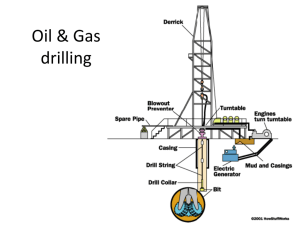

PE 4210 Lab #Number, Section A, B, or C – The Lab Title Author: YOUR NAME Abstract (3 points) Writing scientific reports is an important skill for petroleum engineering students. This document explains how to write reports for the PE4210 laboratory reports but should be transferable to other courses where reports are required as well. Including an abstract is required for the PE4210 laboratory exercises. An abstract should be a “stand alone” document where you should synthesize the whole report. Avoid referring to the paper in the abstract. Introduction (6 points) Technical writing is an important skill for you to have. Therefore I put some emphasis on the technical writing of laboratory reports in this course. The appropriate length of a report is typically 2 to 5 pages. The points for each portion of the report are given in each heading. Each section will be evaluated based on, structure, analytical content, technical writing and technical appearance. Structure is to get the right stuff in the right place. Keep your introduction in the introduction chapter, your procedure in the procedure chapter and so on. Analytical content evaluates if all analysis is conducted, all procedures described, and all results reported. Technical writing is to evaluate if questions are answered and the reasoning in your answers are clear. Technical appearance is to check if the laboratory report is made according to the standard (the report should look like this document) without different fonts and sizes in the text and with “scientific looking” figures and tables. The introduction section should introduce the background for your experiment and state the objective for the experiment. For this course it only has to be a few paragraphs. Example introduction for Lab 1. The whole purpose of the drilling operation is to create a hole however; the drilling process is very complex and expensive. While the hole is drilled with the drilling bit, drilling fluid is pumped down to remove the drilling cuttings out of the wellbore. After drilling for a certain depth, a certain casing has to be applied to the wellbore to secure the wellbore and prevent the groundwater from entering the wellbore. Also, to prevent the leakage in the wellbore, the casing has to be cemented. After the cement is solidified the well can be drilled deeper but the wellbore has to be smaller than the inside diameter of the casing. The objective of this experiment is to learn how to use the i-handbook software. Also, creating 3 different wellbore schematics using the ihandbook software and by using the ihandbook we will be able to find the volume of the annular, surface casing, intermediate casing, and production casing etc. we will also find the displaced volume due to the surface casing. Example procedure for Lab 1. To sketch a wellbore, first open the ihandbook software. In the upper right of the software click on the “wellbore” tab. You will see a new window that appeared. First, click on the “wellbore hardware” button and new window will appear. Choose “open hole” while holding the mouse button, move it to the wellbore diagram and held the curser to the red rectangle that will appear in the wellbore diagram and release the mouse. A new properties window will open and let you change the diameter and depth. Second, to choose a casing click on the “pipe” button. A new will appear has many casings, scroll down and find the casing needed. Click on the casing needed and hold the mouse and drag it over the wellbore diagram and change the casing depth when a new properties window appeared. Third, to find any volume needed, click on the on the “start volume” icon and choose the volume you need to find then select “end volume” and the value of the volume will appear in bbl. Results (20 points) Make a paragraph where you present your results. All tables and figures should be referred to in this text. Examples: Table 1 is an example of how table should look like. In scientific writing reporting data in tables and graphs is very important. First a note on tables, ALWAYS include a Table heading above the table itself with a number and explanation of the table. Table 1: Viscometer readings results for the 3 tested muds. Mud A Mud B Mud C 100 (RPM) 1° 2° 6° 300 (RPM) 1° 5° 12° 600 (RPM) 1° 7° 15° Figure caption should always be included on Figures. Figure 1 is a scientific looking figure in black and white where all axis and data are referenced. Figure 2 is an example of how figures should NOT look like. Shear stress (viscometer degrees) Procedure (10 points) In this section you need to present the actual procedure which you used in the class. The procedure needs to be detailed enough that others can replicate your work. Write the procedure IN YOUR OWN WORDS. You can reference the equipment details from the lab manual, but if you do, you need to reference it correctly. Equations you need for analyzing the results should be included in the procedure chapter. You should also only describe the experiments you did. If the exercises are modified or reduced to accommodate the 2 hours you have for the lab you should only report your results. 16 14 Mud C 12 10 8 6 Mud B 4 2 Mud A 0 0 100 200 300 400 500 600 700 Shear rate (RPM) Figure 1: This is how a scientific figure looks like. 16 14 12 10 Series1 8 Series2 6 Series3 4 2 0 0 100 200 300 400 500 600 700 Figure 2: This is not how a figure should look like with a lot of unnecessary colors and lack of axis labeling. Discussion (5 points) This is the section where you answer the questions asked in the lab manual. You can write it as a single answer for each question and number them according to the question in the lab manual or as a paragraph that answer all the questions. Write full sentences and explain your reasoning for your answers. Refer to figures and table when it is appropriate. Conclusions (5 points) State the important conclusions or findings of your experiments in YOUR OWN WORDS. Use short but clear statements. There should be no new information in the conclusion. References (1 point) 1. Drilling Laboratory handout #1 PE 4210 (2009) 2. Bourgoyne, A., et al., (1986) Applied Drilling Engineering, SPE text book series V 2.