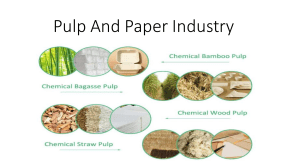

Paper is made through a process that involves breaking down raw materials, primarily wood fibers, into a pulp, then forming and drying the pulp into thin sheets. Here's an overview of the paper-making process: ● Raw Material Selection: The primary raw material for papermaking is wood, typically sourced from trees like pine, spruce, or fir. However, paper can also be made from other materials like recycled paper, cotton, or even bamboo. ● Pulping: - Mechanical Pulping: In this method, wood logs are mechanically ground down using large machines with grinding stones or refiners. This process retains most of the wood's original fibers but can result in shorter and coarser fibers. - Chemical Pulping: In chemical pulping, wood chips are treated with chemicals like sodium hydroxide (caustic soda) and sodium sulfide to break down lignin, which holds the wood fibers together. This method produces longer and stronger fibers. - Semi-Chemical and Chemi-Mechanical Pulping: These processes combine elements of both mechanical and chemical pulping. ● Cleaning and Screening: The pulp is cleaned to remove impurities like dirt, bark, and other non-fibrous materials. It is then screened to separate out the coarse and fine fibers. - Bleaching (if necessary): Depending on the desired quality and color of the paper, the pulp may undergo a bleaching process to remove any remaining lignin and achieve a whiter appearance. Paper Formation: ● The cleaned and screened pulp is mixed with water to create a papermaking slurry or suspension. ● This slurry is then poured onto a continuously moving wire mesh conveyor known as a Fourdrinier machine or cylinder mold machine. ● Water drains from the pulp, and the fibers start to bond together to form a mat or sheet. - Pressing: The formed paper sheet passes through rollers to squeeze out more water and compress the fibers. Drying: The paper is then dried through various methods, including heated rollers, steam cylinders, or air drying. Finishing: After drying, the paper may undergo additional processes, such as calendering (smoothing and flattening) and cutting into standard sheet sizes. Quality Control: The finished paper is inspected for quality, thickness, and other characteristics. Any defects are usually trimmed away. Packaging: The final paper rolls or sheets are packaged for distribution and use. The specific details of the paper-making process can vary depending on the type of paper being produced, whether it's for newspapers, cardboard, printing, or specialty papers. Additionally, many modern paper mills have adopted environmentally friendly practices, such as recycling and reducing chemical use, to minimize their environmental impact.