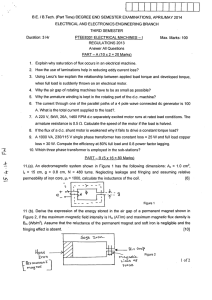

DC MACHINES / COMMUTATING MACHINES DC GENERATOR DC MOTOR Separately Excited Shunt Self-Excited Series Permanent Magnet Compound Separately Excited Shunt Self-Excited Series Permanent Magnet Compound DC Motor: Armature Windings Stator Pole Shoe Rotor Rotation of shaft (mechanical output) Working Principle- When current flows through the armature winding (more coils are used to generate more torque) in the magnetic field created by current flowing (excitation current) through field winding on the stator, the rotor rotates as well as rotating the shaft and creating mechanical work from the DC supply given at the terminals. Types of DC Motor: Separately Excited DC Motor: Usually, in other DC motors, the field coil and the armature coil both are energized from a single source. The field of them does not need any separate excitation. But, in separately excited DC motor, separate supply is provided for excitation of both field coil and armature coil. Here, the field coil is energized from a separate DC voltage source and the armature coil is also energized from another source. Armature voltage source may be variable. But independent constant DC voltage is used for energizing the field coil. In separately excited motor field is supplied from constant voltage so that the field current is constant. Eb=V-Ia Ra Eb = PØNZ/60A (where, P = no. of poles, Ø = flux/pole, N = speed in rpm, Z = no. of armature conductors, A = parallel paths) Speed of motor = Eb/flux Field controlFlux (decreases) -> speed (increases) Field rheostat control - Here a variable resistance is connected in series with the field coil. Thus, the speed is controlled by means of flux variation. Armature ControlArmature resistance control- Here, the speed is controlled by varying the source voltage to armature. Generally, a variable resistance is provided with the armature to vary the armature resistance. Armature Terminal Voltage- Involving variation of variation of voltage in armature circuit. Self-Excited DC Motor: Series Motor: Series motor has field coil connected in series to the armature winding. For this reason, relatively higher current flows through the field coils. Therefore, field coils have less number of turns with the heavier wire of larger diameter such that resistance is less. For series DC motor I = If = Ia If ∝φ τa∝φIa τa∝Ia2 If=Ia=φ τa∝I2a τa∝ φ2 N= Eb/ φ N∝ 1/√τa Ia = increase then Torque will increase by it’s square. Thus, decreasing the speed of motor. As the load goes on increasing speed of DC series motor will drop rapidly. Series motors are generally operated for a very small duration, about only a few seconds, just for the purpose of starting. Because if its run for too long, the high series current might burn out the series field coils thus leaving the motor useless. As in this case relatively higher current flows through the circuit, heavy series field winding with thicker diameter is used, the electromagnetic torque produced here is much higher than normal. This high electromagnetic torque produces motor speed, strong enough to lift heavy load overcoming its initial inertial of rest. And for this particular reason the motor becomes extremely essential as starter motors for most industrial applications dealing in heavy mechanical load like huge cranes or large metal chunks etc. Shunt Motor: In DC Shunt motor the field winding is connected in parallel with armature winding. Shunt wound DC motor is called a constant flux motor because their field winding is directly connected across the supply voltage which is assumed to be constant. I total = If+Ia If=V/Rf (V is constant, assuming that motor is running and Rf is not changing) Therefore, If= constant If ∝φ Therefore, φ=constant τa∝φIa But, φ = constant Therefore, τa ∝Ia Therefore, Torque is directly proportional to armature current as flux is constant. Hence, large current is required to start a heavy load. Thus, the shunt motor should not be started on heavy loads. The armature winding must be exposed to an amount of current that’s much higher than the field windings current, as the torque is proportional to the armature current. So field winding has many turns such that most of the current goes through armature. But the wire is kept thin as opposed to that of series motor field winding which needs thicker wire to carry large current. So, in static condition, DC series and shunt motor can be distinguished by this characteristic of wires. N α Eb/Ф Eb is back emf of armature But, φ = constant Therefore, N α Eb Eb = V-IaRa But V is constant With an increase in the armature current with a load, the back EMF decrease very small due to small IaRa voltage drop as armature resistance is very low. Thus, the ratio of Eb/Φ remains almost constant, and the speed of the motor is almost constant with an increase of armature current with loading. Therefore, the DC shunt motor is a constant speed motor. Compound Motor: In DC Compound Motor, the field winding is both in series and parallel with armature winding. We know that the compound motors are made with a combination of shunt and series field windings with the armature winding. Hence the characteristics of dc compound motors will be combined characteristics of shunt and series motors. But the characteristics depend upon how the two field windings are connected. In a cumulative compound motor, the flux produced by the series field winding assists the flux produced by the shunt field winding. Cumulative compound motors are used where series characteristics are required but the load is likely to be removed completely. Series winding takes care of the heavy load, whereas the shunt winding prevents the motor from running at dangerously high speed when the load is suddenly removed. These motors have generally employed a flywheel, where sudden and temporary loads are applied like in rolling mills. In differential compound motor, the series field flux opposes the shunt field flux (reduction in resultant flux). Since in differential field motors, series flux opposes shunt flux, the total flux decreases with increase in load. Due to this, the speed remains almost constant or even it may increase slightly with increase in load (N ∝ Eb/ɸ). Differential compound motors are not commonly used, but they find limited applications in experimental and research work. Ia=Isc I total=Ia + Ish τa∝φIa if Ia (load) increases τa also increases N= Eb/ φ In cumulative the total φ increases, while in differential the total φ decreases With increase/decrease in φ, speed will decrease and increase respectively Permanent Magnet DC Motor A permanent magnet DC Motor is a DC Motor which uses permanent magnet instead of electromagnet. As the magnetic field strength of a permanent magnet is fixed it cannot be controlled externally, field control of this type of DC motor cannot be possible. The permanent magnets are mounted in such a way that the N-pole and S-pole of each magnet are alternatively faced towards armature. Although field coil is not required in permanent magnet DC motor still it is sometimes found that they are used along with permanent magnet. This is because if permanent magnets lose their strength, these lost magnetic strengths can be compensated by field excitation through these field coils. Generally, rare earth hard magnetic materials are used in these permanent magnets. The rotor of a PMDC motor is similar to other DC motors. The PMDC Motor circuit: (no field coils) No input power in consumed for excitation which improve efficiency of DC motor. V=IaRa + Eb PMDC motor is extensively used where small DC motors are required and also very effective control is not required, such as in automobiles starter, toys, wipers, washers, hot blowers, air conditioners, computer disc drives and in many more. DC Generator: Supply: DC supply generated Note: Supply is not coming out of stator; it is coming out of rotor (armature winding) itself Shaftmoved by crank Working Principle- In a DC generator, field coils produce an electromagnetic field (DC supply given for the field excitation) and the armature conductors are rotated in this field. This induces induced emf and current (Fleming’s right hand rule) in the armature winding. Finally, getting DC current through armature. Separately Excited DC Generator: A separately excited DC Generator is one in which field winding is excited by a separate independent DC source like battery. The magnitude of generated voltage depends upon the speed of rotation of armature and the field current, i.e., greater the speed and the field current, higher is the generated voltage. In practice, the separately excited DC generators are rarely used. V=Eb-IaRa Power Developed: Eb Ia Power Delivered to the Load: Eb Ia – Ia2Ra Self-Excited DC Generator Self-excited DC generators have field magnets that are energized by their own supplied current, and the field coils are connected to the armature internally. There is always some flux in the poles because of the residual magnetism. As the armature rotates, some current is produced, and this small current flows through the field coils with the load and strengthening the pole flux. By increasing the pole flux, the EMF and the current increase, and the accumulative process is continuing until the excitation is necessary. Series DC Generator In Series Generator, field winding is in series with armature winding so that whole armature current would flow through the field winding as well as the load. Since the load current flows through the field winding of the generator, so the field winding has a few turns of thick wire having low resistance. The DC series generators are used in special applications like boosters. Ia=If=Il V=Eb-IaRa-If Rf Power Developed: Eb Ia Power Delivered to the Load: EbIa-Ia2Ra-If2Rf = EbIa-Ia2 (Ra + Rf) Shunt DC Generator In case of a shunt generator, the field winding is connected in parallel with the armature of the generator so that terminal voltage of the generator is applied across it. The shunt field winding has many turns of thin wire having high resistance so that only a fraction of armature current flows through the shunt field winding and the rest flows through the load. Ia= If + IL V=Eb-IaRa Power Developed: Eb Ia Power Delivered to the Load: V IL= (Eb Ia-Ia2 Ra – Ish2Rsh) Compound DC Generator In case of a compound generator, there are two field winding on each pole – one is in series and the other is in parallel with the armature. The DC compound generators are of two types – Short shunt compound generator In a short shunt generator, only shunt field winding is connected in parallel with the armature. IL=Ish (Rsh = Rsc) Eb-IaRa-IL Rsc-V=0 V= Eb-IaRa-IL Rsc or V=Eb-IaRa-Ish Rsc Power Developed: Eb Ia Power Delivered to Load: V IL = Eb Ia – Ia2 Ra – IL2Rsc – Ish2Rsh Important − In compound generator, the majority of MMF is established by the shunt field winding. If the series field flux assists the shunt field, then the generator is called cumulatively compounded and when they oppose each other, the generator is called differentially compounded. Long shunt compound generator In a long shunt generator, the shunt field winding is connected in parallel with both series field and armature winding. Ia = IL + Ish V= Eb-Ia Ra-Ia Rse Power developed =Eb Ia Power Delivered to the Load= V IL = Eb Ia – Ia2 Ra – Ia2 Rse-Ish2 Rsh Permanent Magnet DC Generator: Ia Ra L O A D Eb-IaRa=V Power developed = Eb Ia Power delivered to load =Eb Ia – Ia2Ra The Permanent Magnet DC Generator can be considered as a separately excited DC brushed motor with a constant magnetic flux. In fact, nearly all permanent magnet direct current (PMDC) brushed motors can be used as a permanent magnet PMDC generator, but as they are not really designed to be generators, they do not make good wind turbine generators. These DC machines consist of a stator having rare earth permanent magnets such as Neodymium or Samarium Cobalt to produce a very strong stator field flux instead of wound coils. The main advantage over other types of DC generator is that the permanent magnet DC generator responds to changes in wind speed very quickly because their strong stator field is always there and constant. Permanent magnet DC generators are generally lighter than wound stator machines for a given power rating and have better efficiencies because there are no field windings and field coil losses. Also, as the stator is provided with a permanent magnet pole system, it is resistant to the effects of possible dirt ingress. However, if not fully sealed, the permanent magnets will attract ferromagnetic dust and metallic swarf (also called turnings or filings) which may cause internal damage. The permanent magnet DC generator is a good choice for small scale wind turbine systems as they are reliable, can operate at low rotational speeds and provide good efficiency especially in light wind conditions as their cut-in point is fairly low. The DC voltage generated by a permanent magnet DC machine is governed by the following three factors: The magnetic field developed by the stator. This depends upon the physical size of the generator and the strength and type of the permanent magnets used. The number of turns or loops of wire on the armature. This value is fixed by the physical size of the generator and armature and by the size of wire conductor. The more turns used the higher the output voltage. Likewise, the larger the wire diameter or crosssectional area the higher the current. The rotational speed of the armature which is governed by the speed of the wind turbine rotor blades relative to the wind velocity. For PMDC generators and motors, output voltage is proportional to speed and is generally linear. One of the main disadvantages of a permanent magnet DC generator, is that these machines have commutating brushes that carry the full output current of the generator so DC machines used as dynamos and generators require regular maintenance as the carbon brushes used to extract the generated current quickly wear out and produce a lot of electrically conductive carbon dust inside the machine. Therefore, AC alternators are sometimes used. The Permanent Magnet DC Generators is a low-speed generator that are pretty reliable and efficient in light winds for use in “off-grid” stand alone systems to charge batteries, or to power low voltage lighting and appliances. They generally have linear power curves with low cut-in speeds of around 10 mph. Induction Motor: Air Gap Stator Windings Rotor Windings We need to give double excitation to make a DC motor to rotate. In the DC motor, we give one supply to the stator and another to the rotor through brush arrangement. But in induction motor, when we give three phase supply to the induction motor, rotating magnetic field/flux gets produced as a current carrying coil produces magnetic field (windings are places 120 degree apart to create rotation). The flux from the stator cuts the short-circuited coil in the rotor. As the rotor coils are short-circuited at the ends (if kept open circuited no current will flow) , according to Faraday’s law of electromagnetic induction, the current will start flowing through the coil of the rotor. When the current through the rotor coils flows, another flux gets generated in the rotor. Now there are two fluxes, one is stator flux, and another is rotor flux. The rotor flux will be lagging with respect to the stator flux. Because of that, the rotor will feel a torque which will make the rotor to rotate in the direction of the rotating magnetic field. Theoretically induction motor cannot run on synchronous speed. However if by some external force, or system fault such as surge voltage, somehow if speed of rotor becomes equal to synchronous speed there will be no torque produced and motor will stop running. Therefore, induction motors are also called asynchronous motors because they operate at speed less than that of their synchronous speed. Torque slip characteristics of Three Phase Induction Motor Torque generated by Induction Motor under running condition: T = P / ws T = 3 *E2 I2 cosɸ2 / (2 𝜋 𝑁𝑠) If k1 = 3 / 2πNs Therefore, T = k1 E2 I2 cosɸ2. Rotor side equivalent Circuit: 𝑍𝑟 = √𝑅2 2 + (𝑠𝑋2 )2 𝑇 = 𝐾1 𝐸2 ( 𝑠𝐸2 𝑅2 2 𝑅2 + 𝑠 2 𝑋2 2 ) = 𝐾1 𝐸2 2 ( 𝑠𝑅2 2 𝑅2 + 𝑠 2 𝑋2 2 )= 3 𝑠𝑅2 𝐸2 2 ( 2 ) 2πNs 𝑅2 + 𝑠 2 𝑋2 2 The variation of slip can be obtained with the variation of speed that is when speed varies the slip will also vary and the torque corresponding to that speed will also vary. 𝑠= 𝑁𝑠−𝑁𝑟 𝑁𝑠 3 𝑅2 2 +𝑋 2 ) 2 Starting Torque / Locked Rotor Torque: When Nr=0, s=1, Tst= 2πNs 𝐸2 2 (𝑅 Nr increases and slip decreases, so torque will increase (increases till T max (break-down troque)) (𝑇 ≅ 1/𝑠) 2 o 𝜕𝑇 o We get, o Substituting 𝜕𝑠 =0 𝑠= 𝑅2 𝑋2 𝑠= 𝑅2 𝑋2 in T equation 𝑘 𝐸2 2 o Tm = 2 𝑋2 Now, Nr reaches Ns as Nr=Ns s=0 and thus T= 0 Unstable Region Stable Region Break-down Torque Full Load Operating Torque Pull-up Torque 𝑠= s=1 𝑅2 𝑋2 s=0 and T=0 s Nr Motoring Region Stability means that even for a small variation in the torque the speed of the machine must not vary significantly. This is what happens in the 0-10% slip region of the curve. That means, slip varies almost linearly with the torque. On the other hand, this is not the case on the other region of the curve where for a small variation in torque the speed of the machine changes drastically (the Rectangular Hyperbola). Hence, it’s an unstable region. And IM must always be operated in the stable region. Single Phase Induction Motor: A single-phase induction motor is similar to the three-phase squirrel cage induction motor except there is single phase two windings instead of one three phase winding in 3-phase motors, mounted on the stator. The rotor of single-phase induction motor is the same as a rotor of squirrel cage induction motor. Instead of rotor windings, rotor bars are used and it is short-circuited at the end by end-rings. Single-phase AC supply is given to the stator winding (main winding). The alternating current flowing through the stator winding produces magnetic flux. This flux is known as the main flux. The flux is alternating in nature and not rotating as in three phase induction motor. If we place rotor in this field then it will not rotate but it will produce humming. But if we assume that the rotor is rotating and it is placed in a magnetic field produced by the stator winding. According to Faraday’s law, the current start flowing in the rotor circuit as it is a close path. This current is known as rotor current. Due to the rotor current, the flux produced around the rotor bars. This flux is known as rotor flux. There are two fluxes; main flux which is produced by stator and second is the rotor flux which is produced by the rotor. Interaction between main flux and rotor flux, the torque produced in the rotor and it starts rotating. So, single phase IM is not self-starting. Therefore, we need to make some arrangements for selfstarting: The single-phase induction motors are classified as: Split Phase Induction Motor Shaded Pole Induction Motor Capacitor Start Induction Motor Capacitor Start Capacitor Run Induction Motor Permanent Capacitor Induction Motor Split Phase IM: In this type of motor, an extra winding is wounded on the same core of the stator. So, there are two windings in the stator. One winding is known as the main winding or running winding and second winding is known as starting winding or auxiliary winding. A centrifugal switch is connected in series with the auxiliary winding. The auxiliary winding is highly resistive winding and the main winding is highly inductive winding. The auxiliary winding has few turns with a small diameter. The aim of auxiliary winding is to create a phase difference between both fluxes produced by the main winding and rotor winding. The connection diagram is as shown in the below figure. The current flowing through the main winding is IM and current flowing through the auxiliary winding is IA. Both windings are parallel and supplied by voltage V. The auxiliary winding is highly resistive in nature. So, the current IA is almost in phase with supply voltage V. The main winding is highly inductive in nature. So, the current IM lags behind the supply voltage with a large angle. The total stator flux is induced by the resultant current of these two winding. Auxiliary winding only uses to start the motor. This winding is not useful in running condition. When the motor reaches 75 to 80 % of synchronous speed, the centrifugal switch opens. So, the auxiliary winding is out from the circuit. And motor runs on only main winding. The phase difference creates by this method is very small. Hence, the starting torque of this motor is poor. So, this motor is used in low starting torque applications like a fan, blower, grinder, pumps, etc. Shaded Pole IM This type of motor does not require auxiliary winding. This motor has stator salient pole or projecting pole and the rotor is the same as squirrel cage induction motor. The stator poles are constructed specially to create a rotating magnetic field. A pole of this motor is divided into two parts; shaded part and un-shaded part. It can be created by cutting pole into unequal distances. A copper ring is placed in the small part of the pole. This ring is a highly inductive ring and it is known as a shaded ring or shaded band. When an alternating supply is passed through the stator winding, an alternating flux is induced in the stator coil. This flux induces eddy currents in the shaded ring, producing some amount of flux in it. According to Lenz law, the flux produced due to this shaded ring will oppose the main flux. So, it will create a phase difference between the main flux and the induced flux in the ring by approximately 90 degrees and this phase difference aids to rotate the rotor. By this method, a phase difference is very less. Hence, the starting torque is very less. It is used in applications like toy motor, fan, blower, record player, etc. Capacitor Start Induction Motor: This type of motor is an advanced version of the Split phase induction motor. The disadvantage of split-phase induction is low torque production. Because in this motor, the phase difference created is very less. This disadvantage compensates in this motor with the help of a capacitor connected in series with auxiliary winding. The circuit diagram of this motor is as shown in the below figure. The capacitor used in this motor is a dry-type/electrolytic capacitor. This is designed to use with alternating current. But this capacitor is not used for continuous operation. In this method also, a centrifugal switch is used which disconnects the capacitor and auxiliary winding when the motor runs 75-80% of synchronous speed. The current through auxiliary will lead the supply voltage by some angle. This angle is more than the angle increased in a split-phase induction motor. So, the starting torque of this motor is very high compared to the split-phase induction motor. The starting torque of this motor is 300% more than the full load torque. Due to high starting torque, this motor is used in the applications where high starting torque is required like, a Lath machine, compressor, drilling machines, etc. Capacitor-start, Capacitor-run single-phase induction motor Although the use of an electrolytic capacitor increases the starting torque, the capacitor gets damaged if operated too frequently for shorter durations or if operated for longer durations (as they are rated for short-duty service). Therefore, we use two capacitors parallel to each other such that during starting of the motor both the capacitors and the armature remains in the circuit and high torque is generated. The first one is an oil-impregnated capacitor (Cr). It is a continuous rating capacitor with a smaller value. The second one is an electrolytic capacitor (Cs). It is a short-duty capacitor with a higher value. When the motor picks 75% of the synchronous speed, the centrifugal switch disconnects the starting capacitor (Cs) from the circuit. Thus, after that, only the running capacitor (Cr) remains with the auxiliary winding. Here, the auxiliary winding remains connected in the circuit at all times, i.e., both starting and running. Due to a better starting and running torque, these motors are ideal for compressors, refrigerators, and pumps. Their low noise feature makes them beneficial to use in hospitals and studios. Permanent Split Capacitor Motor: This motor uses only one capacitor in series with the auxiliary winding. Here, the capacitor remains connected in the circuit during the starting as well as running. So, there is no need for a centrifugal switch, as discussed in the above types of single-phase induction motors. The advantages of this motor are similar to that of a capacitor start, capacitor run induction motor. But due to the use of only one capacitor, this motor can’t give optimum starting and running conditions. It uses a Pyranol insulated foil paper capacitor. They are ideal for ceiling fans, blowers, room coolers, and other domestic applications. Due to the simple reversal of the motor, they are best for induction regulators and furnace controls.