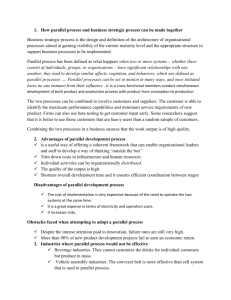

Ergonomics and Manual Material Handling Conductor Section 1. Cutting 1. Transfer from cart to machine conveyer 2. Cut the left side 3. Push to second stopper and cut right side 4. Transfer to wooden board on main conveyer line for next process 2. Configuration Pressing 1. Transfer from main conveyer line to machine conveyer 3. Align and press left side 2. Align and press right side 4. Transfer from machine conveyer back to main conveyer line on wooden board 5. Line up portable conveyer table at end of main conveyer line 6. Push the material onto the portable conveyer table 7. Push the portable conveyer table to next process 3. PLG Stamping 1. Transfer from cart to machine conveyer 2. Hold tightly and stamp 3. Slide to next process Copper is carried by 2 persons 3. PLG Pressing 1. Insert PLG Clip 2. Hold tightly and press 3. Transfer from machine conveyer to cart and push to next process Copper is carried by 2 persons Examples of Awkward Postures Tips to Minimize Repetition • Change tasks, stretch, or take a break from repetitive tasks. • Request for job rotation where applicable. • Arrange work to avoid unnecessary motions • Change hands or motions frequently • Spread repetitive work out during the day Tips & Reminders 1. Utilized conveyer system as much as possible. 2. Handle conductor bars in pair, especially larger ones and copper bars 3. Maintain handling in power zone, between shoulders and knees, as close to the body as possible 4. Communicate and establish personal cue with partners when handling materials to prevent postural mismatch and imbalance. 5. Discuss lifting plan so you don’t make surprise movements. 6. Do not twist your body. Step to one side or the other to turn 7. Plan the workflow to eliminate unnecessary carrying 8. Slide or push instead of carrying and lifting, when appropriate