Uploaded by

Shawon Chowdhury Pantha

Chemical Reaction Engineering Homework: Reactor Design

advertisement

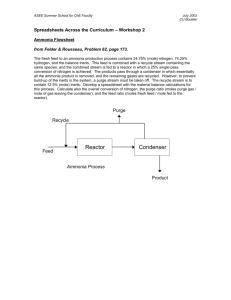

Department of Chemical Engineering Faculty of Engineering & Engineering Technology Abubakar Tafawa Balewa University, Bauchi CHE411: Chemical Reaction Engineering I Homework Submission Date: 23rd November, 2022 Problem 1: Water containing a short-lived radioactive species flows continuously through a well-mixed holdup tank. This gives time for the radioactive material to decay into harmless waste. As it now operates, the activity of the exit stream is 1/7 of the feed stream. This is not bad, but we'd like to lower it still more. One of our office secretaries suggests that we insert a baffle down the middle of the tank so that the holdup tank acts as two well-mixed tanks in series. Do you think this would help? If not, tell why; if so, calculate the expected activity of the exit stream compared to the entering stream. Solution Before insertion of baffle CAo CA1 = 1/7 CAo 𝑉1, 𝜏1 After insertion of baffle CAo CA2 = ? CAo 𝑉1 /2, 𝜏1 /2 𝑉1 /2, 𝜏1 /2 For the single mixed reactor, the performance equation is 𝜏1 = 𝑘𝜏1 = 𝐶𝐴0 − 𝐶𝐴1 𝑘𝐶𝐴1 𝐶𝐴0 −1 =7−1=6 𝐶𝐴1 After insertion of baffle, we have two well mixed tanks in series with the following performance equation For tank 1 𝜏1 𝐶𝐴0 − 𝐶𝐴1 = 2 𝑘𝐶𝐴1 𝐶𝐴1 1 = 𝐶𝐴0 1 + 𝑘𝜏1 2 𝜏1 𝐶𝐴1 − 𝐶𝐴2 = 2 𝑘𝐶𝐴2 𝐶𝐴2 1 = 𝐶𝐴1 1 + 𝑘𝜏1 2 For tank 2 Therefore 𝐶𝐴2 𝐶𝐴2 𝐶𝐴1 1 1 1 1 1 )( )=( )( )= = =( 𝑘𝜏 𝑘𝜏 𝐶𝐴0 𝐶𝐴1 𝐶𝐴0 1+3 1+3 16 1 + 21 1 + 21 Hence, for the two well mixed tanks in series the expected activity of the exit stream is 1/16 of the feed stream. Problem 2: Aqueous feed containing reactant A (CA0 = 2 mol/liter) enters a plug flow reactor (10 liter) which has a provision for recycling a portion of the flowing stream. The reaction kinetics and stoichiometry are and we wish to get 96% conversion. Should we use the recycle stream? If so, at what value should we set the recycle flow rate so as to obtain the highest production rate, and what volumetric feed rate can we process to this conversion in the reactor? Solution Given 𝐴 → 𝑅 𝜀𝐴 = 0, 𝐶𝐴0 = 2 −𝑟𝐴 = 1𝐶𝐴 𝐶𝑅 𝑚𝑜𝑙 , 𝑙𝑖𝑡𝑒𝑟 𝑚𝑜𝑙 𝑙𝑖𝑡𝑒𝑟. 𝑚𝑖𝑛 𝑉 = 10 𝑙𝑖𝑡𝑒𝑟, 𝑋𝐴𝑓 = 0.96 Recall that the performance equation for recycle reactor is 𝑋𝐴𝑓 𝑉 1 = (𝑅 + 1) ∫ 𝑅𝑋 𝑑𝑋 𝐴𝑓 𝐹𝐴0 (−𝑟𝐴 ) 𝐴 𝑋𝐴1 = 𝑅+1 The optimum recycle ratio that minimizes the reactor volume or space time (or maximizes the production rate) is given by 𝑋𝐴𝑓 1 | −𝑟𝐴 𝑋 𝐴𝑖 Which can also be written as = 1 𝑑𝑋𝐴 𝐴𝑖 (−𝑟𝐴 ) ∫𝑋 (𝑋𝐴𝑓 −𝑋𝐴𝑖 ) 1 | −𝑟𝐴 𝑋 𝐴𝑖 𝑋 1 (𝑋𝐴𝑓 − 𝑋𝐴𝑖 ) = ∫𝑋 𝐴𝑓 (−𝑟 ) 𝑑𝑋𝐴 𝐴𝑖 (1) 𝐴 We know that 𝐶𝐴 = 𝐶𝐴0 (1 − 𝑋𝐴 ) 𝐶𝑅 = 𝐶𝐴0 𝑋𝐴 2 −𝑟𝐴 = 𝑘𝐶𝐴 𝐶𝑅 = 𝑘𝐶𝐴0 (1 − 𝑋𝐴 )𝐶𝐴0 𝑋𝐴 = 𝑘𝐶𝐴0 𝑋𝐴 (1 − 𝑋𝐴 ) (2) Substituting eq. 2 into the left-hand side of eq. 1 gives 1 1 | (𝑋𝐴𝑓 − 𝑋𝐴𝑖 ) = 2 | (𝑋𝐴𝑓 − 𝑋𝐴𝑖 ) −𝑟𝐴 𝑋 𝑘𝐶𝐴0 𝑋𝐴 (1 − 𝑋𝐴 ) 𝑋 𝐴𝑖 𝐴𝑖 But 𝑋𝐴𝑖 = 𝑅𝑋𝐴𝑓 𝑅+1 Therefore 1 | −𝑟𝐴 𝑋 𝐴𝑖 (𝑋𝐴𝑓 − 𝑋𝐴𝑖 ) = 𝑅𝑋𝐴𝑓 ) 𝑅+1 𝑅𝑋𝐴𝑓 𝑅𝑋𝐴𝑓 (𝑋𝐴𝑓 − 2 𝑘𝐶𝐴0 𝑅+1 (1− 𝑅+1 = ) 𝑋𝐴𝑓 (𝑅+1) 2 𝑘𝐶𝐴0 𝑅𝑋𝐴𝑓 (1+𝑅−𝑅𝑋𝐴𝑓 ) (3) Now let us know evaluate the right-hand side of eq. 1 𝑋𝐴𝑓 𝑋𝐴𝑓 1 1 𝑑𝑋𝐴 = ∫ 𝑑𝑋𝐴 2 𝑋𝐴𝑖 (−𝑟𝐴 ) 𝑋𝐴𝑖 𝑘𝐶𝐴0 𝑋𝐴 (1 − 𝑋𝐴 ) 𝑋𝐴𝑓 1 1 = ∫ 𝑑𝑋 2 𝑘𝐶𝐴0 𝑋𝐴𝑖 𝑋𝐴 (1 − 𝑋𝐴 ) 𝐴 From Table of integrals, we get 1 1 𝑥 ∫ = 𝑙𝑛 ( ) 𝑥(𝑎𝑥 + 𝑏) 𝑏 𝑎𝑥 + 𝑏 Thus, 𝑋𝐴𝑓 𝑋𝐴𝑓 1 1 1 𝑋𝐴 )| 𝑑𝑋𝐴 = 2 𝑙𝑛 ( 2 ∫ 1 − 𝑋𝐴 𝑋 𝑘𝐶𝐴0 𝑘𝐶𝐴0 𝑋𝐴𝑖 𝑋𝐴 (1 − 𝑋𝐴 ) ∫ 𝐴𝑖 𝑋𝐴𝑓 1 1 𝑋𝐴𝑖 = 2 𝑙𝑛 (1 − 𝑋 ) − 2 𝑙𝑛 (1 − 𝑋 ) 𝑘𝐶𝐴0 𝑘𝐶𝐴0 𝐴𝑓 𝐴𝑖 Substituting 𝑋𝐴𝑖 = 𝑅𝑋𝐴𝑓 𝑅+1 gives 𝑅𝑋𝐴𝑓 𝑋𝐴𝑓 𝑋𝐴𝑓 1 1 1 1 𝑅 +1 ) 𝑑𝑋𝐴 = 𝑙𝑛 ( )− 𝑙𝑛 ( 2 ∫ 2 2 𝑅𝑋𝐴𝑓 1 − 𝑋𝐴𝑓 𝑘𝐶𝐴0 𝑋𝐴𝑖 𝑋𝐴 (1 − 𝑋𝐴 ) 𝑘𝐶𝐴0 𝑘𝐶𝐴0 1−𝑅+1 = Thus 1 + 𝑅(1 − 𝑋𝐴𝑓 ) 1 ) 2 𝑙𝑛 ( 𝑘𝐶𝐴0 𝑅(1 − 𝑋𝐴𝑓 ) 𝑋𝐴𝑓 ∫𝑋 𝐴𝑖 1 (−𝑟𝐴 ) 𝑑𝑋𝐴 = 1 2 𝑘𝐶𝐴0 𝑙𝑛 ( 1+𝑅(1−𝑋𝐴𝑓 ) 𝑅(1−𝑋𝐴𝑓 ) ) (4) By substituting eq. 3 and eq. 4 in eq.1, we get 𝑋𝐴𝑓 (𝑅 + 1) 1 + 𝑅(1 − 𝑋𝐴𝑓 ) 1 = ) 2 2 𝑙𝑛 ( 𝑘𝐶𝐴0 𝑅𝑋𝐴𝑓 (1 + 𝑅 − 𝑅𝑋𝐴𝑓 ) 𝑘𝐶𝐴0 𝑅(1 − 𝑋𝐴𝑓 ) Or 1 + 𝑅(1 − 𝑋𝐴𝑓 ) 𝑅+1 = 𝑙𝑛 ( ) 𝑅(1 + 𝑅 − 𝑅𝑋𝐴𝑓 ) 𝑅(1 − 𝑋𝐴𝑓 ) Substituting 𝑋𝐴𝑓 = 0.96 gives 𝑅+1 1 + 0.04𝑅 ) = 𝑙𝑛 ( 𝑅(1 + 0.04𝑅) 0.04𝑅 Solving by trial-and-error method gives 𝑅 = 0.28 The production rate is then calculated from the following equation for recycle reactor 𝑋𝐴𝑓 𝑉 1 = (𝑅 + 1) ∫ 𝑅𝑋 𝑑𝑋𝐴 𝐴𝑓 (−𝑟 ) 𝐹𝐴0 𝐴 𝑋𝐴1 = 𝑅+1 (𝑅 + 1) 1 + 𝑅(1 − 𝑋𝐴𝑓 ) 𝑉 = 𝑙𝑛 ( ) 2 𝐹𝐴0 𝑘𝐶𝐴0 𝑅(1 − 𝑋𝐴𝑓 ) 2 𝑉𝑘𝐶𝐴0 1 𝐹𝐴0 = (𝑅 + 1) 1 + 𝑅(1 − 𝑋𝐴𝑓 ) 𝑙𝑛 ( ) 𝑅(1 − 𝑋𝐴𝑓 ) Substituting the known values gives the production rate as 𝐹𝐴0 = 10(1)(2)2 (0.28 + 1) 1 = 6.9 𝑚𝑜𝑙/𝑚𝑖𝑛 1 + 0.28(1 − 0.96) ) 𝑙𝑛 ( 0.28(1 − 0.96) And the volumetric feed rate is calculated as 𝜐= 𝐹𝐴0 6.9 = = 3.45 𝑙𝑖𝑡𝑒𝑟/𝑚𝑖𝑛 𝐶𝐴0 2 Thus, for the given reactor, by setting the recycle ratio at 0.28 we can achieve the highest production rate of 6.9 mol/min and the volumetric feed rate we can process to get 96% conversion in the reactor is 3.45 liter/min.