.667

1

1.688

0.667

2

6.375

Xo

1

2

3

t (hrs)

1.688

4.687

6.687

(a)

<100> Silicon - Wet Oxygen

- 11 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

T

850

B/A

6.116E-02

B

1.219E-01

Xi

0

tau

0

Xo

0.01

t (hrs)

1.643E-01

0.164 hours represents only 9.86 minutes and is too short a time for good control.

- 12 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

3.5

(b)

T

1000

3.6

B/A

4.478E-02

<100> Silicon - Dry Oxygen

B

Xi

tau

1.042E-02

0.025 6.182E-01

Can't grow 0.01 um (< 0.025 um)

Xo

0.01

t (hrs)

---

(a) Slightly over six hours

(b)

T

1150

3.7

B/A

5.322

<100> Silicon - Wet Oxygen

B

Xi

tau

0.667

0.000

0.000

(a) Approximately 3 hours in wet oxygen

Xo

2.000

t (hrs)

6.375

(b) Over 70 hours in dry oxygen

(c)

T

1050

T

1050

3.8

<100> Silicon - Wet Oxygen

B

Xi

tau

4.123E-01

0

0

<100> Silicon - Dry Oxygen

B/A

B

Xi

tau

8.920E-02

1.592E-02

0.025

3.195E-01

B/A

1.504E+00

Xo

1

t (hrs)

3.090

Xo

1

t (hrs)

73.71

(a)

<100> Silicon - Dry Oxygen

T

B/A

B

A

Xi

tau

t

Xo (µ m)

1100

0.169

0.024

0.140

0.025

- 13 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

0.174

0.500

0.074

<100> Silicon - Wet Oxygen

T

B/A

B

A

Xi

tau

t

Xo (µ m)

1100

2.895

0.529

0.183

0.074

0.036

2.000

0.950

<100> Silicon - Dry Oxygen

T

B/A

B

A

Xi

tau

t

Xo (µ m)

1100

0.169

0.024

0.140

0.950

43.931

- 14 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

0.500

0.956

(b)

<111> Silicon - Dry Oxygen

T

B/A

B

A

Xi

tau

t

Xo (µ m)

1100

0.284

0.024

0.083

0.025

0.115

0.500

0.086

<111> Silicon - Wet Oxygen

T

B/A

B

A

Xi

tau

- 15 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

t

Xo (µ m)

1100

4.865

0.529

0.109

- 16 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

3.9

(a)

T

1000

B/A

4.478E-02

B

1.042E-02

T

1100

B/A

2.895

B

0.529

<100> Silicon - Dry Oxygen

A

0.233

<100> Silicon - Wet Oxygen

A

0.183

Xi

0.025

tau

0.618

t

1.000

Xo (µ m)

0.058

Xi

0.058

tau

0.026

t

5.000

Xo (µ m)

1.542

(b) From Fig. 3.6, 1 hr at 1000 oC in dry oxygen produces approximately 0.053 µ m

oxide, and 5 hours at 1100 oC in wet oxygen produces a 1.5 µ m thick oxide. The

0.053-µ m oxide would grow in less than 0.1 hour in wet oxygen at 1100 oC and has

a negligible effect on the wet oxide growth.

3.10

(a)

T

1100

B/A

0.284

B

0.024

T

1100

B/A

4.865

B

0.529

<111> Silicon - Dry Oxygen

A

0.083

<111> Silicon - Wet Oxygen

A

0.109

Xi

0.025

tau

0.115

t

1.000

Xo (µ m)

0.126

Xi

0.126

tau

0.056

t

5.000

Xo (µ m)

1.582

(b) From Fig. 3.7, 1 hr at 1100 oC in dry oxygen produces approximately 0.12-µ m

oxide, and 5 hours at 1100 oC in wet oxygen produces a 1.5 µ m thick oxide. The

0.12-µ m oxide would grow in less than 0.1 hour in wet oxygen at 1100 oC and has a

negligible effect on the wet oxide growth.

3.11

To make a numeric calculation, we must choose a temperature – say 1100 oC. Using

the values from Table 3.1 for wet oxygen at 1100 oC on <100> silicon yields (B/A) =

2.895 µ m/hr and B = 0.529 µ m2/hr. In the oxidized region, the initial oxide Xi =

2

0.2 µ m which gives τ = X i B + X i /(B/ A ) = 0.144 hrs. The time required to reach

a thickness of 0.5 µ m = 0.52/0.53 + 0.5/2.9 - 0.144 = 0.50 hrs. In the unoxidized

region, 0.5 hours oxidation yields

[

2

]

X o = 0.5 (0.183 ) 1 + 4 (0.53 )(0.5 )/(0.183 ) −1 = 0.43 µm

This result can also be obtained using Fig. 3.6 in a manner similar to the solution of

Problem 3.13.

20 nm

50 nm

Original

43 nm

Final

- 17 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

Note that this result is almost independent of the temperature chosen. The growth in

the unoxidized area ranges from 41 nm at 1000 oC to 44 nm at 1200 oC.

3.12

To make a numeric calculation, we must choose a temperature – say 1100 oC. Using

the values from Table 3.1 for wet oxygen at 1100 oC on <100> silicon yields (B/A) =

2.895 µ m/hr, B = 0.529 µ m2/hr and A = 0.183 µ m. In the unoxidized region, we

2

desire Xo = 1 µ m which gives t = Xo B + Xo /(B/ A ) = 2.24 hrs. In the oxidized

2

region, the initial oxide Xi = 1 µ m which gives τ = X i B + X i /(B/ A ) = 2.24 hrs.

The final thickness in the oxidized region is

2.895

X o = 0.5 (0.183µm ) 1 + 4

(4.472 ) − 1 = 1.45 µm

0.183

1 µm

1.45 µm

1 µm

Original

Final

Note that this result is almost independent of the temperature chosen. The total

growth in the oxidized area ranges from 1.49 µ m at 1000 oC to 1.43 µ m at 1200 oC.

The 1-µ m region will appear carnation pink in color, and the 1.45-µ m region will

appear violet.

3.13

Using Fig. 3.6: At 1100 oC, 1.4 µ m of oxide could be grown in 4 hours. However,

the wafer has 0.4 µ m oxide already present and appears to have already been in the

furnace for 0.45 hours. Thus, 3.55 hours will be required to grow the additional 1

µ m of oxide. The oxide will appear to be orange in color.

T

1100

B/A

2.895

(100) Silicon - Wet Oxygen

B

Xi

0.529

0.400

tau

0.441

Xo

1.400

t (hrs)

3.749

3.14

Using Figure 3.10: A four-hour boron diffusion at 1150 oC requires 0.07 µ m of

oxide. A one-hour phosphorus diffusion at 1050 oC requires 0.4 µ m SiO2.

3.15

Using Figure 3.10: A 15-hour boron diffusion at 1150 oC requires a minimum of

approximately 0.15 µ m of oxide as a barrier layer.

- 18 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

3.16

Using Figure 3.10: A 20-hour phosphorus diffusion at 1200 oC requires a minimum of

3 µ m of oxide as a barrier layer.

3.17

Using Table 3.2: The 1-µ m thick oxide region will appear carnation pink in color.

The 2-µ m thick oxide region will also appear carnation pink in color.

3.18

2Xox = kλ /n = 0.57k/1.46 = 0.39k µ m yielding 0.39, 0.78, 1.17 and 1.56 µ m.

3.19

Computer program – Implement oxidation equations.

3.20

Computer program – Implement oxidation equations.

- 19 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

3.21(a) TITLE

INITIALIZE

DIFFUSION

DIFFUSION

DIFFUSION

PRINT

PLOT

STOP

PROBLEM 3.21

<100> SILICON, BORON CONCENTRATION=1E15

THICKNESS=5.0 XDX=0 DX=0.02 SPACE=200

TEMP=1100 TIME=30 DRY02

TEMP=1100 TIME=120 WET02

TEMP=1100 TIME=30 DRY02

LAYERS

CHEMICAL NET LP.PLOT

(b) Change the second statement:

INITIALIZE

<100> SILICON, ARSENIC CONCENTRATION=1E15

For (a) and (b), XO = 0.92 µ m. Problem 3.8 yielded 0.96 µ m. Boron is slightly

depleted at the silicon surface in (a) and arsenic pile-up is exhibited at the surface in

(b).

3.22

TITLE

INITIALIZE

DIFFUSION

DIFFUSION

DIFFUSION

PRINT

PLOT

STOP

PROBLEM 3.22

<111> SILICON, BORON CONCENTRATION=3E15

THICKNESS=5.0 XDX=0 DX=0.02 SPACE=200

TEMP=1100 TIME=30 DRY02

TEMP=1100 TIME=120 WET02

TEMP=1100 TIME=30 DRY02

LAYERS

CHEMICAL NET LP.PLOT

XO = 0.96 µ m. Boron is slightly depleted at the silicon surface. Problem 3.8 yielded

0.99 µ m.

3.23

TITLE

INITIALIZE

DIFFUSION

PRINT

PLOT

STOP

PROBLEM 3.23

<100> SILICON, BORON CONCENTRATION=2.7E15

THICKNESS=5.0 XDX=0 DX=0.02 SPACE=200

TEMP=1150 TIME=408.7 WET02

LAYERS

CHEMICAL BORON LP.PLOT

The result is XO = 2.0 µ m. Boron is slightly depleted at the silicon surface and

approximately uniform in the oxide. Problem 3.6 yielded 2.0 µ m in 6.375 hours

(382.4 min). The simulation requires more time to reach 2 µ m. SUPREM yields a

- 20 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

1.93-µ m oxide in 382 min. The oxidation coefficients are slightly different in

SUPREM.

For phosphorus, change the second statement to:

INITIALIZE

<100> SILICON, PHOSPHORUS CONCENTRATION=2.7E15

The result is unchanged: XO = 2.0 µ m. The phosphous concentration in the oxide is

much lower than for the boron doped substrate.

3.24

TITLE

INITIALIZE

DIFFUSION

PRINT

PLOT

STOP

PROBLEM 3.24

<100> SILICON, BORON CONCENTRATION=5E15

THICKNESS=5.0 XDX=0 DX=0.02 SPACE=200

TEMP=1050 TIME=197.2 WET02

LAYERS

CHEMICAL BORON LP.PLOT

XO = 1.0 µ m.

For dry oxidation:

DIFFUSION

TEMP=1050 TIME=4419 DRY02

For phosphorus, change the second statement to:

3.25

INITIALIZE

<100> SILICON, PHOSPHORUS CONCENTRATION=5E15

TITLE

INITIALIZE

PROBLEM 3.25 Region 1

<100> SILICON, THICKNESS=5.0 XDX=0 DX=0.02

SPACE=200

TEMP=1100 TIME=141.5 WET02

LAYERS

CHEMICAL NET LP.PLOT

DIFFUSION

PRINT

PLOT

STOP

XOX = 1.0 µ m.

TITLE

INITIALIZE

DIFFUSION

DIFFUSION

PRINT

PLOT

STOP

PROBLEM 3.25 Region 2

<100> SILICON, THICKNESS=5.0 XDX=0 DX=0.02

SPACE=200

TEMP=1100 TIME=141.5 WET02

TEMP=1100 TIME=141.5 WET02

LAYERS

CHEMICAL NET LP.PLOT

XO = 1.44 µ m.

- 21 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

If the oxidation times are changed to 134.2 min., the oxide thicknesses are 0.97 µ m

and 1.40 µ m.

- 22 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

CHAPTER 4

xj 2

where D t= 10-8 cm2

(a) 10 = 5x10 exp −

2 D t

15

4.1

18

(

)

x j = 2.92 2 Dt = 5.8 µm

1015

−1

x

=

2

D

t

erfc

(b) j

18

5 x10

(

)

and

x= 5.3 µm

j

(c) Using Fig. 4.16 (b) with a surface concentration of 5 x 1018/cm3 and a background

concentration of 1015/cm3 yields Rs xj = 270 ohm-µ m. Dividing by the junction depth

of 5.8 µ m yields Rs = 47 ohms/. For the erfc profile, use Fig. 4.16(a) yielding 320

ohm-µ m and 60 ohms/ with xj = 5.3 µ m.

10 20

10 19

10 18

10 17

10 16

10 15

10 14

0

1

2

3

4

DistanceFromSurface(um

)

5

6

7

8

(d)

4.2

Using Fig. 3.10: (a) approximately 0.05 µ m (b) 1 µ m

4.3

(a) Using Fig. 4.8, a 1 ohm-cm n-type wafer has a background concentration of 4.0 x

[

2

]

1015 /cm3. So: 5 x1018 exp −(x j / 2 Dt ) = 4.0 x 1015. Solving for Dt with xj = 4 x

- 23 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

10-4 cm yields Dt = 5.61 x 10-9 cm2. 1100oC = 1373K, and D = 10.5 exp (-3.69/kT)

= 2.99 x 10-13 cm2/sec yielding t = 1.88 x 104 sec or 5.21 hours (313 min.).

(b) Using Fig. 4.16(c) with a surface concentration of 5 x 1018/cm3 and a background

concentration of 4.0 x 1015/cm3 yields Rs xj = 330 ohm-µ m or Rs = 83 ohms/❏ for xj

= 4 µ m.

18

−9

14

2

(c) Q = N o πDt = 5x10 π(5.61x10 ) = 6.64 x 10 / cm

(d) Assume a solid-solubility limited constant source predeposition with Q =

2No Dt / π . Try T = 1000 oC. No = 1 x 1021/cm3 and D = 10.5 exp (-3.69/8.617 x

10-5 x 1273) = 2.58 x 10-14. Solving for Dt yields Dt = 3.46 x 10-13 and t = 13.4 sec

which is a too short to control. Try T = 900 oC. No = 5.5 x 1020/cm3 and D = 1.47 x

10-15. Solving for t yields 13.0 minutes which is short but probably usable.

4.4

(a) An 1 ohm-cm n-type wafer has a doping NB = 4 x 1015/cm3 from Fig. 4.8. For the

boron profile, N(x) = 5 x 1018 exp -(x2/4Dt). Setting N(4µ m) = NB yields 2 Dt =

1.5 x 10-4 cm. For phosphorus at 950 oC, Ns = 7 x 1020/cm3, and D = 6.53 x 10-15

cm2/sec. Using t = 1800 sec yields 2 Dt = 6.86 x 10-6 cm. The junction occurs for:

4x1015+7x1020erfc (xj/6.86x10-6) = 5x1018exp [-(xj/1.5x10-4)2]

This equation can be solved approximately by realizing that the boron profile is

almost constant near the surface. Thus, 7 x 1020 erfc (xj/6.86 x 10-6) ≈ 5 x 1018.

Solving for xj yields a junction depth of 0.154 µ m. Checking the boron profile at

this depth yields N = 4.95 x 1018 /cm3 so that the approximation is justified.

(b) Working iteratively with Fig. 4.21, one finds that the phosphorus and boron

profiles each have a value of approximately 4 x 1018/cm3 at a depth of 0.75 µ m

which is the junction depth.

(c) Using Fig. 4.12, we find that the 30 min curve reaches 5 x 1018/cm3 at a depth of

slightly over 0.7 µ m.

(d) From Prob. 4.3, Dt = 1.14 x 10-12 cm2 for the predeposition step, and Dt = 5.61 x

10-9 cm2 for the drive-in step. The total is Dt = 5.61 x 10-9 cm2. The Dt product for

the phosphorus step is 1.18 x 10-11 cm2, which is much smaller than the total Dt

product for the boron step. Thus, the assumption is justified.

4.5

(a) From Fig. 4.8, a 5 ohm-cm n-type wafer corresponds to NB = 9 x 1014/cm3, and Rs

xj = 7500 ohm-µ m. A p-type Gaussian diffusion gives NS = 5 x 1016/cm3. So 9 x

1014 = 5 x 1016 exp -(7.5 x 10-4/ 2 Dt ). Solving for Dt yields = 3.5 x 10-8 cm2.

Using Fig. 4.5 to find an appropriate temperature: at 1100 oC, D is of the order of

10-13cm2/sec which gives a time over 25 hours - so we will try 1150 oC. For Do = 10.5

- 24 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

and EA = 3.69 eV, D = 9.05 x 10-13cm2/sec at T = 1423 K, yielding t = 3.87 x 104 sec =

10.7 hours. The diffusion schedule would be 1150 oC for 10.7 hours. A similar

calculation using 1100 oC yields t = 32.1 hours which is a little long.

(b) As found above, NS = 5 x 1016/cm3

(c) Q = NS πDt = 1.66 x 1013/cm2

(d) Using 900 oC for 15 minutes (about as short as can be controlled), yields D = 1.49

x 10-15 cm2/sec for boron. Q = 2NO Dt π = 6.93 x 1014/cm2. This dose is almost

two orders of magnitude too high. It is very difficult to get a low enough dose by

direct diffusion.

4.6

(a) At 1000 oC, Fig. 4.6 indicates the arsenic surface concentration will be 1021/cm3.

The Dt product can be found from Eq. 4.10:

Dt =

xj

2µm

=

N

016

2 ln B 2 ln 3x1 21

NO

10

→

-11

2

D t= 1 .1 8 9 x 1 0c m

(b) At 1000 oC, D = 0.32 exp(-3.56/(8.62 x 10-5)(1273)) = 2.603 x 10-15 cm2/sec, and t

= 4567 sec or 1.27 hrs, a satisfactory time.

(c) From Fig. 4.11 and Table 4.2, x j = 2.29 NODt n i .

EG

1.1 2

3

2

31 3

31

n i = 1.0 8x1 0 T e x p−

= 1.0 8x1 0 (1 2 7 3) e x p −

k T

8.6 2x1 0−5 x1 2 7 3

and ni = 9.07 x 1017/cm3.

0.2x10 −4 cm 2 9.07x1017

= 6.92 x 10−14 cm2

D t =

21

2.29

10

The calculation in (c) is a much smaller value.

4.7

Using Fig. 4.10 for a constant-source diffusion with N/NO = 10-4, the normalized

vertical xj = 2.75 units, and the normalized horizontal xj at the surface = 2.25 units.

Thus horizontal xj = (2.25/2.75) x vertical xj. The lateral diffusion = 0.5 µ m x

(2.25/2.75) or 0.41 µ m. L = Lox - 2∆ L = 3 – 0.82 = 2.18 µ m.

4.8

(a) As drawn in the figure, the body of the resistor is L/W = 100 µ m/10µ m or 10

squares, and each resistor terminal will contribute 0.35 squares for a total or 10.7

squares.

- 25 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

100 µm

90 µm

30 µm

(b) Lateral diffusion is 5 µ m, so the length and width of the resistor body become 90

µ m and 20 µ m respectively, and L/W = 4.5 squares. Each terminal now contributes

0.65 squares for a total of 5.8 squares.

- 26 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

(c)

A base diffusion is usually a Gaussian diffusion. Using Fig. 4.16(d) with a surface

concentration of 5 x 1018/cm3 and a background concentration of 1015/cm3 yields RS xj

= 400 ohm-µ m. For xj = 6 µ m, RS = 67 ohms/❏. At the mask level, the resistor

appears to have a resistance of 710 ohms. The resistor will actually have a resistance

of 330 ohms when fabricated.

4.9

(a) N = (110 µ m/20 µ m) + 2(0.14) = 5.78 ❏. A surface concentration of 5 x 1018

can be achieved by a two step-diffusion or an implant; either yields a Gaussian

profile. Using Fig. 4.10(b) with N/NO = 1016/5x1018 = 2 x 10-3, we find the ratio of

lateral to vertical diffusion to be 2.1/2.6, and the lateral diffusion = 3 µ m(2.1/2.6) =

2.4 µ m.

(b) Now N = (110 µ m/24.8 µ m) + 2(0.14) = 4.72 ❏ where the ends still contribute

approximately 0.14 ❏ each.

(c) We find RS xj = 250 Ω -µ m using Fig. 4.16(d) with NO = 3 x 1018 and NB = 1016.

For xj = 3 µ m, RS = 83 Ω /❏. R = (7.72 ❏)(83 Ω /❏) = 390 Ω .

4.10

(a)

2λ

3λ

2λ

2λ

3λ

7λ

3λ

(b) There are 3 long legs, 2 shorter legs, 4 vertical links, 8 corners and 2 contacts.

N = 3(22/2) + 2(20/2) + 4(3/2) + 8(0.56) + 2(0.35) = 64.2 ❏.

- 27 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

3λ

2λ

2λ

3λ

19λ

3λ

(c) N= 3(21/3) + 2(19/3) + 4(2/4) + 8(0.56) +2(0.5) = 41.2 ❏ where the contacts have

been estimated to contribute 0.5 squares each.

- 28 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

(d) Assume a Gaussian profile. Using Fig. 4.10(b) with N/NO = 1016/1019 = 10-3, we

find the ratio of lateral to vertical diffusion to be 2.2/2.7, and the lateral diffusion = 2

µ m (2.2/2.7) = 1.63 µ m.

N=3

22(2 ) − 2(1.63 )

20 (2) − 2 (1.63)

6 − 2 (1.63 )

+2

+4

+ 8(0.56) + 2(0.65 ) N =

2 (2) + 2(1.63 )

2(2 ) + 2(1.63 )

2(2 ) + 2(1.63 )

34.2 ❏.

(e) In this case, the lateral diffusion = 3 µ m(2.2/2.7) = 2.45 µ m, and

N=3

22(2 ) − 2(2.45)

20(2 ) − 2(2.45)

6 − 2 (2.45)

+2

+4

+ 8(0.56) + 2 (0.65)N =

2 (2) + 2(2.45)

2(2) + 2(2.45)

2(2 ) + 2(2.45)

27.3 ❏.

4.11

D(t) = DO exp -EA/k(To-Rt) ≈ DO exp -EA/kTo)(1+Rt/To) for Rt/To << 1. The integral

becomes

to

(Dt)eff = Do exp(−EA kTo )∫ exp(− EA Rt kTo2 )dt

0

and

(Dt )eff

2

= D(To )(kT o E AR ) for large enough to.

4.12

x j = 2 D o exp(− E A kT ) t ln(NO N B ) = 2 exp(− EA kT ) t ln(NO N B )

dx j dT =2 exp(−E A kT )(E A 2kT 2 ) t ln (N O NB )

x

S Tj =

dx j T EA

=

x j dT kT

For boron or phosphorus, EA = 3.69 eV:

xj

ST =

3.69

= 31.2

8.62x10−5 (1373)

and

dx j

xj

10

= 31.2

= 0.227

1373

A 10-K error in temperature results in a 23% error in junction depth!

4.13

From Fig. 4.8, a 10 Ω -cm p-type wafer corresponds to a doping of NB = 1.2 x

1015/cm3. The two-step diffusion results in a Gaussian profile. For NO = 5 x 1016/cm3

with xj = 5 µ m, 1.2 x 1015/cm3 = 5 x 10 16/cm3 exp -( 5 µ m/2 Dt )2, and Dt = 1.676

x 10-8 cm2. Choose phosphorus as the impurity (As and Sb diffuse too slowly). After

- 29 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

several attempts, T = 1125 oC is found to give a satisfactory time. The results are D =

10.5 exp (-3.69/(8.62x10-5)(1398)) = 5.17 x 10-13 cm2/sec which then yields t = 3.24 x

104 sec or 9.00 hrs. The drive-in step is 1125 oC for 9 hours.

16

−8

13

3

The dose Q = N O πDt = 5x10 π(1.676 x10 ) = 1.147 x10 /cm . For the pre-

13

2

deposition step, N O Dt = Q π 2 = 1.017x10 / cm . This is a low dose, so let us

try 900 oC, the lowest temperature in Fig. 4.6. From Fig. 4.6, N O = 5.3 x 1020/cm3

which yields Dt = 3.682 x 10-16 cm2. At 900 oC, D = 10.5 exp (-3.69/(8.62x10-5)

(1173)) = 1.449 x 10-15 cm2/sec, and t = 0.254 sec! Even at this low temperature, we

cannot achieve a controllable time. We will have to drop to 800 oC and try again. At

800 oC, NO ≈ 4 x 1020/cm3 which yields Dt = 8.223 x 10-16 cm2. At 800 oC, D = 4.954 x

10-17 cm2/sec, and t = 16.6 sec – still not workable. We will have to use an ionimplantation step (discussed in the next chapter). Another possibility is a liquid

“spin-on” doping source with a fixed concentration.

4.14

NB = 1016/cm3 and xj = 2 um,

−4

18

16

2 Dt = 2x10

ln (2x10 10 )= 8.689 x 10-5 cm. Using Eq. 4.13,

x j

−1

2x10 −4

x 2 −1

R S = ∫ qµ p N A (x)dx = 1.602x10−19 (300)(2x1018 ) ∫ exp −

dx

2

Dt

0

0

For

NO

=

2

x

1018/cm3,

Integrating with the QUAD function in MATLAB® yields RS = 135 Ω /❏.

4.15

(a) From Fig. 4.8, a 0.3 Ω -cm p-type wafer corresponds to NB = 5 x 1016/cm3. For NO

−4

20

16

ln (

10

5x10 )= 7.254 x 10-5 cm.

= 1020/cm3, and xj = 2 um, 2 Dt = 2x10

−1

0.5x10−4

x 2

−19

20

R S = 1.602x10 (100) 10

exp −

dx = 14.5 Ω / s q.

∫

2 Dt

0

1.0x10 − 4

x 2 −1

−19

20

R S = 1.602x10 (100) 10

exp −

dx = 34.9 Ω /sq.

∫

2 D t

0.5x10 − 4

1.5x10−4

x 2 −1

R S = 1.602x10−19 (100) 1020 ∫ exp −

dx = 203 Ω /sq.

2 D t

1.0x10−4

2.0x10−4

x 2 −1

R S = 1.602x10−19 (100) 1 020 ∫ e xp −

dx = 2890 Ω /sq.

2 Dt

1.5x10 −4

(b) Putting these four sheet resistance values in parallel yields RS = 9.72 Ω /❏.

( )

( )

( )

( )

(c) Irvin’s curves for an n-type Gaussian layer with NB = 5 x 1016/cm3 and NO =

1020/cm3 gives RS xj = 25 Ω -µ m, and Rs = 12.5 Ω /❏.

- 30 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

4.16

Find the surface concentration and junction depth after predeposition and drive-in for

boron with a 900 oC 15-minute pre-deposition and a 5-hr 1100 oC drive-in. From

Table 4.2: xj = N ODt ni ; D = 3.17exp(-3.59/kT), NO = 2.78 x1017(RS xj)-1 and Q =

0.67 NO xj. At 900 oC, NO = 1.1x1020/cm3 from Fig. 4.6, and D = 1.21 x 10-15cm2/sec.

x j = 2.45 (1.1x10 20 )(1.21x1015 )(900)/ 4x1018 = 0.134 µm

and Q = 9.9x1014/cm2 (7 times larger than in Ex. 4.3).

From Ex. 4.2, NB = 3 x 1016/cm3, D = 2.96 x 10-13 cm2/sec and t = 18000 sec. After

the drive-in, x j = 2 Dt ln(NO N B ) = 3.44 µm (24% greater).

4.17

Using Laplace Transforms, we get an ordinary differential equation:

N(x,t = 0 − )

d 2 N(x,s) sN(x,s)

(1)

−

=−

dx2

D

D

where N(x, t = 0-) = 0 for no impurities in the wafer until t > 0. For this case the

solution is N(x,s) = A (s)exp (−x s D )since N must be finite at d = ∞.

Constant Source Diffusion: For this case, the boundary condition is N(0,t) = N Ou(t),

and

x

N

s

N(x,s ) = O exp −x

.

. Using transform tables, N(x,t ) = N Oerfc

2 Dt

s

D

Limited Source Diffusion: For this case the boundary condition is N(x, t = 0 -) =

Qδ (x) where Q is the impurity dose in atoms/cm2. Integrating equation (1) for x = 0to x = 0+ yields dN(x,s)/dx = -Q/D, and therefore A (s) = Q/ Ds . From the

transform tables,

x2

Q

N(x, t ) =

exp −

πDt

4Dt

4.18

RS = 1/σ t where t is the layer thickness. From Fig. 4.6, the maximum electrically

active concentration for boron is 4.3 x 1020/cm3 and 5 x 1020/cm3 for arsenic. From

the expressions in Prob. 4.24, the limiting mobilities at high concentration are 48 and

92 cm2/V-sec for holes and electrons, respectively.

Boron: RS = 1/qµ Nt = 1/(1.6x10-19 x 48 x 4.3x1020 x 10-4) = 3.0 ohms/❏ for t = 1

µ m, and 12.1 ohms/❏ for t = 0.25 µ m.

- 31 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

Arsenic: RS = 1/(1.6x10-19 x 92 x 5x1020 x 10-4) = 1.4 ohms/❏ for t = 1 µ m, and 5.4

ohms/❏ for t = 0.25 µ m.

4.19

We must find the time t such that 1016 = 1018erfc(xj/2 Dt ) for xj = 4 x 10-2 cm. This

yields Dt

= 1.82. From Fig. 4.5, gold has a diffusion coefficient of

approximately 4 x 10-7 at 1000 oC, and t = 300 seconds. Only 5 minutes is required

for gold to completely diffuse through the wafer!

- 32 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

4.20

$SUPREM IV -- Use Default Grid

INITIALIZE

<100> SILICON PHOSPHORUS=3E16 WIDTH=6.5

$Diffusion Barrier

DEPOSITION

OXIDE THICKNESS=0.5

ETCH

OXIDE RIGHT P1.X=4

$Predeposition

DIFFUSION

TEMP=900 TIME=15 BORON GAS.CONC=1.2E21

$Reflect about right edge to complete structure

STRUCTURE REFLECT RIGHT

$Plot Boron Contours

SELECT

Z=LOG10(BORON) TITLE=”Contours of Boron Concentration”

PLOT.2D

SCALE Y.MAX=13 Y.MIN=0

FOREACH

X (16 17 18 19)

CONTOUR VAL=X COLOR=2

END

CONTOUR

VALE=3E16 LINE.TYP=2 COLOR=2

4.21

TITLE

INITIALIZE

DIFFUSION

PRINT

PLOT

DIFFUSION

PRINT

PLOT

DIFFUSION

PRINT

PLOT

PLOT

ETCH

DIFFUSION

PRINT

PLOT

PLOT

STOP

PROBLEM 4.21 TWO STEP DIFFUSION FROM EXAMPLE 4.3

<100> SILICON, PHOSPHOUS CONCENTRATION=4E15

THICKNESS=6.0 XDX=0 DX=0.015 SPACE=400

TEMP=900 TIME=15 BORON GAS.CONC=1.2E21

LAYERS

CHEMICAL BORON LP.PLOT

TEMP=1100 TIME=304 DRY02

LAYERS

CHEMICAL BORON LP.PLOT

TEMP=1100 TIME=76 WET02

LAYERS

CHEMICAL BORON LP.PLOT

CHEMICAL NET LP.PLOT

OXIDE

TEMP=950 TIME=30 PHOSPHORUS SOLIDSOL

LAYERS

CHEMICAL PHOSPHORUS LP.PLOT

CHEMICAL NET LP.PLOT CMIN=1E13

Boron concentration is high in the oxide and becomes somewhat depleted below the

1018 level at the surface of the final profile. The boron junction depth is predicted to

be 4.3 µ m, slightly greater than the 4 µ m calculated by hand. The second pn

junction occurs at a depth of 0.48 µ m. Using Fig. 4.12, the 30 min. curve intersects

a level of 1018 at a greater depth of 0.9 µ m.

- 33 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

4.22

V=

IRS ln(2)

ln(2 )

= (1 0−5 )(3 0 0)

= 0.6 6 2 m V

π

π

- 34 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

4.23

(a) The cylinder contains 100 ft3 x 0.001 = 0.1 ft3 of diborane. The volume of the

room is 10 x 12 x 8 or 960 ft3. 0.1 ft3/960 ft3 = 1.04 x 10-4 or approximately 100 ppm.

(b) Life threatening exposure is 160 ppm for 15 min. Evacuate rapidly!

(c) Life threatening exposure is 6-15 ppm for 30 min. Evacuate immediately!

4.24

From Prob. 4.15, 2 Dt = 7.254 x 10-5 cm.

2x10 −4

−1

x 2

20

RS =

qµ N(x))N(x)dx

where N(x) = 10 exp −

∫ (

2

Dt

0

and µ n(N) is given in this problem. Using QUAD integration in MATLAB® yields

RS = 9.81 Ω /❏ for the n-type diffusion. Repeating with µ p(N) yields RS = 19.3

Ω /❏ for a p-type layer.

- 35 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

CHAPTER 5

5.1

From Figs. 5.3 (a) and (b), 60 keV through 0.25 µ m SiO2 yields Rp = 0.19 µ m and

∆ Rp = 0.09 µ m. For the Gaussian implant, N(x) = Np exp[-(x-Rp)2/2∆ Rp2] with NP =

Q/∆ Rp 2π = 4.43 x 1018/cm3.

(a) N(0.25 µ m) = 4.43 x 1018exp [-(0.25-0.19)2/2(0.09)2] = 3.5 x 1018/cm3.

∞

(x − 0.19µm)2

18

dx = (0.751) 2πN ∆R

(b) QSi = ∫ 4.43x10 exp −

p

p

2(0.09µm )2

0.25µm

QSi = 7.5 x 1013/cm2

(c) 3 x 1015 = 4.43 x 1018exp [-(xj –0.19)2/2(0.09)2], and xj = 0.34 + 0.19 = 0.53 µ m

from the implant peak; 0.47 µ m from the Si-SiO2 interface.

5.2

From Fig. 5.3 for boron at an energy of 10 keV, Rp = 0.031 µ m and ∆ Rp = 0.015

µ m. In this case, Rp is only two times ∆ Rp, and the full Gaussian profile will not be

completely below the surface. The dose Q is given by

∞

x − 0.031 2

Q = ∫ NP exp−

dx with x inµm

0.015

2

0

Numerical integration with MATLAB® shows that only 98.06% of the profile is in the

silicon, so that

Q=

[ 2πN

P

(0.015µm )](0.9806 ) and NP = 5.42 x 1020/cm3 for Q = 2 x 1015/cm2.

x − 0.031 2

j

= 1016 yields xj = 0.10 µm which agrees

5.42x10 exp −

Then:

0.015 2

well with the graph of the profile given below.

20

- 36 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

10 21

10

20

10

19

10 18

10 17

10

16

10 15

0

0.05

0.1

0.15

0.2

0.25

0.3

Distance From Surface (um)

0.35

0.4

0.45

0.5

5.3

1 µ m SiO2 is equivalent to 1 µ m of Si. From Fig. 5.3, an implant of phosphorus to

a depth of 1µ m requires an energy of 900 keV, and yields ∆ RP = 0.13 µ m.

5.4

First, calculate the total oxide thickness needed to ensure that the implanted impurity

concentration is less than 1015/10 = 1014/cm3 at the Si-SiO2 interface. We know that

RP = 0.05 µ m, the thickness of the oxide. For arsenic, this requires E = 80 keV from

Fig. 5.3, and ∆ Rp = 0.017 µ m. NP = Q/∆ RP 2π = 2.35 x 1017/cm3. From Eqn.

(5.9) with NP/NB = 235, XO = RP + 3.94∆ RP. XO = 0.05 + 3.94(0.017) = 0.117 µ m of

oxide. The additional oxide required is 3.94(0.017) = 0.067 µ m. However, Xnitride =

0.85 XO so only 0.057 µ m of silicon nitride is required.

5.5

Using Irvin's curves for a p-type Gaussian layer, Fig. 4.16(d), with R S xj = 625 ohmµ m yields NP = 2.7 x 1018/cm3. At x = xj, 2.7 x 1018exp[-(5x10-4/2 Dt )2] = 1016,

and Dt = 1.06 x 10-4 cm. For the final layer, the dose in silicon is Q Si = NP πDt

= 5.1 x 1014/cm2. With the pre-deposition implant peak at the surface, the implanted

dose will be 2 x QSi or 1.0 x 1015/cm2. D = 10.5 exp (-3.69/kT) = 2.96 x 10-13 at T =

1373 K, and the drive-in time is t = 3.80 x 104 sec or 10.5 hours.

5.6

Using Irvin's curves for a p-type Gaussian layer, Fig. 4.16(d), with R S xj = 400 ohmµ m yields NP = 4 x 1018/cm3. At x = xj, 4 x 1018exp[-(2x10-4/2 Dt )2] = 1016, and

Dt = 4.09 x 10-5 cm. For the final layer, the dose in silicon is Q Si = NP πDt =

2.9 x 1014/cm2. With the pre-deposition implant peak at the surface, the implanted

dose will be 2 x QSi or 5.8 x 1015/cm2. D = 10.5 exp (-3.69/kT) = 2.96 x 10-13 at T =

1373 K, and the drive-in time is t = 5.64 x 103 sec or 1.57 hours.

- 37 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

5.7

Using Irvin's curves for a p-type Gaussian layer, Fig. 4.16(d), with R S xj = 62.5 ohmµ m yields NP = 6 x 1019/cm3. At x = xj, 6 x 1019exp[-(2.5x10-5/2 Dt )2] = 1016, and

Dt = 4.24 x 10-6 cm. For the final layer, the dose in silicon is Q Si = NP πDt =

4.5 x 1014/cm2. With the pre-deposition implant peak at the surface, the implanted

dose will be 2 x QSi or 9.0 x 1014/cm2. D = 10.5 exp (-3.69/kT) = 2.96 x 10-13 at T =

1373 K, and the drive-in time is t = 60.7 sec! This very short time will require rapid

thermal annealing, or the drive-in temperature could be reduced.

5.8

From Fig. 5.3 for phosphorus at an energy of 20 keV, R p = 0.025 µ m and ∆ Rp =

0.012 µ m. In this case, Rp is only two times ∆ Rp, and the full Gaussian profile will

not be completely below the surface. The Dose Q is given by

∞

x − 0.025 2

Q = ∫ NP exp−

dx with x inµm

0.012 2

0

Numerical integration with MATLAB® shows that only 98.14% of the profile is in the

silicon, so that

Q=

[ 2πN

P

(0.012µm )] (0.9814 ) and NP = 3.39 x 1020/cm3.for Q = 1015/cm2.

x − 0.025 2

j

= 1016 yields jx= 0.80 µm which agrees

3.39x10 exp −

Then:

0.012

2

well with the graph of the profile given below.

20

10

21

10

20

10

19

10 18

10

17

10

16

10

15

0

0.05

0.1

0.15

Distance From Surface (um)

- 38 -

0.2

0.25

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

5.9

(a) Irvin's curves can be used for each half of the distribution. We have 10 15 =

1019exp[-(xj-1)2/2(.11)2] with xj in µ m. Solving this equation yields (xj - RP) = 0.47

µ m which corresponds to xj normally used in Irvin's curves. From Irvin's curves

with NP = 1019/cm3, RS xj = 230 ohm-µ m, and RS = 490 ohms/❏ for xj = 0.47 µ m.

We effectively have two of these regions in parallel, so the total RS = 245 ohms/❏.

(b) Q = NP∆ RP 2π = 2.76 x 1014/cm2.

(c) RP = 1 µ m requires 470 keV for boron from Fig. 5.3.

(d) From (a) xj = 1 ± 3.03 ∆ RP 2π = 1.47 µ m and 0.53 µ m.

5.10

(a) Using Fig. 5.3 for 50-keV boron, Rp = 0.15 µ m and ∆ Rp = 0.050 µ m. Since the

concentrations are not known, let us assume a worst-case situation with NP = 1021/cm3

and NB = 1014/cm3. Also, remember that photoresist also requires 80% more

thickness than Si or SiO2. Thus the minimum photoresist thickness will be

X PR = 1.8 (R P + 6.1∆RP ) = 0.82 µm

(b) For 50-keV phosphorus, Rp = 0.060 µ m and ∆ Rp = 0.025 µ m. XPR = 0.38 µ m.

(c) For 50-keV arsenic, Rp = 0.033 µ m and ∆ Rp = 0.012 µ m. XPR = 0.19 µ m.

- 39 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

5.11

mv2

2E

or v=

; Also, remember 1 Joule = 1 kg-m2/sec2.

2

m

(a) For B+, m = 10.811(1.673 x 10-27 kg) = 1.809 x 10-26 kg.

E=

v=

2(5keV)(1.602x10 −19 J/ eV)

1.809x10

−26

kg

= 2.98 x 105 m /sec

(b) For (BF2)++, m = [10.811+2(18.998)](1.673 x 10-27 kg) = 8.17 x 10-26 kg.

v=

2(10keV)(1.602x10 −19 J /eV )

8.165x10

−26

kg

5

= 1.98 x 10 m /sec

(a) For (B10H14)+, m = [10(10.811)+14(1.079)](1.673 x 10-27 kg) = 2.05 x 10-25 kg.

v=

5.12

2(5keV)(1.602x10 −19 J/ eV)

2.045x10 −25 kg

= 8.85 x 10 4 m/ sec

From Fig. 5.4 we see that the concentration is largest at x = R P. Using Eqn. 5.7, N(y)

= 0.5 x 1020{erfc [(y-a)/ 2 (.022)]} = 1016 for the junction edge. (y-a) = 2.63 2

(0.022) = 0.082 µ m. ∆ L = 2(.082) = 0.16 µ m. A graph of the concentration at x =

RP is given below. A blowup of the junction region agrees with the above

calculation.

- 40 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

10

21

10 20

10 19

10 18

10 17

10

16

10 15

10 14

0

0.2

0.4

0.6

0.8

DistancefromCenter of Opening(um)

- 41 -

1

1.2

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

5.13

100 keV: RP = 0.30 µ m and ∆ RP = 0.07 µ m.

200 keV: RP = 0.55 µ m and ∆ RP = 0.09 µ m.

The doses are given by Q = 2πNP ∆R P and are 8.77 x 1013/cm2 and 1.13 x

1014/cm2 for the two implants with NO = 5 x 1018/cm3.

x − 0.3 2

x − 0.55 2

+ exp −

as plotted below.

So: N( x) = 5x10 exp−

0.07 2

0.09 2

18

From the graph above, it is clear that the shallow profile controls the position of the

first junction and the deep profile controls the second junction.

x − 0.3 2

j1

18

= 1 016 yie ld s j1x = 0.0 53 µm

5x1 0 e xp−

0.0 7 2

x − 0.5 5 2

j2

= 1 016 yie ld s j2x = 0.87 µm

5x10 e xp−

0.0 9 2

These two junction values agree well with the graph of the profile.

18

5.14

Approximately (5 x 1022) x (0.2 x 10-4) = 1 x 1018 silicon atoms/cm2 are in the layer to

be formed. We need to implant two oxygen atoms per silicon atom for a total of 2 x

1018 oxygen atoms/cm2. The 125 mm wafer has an area of 123 cm2, so the total

- 42 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

number of atoms required is 2.45 x 1020 oxygen atoms. If this number is implanted in

15 minutes, 2.45 x 1020/(15 x 60) = 2.73 x 1017 atoms/sec are required. If each atom

carries a single charge, the beam current will be 43.6 mA, and the power in the 5MeV beam is 218 kW. The wafer will melt away!

5.15

∆ VT = 0.75 volts; ε ox = 3.9 x 8.854 x 10-14 F/cm; Cox = ε ox/4 x 10-6 cm = 8.63 x 10-8

F/cm2. ∆ VT = qQ/Cox and Q = Cox ∆ VT/q = 4.0 x 1011/cm2.

5.16

(1015/cm2)(π )(20/2)2 cm2 = 3.14 x 1017 total boron atoms. 10-5 A corresponds to (10-5

Coul/sec)/(1.6 x 1019 Coul/charge) or 6.25 x 1013 charges/sec. 3.14 x 1017 atoms/6.25

x 1013 atoms/sec = 5030 sec or approximately 84 minutes.

5.17

The sheet resistance is found by evaluating Eq. (4.13). N(x) is a Gaussian profile and

the mobility can be modeled by the mathematical approximations given in Prob. 4.24.

For given values of RP and ∆ RP, xj1 and xj2 can be found and the integral can be

evaluated with the QUAD function in MATLAB®, for example. Xj1 will be zero if

the Gaussian profile interests the semiconductor surface.

x j2

−1

R S = q ∫ µ (N) N(x ) dx

x j1

1270

µ n = 92 +

0.091

N

1+

1.3x1017

(x − R )2

P

N( x) = N P exp −

2∆R 2P

µ p = 48 +

447

0.076

N

1+

6.3x1016

5.18

For a boron dose of 1015/cm3, 1000/T = 6.5 or T ≤ 154 K. For a phosphorus, 1000/T

= 3.25, and T ≤ 308 K.

5.19

Integrating numerically using a spreadsheet yielded 5.60 x 10-12 cm2. At 1050 oC

(1323 K), D = 9.10 x 10-14 cm2/sec, and Dt = 5.46 x 10-12 cm2.

5.20

Integrating numerically using a spreadsheet yielded 5.97 x 10-13 cm2. At 1050 oC

(1323 K), D = 9.10 x 10-14 cm2/sec, and Dt = 4.55 x 10-13 cm2.

5.21

Integrating numerically using a spreadsheet yielded 1.82 x 10-12 cm2. At 980 oC (1253

K), D = 1.49 x 10-14 cm2/sec, and Dt = 1.79 x 10-12 cm2.

- 43 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

5.22

Integrating numerically using a spreadsheet yielded 2.51 x 10-13 cm2. At 980 oC (1253

K), D = 1.49 x 10-14 cm2/sec, and Dt = 2.24 x 10-13 cm2.

- 44 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

CHAPTER 6

6.1

Φ = 2.63 x 1020 (1.013 x 105)/ 32 • 300 = 2.73 x 1023 molecules/cm2-sec. For close

packing with radius r, the area of one atom is 4r2cos(30o). For oxygen with r = 3.6 Å

(See Ex. 6.2), there are 2.23 x 1014 molecules/cm2 which yields t = 820 psec.

6.2

Φ = 2.63 x 1020 (10-3)(1.013 x 105)/ 32 • 300 = 2.73 x 1020 molecules/cm2-sec. For

close packing with radius r, the area of one atom is 4r2cos(30o). For oxygen with r =

3.6 Å (See Ex. 6.2), there are 2.23 x 1014 molecules/cm2 which yields t = 0.82 µ sec.

6.3

M = 32, T = 300 K, P = 10-4 Pa.

Φ = (2.63 x 1020)(10-4)/ 32 • 300 = 2.68 x 1020 molecules/cm2-sec

λ=

kT

(1.38x10 −23 J /K )(N − m / J )(10 2 cm/ m )(300K ) = 7190 cm

=

2

2

2πpd

2π (10 −4 N/ m2 )(10 −4 m 2 /cm 2 )(3.6x10 −8 cm )

or 71.9 m. (10-4 Pa)(0.0075 torr/Pa) = 7.5 x 10-7 torr

6.4

n=

10 −8 Pa(1 N/ m 2 /Pa)

P

=

= 2.42x1012 /m 3

kT 1.38x10−23 J /K (300K )(1 N - m/J)

n = 2.42x106 molecules/cm 3

6.5

P = nkT = (1000/ cm3 )(10 6 cm3 / m 3 )(1.38x10 −23 J/ K)(300K)(1 N - m/J)

P = 4.14x10 −12 N/ m 2 = 4.14x10−12 Pa

6.6

From Prob. 6.1, close packing of 5-Å spheres will yield = 4.62 x 1014 Al atoms/cm3.

100 nm/min = 10-5 cm/min. (10-5cm/min)/(5x10-8cm x cos(30o)/atom) = 231 atomic

layers/min = 7.70 atomic layers/sec.

Φ = (7.70 layers/sec)(4.62 x 1014 atoms/cm2-layer) = 3.56 x 1015 atoms/cm2-sec. M =

27 for Al and using T = 300 K, P = (3.56 x 10 15) 27 • 300 /2.63 x 1020 or P = 1.22 x

10-3 Pa.

6.7

Choosing φ = 0 for simplicity, cos φ = 1. At the edge of the wafer, r = 802 + 5 2 ,

and cos φ = (80/80.16). So at the wafer center, G 1 = m(12)/π ρ (802). At the wafer

- 45 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

edge G2 = m(80/80.16)2/π ρ (80.16)2. G2/G1 = (80/80.16)4 = 0.992 or 0.008 µ m

thickness variation.

6.8

Using the result from Prob. 6.7, G2/G1 = (2ro/r)4. r = 100 2 + 10 2 , = 100.5 cm. G2/G1

= (100/100.5)4 = 0.980. A 0.02 µ m thickness variation will occur.

6.9

Using the result from Prob. 6.7, G2/G1 = (2ro/r)4. G2/G1 = 0.55µ m/0.6µ m and d/r =

0.9785. r = d 2 + 15 2 and d/ d 2 + 15 2 = 0.9785. d = 71.1 cm.

6.10

4 hours = 1.44 x 104 sec. Assume oxygen molecules for example. From Ex. 6.2, NS

= 2.23 x 1014 molecules/cm2 with M = 32. t = N S/Φ and P = (2.23x1014) 32 • 300 /

(2.63 x 1020)(1.44 x 104) = 5.77 x 10-9 Pa = 4.33 x 10-11 Torr - an ultrahigh vacuum

(UHV) system.

6.11

v = (Ng/N) ks hg/(ks+hg). ks = 2 x 106 exp (-1.9)(1.6 x 10-19)/(1.38 x 10-23)(1473) = 0.64

cm/sec. hg = 1 cm/sec, Ng = 3 x 1016 atoms/cm3. v = (0.64 x 1/1.64)(3 x 1016/5 x 1022)

= 2.3 x 10-7 cm/sec or 0.14 µ m/min.

(b) At T = 1498 K, ks becomes 0.82 cm/sec, and v increases to 0.16 µ m/min. The

change is 0.02 µ m/min, a 14% increase.

(c) Setting ks = 1 yields T = 1520 K or 1247 oC.

(d) From the SiH4 curve, ks = 0.2 µ m/min at 1000/T = 0.93 and 0.01 µ m/min at

1000/T = 1.1. EA = -1000 k (∆ ln ks/∆ (1000/T)) = -1000 x 8.617 x 10-5 x (ln(.2)ln(.01))/(.93-1.1) = 1.52 eV.

6.12

The graph on the next page is generated with MATLAB ® using equations 6.31 and

6.32. For both boron and phosphorus at 1200 oC, D = 10.5 exp (-3.69/(8.617x10-5)

(1473) = 2.49 x 10-12cm2/sec. xepi = 10 µ m and vx = 0.2 µ m/min give the growth

time t = 3000 sec. 2 Dt =1.73 µ m. The two profiles are given by

x − xepi

1018

N1 (x ) =

1 + erf

2

1.73µm

x − xepi

x + xepi

1016

x

+ exp

erfc

N 2 (x) =

erfc

2

1.73µm

0.0747µm

1.73µm

From a blow-up of the graph, xj = 7.2 µ m.

- 46 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

6.13

Evaporation and sputtering require good vacuum systems, whereas CVD can be done

at higher pressure or in some cases even at atmospheric pressure. Evaporation is

limited to elemental materials that can be melted. On the other hand, sputtering

replicates the target material, and metals, dielectrics and composite materials can all

be sputtered. Evaporation and sputtering tend to be low temperature processes. CVD

systems can do large wafer lots at one time, but elevated temperatures are often

involved and limit the points that CVD can be introduced into a process.

- 47 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

Graph for Problem 6.12.

10 19

10 18

10 17

10 16

10 15

0

2

4

6

8

DistanceFromSurface(um

)

10

12

14

16

6.14

The volume of aluminum required is π r2t = π (5cm)2(10-4cm) = 7.85 x 10-3 cm3.

Only 15% of the Al actually is deposited on the wafer, so the total volume of Al

required is 5.24 x 10-2 cm3. Aluminum has a density of 2.7 x 10-3 kg/cm3. One kg of

Al has a volume of 370 cm3 and can be used to deposit a film on approximately 7100

wafers.

6.15

(a) Using the result from Prob. 6.7, G2/G1 = (2ro/r)4. r = 200 2 + 50 2 = 206.2 mm.

G2/G1 = (200/206.2)4 = 0.886. A 0.11 µ m thickness variation will occur.

(b) For a 200 mm wafer 40 cm above the source: r = 400 2 + 100 2 = 412.3 mm.

G2/G1 = (400/412.3)4 = 0.886. A 0.11 µ m thickness variation will occur. For a 300

mm wafer 40 cm above the source: r = 400 2 + 150 2 = 427.2 mm. G2/G1 =

(400/427.2)4 = 0.769. A 0.23 µ m thickness variation will occur.

6.16

From Fig. 6.10, the growth rate at 1100 oC in SiCl4 is 0.1 µ m/min. The 1-µ m film

takes 600 sec to grow. D = 0.32 exp (-3.56/(8.617x10 -5)(1373)) = 2.74 x 10-14

cm2/sec, and 2 Dt = 0.081 µ m. N(x) is given by (x in µ m – see graph on next

page)

x −1

N(x ) = 5x1019 1 + erf

cm-3

0.081

- 48 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

6.17

From Fig. 6.10, the growth rate at 950 oC in SiH4Cl2 is 0.15 µ m/min. The 2-µ m

film takes 800 sec to grow. D = 10.5 exp (-3.69/(8.617x10-5)(1223)) = 6.45 x 10-15

cm2/sec, and 2 Dt = 0.045 µ m. N(x) is given by (x in µ m)

x − 2

20

-3

N(x) = 10 1 + erf

cm

0.045

Graph for Problem 6.16

10

21

10

20

10

19

10 18

10 17

10 16

10

15

10 14

0

0.5

1

1.5

Distance From Surface (um)

2

2.5

3

Graph for Problem 6.17

- 49 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

10

21

10

20

10

19

10 18

10 17

10

16

10 15

10

14

0

0.5

1

1.5

Distance From Surface (um)

2

2.5

3

CHAPTER 7

7.1

(a) RS = ρ /t = 3.2 x 10-6 Ω -cm/10-4cm = 0.032 Ω /❏.

(b) R = RS (L/W) = 0.032Ω /❏ x (500µ m/10µ m) = 1.6 Ω .

(c) Cox = (3.9)(8.854 x 10-14F/cm)/10-4cm = 3.5 x 10-9 F/cm2.

C = Cox (WL) = (3.5 x 10-9 F/cm2)(0.05 cm)(0.001 cm) = 0.175 pF.

(d) RC = 1.6Ω x (0.175 x 10-12F) = 0.28 ps.

7.2

(a) RS = 500 x 10-6 Ω -cm/10-4cm = 5 Ω /❏. R = RS (L/W) = 5Ω /❏ x

(500µ m/10µ m) = 250 Ω . Cox = (3.9)(8.854 x 10-14 F/cm)/10-4cm = 3.5 x 10-9 F/cm2.

C = Cox (WL) = (3.5 x 10-9 F/cm2)(0.05 cm)(0.001 cm) = 0.175 pF. RC = 250Ω x

(0.175 x 10-12 F) = 43.8 ps.

(b) RS = 25 x 10-6 Ω -cm/10-4cm = 0.25 Ω /❏. R = RS (L/W) = 0.25Ω /❏ x

(500µ m/10µ m) = 12.5 Ω . Cox = (3.9)(8.854 x 10-14 F/cm)/10-4cm = 3.5 x 10-9

F/cm2. C = Cox (WL) = (3.5 x 10-9 F/cm2)(0.05 cm)(0.001 cm) = 0.175 pF. RC =

12.5Ω x (0.175 x 10-12 F) = 2.19 ps.

(c) RS = 1.7 x 10-6 Ω -cm/10-4cm = 0.017 Ω /❏. R = RS (L/W) = 0.017Ω /❏ x

(500µ m/10µ m) = 0.85 Ω . Cox = (3.9)(8.854 x 10-14 F/cm)/10-4cm = 3.5 x 10-9

F/cm2. C = Cox (WL) = (3.5 x 10-9 F/cm2)(0.05 cm)(0.001 cm) = 0.175 pF. RC =

0.85Ω x (0.175 x 10-12 F) = 0.149 ps.

- 50 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

7.3

(a) RS = 1/σ t = 1/qµ Nt

For boron: RS = 1/(1.6x10-19)(75)(4.3x1020)(0.25x10-4) = 7.8 ohms/❏.

For arsenic: RS = 1/(1.6x10-19)(100)(5x1020)(0.25x10-4) = 5.0 ohms/❏.

(b) At high surface concentrations, the curves of Fig. 4.16 stop at RS xj = 10 Ω -µ m.

A junction depth of 0.25 µ m yields a sheet resistance of 40 Ω /❏.

7.4

D = 0.04 exp (-0.92/723 x 8.62x10-5) = 1.55 x 10-8cm2/sec. t = 30 min = 1800 sec and

Dt = 52.7 µ m. The volume of aluminum that will absorb silicon is V = (2 x

53µ m)(15µ m)(1µ m) = 1590 µ m3. At T = 450 oC, the equilibrium concentration

of silicon in aluminum is 0.5%, so the volume of silicon required is VSi = 5 x 10-3VAl.

Dividing by the contact area of 100 µ m2 yields a depth of 0.08 µ m.

7.5

(a) ρ c = RA = (0.5 Ω )(10-8cm2) = 5 x 10-9 Ω -cm2.

(b) R = ρ c/A = ρ c /10-10cm2 = 50 Ω . This value is large, but it is difficult to do

much better.

7.6

(MTF2/MTF1) = exp(-0.5/k)(1/T2 - 1/T1).

For T2 = 300K and T1 = 400K, the ratio is 126.

For T2 = 77K and T1 = 400K, the ratio is 2.67 x 1026!

7.7

(a) 50% of the failures have occurred at 40 time units.

(b) 50% of the failures have occurred at 430 time units.

The copper line is 10 times more resistant to electromigration than the AlCu line.

7.8

(a) For minimum resistance we would use a constant source diffusion resulting in an

erfc profile. Using Irvin's curves, RS xj = 90 Ω -µ m and RS = 23 Ω /❏ for a 4-µ m

deep junction.

(b) The surface area per unit length including the sidewall contribution is (15+4+4) =

23 µ m2 per µ m of length. For NB = 1015,

1015

φ bi = 0.56V + (25.8m V) ln 10 = 0.857 V

10

- 51 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

For VR = 0, with KS = 11.7,

C=

7.9

1.602x10−19 (1015 )(11.7)(8.854 x10 −14 )

(25x10 ) = 2.46 fF /µm

2(0.857)

−8

I = JA = (5 x 105A/cm2)(10-4cm)(4 x 10-4cm) = 20 mA.

7.10 I = JA = (106A/cm2)(0.25 x 10-4cm)(0.5 x 10-4cm) = 1.25 mA.

L

7.11 R = ρ A = (5µΩ − cm )

10 −4 cm

(0.25 x10

−4

2

cm )

= 0.80 Ω

7.12 (a) RS = ρ /t = 1.7 x 10-6 Ω -cm/0.5x10-4cm = 0.034 Ω /❏.

(b) R = RS (L/W) = 0.034Ω /❏ x (50µ m/0.5µ m) = 3.4 Ω .

(c) Cox = (2)(8.854 x 10-14 F/cm)/10-4cm = 1.77 x 10-9 F/cm2.

C = Cox (WL) = (1.77 x 10-9 F/cm2)(50x10-4cm)(0.5x10-4cm) = 0.443 fF.

(d) RC = 3.4Ω x (0.443 x 10-15 F) = 1.5 fsec.

- 52 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

CHAPTER 8

8.1

Sheet resistance, contact resistance, threshold voltage, junction depth, alignment

errors, current gain, transconductance, oxide thickness, breakdown voltage, channel

length, etc.

8.2

2115 = 4.15 x 1034 states. At 10-7 sec/state, each die will take 4.15 x 1027 sec. There

are 3.15 x 107 sec/year, so each die will require 1.3 x 1020 years. Wafer test will

require 1.3 x 1022 years.

8.3

(a) 10 mm x 1000 µ m/mm = 104 µ m. 15 mm x 1000 µ m/mm = 1.5 x 104 µ m.

Along the 10 mm edge, there will be room for (104/125) - 2 = 78 pads. Along the 15

mm edge, there will be room for (1.5x104/125) - 2 = 118 pads. The total number of

pads is 2(78+118) = 392 pads.

(b) Along the 10 mm edge, there will be room for (10 4/100) - 2 = 98 pads. Along the

15 mm edge, there will be room for (1.5x104/100) - 2 = 148 pads. The total number

of pads is 2(98+148) = 492 pads.

(c) Along the 10 mm edge, there will be room for (104/200) = 50 solder balls. Along

the 15 mm edge, there will be room for (1.5x104/200) = 75 solder balls. The total

number of solder balls is (50 x 75) - 4 = 3746.

8.4

DoA = 10 and α = 1.0

Yield Formula

8.5

Y

Number of Good Dice

100 mm: N = 254

150 mm: N = 616

exp(-DoA)

4.54 x 10-5

0

0

(1+DoA/5)-5

4.12 x 10-3

1

2-3

{[1- exp(-DoA)]/DoA}2

0.01

2-3

6

[1- exp(-2DoA)]/2DoA

0.05

12 - 13

30 - 31

1/(1+DoA)

0.09

23

56

The yield depends on the exact positioning of the die sites. The best-case die map

yields 2 good die when DoA = 4 giving a yield of 2/26 or 7.7%. The worst-case

- 53 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

partitioning would yield no good die for 0% yield. Poisson statistics predicts Y =

exp(-4) or 1.8%. For our wafer, Y = {0.43, 0.22, 0.077} for DoA = {1, 2, 4}. For Y =

α

[1 + DoA/α ]- , numerical fitting yields an excellent fit for α = 3.1.

- 54 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

8.6

(a) Do = 10 and A = 0.4 cm2. Y = [1-exp(-8)]/8 = 0.125. N = π (R-S)2/S2 =

π (62.5mm - 6.3mm)2/(6.3mm)2 = 248 die, where S has been approximated by 40

mm. Thus, there will be Y x N = 31 good dice. The total cost will be $1.60 +

$250/31 = $9.67/die.

(b) The area of each die becomes 1.15(20) = 23 mm2. S is approximated by A =

4.8 mm, and N = 455 dice. Yield Y = [1-exp(-4.6)]/4.6 = 0.215, and Y x N = 98 good

dice. The new cost per packaged die is $1.60 + $250/98 = $4.15/die. The total cost

of the two-die set is $8.30, which is more economical!

8.7

(a) Do = 5, and wafer cost = $150. A = 40 mm2, and S = 40 mm. N = 248, and Y

= 0.245. Y x N = 61 dice, and C = [1.60 + 150/61] = $4.06. For two dice, A = 23

mm2, N = 455, Y = 0.391 and Y x N = 178. The total cost is 2[1.60 + 150/178] =

$4.89 which is more expensive.

(b) For a single chip, C = [1.60 + 300/61] = $6.52. For two dice, C = 2[1.60 +

300/178] = $6.57.

8.8

(a) For the first process: A = 25 mm2, and N = π (50-5)2/52 = 254 dice. Y = [1 – exp

(-2 x 2 x 0.25)] / (2 x 2 x 0.25) = 0.632. Y x N = 161 good dice. The cost per die is

C1 = M/161 for a wafer cost of M $/wafer. For the second process: A = 12.5 mm 2. N

= π (50-3.54)2/12.5 = 543 die, and Y = [1 - exp(-2 x 10 x 0.125)] / (2 x 10 x 0.125) =

0.367. Y x N = 199 good die per wafer. C 2 = 1.3M/199 = M/153. The new die is

only slightly more expensive even at a defect level of 10 defects/cm 2. The change is

not economical at the present time, but as the defect density improves with time, the

second process will become more economical.

(b) For equal die cost in the new process, we need Y x N = 1.3 x 161 = 209 good die.

This requires Y = 209/543 = [1 - exp (-2 x 0.125Do)]/(2 x 0.125Do). Letting X =

0.25Do, results in the equation 0 = 1 - 0.385X - exp(-X) which may be solved

numerically using Newton's method or the solver on a calculator yielding X = 2.35

and Do = 9.4

(c) We would switch since we expect the new process to improve, and the die cost

will be less as we move down the learning curve.

(d) The cost in the first process is M/161. In the new process, N = π (50- A )2/A

and Y = [1 – exp(-0.2A)]/0.2A (A in mm2). For equal cost we must have Y x N =

1.3(161), and we must solve the equation below for A (A in mm2).

π (50- A )2[1-exp(-0.2A)]/0.2A2 = 1.3(161)

Using Newton's method or a calculator solver yields A = 12.17 mm2.

8.9

α

lim (1 + DoA/α )-

α

= lim 1/(1 + DoA/α ) = exp(-DoA).

- 55 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

α →∞

α →∞

- 56 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

8.10

DoA

exp(-DoA)

α =5

α = 5000

1

2

3

4

5

6

7

8

9

10

3.68E-01

1.35E-01

4.98E-02

1.83E-02

6.74E-03

2.48E-03

9.12E-04

3.35E-04

1.23E-04

4.54E-05

4.02E-01

1.86E-01

9.54E-02

5.29E-02

3.13E-02

1.94E-02

1.26E-02

8.42E-03

5.81E-03

4.12E-03

3.68E-01

1.35E-01

4.98E-02

1.83E-02

6.75E-03

2.49E-03

9.16E-04

3.38E-04

1.24E-04

4.59E-05

8.11

N = (0.1)(π d2/4). N = 17.7, 31.4, and 70.7 for the 15, 20 and 30 cm diameter wafers.

8.12

For both wafers, Yx = (1 + 10Ax/2)-2 = 1/(1 + 5Ax)2. For the 100 mm wafer, N1 =

π (50- A 1 )2/A1 , and the cost per die is $150/N1Y1.

For the 150 mm wafer, N2 = π (75- A 2 )2/A2 , and the cost per die is $250/N2Y2.

For equal cost, $150/N1Y1 = $250/N2Y2. For a given A1, we can find the

corresponding A2. Thus we need to choose some cost, say $1/die. Setting $150/N 1Y1

= $1 and $250/N2Y2 = $1 and solving for the areas gives A1 = 14.8 mm2 and A2 =

17.8 mm2.

8.13

There are now 10 good dice out of 60 sites for a yield of 17%. Two good dice exist

out of with 24 sites with 4 times the area for a yield of 8.3%.

∞

8.14

Y = ∫ exp(−DA ) f (D) dD . After substitution of our f(D) and changing variables

0

with Z = D/Do, the integral becomes

2

2

2

Y1 =

exp[− Z(D o A )] exp -4(Z -1) dZ

∫

π0

This can be integrated numerically, and the results are compared below with Y2 = [1exp(-DoA)/DoA]2.

[

DoA

Y1

Y2

1

0.39

0.40

- 57 -

]

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

2

3

4

5

0.17

0.084

0.046

0.028

0.19

0.10

0.060

0.040

- 58 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

6

7

8

9

10

8.15

0.018 0.028

0.012 0.020

0.0092 0.016

0.0071 0.012

0.0056 0.010

We need to evaluate Pk = [n!/k!(n-k)!]Nn(N-1)n-k for N = 120 and k = {0,1,2,3,4,5}.

Let λ = n/N. For N = 120, n = 120, λ = 1. Pk may be approximated by

Pk = [λ n exp(-λ )]/k! = exp(-1)/k!.

# of

defects

0

1

2

3

4

5

8.16

N x Pk

44

44

22

7

2

0

D o A −5

(a) 0.70 = 1 +

yields DoA = 0.370. Do = 0.370/1.5 = 0.247 defects/cm2.

5

Do A −5

(b) 0.80 = 1 +

yields DoA = 0.228. Do = 0.228/1.5 = 0.152 defects/cm2.

5

D o A −5

(c) 0.90 = 1 +

yields DoA = 0.107. Do = 0.107/1.5 = 0.071 defects/cm2.

5

8.17

D o A −6

(a) 0.75 = 1 +

yields DoA = 0.295. Do = 0.295/4 = 0.0737 defects/cm2.

6

Do A −6

(b) 0.85 = 1 +

yields DoA = 0.165. Do = 0.295/4 = 0.0412 defects/cm2.

6

- 59 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

CHAPTER 9

9.1

10 nm = 10-8 m = 10-6 cm = 100Å. V = (5 x 106 V/cm) x Tox = 5 x 106 x 10-6 = 5 volts.

9.2

(a) The built-in potential = 0.56 + 0.0258 ln (1015/1010) = 0.857 V. The total voltage

across the junction is (3 + 2 + 0.857) = 5.86 volts. Dividing by the background

concentration yields a value of 5.86 x 10-15 V-cm3. From Fig. 9.4, the depletion layer

width will be 3.0 µ m. The minimum line spacing must be twice this value or 6.0

µ m.

Using Eq. 9.3 directly, 2Wd = 2

2(11.7 )(8.854 x10 −14 )(5.86 )

1.602 x10 −19 (10 15 )

= 5.51 µm .

(b) The built-in potential = 0.56 + 0.0258 ln (3x1016/1010) = 0.945 V.

2Wd = 2

9.3

2(11.7 )(8.854x10−14 )(5.95)

1.602x10−19 (3x1016 )

= 1.01 µm

The built-in potential is Φ bi = 0.56 + 0.0258 ln (3x1016/1010) = 0.945 V. For NB = 3

x1016 /cm3, Eqn. 9.3 becomes W = 2.08 x 10-5 VA + Φbi . At the source side, the

depletion layer has only the built-in potential across the junction, and Wd = 0.202

µ m. At punch-through, the depletion-layer width at the drain will be (1-0.202) =

0.798 µ m. Finding VA for Wd = 0.798 µ m yields an applied voltage of 13.8 volts.

9.4

- 60 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

4

3

2

1

0

-1

-2

-3

-4 14

10

10 15

10 16

10 17

3

Doping Concentration (#/cm )

- 61 -

10 18

10 19

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

9.5

An NMOS transistor is an enhancement-mode device if VTN > 0. Fig. 9.2 is for

polysilicon gate devices with 10-nm gate oxides. From this graph, VTN > 0 for N > 2

x 1016/cm3. A more exact estimate can be obtained from Eq. (9.2):

1.12

VTN = −

+ Φ F + 2(11.7 )(8.854x10−14 )(1.602x10−19 ) NB Φ F /CO for

2

NB

3.9(8.854x10 −14 )

Φ F = 0.0258 ln 10 and CO =

= 3.45 x 10-7 F /cm 2

10

10 −6

Using a spreadsheet or solver yields NB = 2.9 x 1016/cm3.

9.6

From Fig. P9.6, NB = 2 x 1015/cm3. Using Eq. 9.2, the threshold voltage with no

implant would be VTN ≅ 0 V. The shift caused by the implant is ∆ VTN = qQi/CO, so

we need the implanted dose which is given by Q = 2π N P ∆R P with the implant

peak at the surface. The characteristics of the implant are found by subtracting the

background concentration from the profile in Fig. P9.6. The peak concentration of

the implant is 2 x 1016/cm3 at x = 0, and the implanted profile drops to 4 x 1015 at x =

0.25 µ m. The projected range is found from 4 x 10 15 = 2 x 1016 exp-(0.25)2/2∆ Rp2,

16

−5

and the projected range is 0.139 µ m. The dose Q = 2π (2x10 ) (1.39 x10 ) =

6.99 x 1011/cm2. The oxide capacitance is 1.73 x 10-7 F/cm2 for a 20 nm gate oxide.

∆ VTN = (1.602 x10-19)(6.99x1011)/(1.73x10-7) = 0.647 V. So the resulting threshold

voltage is 1.61V.

9.7

For the rectangular distribution N(x) = Ni for 0 ≤ x ≤ xi:

∞

∞

M1 = ∫ N(x) dx = Ni x i & M2 = ∫ x N( x) dx =

0

0

Ni x2i

2

2

For the Gaussian distribution N(x) = Np exp(-x /2∆ Rp2), and

π

2

M1 =

N ∆R P a nd M2 = N P ∆R P

2 P

Equating moments yields the specified results.

9.8

Scaling factor α = 1/0.25 = 4. The circuit density increases by α 2 or 16 times more

circuits/cm2. PDP ∝ 1/ α 3, so the power-delay product is reduced (improved) by a

factor of 64.

- 62 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

K ε

*

I D = µ n O O

XO

α

9.9

W

α

VD S

V

−

V

−

VD S = α ID

G

S

TN

L

2

α

ID increases by the scale factor α .

P* = α ID VDD = α P - Power/circuit increases by the scale factor.

P * αP

3 P

* = A = α

A

A

α2

-

The power density increases by the cube of the scale factor

which is very bad!

9.10

The non-implanted device will have a threshold given by

1.12

−14

−19

16

+ Φ F + 2(11.7 )(8.854 x10 )(1.602 x10 )(3x10 ) Φ F /CO = 0.721V

2

A

3x1016

3.9(8.854 x10 −14 )

-8

2

for ΦF = 0.0258 ln

and

C

=

=

6.91

x

10

F

/cm

O

10

−6

10

5x10

VTN = −

threshold voltage shift of 3.72 volts is required to achieve a -3-V threshold. The

required dose Q = CO∆ VTN/q = 1.61 x 1012/cm2.

9.11

In Fig. 1.8, reverse all the n- and p-type regions as well as the arsenic and boron

implantations.

9.12

A = 110 λ 2 versus 168 λ

2

- 63 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

22 α 11

= λ

20 α 10

= λ

- 64 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

9.13

(a) The well doping is almost constant and equal to the surface concentration in the

depletion-region beneath the gate of the MOSFET. So the substrate doping for the

NMOS device is 3 x 1015/cm3 and 3 x 1016/cm3 for the PMOS device. VTN is

calculated using Eqns. 9.2 with CO = 2.30 x 10-7 F/cm2 for a 15 nm oxide thickness.

3x1015

= 0.325 V

Φ F = 0.0258ln

1010

VTN = −0.56 + 0.325 + 2(11.7)(8.854x10 −14 )(1.602x10−19 )(3x1015 )(0.325)/ CO = −0.16 V

3x1016

= 0.385 V

Φ F = 0.0258ln

1010

VTP = −0.56 − 0.385 − 2(11.7)(8.854x10 −14 )(1.602x10−19 )(3x1016 )(0.385 ) /CO = −1.21V

(b) The NMOS device requires a +1.16-V shift, and the PMOS device requires a

+0.21-V shift. The required dose is given approximately by Q = C O∆ VT/q. The dose

for the NMOS device is 1.67 x 1012/cm2, whereas it is 3.02 x 1011/cm2 for the PMOS

device. Note that both shifts are positive and would utilize boron implantations.

9.14

0V

8V

0V

8V

p+

n+

3 x 1015 /cm3

n

5 x 1016 /cm3

p-well

p+n junction with 8 V bias:

Φbi = 0.56 + 0.0258 ln(3x1015 1010 ) = 0.885V

Wd =

2(11.7 )(8.854x10 −14 )(8.885 )

1.602x10 −19 (3x1015 )

= 1.96 µm

n+p junction with 8 V bias:

Φbi = 0.56 + 0.0258 ln(5x10

Wd =

16

10

10

) = 0.958V

2(11.7 )(8.854x10 −14 )(8.958 )

1.602x10 −19 (5x1016 )

= 0.481 µm

Two-sided formula for the well-substrate junction:

3x1015 • 5x1016

kT N AN D

= 0.723V

Φ bi =

ln 2 = 0.0258ln

20

q ni

10

- 65 -

© 2002 Prentice Hall

Introduction to Microelectronic Fabrication – Second Edition

Wd =

2K S ε o (V A + Φbi ) N A ND

q

N A + ND

Wd =

2(11.7 )(8.854x10 −14 )(8.732 ) 3x1015 • 5x10 16

= 2.00 µm

−19

16

1.602x10

5.3x10

The minimum spacing is W = 1.96 + 0.48 + 2.00 = 4.44 µ m with no safety margin or

alignment tolerances considered.

9.15

(a) 10 Ω -cm ν (n-type) material has a doping of 4.2 x 1014/cm3 based upon Fig. 4.8.

For a junction depth of 2 µ m, we have

2x10−4 2

14

16

→ Dt = 3.154x10−9 cm2

4.2 x10 = 10 exp −

2 Dt

For boron at 1075 oC, D = 10.5 exp[-3.69/(8.617 x 10-5 x 1348)] = 1.678 x 10-13

cm2/sec, and the drive-in time t = 5.22 hours. The dose Q = NO πDt = 9.95 x

1011/cm2. From Fig. 4.10(b) with N/NO = 0.042, X Y = 1.3/1.8 = 0.722. Lateral

diffusion = 1.4 µ m.

(b) For this case, we have

4.2 x10

14

1.5x10−4 2

→ Dt = 1.177x10 −9 cm2

= 5x10 exp −

2

Dt

16

D for phosphorus is the same as D for boron, and the drive-in time t = 1.95 hours.

The dose Q = NO πDt = 3.04 x 1012/cm2. From Fig. 4.10(b) with N/NO = 0.0084,