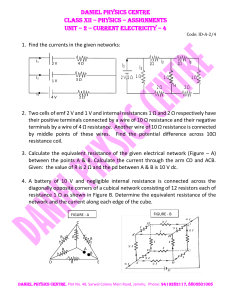

PRODUCT TRAINING MANUAL for ELECTRICAL PRODUCTS designed for $5.95 TABLE OF CONTENTS Electrical Page Electrical System Course Outline . . . . . . . . . . . .1 Electrical System Overview . . . . . . . . . . . . . . . . .2 Electrical Training . . . . . . . . . . . . . . . . . . . . .3-18 Seal-A-Crimp Terminals . . . . . . . . . . . . . . . .19-20 Wire and Cable . . . . . . . . . . . . . . . . . . . . . . . . . .21 Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . .22 Self-Evaluation . . . . . . . . . . . . . . . . . . . . . . . . . .23 PHONE: 1-800-558-2808 FAX: 1-800-553-8769 WEB: www.imperialsupplies.com ELECTRICAL SYSTEMS COURSE OUTLINE PURPOSE: To understand the basics of electricity and how they apply to daily electrical repairs. OBJECTIVES: To be able to: • Demonstrate basic knowledge of voltage, amperage, and resistance. • Identify common electrical failures and their causes. • Exhibit skills for making proper electrical connections. Cut Skive Connect Protect Identify Attach • Identify terminal styles. I. Electrical System Overview II. Understanding Electrical Systems A. OHM’s Law Explained B. Voltage, Amperage, Resistance C. Three types of circuits D. Testing voltage drop. III. Solderless Terminals A. Design and Features B. Barrel Styles and Lengths C. Tongue Configurations, Tool Crimp Location and Color Coating. D. Performance E. Crimping, Testing, and Checking IV. Seal-A-Crimp Terminals A. Heavy Duty Heat Shrink Butt Connectors B. Heat Shrink Terminals and Splices C. Simple Installation V. Wire and Battery Cable VI. Terminology PHONE: 1-800-558-2808 FAX: 1-800-553-8769 WEB: www.imperialsupplies.com 1 I. OVERVIEW OF THE ELECTRICAL SYSTEM Imperial has recognized that over 75% of all truck problems can be directly related to the electrical system. The problem is not always related to the batteries, starters and alternators, but rather the connections and the connectors. Too much resistance in the connectors that provide electrical current to and from electrical devices such as batteries, starters, alternators, headlamps, horns, stop/turn/tail lights and other electrical devices are an underlying cause for their failure. A known fact is that a one volt drop at the starter can decrease its life expectancy as much as 50%. (Generally 3/10ths of a volt is the maximum allowable voltage drop). When replacing a major component, like a starter or alternator, especially if this vehicle has had multiple electrical repairs, take a few extra moments to look at and perform the necessary inspection of the electrical connectors, cables and wires. Excessive resistance at the battery or starter terminal connections require cleaning or replacement of the connections. Failure to correct these high resistance areas will cause components to work harder under less voltage and it will fail prematurely. PHONE: 1-800-558-2808 FAX: 1-800-553-8769 WEB: www.imperialsupplies.com 2 II. UNDERSTANDING ELECTRICAL SYSTEMS A.) OHM’S LAW EXPLAINED “The amount of current flowing in a circuit made up of pure resistances is directly proportional to the electromotive forces impressed on the circuit and inversely proportional to the total resistance of the circuit.” Don’t let that quote scare you. It is not as scholarly as it sounds. Now, before going further, make sure you understand two things. What composes a circuit and what voltage, current, and resistance are. In simpler terms, Ohm’s Law means: 1. A steady increase in voltage, in a circuit with constant resistance, produces a constant linear rise in current. 2. A steady increase in resistance, in a circuit with constant voltage, produces a progressively (not a straight-line if graphed) weaker current. Ohm’s law is a set of formulas used in electronics to calculate an unknown amount of current, voltage, or resistance. It was named after the German physicist George Simon Ohm. Knowledge of the law is often underestimated by beginners. Unless you know this basic fundamental building block of electronics, you will never have a strong understanding of this field. PHONE: 1-800-558-2808 FAX: 1-800-553-8769 WEB: www.imperialsupplies.com 3 B.) VOLTAGE, AMPERAGE, RESISTANCE Ohm’s Law is a formulation of the relationship of voltage, current, and resistance, expressed as: E=IxR -orI= E R=E R I WHERE: E is the Voltage measured in volts I is the Current measured in amperes R is the resistance measured in Ohms THEREFORE: Volts = Amps x Ohms Ohms Law is used to calculate a missing value in a circuit. In this simple circuit there is a current of 12 amps (12A) and a resistive load of 1 Ohm (1Ω). Using the first formula from above we determine the Voltage: E = 12 x 1 : E = 12 Volts (12V) If we knew a battery was supplying 12 volts of pressure (voltage), and there was a resistive load of 1 Ohm placed in series, the current would be: I = 12/1 : 1 I = 12 Amps (12A) If we knew the battery was supplying 12 V and the current being generated as 12A, then the Resistance would be: R = 12/12 : R=1Ω NOTE: Remember a battery is not measured in amperage. The battery supplies the pressure that creates the flow (current) in a given circuit. PHONE: 1-800-558-2808 FAX: 1-800-553-8769 WEB: www.imperialsupplies.com 4 An easy way to remember the formulas is by using this diagram. To determine a missing value, cover it with your finger. The horizontal line in the middle means to divide the two remaining values. The “X” in the bottom section of the circle means to multiply the remaining values. • If you are calculating voltage, cover it and you have I x R left (E = I x R). • If you are calculating amperage, cover it, and you have E ÷ R left (R = E ÷ R). • If your are calculating resistance, cover it, and you have E ÷ I left (R = E ÷ I). PHONE: 1-800-558-2808 FAX: 1-800-553-8769 WEB: www.imperialsupplies.com 5 C.) THREE TYPES OF CIRCUITS Circuits Circuits ❏ Series Circuits ❏ Parallel Circuits - Two or more resistant values - One path of electricity - Current will be the same throughout - Voltage drop will be different if resistant values are different - @ of E drop = Source E - Two or more resistant values - More than one path flow - Current throughout each branch will be different if the resistance is different - No voltage drop Example: Old style Christmas lights. If one light burns out, you have to search the entire string to find the problem bulb. Example: New style Christmas lights. If one burns out, the other bulbs still work. Circuits ❏ Series Parallel - Represents a combination of both • Examples: - dashboard lights - some fuel sending units Example: Combination of the two styles. Having a dimmer switch on the light system. THE DIFFERENCE BETWEEN SHORT CIRCUITS AND OPEN CIRCUITS LOAD SOURCE A B C D GROUND The schematic above shows a simple electrical circuit. The power comes from a source (the battery), passes through the “hot” wire (from A to B), through the load (a light bulb, motor, etc.), and then to ground (C and D). A SHORT occurs when an inadvertent connection is made to ground, along the hot wire or within the load, bypassing all or part of the load. An OPEN circuit occurs if a break exists anywhere along the length of the circuit (from A to D) that interrupts current flow. PHONE: 1-800-558-2808 FAX: 1-800-553-8769 WEB: www.imperialsupplies.com 6 D.) TESTING VOLTAGE DROP LET IMPERIAL SHOW YOU HOW TO REDUCE REPLACEMENT OF THESE ITEMS Imperial has recognized that over 75% of all truck problems can be directly related to the electrical system. The problem is not always related to the batteries, starters and alternators, but rather the connections and the connectors. Too much resistance in the connectors that provide electrical current to and from electrical devices such as batteries, starters, alternators, headlamps, horns, stop/turn/tail lights and other electrical devices are an underlying cause for their failure. A known fact is that a one volt drop at the starter can decrease its life expectancy as much as 50%. (Generally 3/10ths of a volt is the maximum allowable voltage drop). Typical Voltage Drop Test Typical voltage drop test, please refer to your shop manual for specific applications Excessive resistance at the battery or starter terminal connections require cleaning and/or replacement of the connections. Failure to correct this high resistance area will cause the starter to work harder under less voltage (fail prematurely); the alternator will try to recharge the battery (it has to put out more to overcome resistance); therefore, the battery will be discharged, which will in turn accelerate this problem area. Imperial has put together a simple 6 step approach to reduce potential problems in this area: PHONE: 1-800-558-2808 FAX: 1-800-553-8769 WEB: www.imperialsupplies.com 7 SIX STEP APPROACH Cut Cut the wire or cable clean and square at the ends. This needs to be done to insure proper connection at the terminal, and equally important not to break any strands in the wire or cable that will increase resistance. Skive Skive the insulation off the wire or cable so only the insulation is removed. Be careful not to cut into the individual strands as this will reduce the wire or cable diameter, and increase resistance. Connect When making the connection (crimping, soldering, etc.), make sure the components are clean from dirt, oil, and other contaminants. This will minimize the amount of voltage drop through the connection. If crimping terminals, use the proper tool to insure the connection is crimped evenly and securely. Protect It is important to use the proper type of protection on the terminal. This will insure the connection will not corrode, which will impede current flow. Any connection outside of the cab should be protected with one or more of the following: heat shrink tubing, sealing compound, electrical tape, split loom, and fittings. Identify Use different wire colors, wire markers, or cable ties when making repairs for proper identification on different electrical circuits. This will make the job easier if you or others need to inspect the repair somewhere down the road. Attach To prevent the wire or cable from vibration and the problems resulting from vibrations (opens and shorts) use frame clips, cable ties, and tube clamps to minimize the vibration and provide the greatest longevity. By following this simple six step process, you will reduce the failure and downtime that is associated with electrical failures. Avoid these common errors in electrical wiring! • Twisting the tool to “cut” the insulation will add .05 ohms of resistance • Cutting/nicking the wire will add .05 ohms of resistance per wire • Stretching the wire will add .05 ohms of resistance • Using your fingers to twist the wire strands will add .05 ohms of resistance • Using your mouth to bite the insulation off will add .10 ohms of resistance • Poor crimp (with air gaps) will add .05 ohms of resistance Your goal should be zero ohms of resistance. PHONE: 1-800-558-2808 FAX: 1-800-553-8769 WEB: www.imperialsupplies.com 8 III. SOLDERLESS TERMINALS A.) DESIGN AND FEATURES OF SOLDERLESS TERMINALS A. The quality of the base material must be evaluated. The material (metal) is either copper or brass depending on the product. 1. Base metals are purchased, inspected, and received to Military specifications. 2. Products use the guidelines of Mil-T-7928, set by the United States Federal Government. B. Where preinsulated parts are used (ones with insulation), you must insure it is of a good quality. Mil specifications, as well as U.L., covers this material. C. Barrel Serration/Dimples When quality solderless terminals are stamped, the inside of the barrel is scored with serrations or dimples. Serrations “V” or Dimples 1. When the crimp is made and the metal terminal barrel is drastically deformed, the tin plating on the inside of the barrel is fractured at the serrations, thus causing bare copper to contact between the wire and the terminal barrel. This greatly enhances electrical conductivity. 2. If properly designed, the serrations or dimples have angled grooves, that during the crimping operation will bite into the wire which greatly increases the mechanical integrity of the crimp. Some manufacturers save money and time by not putting these serrations in their parts. D. A quality solderless terminal has features built into the barrel that insures a quality crimp. 1. The non-insulated part will have a chamfer at the wire insertion end so the individual strands will not bump against the end of the metal. “Beveled” Chamfer 2. When you have an insulated part, the insulation should have a funnel entry. This acts as a slide for the wires to enter the barrel smoothly. These are two basic styles of insulated barrels. Both have a funnel feature. Plain Insulation Insulation W/Support Sleeve Nylon Sleeve Tin Plated Brass Sleeve PHONE: 1-800-558-2808 Plastic Insulation Sleeve FAX: 1-800-553-8769 WEB: www.imperialsupplies.com 9 Butted Seam B. DIFFERENT BARREL STYLES Transition or Throat A. The barrel is the part of the terminal that is crimped around the wire. Barrel Tongue (Style Varies) B. These are the five basic forms. Metal Sleeve 2. Brazed Seam 1. Butted Seam 3. Insulation Only 4. Extra Metal Support Sleeve #1 is the least expensive barrel type. #2 is the same as #1 except the seam is brazed (welded closed). This allows for crimping from any direction without the barrel opening up, and provides greater tensile strength. #3 adds insulation protection to the barrel area. In wire sizes 22-10 AWG this insulation material is PVC (polyvinyl chloride). This barrel style can be made from extruded or molded PVC, as well as molded or extruded nylon. Molded Extruded #4 provides insulation as well as an insulation grip. The insulation is made of nylon, and has a secondary metal sleeve added. This metal support sleeve is crimped around the wire insulation providing a strain relief, so the wire does not vibrate, loosen, fray, or break. PHONE: 1-800-558-2808 FAX: 1-800-553-8769 WEB: www.imperialsupplies.com 10 C. VARIOUS TONGUE CONFIGURATIONS The “tongue” is the end of the part that attaches to other components (switch, stud, transformer, etc.). These tongue configurations are varied, some of them are: Quick Disconnects Flanged Spades Rings Spades Snap Spades Flag Rings Hooks Multi Studs WHAT DOES THE COLOR OF THE INSULATION MEAN? A. The colors (red, blue, and yellow) are used to tell you the wire range that can be used in the part. This is an industry standard color coding. Example: Blue = 16 or 14 AWG wire The colors repeat over and over, and are an industry standard, i.e.... Yellow = 26-24 Red = 22-18 Blue = 16-14 Yellow = 12-10 Red = 8 AWG Blue = 6 AWG Yellow = 4 AWG B. Remember there are different kinds of barrels. With this in mind you will note that different shades of color are used for different barrel styles. Also, PVC and nylon take the color differently. In the 16-14 AWG range (blue), for example, the PVC barrels will be dark blue. When using the lighter blue parts, the secondary sleeve will be crimped in addition to the wire barrel crimp. The actual shape or color has nothing, per se, to do with quality of the insulation. PHONE: 1-800-558-2808 FAX: 1-800-553-8769 WEB: www.imperialsupplies.com 11 D. ELECTRICAL PERFORMANCE VS. MECHANICAL PERFORMANCE The Crimp Area A. If you crimp real hard you can get a good mechanical performance, but if you crimp too easy, of course, the part won’t hold. B. However, if you crimp too hard you can extrude (stretch) the wire in the crimp area so it is thinner than the wire. This causes resistance and a poor electrical connection. Causing potential failure mode or future break or fracture point. Wire is deformed or compressed beyond normal yield point. Excessive crimp depth. Single strand wire. Excessive bell mouth. Terminal wire braid. So the hard crimp which might give a good mechanical performance may cause electrical problems. As shown in the chart below, the perfect crimp is a compromise between good mechanical and electrical connection. C B Increasing Mechanical Strength And Electrical Performance A Increasing Crimping Force Point A gives the best Mechanical Connection, Point B gives the best Electrical. The optimum is in between at Point C. WHAT CAN CAUSE A BAD ELECTRICAL CRIMP A. Loose crimp (not crimped hard enough). B. Over crimped (elongated and weakened strands). C. Void or air space in the crimp area. Void End View of Barrel Before Crimp PHONE: 1-800-558-2808 Under-Crimped Part Showing Void FAX: 1-800-553-8769 WEB: www.imperialsupplies.com 12 E. THE CRIMPED JOINT 1. Importance of Proper Crimping Once the correct terminal is selected, proper attachment to the wire is critical. One indication of the importance of proper crimping is evident in a study for the Space Shuttle program that traced 28% of all defects to improperly assembled wiring and connections. Mechanical as well as electrical connections are important - The end result of a properly crimped joint is a reliable mechanical and electrical connection. The mechanical connection is the crimping of the terminal to the conductor. The desired result is sufficient force on the outside of the barrel to tightly form it around the conductor. It must be secure enough so that it will not vibrate loose or be pulled off through normal use. Just as important are the electrical characteristics. The major concern is the amount of electrical resistance caused by the mechanical joint. This electrical resistance will determine the crimped joint’s ability to conduct current. If you buy a quality product, you will find that in many cases the mass of the metal barrel after crimping actually aids the conduction. The extra mass allows for little or no resistance over the crimp - as long as the crimp is made properly. 2. Operation To achieve a positive relationship between the mechanical and electrical connection in the crimped joint, the following conditions are required: 1. The terminal must be of sufficient cross section size and conductive material that is as good as an electrical conductor as the wire. 2. The surfaces of the wire and terminal that will be pressed into contact in the crimp must be clean and free of heavy, non-conductive films such as oxides, sulfides, and similar substances. Some reasons for failure of crimped joints to meet minimum tensile requirements include nicked wires, nicked or ruptured strands, strand turn back at crimp joint, and ruptured wires outside of the crimped terminal. To avoid these problems, use the correct size wire for the barrel, prepare your wire carefully, and use the proper matching tool. 3. Electrical Resistance The electrical resistance across the crimp is compared to the resistance of an equal length of wire, and expressed as relative resistance for a particular wire size. Relative resistance of the crimp to the wire: RC RW RC = Resistance over Crimp RW = Resistance of Wire PHONE: 1-800-558-2808 FAX: 1-800-553-8769 WEB: www.imperialsupplies.com 13 Relative resistance values of less than 1.0 denote a crimped joint with less resistance than the wire. Values more than 1.0 indicate greater resistance than the wire. Usually it is easier to measure the voltage drop across the crimped joint. Many specifications state the requirements in terms of voltage drop at a specified current. Voltage drop is the more commonly used term in the industry. If the resistance value is desired it may be calculated from Ohms Law: R (ohms) = E (volts) I (amps) Crimp voltage drop and resistance values are quite small and are expressed in terms of millivolts (.001 volts) and milliohms (.001 ohms). The resistance increase or millivolt drop will indicate a poor crimp joint and could be caused by several factors: 1. The presence of air pockets or voids in the crimped joint will cause a higher resistance. 2. These same voids cause higher resistance and will cause a temperature rise which in turn increases the corrosion rate and further increases the resistance. 3. A crimped joint that has been over crimped and the conductor (wire) elongated out of shape could cut the circular area of the conductor and cause a greater resistance at this weakened point. PHONE: 1-800-558-2808 FAX: 1-800-553-8769 WEB: www.imperialsupplies.com 14 FACTS ABOUT CRIMPED JOINTS A finely stranded wire (large number of small diameter strands) usually improves crimped joint performance. A wire composed of a few strands of a larger size will tend to act as a solid wire in the crimp. Some stranded wire crimp configurations are not satisfactory for solid wire. More deformation must be imposed in order to form wire and barrel into a solid mass. On the other hand, finer strands will more readily fill the inside contour of the crimp shape and more evenly distribute strand formation. Brazed barrel terminals usually give higher tensile test than the non-brazed (for specific values, tensile tests must be performed on each part). WHAT GIVES QUALITY TO A SOLDERLESS TERMINAL A. Quality is something that must be measured by some set of criteria. There are four major agencies that give test criteria for solderless terminals. They are: 1. U.L. (Underwriters Laboratories) 2. CSA (Canadian Standard Association) 3. NEMA (National Electronic Manufacturers Association) 4. Federal Government Spec - Mil-T-7928 B. In all the above standards, specific reference is made to the following areas: 1. Copper or brass quality specifications. 2. Tin plating specs to kind and thickness. 3. Smoothness of edges and lack of burrs. 4. Firmness of fit between metal and insulation. 5. There is a series of tests to be performed on the crimp area after the crimp was made: • Tensile test • Dielectric withstand • Salt spray • Vibration • Heat rise The most widely used field test for testing the quality of the crimp is the pull test or tensile test. The two most widely used measurements are the U.L. and Military Tensile values. Note that the Military is higher than the U.L. PHONE: 1-800-558-2808 FAX: 1-800-553-8769 WEB: www.imperialsupplies.com 15 QUALITY CHECKS BEFORE CRIMPING Checking the Wire Check the stranded wire to see if any strands have loosened and expanded to be larger than the wire and the insulation together. If this has occurred, retwist the wires to the size they were before they were stripped. Be sure that the stranded wire is within the outside diameter of the insulation after you have retwisted them. ACCEPT REJECT Expanded Strands Loose Wire Wire Within Outside Diameter Outside Wire Diameter Exceeds Outside Diameter Check to see if a stripping tool or machine has cut or nicked any of the wires. If you see a nicked wire, you must cut and restrip the wire before crimping to be sure that the amount of current that can be carried is not reduced. ACCEPT REJECT Improper Stripping “nicked” Strands Proper Stripping Undamaged Strands Improper Stripping Cut Strands Checking the Insulation 1. Check the insulation to ensure that there has been a nice clean cut. 2. Wires with damaged insulation should not be used. ACCEPT REJECT Insulation Wiskers Insulation Thickness Damage 1/2 Of Insulation Thickness Or Greater Damage Less Than 1/2 Of Insulation Thickness Split Cut Burned Or Charred PHONE: 1-800-558-2808 FAX: 1-800-553-8769 WEB: www.imperialsupplies.com 16 HAND CRIMPING INSTRUCTIONS Insure the tool is designed to crimp the size wire and specific terminal you want to use. Check the wire’s insulation thickness and then adjust the hand tool’s crimp pressure on the insulation sleeve to the correct setting, using the appropriate method for that specific hand tool. Strip the wire. Place the terminal in the tool. Select the proper crimp station. Insert the wire. Squeeze the handle. Check the finished crimp to see that the wire’s insulation is held firmly by the insulation support barrel, the wires are visible, and a bell mouth is present. Insure that your hand tools are calibrated regularly. Easy as . . . PHONE: 1-800-558-2808 1 Select the correct splice size for the wire gauge. Strip the wires 0.3" (7.6mm) from the end and insert into the crimp barrel. 2 Making sure the wire end is properly seated, make the crimp connection using a tool designed for insulated splices. 3 Apply heat directly to the splice, working from the center out to the edges, using a hot air gun or other heat source, until the tubing recovers and the adhesive flows. Allow to cool before inspecting splice and checking integrity. FAX: 1-800-553-8769 WEB: www.imperialsupplies.com 17 Mechanical The tensile test or pull test is a means of evaluating the mechanical properties of the crimped connection. The chart below shows the UL and Government Specifications (MIL-T-7982) for various wire sizes. The tensile strength is shown in pounds and indicates the minimum acceptable force to break or separate terminal from the conductor. When the crimp is made, there must be enough pressure applied so that the oxides that may build up on the stripped conductor and the tin plating on the inside of the terminal barrel are broken down and there is good metal-to-metal contact. If this situation does not occur, resistance can again build in the connectors. Dielectric Testing (The term “dielectric” refers to an insulator) Some terminals are covered with insulation so that electrical contact can be made only where it is desirable. The crimp is made through (on) this insulation which is compressed and extruded due to the pressure of the crimping dies. Obviously, not all insulation materials can withstand this treatment and even with the strongest materials, the crimp must be correctly designed so as not to rupture the insulation. Dielectric tests are made on insulated terminals after crimping to determine that the crimp process is not rupturing the insulation or thinning it out so it will not withstand impressed voltages. The test is made by impressing a voltage between the wire to which the terminal is crimped and conductive materials contacting the terminal insulation. The voltage is gradually increased until the requirements are reached or until a breakdown occurs which means the insulation breaks. Depending on the use and the specifying agency, dielectric withstanding requirements normally range from 1500 to 8000 volts, resulting in a 300 to 600 volt rating. Wire Size Tensile Strength Pounds UL Tensile Strength Pounds UL Quick Disconnects Tensile Strength Pounds MIL-T-7928 26 24 22 20 18 16 14 12 10 8 6 4 2 1 1/0 2/0 3/0 4/0 250MCM 300MCM 350MCM 3 5 8 13 20 30 50 70 80 90 100 140 180 200 250 300 350 450 500 550 600 — — 8 13 20 30 50 70 80 — — — — — — — — — — — — 7 10 15 19 38 50 70 110 150 225 300 400 550 650 700 750 825 875 1000 1120 1125 TESTING PHONE: 1-800-558-2808 FAX: 1-800-553-8769 WEB: www.imperialsupplies.com 18 IV. SEAL-A-CRIMP HEAT SHRINK A. HEAVY DUTY HEAT SHRINK BUTT CONNECTORS Waterproof Adhesive Seal Heavy Duty Seal-A-Crimp butt connectors give a long-lasting, moisture-proof connections that withstand water, salt, condensation, corrosion and heat, all of which cause serious problems for conventional, unsealed splices. The inner wall of a heat shrinkable Heavy Duty Seal-A-Crimp sleeve is lined with a special hotmelt adhesive which is inert at room temperature, permitting wires to be inserted easily into the butt connector. As the sleeve is heated, the adhesive melts and flows under pressure from the tubing. This action fills any existing voids and creates a seal which repels moisture incursion, even during pressure cycling, and stands up to some of the most rigorous tests that can be applied to high performance splices. Features and Benefits • Wall thickness is significantly thicker than the polyolefin or nylon products, providing excellent durability. • Shrinks fast! Up to 40% faster than polyolefin and nylon products, saving installation costs and dramatically reducing the potential to wire jacket damage. • Excellent chemical properties Seal-A-Crimp will keep on working even when immersed in the following chemicals: Antifreeze, brake fluid, gasoline, motor oil, trichloroethylene, diesel fuel, salt, water and battery acid. • Minimum shrink temperature 90 degree C. B. HEAT SHRINK TERMINALS AND SPLICES Features and Benefits • A totally environmental sealed terminal connection. • Simply crimp and heat. A special heat shrink tubing is utilized with an adhesive inner liner that melts and adheres as the tubing shrinks, providing a complete environmental seal. • This dual-wall, heat seal terminal is specifically suited for those applications which require “environment proof” connections. • The construction of this unique terminal begins with a funnel entry terminal made of pure electrolytic (EPT) copper and is plated to resist corrosion. • Seal-A-Crimp splices and terminals are color coded for easy identifications of wire gauge sizes. • Available in many different sizes and styles. PHONE: 1-800-558-2808 FAX: 1-800-553-8769 WEB: www.imperialsupplies.com 19 C. SIMPLE INSTALLATION Heavy Duty Seal-A-Crimp and Seal-A-Crimp connectors are best to be installed using a barrel and wire double crimping tool (Imperial offers a ratchet hand crimping tool of this type). The ratcheting tool insures fifty pounds of equal and exact crimping pressure on electrical terminals that Underwriters Laboratory recommends. Heavy Duty Seal-A-Crimp and Seal-A-Crimp connectors are color coded for easy identification of wire gauge sizes. The ultra clear insulation allows for visual inspection of the finished splice. RATCHET HAND TOOL Imperial part number 71498 PHONE: 1-800-558-2808 FAX: 1-800-553-8769 WEB: www.imperialsupplies.com 20 V. IMPERIAL CROSS-LINK WIRE and COLOR-CODED BATTERY CABLE Cross-linked polyethylene insulation provides better durability and outstanding heat resistance. When vulcanized, it provides a thermosetting insulation and is superior to thermoplastic because it will not melt when exposed to heat. Cross-link remains flexible in -700F. temperatures and is noted superior to any other primary wire in pinch, abrasion, and heat aging test. Superior resistance to elements, abrasion, and where temperature extremes are encountered. Complies with SAE specification J1128. Temperature range: -400C to +1050C. Voltage range: 50 volts maximum. Lock-Out Item: Thermoplastic Primary Wire Imperial is recommending Color-Coded Battery Cable to match the color coded terminals. Battery Cable is OEM standard. The battery cable meets or exceeds the standards established by the SAE. Battery cable is insulated with PVC which is flame-retardant, resistant to fuel, oil, acid, and salt. The wire is 100% copper. Three reasons we recommend using color coded battery cable: Easy and fast identification of the wire gauge. The color coding machines the wire to the terminal for less errors. The color stripe helps you measure the length of your cable. Lock-Out Item: Standard Black Battery Cable PHONE: 1-800-558-2808 FAX: 1-800-553-8769 WEB: www.imperialsupplies.com 21 VI. TERMINOLOGY Crimping Tool A device with built-in aids to ensure ease of use that’s designed with a stop that prevents it from crushing the terminal by over crimping. Designed so that it cannot be opened until it has been completely closed to prevent under crimping. It has a part number that corresponds to the types of terminals with which it can be used to ensure that the terminal used with a certain tool is the correct one. Dielectric Test This is a test to ensure the crimping procedure did not puncture or destroy the insulation material on the terminal. Flash An abnormal protrusion on the wire barrel (either insulation material or metal) that indicates that your crimping tool is either misaligned or worn and thus should not be used. Gas Tight Seal The result of all the wires and the terminal being compressed so tightly that air cannot get through. This contributes to an excellent crimp because it ensures that oxidation (which will cause a decrease in electrical efficiency) does not take place. This also adds to reliability because it ensures that an intermittent condition (sometimes working, sometimes not) caused by a loose crimp, does not occur. Hand Crimping An easy mechanical means of joining terminals to wires. It’s an important way of ensuring quality control of harness materials by replacing terminals that are found to be defective. It’s a necessary skill to know, especially in cases of short production runs. Harness A bundle of prepared wires and terminals that have been formed as an assembly so that they are ready to be attached to the various electronic components and allow them to function as a whole. Mechanical Strength To insure how strong the connection is or how much the wire and terminal must be squeezed to get a gas tight seal, it’s important to crimp the wires tight enough to keep them from slipping out of the connector, but not so tight as to crush the wires in the terminal, causing them to break off. The connection is weakened if the wires are cut or nicked. Pull Test Machine method of determining mechanical strength. Done by testing how much force it takes to pull the wire out of the crimp. Tensile Test A pull test to determine the mechanical strength of the crimped wire. There are specific values set for each wire size. Terminal A convenient, reliable device that is used to attach a wire or cable to an electrical component. Two main types include the open barrel and the closed barrel. Parts of the terminal are: • Insulation barrel - Where the wire’s insulation will be crimped or supported so that it is firmly gripped. • Wire barrel - Where the bare wire will be crimped. • Contact area - Where the terminal will be attached to the equipment. Voltage Drop Test A test of the electrical integrity of the crimp. Wire Generally, there are two types, solid wire (which is a single strand of material) and the more commonly used stranded wire (several wires twisted together to act as one). Wire Size Wires have varying sizes or gauges that carry different amounts of electrical current with each wire used for a separate purpose. The size is called out with a number, such as 8 to 10, followed by the letters AWG (American Wire Gauge). PHONE: 1-800-558-2808 FAX: 1-800-553-8769 WEB: www.imperialsupplies.com 22 ELECTRICAL SYSTEMS SELF-EVALUATION Directions: Answer the following questions by circling True or False. True False 1. 75% of all breakdowns are caused by electrical failure. True False 2. Nicked or uneven strands of wire cause a reduced amount of current that can be carried in a wire. True False 3. Stripping insulation with a knife will ensure a clean and even cut. True False 4. Twisting the wires with your fingers will ensure an even fit and clean connection. True False 5. Cable ties and tube clamps minimize vibration and prevent opens and shorts in the system. True False 6. Heat from a flame is the best source when installing shrink tubing to protect an electrical connection. True False 7. Double crimping an electrical terminal is best to ensure a good electrical contact and a secure mechanical connection. True False 8. Proper protection of an electrical connection will ensure that moisture will not corrode the wire and cause additional resistance in the system. True False 9. Ohm's Law is E (voltage) = I (current) x R (resistance) Directions: Circle the best answer. 10. The colors (red, blue, and yellow) are used to tell you A. The different styles of electrical connectors. B. The wire range that can be used in the part. C. The size fuse that must be used in the system. D. The color of wire that should be used. 11. Electricity is the: A. Current flow of ionic particles. B. Mass movement of electrons around a conductor. C. Relative resistance values of less than 6.24 billion. D. All of the above Answers: 1.) True, 2.) True, 3.) False, 4.) False, 5.) True, 6.) False, 7.) True, 8.) True, 9.) True, 10.) B, 11.) B PHONE: 1-800-558-2808 FAX: 1-800-553-8769 WEB: www.imperialsupplies.com 23