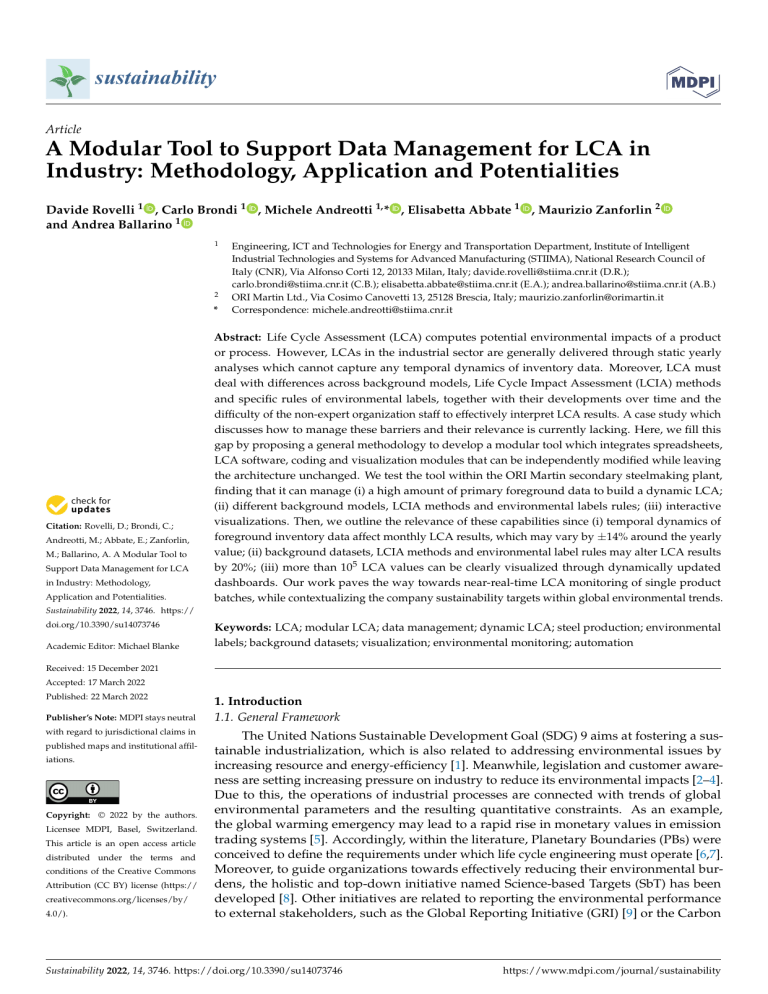

sustainability Article A Modular Tool to Support Data Management for LCA in Industry: Methodology, Application and Potentialities Davide Rovelli 1 , Carlo Brondi 1 , Michele Andreotti 1, * , Elisabetta Abbate 1 , Maurizio Zanforlin 2 and Andrea Ballarino 1 1 2 * Citation: Rovelli, D.; Brondi, C.; Andreotti, M.; Abbate, E.; Zanforlin, M.; Ballarino, A. A Modular Tool to Support Data Management for LCA in Industry: Methodology, Application and Potentialities. Engineering, ICT and Technologies for Energy and Transportation Department, Institute of Intelligent Industrial Technologies and Systems for Advanced Manufacturing (STIIMA), National Research Council of Italy (CNR), Via Alfonso Corti 12, 20133 Milan, Italy; davide.rovelli@stiima.cnr.it (D.R.); carlo.brondi@stiima.cnr.it (C.B.); elisabetta.abbate@stiima.cnr.it (E.A.); andrea.ballarino@stiima.cnr.it (A.B.) ORI Martin Ltd., Via Cosimo Canovetti 13, 25128 Brescia, Italy; maurizio.zanforlin@orimartin.it Correspondence: michele.andreotti@stiima.cnr.it Abstract: Life Cycle Assessment (LCA) computes potential environmental impacts of a product or process. However, LCAs in the industrial sector are generally delivered through static yearly analyses which cannot capture any temporal dynamics of inventory data. Moreover, LCA must deal with differences across background models, Life Cycle Impact Assessment (LCIA) methods and specific rules of environmental labels, together with their developments over time and the difficulty of the non-expert organization staff to effectively interpret LCA results. A case study which discusses how to manage these barriers and their relevance is currently lacking. Here, we fill this gap by proposing a general methodology to develop a modular tool which integrates spreadsheets, LCA software, coding and visualization modules that can be independently modified while leaving the architecture unchanged. We test the tool within the ORI Martin secondary steelmaking plant, finding that it can manage (i) a high amount of primary foreground data to build a dynamic LCA; (ii) different background models, LCIA methods and environmental labels rules; (iii) interactive visualizations. Then, we outline the relevance of these capabilities since (i) temporal dynamics of foreground inventory data affect monthly LCA results, which may vary by ±14% around the yearly value; (ii) background datasets, LCIA methods and environmental label rules may alter LCA results by 20%; (iii) more than 105 LCA values can be clearly visualized through dynamically updated dashboards. Our work paves the way towards near-real-time LCA monitoring of single product batches, while contextualizing the company sustainability targets within global environmental trends. Sustainability 2022, 14, 3746. https:// doi.org/10.3390/su14073746 Academic Editor: Michael Blanke Keywords: LCA; modular LCA; data management; dynamic LCA; steel production; environmental labels; background datasets; visualization; environmental monitoring; automation Received: 15 December 2021 Accepted: 17 March 2022 Published: 22 March 2022 Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. Copyright: © 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https:// creativecommons.org/licenses/by/ 4.0/). 1. Introduction 1.1. General Framework The United Nations Sustainable Development Goal (SDG) 9 aims at fostering a sustainable industrialization, which is also related to addressing environmental issues by increasing resource and energy-efficiency [1]. Meanwhile, legislation and customer awareness are setting increasing pressure on industry to reduce its environmental impacts [2–4]. Due to this, the operations of industrial processes are connected with trends of global environmental parameters and the resulting quantitative constraints. As an example, the global warming emergency may lead to a rapid rise in monetary values in emission trading systems [5]. Accordingly, within the literature, Planetary Boundaries (PBs) were conceived to define the requirements under which life cycle engineering must operate [6,7]. Moreover, to guide organizations towards effectively reducing their environmental burdens, the holistic and top-down initiative named Science-based Targets (SbT) has been developed [8]. Other initiatives are related to reporting the environmental performance to external stakeholders, such as the Global Reporting Initiative (GRI) [9] or the Carbon Sustainability 2022, 14, 3746. https://doi.org/10.3390/su14073746 https://www.mdpi.com/journal/sustainability Sustainability 2022, 14, 3746 2 of 31 Disclosure Project (CDP) [10]. Furthermore, the number of sustainability-related standards under development amounts to almost 200 only within the International Organization for Standardization (ISO) technical committees [11] and regards a wide range of reporting areas, from sustainable finance to water and energy savings. Within this context, Life Cycle Assessment (LCA) is one of the main methodologies to compute potential environmental burdens of a product or service, across all life cycle stages and several categories [12]. This evaluation improves the management of potential environmental impacts by monitoring industries and accordingly setting targets [13]. However, relevant barriers for LCA diffusion in industry are still unsolved. They are detailed in the following sections, together with opportunities for improvements. 1.2. Literature Review 1.2.1. Issue 1: Capturing Relevant Temporal Dynamics of Industrial Processes Conventionally, LCAs are delivered as static ex-post analyses on production data collected at the yearly level, as happens for type III Environmental Product Declarations (EPDs) [14]. Accordingly, several studies outlined the difficulty with LCA concerning capturing relevant temporal dynamics of industrial processes due to its static nature [15–17]. On this topic, Beloin-Saint-Pierre et al. [18] outlined that the inclusion of temporal aspects to increase the representativeness of LCA is still uncommon. Moreover, they found a lack of consistency in the terminology employed in discussions on temporal considerations. Therefore, they carried out a comprehensive review on this field, providing a glossary of proposed key terms, which complemented several other studies in the field [19–21]. Within this study, dynamic LCAs are defined as “LCA studies where relevant dynamic of systems and/or temporal differentiation of flows are explicitly defined and considered” [18]. Moreover, the temporal resolution of an LCA study is defined as the “time granulometry when temporal differentiation is carried out” [18]. Temporal dynamics in the Life Cycle Inventory (LCI) may happen both at the level of primary or secondary data. Primary data are defined as data directly collected within the LCA study, while secondary data are used when the former are missing [22]. In the industrial context, primary data are generally collected from the production facility under study, which constitutes the foreground system of the LCA. In contrast, secondary data are generally employed for the background system of the LCA, i.e., processes outside the boundaries of the production facility, such as the supply chain of raw materials used for manufactured products. Still within the industrial context, the generation of LCAs is scarcely automated, with the chosen time resolution being generally much greater than the product or process lead time [23]. This means that primary data from production processes are collected at a low frequency and LCAs are computed relatively to the cumulated production, obtaining results for an average product related to a yearly time horizon, which coincides with the yearly temporal resolution of the study. As a consequence, LCAs in industry do not point out the details of the single products, which can yet vary over short time scales [17]. Therefore, static LCAs may not reflect in a satisfactory way the reality of industrial processes, reducing the already limited awareness of decision makers about possible efficiency improvements of production and trade-offs between costs and environmental benefits [15,16]. In addition, the difficulty concerning retrieving high temporal resolution primary data which can be readily used to identify hotspots and trade-offs discourages the systematic and periodic use of environmental assessments within quality management systems in industry [24,25]. 1.2.2. Issue 2: Management of Multiple Datasets, Environmental Labels-Specific Rules and Global Sustainability Initiatives LCA results were found to be highly sensitive to the inclusion of different secondary datasets for modelling the background system, Life Cycle Impact Assessment (LCIA) methods and environmental Label-Specific Rules (LSR) [26–28]. Their management constitutes another challenge for LCAs to be integrated as an environmental management tool in industry. Sustainability 2022, 14, 3746 3 of 31 Firstly, despite data on background processes can be theoretically mapped and audited, this does not mean that these measurements are feasible in practice [29], thus the retrieval and use of secondary data is always a necessity. However, these datasets are typically extracted from databases [26], which may apply different hypotheses in the modelling of processes and products, thus leading to variations of LCA results. Accordingly, the choice of secondary LCI datasets for the background system was shown to be relevant [26], even leading to LCA results variations ranging between 10–100% [30]. Similarly, LCA results of bio-based plastics across different manufacturing countries were found to vary up to +165% and −95% with respect to the average value [31]. Moreover, Pauer et al. [32] analysed six packaging systems with 3 databases (GaBi, Environmental Footprint and ecoinvent 3.6), finding remarkable discrepancies in LCA results, too. Moreover, Modahl et al. [33] showed that a remarkable variability arises by using datasets of different specificity, thus highlighting the need for reducing the use of generic, or proxy, data. This need is reflected by programme operators for environmental labels, too. For instance, the General Programme Instructions (GPI) of the International EPD System allows for a maximum 10% contribution of proxy data [14]. Then, Testa et al. [3] concluded that policymakers could remove barriers to LCA adoption by, e.g., realizing open-access high-quality LCA databases (see, e.g., the Global LCA Data Access [34]), which may further be employed in LCA screening and development. Finally, datasets develop over time, too: Therefore, environmental monitoring tools may become quickly outdated. For instance, since the ecoinvent version 3 release in 2013, eight new versions were released, up to the current ecoinvent 3.8 version. Secondly, concerning LCIA characterization factors, different methods may be applied to model the environmental damage due to a specific substance release, leading to different unitary impacts [35]. Similarly to LCI databases, LCIA methods improve over time with the progress of the related science, too; e.g., the characterization factor of CH4 and N2 O, respectively, changed from 25 and 298 kg CO2 -eq in the fourth assessment report of the Intergovernmental Panel on Climate Change (IPCC) [36] to 28 and 265 kg CO2 -eq in IPCC fifth assessment report (2014) [37]. Thirdly, concerning LSRs, several studies found wide discrepancies and misalignments across LCA labels [27,28]. Minkov et al. [38] analysed an overview of 39 programmes providing Product Category Rules (PCR), concluding that only 75% of them are fully ISO-compliant. In particular, a large debate on the latest years focused on the European Commission’s Product Environmental Footprint (PEF) scheme [39]. The PEF was criticized in terms of misalignment with respect to existing main LCA labels, noncompliancy with ISO 14044 standard and risk of environmental labels proliferation [35,40,41]. Del Borghi et al. [28] also found out misalignments between the PEF and the International EPD system schemes across cut-off rules, modelling approach, allocation rules and impact categories, leading to low comparability between the two. However, even across type III EPDs, the heterogeneity of LCA developments and programme operators hampers their comparability, despite the EPD was created with the goal of comparability [42]. Moreover, Manfredi et al. [43] pointed out that the PEF method solves some limitations of the most relevant environmental accounting methods (ISO 14040 and 14044, ISO/TS 14067, ILCD Handbook, PAS 2050, Greenhouse Gas Protocol, Ecological Footprint and BPX 30-323-0), in terms of relevance, transparency, completeness, accuracy and consistency across 9 core criteria. Finally, similarly to LCI and LCIA datasets, LSRs develop over time, too; for instance, the GPI of the International EPD System [14] is currently at its 4.0 version. 1.2.3. Issue 3: Provision of a Correct LCA Interpretation to a Non-Expert Audience LCA results are complex and they are constituted by disaggregated process contributions, spread across different impact categories. Accordingly, another major issue for the diffusion of LCA in industry is the difficulty in providing an effective interpretation of LCA results to a non-expert target audience (i.e., marketing professionals, management boards of an organization or external stakeholders) [3,44–46]. In order to deliver useful information out of the wide quantity of managed data in LCA, efficient visualization approaches were investigated [47,48]. However, literature studies could not find any universal guidance for Sustainability 2022, 14, 3746 4 of 31 visualization and only best practices were uncovered [49]. Cerdas et al. [46] highlighted that the current visualization techniques fail in supporting decision makers due to three main defects: (i) They do not outline trade-offs between impact categories and product systems; (ii) they might not clearly show relevant impacts; (iii) they do not distinguish the burdens related to the background system. Concerning visualization techniques, literature studies proposed cluster heat maps [46], 3D visualizations to simplify the huge amount of data associated with LCI and to identify potential environmental hot-spots already in the design phase [50] and dashboards, to convey Life Cycle Sustainability Assessment results to decision-makers [51]. The latter study outlined the need to use a graphical presentation using chromatic scales and ranking scores, to provide a straightforward but comprehensive communication of disaggregated results. Finally, dashboards were also used for Organizational LCA [52,53]. 1.2.4. Opportunities Offered by Automated LCA Architectures Relevant enterprise-software companies are developing automated digital platforms, e.g., for carbon accounting, reporting and environmental impacts reduction [54]. Similarly, Ferrari et al. [24] outlined that an opportunity for overcoming the barriers to LCA diffusion in industry arises from factory Enterprise Resource Planning (ERP) systems. Indeed, these systems retrieve most of the data useful to build the foreground system of the LCI. Analogously, Meinreken et al. [55] computed yearly-level Key Performance Indicators across the entire value chain for 3337 products of a company, with estimated savings of about 200 years full-time equivalent with respect to conventional LCAs. In the steel sector, Moon et al. [56] developed a specific package to automatically perform LCAs due to its connection with the ERP, the environmental management system and an energy server system of the company. They found this method was superior to manual data gathering, considering time, costs and data reliability. Indeed, after the development of a first LCA model and the construction of this infrastructure, the latter can substitute both the company resources to manually look for the data and the LCA practitioner to process these data, apart from infrastructure maintenance and updates, thus lowering costs and time [24]. Moreover, primary LCI data consistently linked to an LCA tool can be dynamically updated at higher temporal resolutions, theoretically up to monitoring a single product batch in a real-time shop-floor LCA [25,57], even in connection with simulation models [2]. iPoint [58] developed a tool to highlight and analyse product batches associated with lower environmental impacts, too. As outlined in Section 1.2.1, by refining the temporal resolution of the LCA study, it is then possible to disclose the variations of LCA results related to changes in the renewable energy supply [2], in configurations/efficiencies [23] and in recycled materials use [25]. Finally, LCA tools may be conceived in a modular way [23]. This means that after identifying all the emissions and consumption patterns, a distinct LCA calculation for each flow is carried out, and eventually all the LCA modules are aggregated into the total burden, enhancing the flexibility of the LCA tool. 1.3. Research Gap, Use Case and Goal of the Paper Section 1.2 outlined that the diffusion of LCA in industry is hampered by three barriers: (i) The difficulty concerning capturing relevant temporal dynamics of industrial processes; (ii) the management of different secondary datasets for modelling the background system, LCIA methods and LSRs, together with their updates over time; (iii) the difficulty in providing an effective interpretation of LCA results to a non-expert target audience. Despite several studies outlined the advantages of automated LCA tools [24,55,56], which may solve the (i) issue, still a methodology that addresses all the three barriers at the same time, together with a discussion of their relevance within an applied case study is currently lacking. Moreover, a discussion on the role of modularity in LCA tools has been overlooked in this context. Within this paper, we aim to present a general methodology for the development of a modular LCA tool, which integrates independent modules with different functions to address the three above outlined barriers and which can be applicable across various Sustainability 2022, 14, 3746 5 of 31 industrial sectors. Then, we discuss current results and future potential outcomes of our methodology through an application within a secondary steelmaking plant with Electric Arc Furnance (EAF) technology, for the ORI Martin company. We developed our study within the Lighthouse project, funded by the Lombardy region and Italian Ministry of Economic Development. The final objective of this project, which is not yet reached, is related to the development of an automated LCA tool for environmental monitoring and decision support. The steel sector shows a number of distinctive features which make the application of our modular LCA framework interesting: • • • It carries relevant environmental burdens across different impact categories, with current regulations being more and more restrictive [59,60]. Thus, there is a need to monitor product batches associated with lower impacts and provide verifiable evidence of a certain measure aimed at reducing environmental burdens. There is a general lack of LCI data regarding steel production processes and consumed materials [59]. Therefore, there is a need to flexibly refine the LCA model once new datasets are released. LCA-specific methodological issues are related to accounting for the recyclability at the end-of-life of steel products, and which impacts should be assigned to recycled steel scraps. Thus, there is a need to flexibly deal with different LSRs. A deeper literature review on each of these issues is provided in Section S1.1 of the Supplementary Materials [59–75]. Here we frame the discussion on the relevance of tackling these issues through three research questions (RQ): • • • Research Question 1 (RQ1): What is the added value that can be provided by an LCA that includes the temporal dynamics of foreground inventory data, with respect to a static LCA? Research Question 2 (RQ2): Why is flexibility towards secondary datasets for the background system of the LCA, multiple LCIA categories and environmental LSRs needed by an LCA tool in industry? Research Question 3 (RQ3): Why are advanced visualization modules useful to handle the full complexity of dynamic LCA results? In particular, using the glossary of Beloin-Saint-Pierre et al. [18], here we analyse the inherent variability of the amounts of intermediate flows belonging to the foreground system, at a monthly temporal resolution. The methodology we followed for the construction of the framework is presented in Section 2. Section 3 presents the charts to answer the three research questions outlined above. These indications are joined within the aim of the paper in Section 4, contextualizing them within the existing literature and outlining the general conclusions valid across different industrial sectors, together with the limitations of the current paper and with possible future works. Finally, Section 5 summarizes the main findings of the paper. 2. Methods and Modelling The present section is divided into two parts. Firstly, Section 2.1 provides a general outline of the plant and its products, in order to contextualize the analysis in which the tool is intended to operate. Then, Section 2.2 provides the methodology we used to develop the modular architecture envisioned in the Introduction. 2.1. General Plant Description The production paths of steel products within the ORI Martin factory are shown by Figure 1. Sustainability 2022, 14, 3746 6 of 31 Figure 1. Production flows of the main steel products of the ORI Martin company. The brown boxes define the main processes, while the blue boxes contain the names of the different products. The black dashed boxes outline a possible aggregation of products into families. The grey dotted boxed group up the three PU of the factory. This plant is articulated into three Production Units (PU). The steelmaking unit produces steel billets, which are either directly sold to the market or undergo the hot-rolling unit, which heats up and then mills the steel, producing either hot-rolled wire rods or hot-rolled round bars. Again, these hot-rolled products may be directly sold to the market or undergo further thermal treatments, which are divided into annealing of wire rods (three different products) and round bars, and quenching and tempering of round bars only (two different products). 2.2. Methodology for the Development of the Modular Architecture Table 1 provides information on the main modules which are connected by the methodology to build a modular LCA tool, which we developed in the present paper. Table 1. Summary of the modules connected in the modular LCA tool. For each module, the first column explains the function, the second column explains the technology employed in the present paper, while the third one outlines the reasons behind our choice. Function Employed Technology Motivation Primary data retrieval Spreadsheets, documents collected by the company Computation of unitary impacts OpenLCA LCA data collection and wrangling Microsoft Excel LCA data manipulation Python LCA results visualization Plotly library, coded in python Currently, the tool is not directly linked with the factory management system. Software in which LCA models used for EPD certification of the ORI Martin products were developed Possibility to gather data from different sources (company files, LCA software results) and to process them, using multiple different rules, to a wrangled format which is easily manageable for python coding; all steps performed within a single spreadsheet. Necessary to manipulate the high amount of data, given the different timesteps, LCIA categories, products. Possibility to implement interactive dashboards Sustainability 2022, 14, 3746 7 of 31 The employed technology refers to our specific case, but our methodology is general and applicable with other softwares and libraries, as far as they are used with the same function. For instance, the Coding module may employ other data management languages, such as R. Otherwise, the Visualization module may also employ Microsoft PowerBI or the Business Intelligence module used by Ferrari et al. [24]. Then, Figure 2 schematizes the connections within our methodology. Every module is independent by the others, i.e., it can be modified while leaving the remaining architecture unchanged: Only the transferred data would change. Figure 2. General methodology for building the modular LCA tool. The figure outlines how the different modules interact, in compliance with environmental LSRs, starting from the available data from factory management systems. Moreover, the Coding module shows the three main equations which are later detailed in this section. The legend and acronyms in the bottom part of the figure clarify the meaning of the presented items. Sustainability 2022, 14, 3746 8 of 31 As Figure 2 shows, compliance to LSR is connected to several modules of the LCA tool. Before starting any development, the environmental labels to be addressed by the architecture must be defined. In our case, the ORI Martin company obtained a Carbon Footprint (CFP) certification and it is currently undergoing the auditing process for an EPD, within by the International EPD system. Therefore, in the present paper, the application of our methodology is related to these two certifications, which are both based on a static LCA model employing yearly data. Thus, data retrieval and LCA results computation for yearly LCA results were already validated through CFP verification and they are being validated for EPD, too. 2.2.1. Primary Data Retrieval This module is built through the identification of the availability of the data which are needed for the dynamic LCA purposes, clustered by the cloud symbol in Figure 2. These data are collected through spreadsheets and documents from the company. Within our case study, the temporal scope of data collection is the year 2018. The first step to build this module concerns with identifying data which are needed for LCA and must be retrieved from the factory managements systems, in compliance to the LSRs to be addressed by the architecture. Indeed for our specific case, not all the data managed by the factory management systems are employed in CFP and EPD; for instance, prices of materials and energy are not employed. Within this step, the same criticalities of a conventional static LCA arise, in terms of collection costs. In our case, the data required by EPD and CFP were sent by the company staff by means of documents and spreadsheets, with a yearly resolution. These data are related to the production of every steel product, the consumption of raw materials (namely steel scraps, pig iron, Hot Briquetted Iron (HBI) and iron alloys), consumables (anthracite, graphite, refractories, oxygen, nitrogen, argon etc.), energy (natural gas, electricity), water, together with transports services; emissions to air and water. Data were classified according to their type (production or consumption/emission data), the PU and the unit process which is related to them. Additional classifications may even relate to specific devices and sensors in the factory. Data classifications are conveyed into the Mapping operation within the Spreadsheet module, as outlined by the connection of Figure 2. Since our tool is still not operatively linked with the data management system of the organization, the second step to build this module concerns with improving the data collection process through spreadsheets containing historical monthly-level data. This step is additional with respect to a conventional LCA. Here, specific attention was devoted to the available temporal resolution (yearly, monthly, other) of different data, to start guiding the data collection process towards the final objective of creating an automated architecture. Data are not gathered at the same temporal resolution, since either this may require costly sensors, or this may just not be possible according to the current monitoring system of the factory, or specific groups of data may only slightly contribute to LCA results. In our case, transport processes were found to be slightly relevant, therefore transport distances were assumed equal to an average yearly value over the selected temporal scope of foreground data. The validity of these assumptions must be tested through a detailed contribution analysis, accounting for the relevance of each driver across the analysed temporal scope. In conclusion, setting a specific time resolution for LCA computation does not mean that all data will be collected at that level. Data values are conveyed into the Input data sheet within the Spreadsheet module, as outlined by the connection of Figure 2. 2.2.2. Computation of Unitary Impacts This module computes unitary impacts of consumption and emissions by means of an LCA software, which is OpenLCA for our case study. Based on the definition of the environmental labels to be addressed by the architecture, LCA models can be developed for consumption and emissions items. Again, the same criticalities of a conventional static LCA arise, in terms of compliancy with LSR, across two aspects: Sustainability 2022, 14, 3746 9 of 31 • • Background models: According to the LSRs of International EPD system scheme [76] and CFP [77], the background model for electricity supply employs the Italian 2018 residual mix (i.e., the mix when all contract-specific electricity that has been sold to other customers has been subtracted from the total consumption mix [14]). Other mixes may be used, such as a specific electricity mix demonstrated by a Guarantee of Origin. LCIA categories: In our case study, the main LCIA method and categories used in this study are chosen according to the requests of the International EPD system scheme [76]. Moreover, the CFP scheme employs the IPCC 2013 LCIA method. However, for the sake of RQ2, we also employed ILCD 2.0 midpoint 2018 method (see Section 3.2). The modularity of the tool provides the possibility to add new impact categories, too. The chosen LCA database is ecoinvent 3.6, attributional cut-off version [72] and literature sources to model specific materials. Given the objective of the present study, the LCIA results for consumption and emission flows from OpenLCA were collected into a dedicated sheet, named Unitary impacts within the Spreadsheet module, as outlined by the connection of Figure 2. 2.2.3. LCA Data Collection and Wrangling This module collects the data from both the factory management systems and the LCA software results, together with the information related to the mapping of each flow, into a single spreadsheet, developed in Microsoft Excel in our case. Here, data are wrangled into a format which can be easily manipulated in the following Coding module. The user interface of the Spreadsheet module allows to both perform different Processing operations for specific data items, and to easily modify datasets within this module. The Processing operations in this module could be performed in the Coding module, too, yet they would require a high amount of complex code. Part of the collections and calculations within this section can be found in a partial version of our Excel spreadsheet, which is provided as Supplementary Materials, using fictitious values due to data confidentiality. The Input data sheet collects monthly primary data withdrawn from the factory management systems. Some of the Input data values are already in a suitable format for being processed in the Coding module, while others need to undergo a Processing operation. The following non-exhaustive list outlines some of the possible calculations which are carried out within the Processing operation of the Spreadsheet module: • • • • Harmonization of time resolution across all primary foreground LCI data, constructing continuous trends to overcome the problem of discontinuous sampling. These LCI data are harmonized according to the selected time resolution, which is monthly in our case. As discussed in Section 2.2.1, some data are only monitored at larger time resolutions. The related equations for harmonizing these data are described in Section S2.1.1 of the supplementary materials. Change in units of measure. See the discussion in Section S2.1.2 of the supplementary materials. Calculation of dependent items. Specific types of data can be dependent on other data, e.g., CO2 emissions are dependent on the amount of natural gas burnt. See the discussion in Section S2.1.3 of the supplementary materials. Calculation of specific items, depending on the case study. See the discussion in Section S2.1.4 of the supplementary materials. Apart from the first point of the above list, all other computation rules were already developed in the static LCA model used for EPD certification, since all Processing calculations must be made in compliance with the LSR. In particular, the LCI analysis which is presented in this paper was developed in accordance to the PCR “2015:03 Basic Iron or Steel products & special steels, except construction steel products” of the International EPD System. The ORI Martin company produces semi-finished products, which are assigned a declared unit of 1 tonne of steel. The considered LCA boundaries are cradle-to-gate, with the products being ready to be shipped to the market. Sustainability 2022, 14, 3746 10 of 31 Eventually, all data are divided into two different sheets: Consumption/emission and Production, in order to eventually carry out Equation (1) described in Section 2.2.4. In these sheets, every single data is stored with a Unique Identifier (UID), in order to allow a connection with the Mapping information, which is carried out within the Coding module. The Mapping information is built based on LSR compliance and on information from factory management systems, as outlined by the connections in Figure 2. The LSR defines how data should be mapped, as for instance: • • The International EPD system allows groups up the consumption of raw materials and consumables into the Upstream phase, while keeping the consumption of energy, waste treatment and emissions into the Core phase [14]. The Greenhouse Gas (GHG) protocol scheme [78] associates emissions to the Scope 1 group, energy provision to the Scope 2 and all the remaining data to the Scope 3. Overall, the Mapping operation carries the following information, for each specific flow: • • • • • • • UID, to allow a connection with Consumption/emission and Production values; Type (production or consumption/emission data), withdrawn from factory management systems, see Section 2.2.1; PU in which the flow was consumed/emitted, withdrawn from factory management systems, see Section 2.2.1; LSR classifications, as outlined in the previous list; Flow key, to allow a connection with Unitary impacts sheet in the Coding module; Unit of measure of the flow value, compatible with the Processing operation; Any additional classification, depending on the company needs: Materials suppliers, detail on unit processes, up to specific sensors and devices etc. The Flow key is a primary key associated to intermediate flows which share the same background LCI. For instance, the electricity consumptions in two different unit processes (e.g., EAF and Ladle Furnace) have a different UID, but they share the same Flow key (see the partial version of our Excel spreadsheet in the supplementary materials for further examples). Accordingly, every Flow key is associated to a specific vector of unitary impacts (e.g., the impacts of electricity across the EPD indicators), in the Unitary impacts sheet of this module. The latter sheet collects the LCIA results for consumption and emission flows from the LCA software module. The organization staff may be interested in exactly knowing which unit process consumes a specific flow (e.g., electricity consumed in the EAF), or they may be interested in gaining a more aggregated view (e.g., electricity consumed by the entire factory). The level of detail associated to every flow may vary, but due to independency between modules, the architecture does not change. Finally, additional sheets may be included in the spreadsheet, depending on the needs of the Coding module and on the complexity of the LCA. 2.2.4. LCA Data Manipulation This module manipulates the wrangled data and information provided by the Spreadsheet module by means of a coding language, which is python in our case. Here, LCA results are computed for every flow, for all products, impact categories and timesteps, also outlining the contributions of different flows. Coding provides the possibility to work with a high amount of data, only through a few simple rules and equations which keep the code manageable. In our case, we managed 155 consumptions/emissions data (those related to steelmaking, which are common across all products, accounts for 100 of them), 9 production data (9 products shown by Figure 1) 37 indicators from EPD and ILCD methods, 12 timestamps (12 months in a year) and different Mapping information. Furthermore, with a Coding module, if either new classifications are added in the Mapping information (columns in Table 2), or new flows are monitored (rows in Table 2), the code structure does not change. The first two operations performed in this module are related to joining the Mapping information with the Production and Consumption/emission data. These two Join operations are carried out based on the UID of the different flows. Here, the data related to the values Sustainability 2022, 14, 3746 11 of 31 of each consumption, emission or production flow, in a specific month, are associated to their related mapping. Table 2 then presents example rows and columns from the Mapped consumption/emission data. The first three columns (UID, Month, Cons/Ems) are derived from the Consumption/emission sheet of the Spreadsheet module, while the remaining columns are derived from the Mapping information built in the Spreadsheet module. For information on how the UIDs are built, see the Excel spreadsheet in the supplementary materials. Table 2. Example of rows and columns from the Mapped consumption/emission data, i.e., after the first join operation. The column Cons/Ems contains consumption and emission data, which are not shown due to confidentiality. The classifications of different labels may be applied: In this case, the EPD and GHG protocol scheme [78]. UID Month Cons/Ems Flow Key Unit UID1 Jan ... Electricity kWh UID2 Jan ... Electricity kWh UID3 Jan ... Gas supply Sm3 UID4 Jan ... Gas supply Sm3 UID5 Jan ... Refractory kg UID6 UID7 Jan Jan ... ... Refractory Scraps kg kg UID8 Jan ... CO2 emissions kg UID9 Jan ... CO2 emissions kg ... ... ... ... ... Very High Detail Electric Arc Furnace Ladle Furnace Burner #1, steelmaking Hot rolling, wire rods Electric Arc Furnace Ladle Furnace Scraps Natural gas, burner #1, steelmaking Natural gas, hot rolling, wire rods #2 ... Medium Detail Low Detail PU Low Detail EPD Scheme Low Detail GHG Protocol Energy Steelmaking Core Scope 2 Energy Steelmaking Core Scope 2 Energy Steelmaking Core Scope 3 Energy Hot rolling Core Scope 3 Consumables Steelmaking Upstream Scope 3 Consumables Materials Steelmaking Steelmaking Upstream Upstream Scope 3 Scope 3 Emissions Steelmaking Core Scope 1 Emissions Hot rolling Core Scope 1 ... ... ... ... The Very high detail column outlines information related to specific unit processes within the same PU. Table 2 shows that through the first join, every consumption and emissions flow is associated to a PU. This information is then used for another Join operation, between the mapped consumption/emission data and the mapped production data. This operation is carried out based on the PU of the different flows. Here, production and consumption/emission data are linked. Thus, every consumption or emission must be divided by the production of the related PU, to evaluate the efficiency of the factory, as shown by Equation (1): L PreliminaryLCIi,j,t = ∑ ( Flowi,l,t /Productionl,t ) (1) l =1 with the Flow term being referred to consumption or emissions, i being the Flow key index, j the considered product (one of the nine products outlined by Figure 1, t the considered timestep, l the production of a specific PU (measured in ton of steel, in accordance to the declared unit of this study) and L the total number of PU in which the selected product was processed (e.g., thermally treated products must carry all the burdens from steelmaking, hot-rolling and thermal treatments units). Equation (1) computes a preliminary LCI, which still needs to undergo a Processing operation. The following non-exhaustive list outlines some of the possible calculations which are carried out within the Processing operation of the Coding module: • Inclusion of co-products produced by the factory. In our study, some types of wastes are sent to recycling and excess heat is provided to the municipality via district heating. The related equations are described in Section S2.2.1 of the supplementary materials [77]. Sustainability 2022, 14, 3746 12 of 31 • • • Treatment of consumptions which are common across products, such as auxiliary services, which are defined at plant level. See the related equations in section S2.2.2 of the supplementary materials. Specific calculations, depending on the case study. See the discussion in section S2.2.3 of the supplementary materials. Further specifications depending on the selected LSR. See the discussion below. As happens for the Processing operation in the Spreadsheet module, the above list of calculations must be compliant with a specific considered LSR. In addition to the three operations listed above, we also designed the Processing operation to select the data needed for a specific environmental label. Indeed, differences in data needs across environmental labels can be found: • • The CFP environmental label allows to perform a mass-based cutoff, if sufficiently motivated [77]. The International EPD system allows at most for a 1% cutoff based on environmental relevance only (not on mass neither on energy) [14]. Therefore, depending on the selected label, some data may be discarded as discussed in Section 3.2. After this operation, the final LCI is computed and it can be coupled with the values of Unitary impacts of every flow key, through another Join operation. In this way, the LCI of every Flow key, at a specific timestep and for a specific product (LCIi,j,t ) can be weighted by its unitary impacts (U Ii,z ), as shown by Equation (2): LCI Ai,j,z,t = LCIi,j,t ∗ U Ii,z (2) with z being the selected impact category of the related LCIA method. Therefore, here the LCI data derived from the previously described steps are converted into LCIA results. As stated at the beginning of this section, overall 5 × 105 LCI Ai,j,z,t values are produced. At this point, by summing up all the i − th flows results, each product j can be assigned total LCIA impacts related to the consumptions and production patterns for the timestep t, in the impact category z. Finally, the LCI (or LCIA) per product may be aggregated at different levels, affecting the way results are presented, ranging from single products to an aggregated family of similar products. Due to this, aggregation of LCA results constitutes a helpful service to be provided to the organization. Equation (3) shows a way to aggregate the LCIs of different products into an average LCI, weighting the LCI of a single product by the quantity (expressed as mass) of its production. The aggregation can be performed both at LCI and LCIA level. M LCI ( A)i,j∗,t = LCI ( A)i,j,t ∗ ( Product j,t / ∑ ( Product j,t ) (3) j =1 with j∗ being a product family, constituted by M products (e.g., the hot rolled steel family is constituted by hot-rolled round bars and hot-rolled wire rods, see Figure 1). Other types of weightings, different from mass-based, may be used: The LCIs (or LCIAs) of different products may be weighted based on the revenues associated to each product. After this stage, LCA results are ready to be visualized in the subsequent Visualization module. 2.2.5. LCA Results Visualization This module aims to guide the user towards outlining which months are associated with product batches characterized by lower LCA impacts. In our case, this module employs the plotly library of the python language and it is directly connected with the LCA results computed by the Coding module. Plotly was selected due to its capability to create interactive dashboards which can deliver hundreds of different results by changing the settings of a visualized chart. Within each dashboard, we accounted for two counteracting visualization needs that arise: Sustainability 2022, 14, 3746 13 of 31 • • Zooming into a specific LCA result: Comparing the contribution of different drivers, grouped by unit processes, production units, EPD and GHG protocol classifications, etc., according to the Mapping information from the Spreadsheet module; Providing the wider picture: Comparing LCA results over time, products, LCIA categories, labels, etc. The first need implies that the chart is used to dig into a specific result, while the second implies that the chart is used to look at the trends of aggregated LCA results, in order to perform comparisons. According to the above description, the Visualization module can be used to visualize a set of downloaded data, for monitoring the trends of LCA results. In addition, our tool foresees a bi-directional interaction with the Coding module, which also allows to work on the creation of prospective what-if scenarios, which manipulate a set of starting data, changing specific variables. 3. Results Figures shown in Sections 3.1 and 3.3 will refer to the same main grouping of processes, which is presented and described by Table 3. Table 2 presented in Section 2.2.4 employed the same classifications. The Flow key of natural gas supply, which belongs to the Energy and Scope 3 groups, does not include the emissions associated to its combustion, which instead belong to the Emissions group. Due to this, most of the impacts in the Energy group are related to electricity consumption. The Emission group also includes the ORI Martin plant direct emissions of CO2 , CO, NOx and SO2 . As already stated in Section 2.1, all results are computed in accordance to the International EPD system LSR, apart from the figure shown in Section 3.2, which focuses on the differences of LCA results computed with the LSR of two different labels. We also remark that within all the presented charts, LCA results are always displayed in a relative way. Absolute LCA results cannot be displayed for confidentiality reasons, even though they will be published, divided by Core and Upstream phases, in the Environdec website once EPD certifications are obtained. Table 3. Description of groups of processes (Medium detail of Flow keys, see Table 2), as presented in this section. The last two columns are related to the classifications of two different labels: The International EPD system and the GHG protocol scheme [78]. Medium Detail Description of Groups of Flow Keys Low Detail EPD Scheme Energy Supply of electricity and natural gas Core Materials Supply of materials which will constitute the final product: steel scraps, Hot Briquetted Iron (HBI), pig iron and iron alloys Supply of coal, quicklime, oxygen, argon, nitrogen, refractories, electrodes and withdrawal of water Treatment of wastes Direct emissions to air and water Transport of wastes to the treatment site Explicitly modelled transports of materials and consumables Consumables Waste treatment Emissions Waste transport Upstream transport Low Detail GHG Protocol Upstream Scope 2 (electricity) Scope 3 (gas) Scope 3 Upstream Scope 3 Core Core Core Scope 3 Scope 1 Scope 3 Upstream Scope 3 3.1. RQ1: Dynamic LCA Results Figure 3 shows the temporal variability of monthly LCA results, due to inherent variations in the primary LCI data of the foreground system. The variability of both total results and the contributions of single drivers is outlined, for two single products (see Figure 1): Steel billets and the first type of quenched and tempered bars, which are referred to with the number 1. Sustainability 2022, 14, 3746 14 of 31 100% 100% 90% 90% 80% 80% 70% 70% 60% 60% 50% 50% 40% 40% 30% 30% 20% 20% 10% 10% 0% 0% 110% 110% 100% 100% 90% 90% 80% 80% 70% 70% 60% 60% 50% 50% 40% 40% 30% 30% 20% 20% 10% 0% 10% Year Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec 0% Year Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Month Group of Flow keys Energy Materials Month Consumables Emissions Waste treatment Upstream Transport Photochemical oxidant formation potential LCA impacts, relative to yearly value [%] Quenched and tempered bars, 1 110% Global warming potential LCA impacts, relative to yearly value [%] Billets 110% Waste Transport Figure 3. Variability of LCA results related to two products (steel billets and quenched and tempered bars, 1) across different months of 2018 year, for two selected impact categories. Flow keys are grouped according to Table 3 classification. Results are relative to the yearly average LCA value, which is set to 100% and it is displayed on the left side of each chart, with a vertical line used as division. The contributions of different groups of drivers are outlined with different colours. The chart related to the Photochemical Ozone Formation Potential (POFP) category and steel billets product shows the highest variability of results, i.e., between +14% and −7%, while the chart of Global Warming Potential (GWP) category and quenched and tempered bars, 1 shows the lowest variability, i.e., between +5% and −2% (see also the indications of Figures S13–S17 of the supplementary materials, for the Total group). Concerning steel billets, June and April, respectively, constitute the worst and best performance months across both impact categories. For the first type of quenched and tempered bars, the month which shows the lowest LCA results is still April. Instead, the month which shows the highest LCA results is August for the GWP category and June for the POFP category. These trends are mostly due to switching in raw materials consumption, between primary (pig iron, HBI and iron alloys) and secondary (steel scraps) materials, with the former having higher unitary impacts, according to the selected LCA model (attributional LCA with ecoinvent 3.6 cutoff). Moreover, not all the drivers of LCA results vary in the same way over time and the contribution to total LCA results varies across the analysed drivers, with Energy and Materials constituting the most relevant groups within the two analyzed categories. Focusing on steel billets, the contribution of Energy, with respect to the yearly LCA result, varies between (42–46%) and (24–26%), respectively, for GWP and POFP impact categories. However, the contribution of Materials is less stable, since it varies between (28–39%) and (48–66%) for GWP and POFP impact categories due to the switching between primary and secondary materials consumption. Conversely, the amount of electricity consumed per unit of steel produced is relatively stable, which makes the contribution of Energy group stable, too. Concerning the first type of quenched and tempered treated bars, the contribution of the Energy driver is greater with respect to steel billets, due to the additional hot-rolling and thermal treatment processes, which consume natural gas and electricity. Moreover, most Sustainability 2022, 14, 3746 15 of 31 of the LCI related to Materials and Consumables groups is consumed in the steelmaking stage, which makes the related contributions decrease with respect to steel billets. For this product, a slightly greater variation of the contribution of the Energy driver is found, being it between (55–63%) and (38–44%) for GWP and POFP impact categories. Conversely, the variability of Materials decreases, due to their lower contributions with respect to steel billets, being them between (18–26%) and (38–52%) for GWP and POFP impact categories. Therefore, for this product, the highest variations of LCA results induced by the Energy and Materials groups are comparable (see also Figure S16 of the supplementary materials). 3.2. RQ2: Variability Due to Background Datasets, LCIA Methods and LSRs The first part of this section investigates the uncertainty on secondary datasets which model the background system. In particular, Table 4 presents the variability of unitary impacts of different LCA models related to the Materials group. Table 4. Unitary impacts in the GWP category (expressed in kg CO2 -eq/kg material) across three cases of secondary datasets for the background system, with related sources. Asterisks (*) are related to the choices made in the other analyses presented in this paper. Dataset Best Case Medium Case Worst Case Steel scraps Value Source 0.0128 [79] 0.0526 [79] Ferrochromium Value Source 3.04 [73] Ferromolybdenum Value Source Value Source 3.16 [74] 3.44 [73] 0.0243 * sorting and pressing of iron scrap (RER) [72] 4.78 * market for ferrochromium, high carbon, 55% Cr (GLO) [72] 8.500 [80] 4.00 [80] Ferrosilicon 5.987 [80] 47.458 * [74] model with ecoinvent database [72] 8.24 * market for ferrosilicon (GLO) [72] As already stated in Section 1.3, the steel sector presents a lack of LCI datasets in the literature and commercial databases. Table 4 shows that even the available datasets present a wide discrepancy of LCA results: The unitary impacts differ even by one order of magnitude, between the best and the worst cases. In particular, reproducing the study of Wei et al. [74] for ferromolybdenum with the ecoinvent database leads to strongly different results. This is due to the choice of economic allocation parameters in the molybdenite mine operation process, which strongly increases the impacts associated to the molybdenite product. Further information can be found in Section S3.2 of the supplementary materials. Despite these datasets contribute to only a limited fraction of total results, changing the unitary impacts as shown by Table 4 may lead to an increase of 11% in the worst case, with respect to the best case (see Figure S18 of the Supplementary Materials). LCA results are especially sensitive to changes in the unitary impacts of steel scraps, due to their high consumed quantity. The second part of this section focuses on the unitary impacts of similar impact categories belonging to two different LCIA methods, presented by Table 5. The water scarcity potential and GWP categories of the international EPD system scheme [76] are, respectively, based on the AWARE Method [81] and CML 2001 baseline LCIA method (2016 version) [82], which is in turn based on the IPCC 2013 method. Sustainability 2022, 14, 3746 16 of 31 Table 5. Comparison of unitary impacts of selected Flow keys, which share the same LCI, across two categories related to water consumption and global warming, for the EPD and ILCD 2.0 midpoint LCIA methods. Impact Category Unit Electricity Gas Supply Pig Iron CO2 Emissions LCIA Method 10−1 10−1 Oxygen 10−1 EPD EPD ILCD 2.0 midpoint ILCD 2.0 midpoint Global warming potential Water scarcity potential climate change total kg CO2 -eq m3 -eq kg CO2 -eq 6.12 × 8.59 × 10−2 6.25 × 10−1 5.80 × 2.45 × 10−2 6.53 × 10−1 3.60 × 1.17 3.67 × 10−1 1.60 8.24 × 10−3 1.71 1.00 0 1.00 dissipated water m3 -eq 8.67 × 10−2 1.85 × 10−2 1.88 × 10−1 1.78 × 10−1 0 - −2.1% −11.2% −1.7% −6.3% 0.0% - - −0.9% 32.4% 519.0% −95.4% - - Unitary impacts vary due to the different hypotheses involved, even if the LCI of these processes is the same. Accordingly, slight differences, up to 11.2%, can be seen for the two global warming categories. Instead, the water use categories may show strongly different unitary impacts, with the ILCD method results for oxygen being 5 times lower than the EPD method ones. Conversely, the ILCD method results for pig iron are 20 times higher than the EPD method ones. This happens because the ILCD method maps elementary flows related to water emitted to air, whereas the EPD-related method maps elementary flows linked to water consumptions and emissions taken from the Resource and Emission to water compartments of ecoinvent [72]; see also Section S3.2 of the supplementary materials. Due to these differences, ILCD results for steel billets are, respectively, 2.9% higher and 18.0% lower than the EPD results (see Figure S21 of the Supplementary Materials). The variation of LCA results in the water-related categories is especially due to the high difference in the unitary impacts of oxygen. Finally, the third part of this section focuses on results provided by different LSRs, starting from the same LCI. Figure 4 shows the comparison of two environmental labels results: CFP and International EPD system. The main difference between the related LSRs lies on the allowed cutoffs, as explained for the Processing operation of the Coding module (see Section 2.2.4). Billets CFP LCA label Variation EPD-ILCD, GWP Variation EPD-ILCD, WSP EPD 0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100% Yearly LCA impacts, relative to max value [%] GHG Protocol classification Scope 1 Scope 2 Scope 3 Figure 4. Comparison of yearly LCA results for steel billets, across two environmental labels: CFP and International EPD system, in the GWP category. Results are relative to the EPD values and processes are grouped according to the GHG protocol classification scheme [78]. For the EPD case, no cutoff on LCA results was performed. For the CFP case, a 5% mass-based cutoff was performed, meaning that only materials and consumables that contribute to 95% of the total consumed mass were modelled. Sustainability 2022, 14, 3746 17 of 31 Steel scraps account for most of Materials and Consumables used by the company, while primary materials, which associated to the highest impacts, constitute a much lower percentage of consumed materials. Therefore, applying a 5% mass-based cutoff implies that a relevant part of the most-impacting materials is not considered in the LCA study, strongly reducing the LCA results. Consequently, the CFP case shows a 19.6% decrease of LCA results with respect to the EPD case, due to the decrease in scope 3 emissions. Steel billets products show the highest sensitivity to changes in the cutoff levels, due to the highest relevance of the Materials and Consumables groups (see Figure 3). 3.3. RQ3: Usefulness of Dashboards Visualizations Static LCAs deal with multiple products, impact categories and methods, LSRs and various ways to aggregate results by groups of processes. Moreover, comparisons between products or scenario analyses may be carried out. In addition to these, our dynamic LCAs also present a temporal dimension of the LCI. The following is a non-exhaustive list of possible visualization variables that the user may interact with: • • • • • • • Product (from steel billets to thermally treated hot rolled steel); Type of product (families, single product, product batches); LCIA category; Groups of processes; Type of charts (line, bar, treemap, pie, heatmap, etc.); LCA labels; Timesteps. Accordingly, Section 2.2.4 explained that the Coding module produces a final dataframe with more than 5 × 105 LCI Ai,j,z,t data values, each of them associated to several Mapping columns as shown by Table 2. In order to show the capabilities of the Visualization module, in terms of communicating the complexity of LCA results, we prepared four dynamic dashboards. Here we present the related figures, extracted in static screenshots. The actual dashboards can be interactively updated depending on the user’s settings. A reproduction of the dashboards operations is provided as supplementary materials, through GIF files. The dashboards are built in order to balance within different visualization needs, as explained by the following list: • • • • Comparison across months and products, with focus on contributions for a specific timestep and product (Figure 5); Comparison of LCA results for selected products over time, with zoom on specific LCI consumptions of that product (Figure 6); Comparison across LCIA categories and products, with a focus on specific impact drivers (Figure 7); Comparison across prospective what-if scenarios (Figure 8). The first dashboard, presented in Figure 5, helps comparing the LCA performance of different products and understanding the reasons behind these trends by zooming into a specific result, to outline the contribution of different drivers. Through the line chart on the left, this dashboard shows that for the GWP category, the monthly trends are similar across product families, with April and June being, respectively, the best- and worst-performance months. This means that the variability of LCA results is mostly due to the variability of the LCI of steel billets. Recalling what Figure 3 showed, this variability is mostly due to variations in the consumption of Materials-related items. Results vary if other LCIA categories are selected, as shown by Figure S22 of the supplementary materials. Then, the dashboard presented in Figure 6 outlines the connection between LCA results (left), and primary foreground data (right). Sustainability 2022, 14, 3746 18 of 31 Figure 5. Screenshot extracted from a dashboard of the Visualization module, showing a line chart comparison of monthly LCA results for a selected impact category, for different products, on the left. Results are relative to the highest value across products and months. On the right, a double pie chart provides a zoom on the contributions of different groups of Flow keys, for a specific month and product (highlighted by the black marker in the left chart), represented by the size of the area. Areas are grouped by PU and by the group of Flow keys presented by Table 3. On the upper part of the dashboard, the selection of impact categories and level of product aggregation is shown. On the lower right part, the selection of product and month for the pie chart is shown. Figure 6. Screenshot extracted from a dashboard of the Visualization module, showing a bar chart comparison of monthly LCA results, relative to the yearly average, for a selected impact category and product, on the left. Flow keys are grouped according to the International EPD system label classification. In the bottom left part, the selection of impact category, process classification, included processes groups. On the right part, monthly foreground LCI data, relative to 1 ton of produced steel, are shown for a series of relevant processes, partly grouped by Table 3 classification. Sliders on the bottom part of each chart can be used to focus on specific consumptions. The y axis and the legend of the lines are not shown here for confidentiality reasons. On the top part, the drop-down menu for the selection of the product. Different trends can be seen on the line charts located on the right: The sum of these trends, weighted by the respective unitary impacts, provides the results on the left part. A wide variety of LCI trends that can be detected within the steelmaking plant is here outlined. Hot-rolled and thermally treated steel would show additional consumptions. However, the sensitivity of LCA results to every LCI variation depends on the unitary Sustainability 2022, 14, 3746 19 of 31 impact of a considered Flow key; for instance, variations on the consumption of secondary materials, such as scraps, are far less impactful than variations on primary materials consumption. Both the dashboards presented in Figures 5 and 6 show only a single impact category at a time. The dashboard represented in Figure 7 aims at overcoming this issue by presenting a comparison across impact categories, outlining their variability both across products (top table) and across groups of drivers of LCA results (bottom table). This dashboard was developed in accordance with the indications of Cerdas et al. [46], resembling the clustered heat maps provided by that study. Indeed, conditional formatting was included to help with results interpretation in a visual way. Figure 7. Screenshot extracted from a dashboard of the Visualization module, for the comparison of LCA results across different impact categories (rows of the two tables). The top table shows the variation of monthly LCA results with respect to the yearly values, related to the month of January, across different products. Depending on the settings above the table, the month can be selected either from a dropdown menu, or according to the best (worst) performing month, i.e., month showing the lowest (highest) LCA results. A scale of green-to-blue colours was used to outline best-to-worst results, while the yellow (grey) cell represent the best (worst) value. The bottom table shows the contributions of different drivers to LCA results for a chosen month and product. A scale of green-toblue colours was used to outline lowest-to-highest contributions. As an alternative, absolute LCA results can also be displayed for both tables. Figure 7 shows that, in January, some impact categories show an increase of LCA results with respect to the yearly value, while the opposite happens for other categories. Moreover, across all the shown impact categories (and not only across GWP and POFP as shown by Figure 3), most of the contributions to impact results are due to Materials, Energy and Consumables groups. Emissions only contribute to few impact categories, depending on the emitted compound. By coupling the information of the two tables in Figure 7, it can be seen that within the categories that show the higher variations of LCA results with respect to the yearly value, the Materials driver presents the highest contributions, with the Energy driver contributing by less than 30%. Thus within certain impact categories, such as Abiotic depletion, elements, the increase of LCA results in January is probably driven by a higher consumption of primary raw materials. Instead, results related to the best and worst performing months show different values, see Figures S23 and S24 in the supplementary materials. Sustainability 2022, 14, 3746 20 of 31 Finally, the dashboard presented in Figure 8 is based on the collected primary data. Due to the bi-directional connection with the Coding module (see Section 2.2.5), this dashboard can outline the sensitivity of LCA results to what-if scenarios. That is, how the factory may behave over time with respect to a setting, in response to certain substitutions (hydrogen in place of natural gas) or efficiency measures (reduction of energy consumptions). Figure 8. Screenshot extracted from a dashboard of the Visualization module, that can be used for the set-up of two what-if scenarios, modifying the amounts of specific consumptions for a specific product (Quenched and tempered bars in this case), selectable from a drop-down menu. The implemented measures are the substitution of natural gas with hydrogen (produced via lowtemperature electrolysis fuelled by electricity from RES, LCA model adapted from Mehmeti et al. [83]), the substitution of grid electricity with RES electricity and the reduction of thermal and electric energy consumptions. A slider in the bottom left part of the figure allows to set up environmental impact reduction targets, with respect to the yearly average LCA value. The charts on the right show LCA values of the base case and the two scenarios, relative to the yearly average LCA value, for two impact categories, selectable from drop-down menus. Exploring Figure 8, the user can derive that the 30% decrease target is never reached by the first scenario, but it is reached by the second one, in the GWP category. However, even the second scenario is not able to reach this target in the month of June. Instead, the Abiotic depletion, elements category even shows an increase of LCA results in the two scenarios, which is mainly driven by Renewable Energy Sources (RES) electricity. This is also true for the second scenario, despite the 10% reduction of energy consumption. Thus, this dashboard outlines the difficulty concerning obtaining a decrease of LCA results across all LCIA categories and all months of the year. 4. Discussion The present section is articulated into three parts. Section 4.1 summarizes and discusses the indications shown by Section 3, across the three RQs. Then, Section 4.2 outlines the limitations in which our discussions are built. Finally, Section 4.3 paves the way for the expected future works on the direction of the main vision of the paper. 4.1. Summary of the 3 Research Questions 4.1.1. RQ1: A Dynamic LCA Discloses a Remarkable Variability of LCA Results A yearly static LCA can disclose the environmental hot-spots: In our case study, Energy and Materials groups constitute the highest contributors to LCA results, apart from the Water scarcity potential category. Conversely, a dynamic LCA can additionally highlights the environmental hot-spots in the steel factory process in a specific timestep and the variability of these contributions over time: In our case study, the variability of results Sustainability 2022, 14, 3746 21 of 31 is mostly due to Materials group, rather than Energy, especially for steel billets. Only by introducing the monthly inherent variations of the foreground LCI, LCA results may even vary by ±14%, depending on the selected product and impact category, with respect to the static results. This leads to the consideration that within the current plant configuration, a higher degree of action to decrease product batches environmental impacts is given by increasing the amount of consumed steel scraps, rather than working on energy consumption, which do not seem to outline a relevant variability. For quenched and tempered bars, the variability of LCA results associated to these two groups is comparable, also due to the decreased relevance of Materials on total LCA results. Therefore, for these products, there seems to be possibilities for optimizing the energy consumption. However, these considerations may vary across different impact categories or environmental labels. The variability of LCA results that was found is comparable with LCA results by Moon et al. [56], which are discussed on Figure S11 of the supplementary materials. However, while Moon et al. [56] highlighted that variability they found was due to variations in the fuel usage, in our case most of the variability is attributable to changes in the Materials group. Finally, aggregation of results through Equation (3) may change temporal trends, too. Indeed, Figure 3 showed that for the first type of quenched and tempered bars, August is the worst-performance month in the GWP category. Instead, Figure 5 shows that considering the aggregated family of quenched and tempered bars, June shows the highest results in the same impact category. 4.1.2. RQ2: LCA Results Are Sensitive to Variations of Background Datasets, LCIA Methods and LSRs Section 3.2 showed a remarkable sensitivity of LCA results to changes in the LCA model, through Figure 4. Tables 4 and 5 made clear that an advanced LCA tool should be able to look at both LCI and LCIA variability, since unitary impacts may even vary by one order of magnitude, due to differences in the modelling hypotheses. Out of the 455 environmental labels worldwide [84], additional indicators and certification schemes may be added, such as the ones related to Circular Economy, PEF or Organizational LCAs. Therefore, an LCA tool needs to manage this complexity, envisioning flexible updates over time, too. We outline here the usefulness of separating LCA data manipulation (Coding module) with respect to LCA data collection and wrangling through a user interface (Spreadsheet module), in order to flexibly modify single datasets (e.g., update unitary impacts, refine the monitored consumptions and productions) or add new Mapping classifications in addition to what is shown by Table 2. Due to the independency across modules in our architecture, working on the Spreadsheet module does not imply dealing with the Coding module, which does not need any modification as far as data are provided in a suitable format. Concerning the LCI models, Ferrari et al. [24] outlined the issue of managing different levels of data quality across the LCI datasets, in particular between primary data of the foreground system (manufacturing) and secondary data of the background system (supply chain and downstream processes). We found the same issue, especially for mapping all consumed ferroalloys. Moreover, to deal with secondary data, we highlight that EPD results along the supply chain may be included in LCAs. This update would be relatively simple, working on the only Spreadsheet module. Moreover, this approach would not require the sharing of primary data across the supply chain, since only aggregated LCA results would be diffused. This vision could be feasible as the number of EPDs released by European programme operators growing, as indicated by Toniolo et al. [85], who mapped almost 5000 EPDs downloaded between September and December 2016. Indeed, several studies withdrew secondary LCI data from the EPD database [86,87]. Even more in general, all background datasets within the LCA may need to be updated according to, e.g., new database releases, linking of supply chain-specific data, suppliers which provide EPD certifications. Otherwise, new Processing operations may be developed Sustainability 2022, 14, 3746 22 of 31 for specific consumptions, such as accounting for alloy content in ferroalloys. Concerning our case study, some iron alloys could only be modelled with proxy datasets, and across the EPD categories, these may even contribute by 5.9% to yearly LCA results for steel billets. Another driver of variability of LCA results may be driven by the use of coal-based or gas-based HBI, which show very different impacts in the GWP category, respectively, equal to 0.78 and 1.21 kg CO2 -eq/kg of HBI [80]. Finally, other possible variations of LCA results may be related to the electriciy mix: If the company decides to purchase guarantees of origin (green certificates), i.e., electricity produced by renewable sources, LCA results may be significantly affected, as Figure 8 shows. Within our system, this type of changes can be easily modelled by updating the electricity-related LCA model in the LCA Software module, which delivers unitary impacts to the Spreadsheet module. 4.1.3. RQ3: Interactive Dashboards Can Handle a High Amount of LCA Results, Together with What-If Scenarios Accounting for the temporal variability of foreground LCI data strongly increases the amount of manipulated data, which is already high in the case of a static LCA. Moreover, the dashboards presented in Section 3.3 showed that to outline which months are associated with lower environmental impacts requires comparing LCA results over time and LCIA categories, while allowing for focuses on LCI consumptions and specific contributions. In addition, the considerations may change across products. We showed that dashboards can work on a wide variety of charts, displaying a high amount of results in a tidy way, depending on the user’s selections. In particular, here we addressed the main limitations of the current visualization techniques outlined by Cerdas et al. [46] and cited in Section 1.2.3. Firstly, the dashboards shown in Figures 7 and 8 presented possible trade-offs between LCA results, presenting that they may increase within specific LCIA categories/months/scenarios/products, while they may decrease in others. Secondly, relevant impact drivers were outlined in Figures 5–7, using two different classifications in accordance to Table 3. Further detail on every LCI Ai,j,z,t result (e.g., showing the contribution of every material within the Materials and Consumables categories) can be provided by the dashboards, but it was omitted here for confidentiality reasons. Thirdly, different groupings of LCA results can also communicate the differentiation between the background and foreground system-related impacts. Indeed, the classification of the International EPD system explicitly considers Upstream impacts, while the GHG protocol classification considers supply-chain specific data into the Scope 3 group and energy supply data in the Scope 2 group. Another useful capability of dashboards is related to their interactivity, which allows a non-specialist user to explore LCA results. Moreover, due to this interaction, also the LCA practitioner can understand what the company needs are, and accordingly customize dashboards useful to non LCA-experts. Finally, due to the bi-directional interaction of Visualization and Coding modules, prospective what-if scenarios can be created, as shown by Figure 8. Concerning our case study, additional efficiency measures that may be investigated are circularity policies aimed at the valorization of wastes, as already studied in the literature [75]. To better evaluate these measures, specific simulation models as made in Rodger et al. [2] may be integrated in the modular architecture, without changing the Visualization module due to the independency across modules. Indeed, Figure 8 was built using LCA models which are only theoretical and do not account for the complexity of actually substituting natural gas with hydrogen in terms of supply chain and steel plant configuration. 4.2. Limitations The main limitations of our modular LCA architecture are related to development costs and the level of detail which is provided to the non-expert organization staff. Firstly, this kind of integrated system requires both distributed competences and availability of data-intensive environments in order to be framed within a proper accountability strategy. Our architecture assumes that good quality primary data can be withdrawn Sustainability 2022, 14, 3746 23 of 31 from factory management systems. That is, a company must be able to perform a primary data collection for developing LCI and LCA models, with the same criticalities of a static LCA, as explained in Section 2.2.1. The latter activities are recognized to be costly [3,88], with total costs for creating a PCR and an EPD being estimated to range between 13,000 and 41,000 USD, with a work load of 22–44 person-days [89]. Moreover, with this architecture, the initial cost would be even higher, due to the additional costs for building the modular tool. It is recognized in the literature that increasing the temporal resolution requires additional effort, which must be compensated by an increased value of LCA results leading to a refinement or even changing the LCA conclusions [2,18]. In general, our modular architecture is particularly helpful for sectors that present some of the following characteristics: • • • • • be increasingly regulated, thus needing to know how to increase their environmental impacts; be characterized by high heterogeneity and variability of products composition, for which a detailed monitoring makes sense; show a lack of high quality LCI datasets on relevant items (e.g., chemicals consumed in the fashion industry); show a remarkable variability of LCA results associated to secondary datasets for the background system (e.g., as found for LCA impacts of bio-based plastics across manufacturing countries [31]); employ a high percentage of recycled materials, or produce products that can be recycled, thus needing specific methodological choices that may vary across LSRs. Secondly, concerning the conclusions from our dynamic LCA study for a non-expert organization staff, we showed a wide range of detailed dashboards, yet we did not provide details on how to convey this complexity towards an actual decision. In practice, either a user within the company is trained to understand LCA results, or a decision support system must be built. The latter can be based on, e.g., normalization and weighting steps across LCIA categories, which were not performed in this paper but they would be helpful to guide the organization staff to a decision. Otherwise, non-expert users may focus on specific impact categories only (e.g., climate change), implicitly applying a weighting process. Due to concision reasons, we did not deal with this topic on this paper. In addition, our conclusions mostly showed that the variability of LCA results is mostly due to variations in the consumption share of recycled steel scraps, rather than consumption of electricity and natural gas. The obvious conclusion from the environmental LCA is to increase the usage of steel scraps. However, the substitution of scraps with cast iron and HBI is also driven by economic reasons (scraps price fluctuations). Adding a Life Cycle Costing (LCC) module within our tool may disclose trade-offs between the environmental (LCA) and the economic (LCC) analyses. Moreover, the technical feasibility of employing lower impact steel scraps should also be considered; e.g., depending on specific technical properties that steel products must have, specific iron alloys must be used. The final choice between environmental, economic performances and actual feasibility of a material substitution measure is left to the organization staff. Concerning the dynamic LCA results, limitations are related to assumptions due to lack of primary data. Indeed, a calculation of monthly values was carried out for items such as steel scraps consumption and emissions to air, as explained in Section S2.1.1 of the supplementary materials. Moreover, while the total quantity of iron alloys was available at the monthly level, the consumption of each specific iron alloy was not available from the primary data of this study. Adding these specific consumption data is likely to lead to additional variability in LCA results, e.g., in the months when higher impact iron alloys (e.g., Ferromolybdenum, see Table 4) are consumed. Indeed, EPDs in the steel sector outline that variations on alloy content have an impact on LCA results, which may more than double between the best and worst cases [90]. Sustainability 2022, 14, 3746 24 of 31 4.3. Towards Near-Real-Time LCA of Single Product Batches and Company-Level Sustainability Targets According with the emerging outcomes from this project, the development of modular systems could support new type of LCA-based monitoring and planning, relying on identifying paths for environmental impact mitigation through a temporally dynamic hot-spot identification. We investigated the variations in the LCI of different product batches, which are still partially averaged over a month. It is thus likely that further variability may arise by narrowing down the temporal resolution of LCAs (e.g., at the weekly or daily level) or even analysing the process lead time of single product batches. This would help reaching the eventual target for organizations, i.e., to improve their environmental performance, being able to implement targeted corrective actions in a quick way. Figure 9 outlines the foreseen integration of our tool within a single automated digital architecture, to effectively deliver the complexity of LCAs to aid the identification of these batches in accordance with what is outlined in the literature [24,54]. Automated data retrieval from factory management systems will be implemented, to dynamically update raw data. It is still to be defined whether the proposed automated LCA architecture will either be integrated within the organization management systems (ERP, Manufacturing Execution Systems, energy server systems, etc.) or it will be an additional tool. We also outline that standardized data frameworks may need to be developed, to introduce a proper automation of these procedures. Indeed, in order to associate our architecture to single product batches, several challenges for our modular tool are still to be overcome. Firstly, challenges on primary data collection are related to a closer linking of production and consumption data, with respect to the present case study. In our paper, we collected cumulated data at the monthly level, i.e., we only needed to retrieve the total consumptions and productions for every month. Instead, if the target is to build LCAs of single product batches, then each consumption item should be linked with a specific product batch, too. However, this requires a more advanced monitoring system, which must be able to follow the product batches while they are processed across the PU of the plant. Secondly, building LCAs of single product batches implies the application of refined Processing operations in the Spreadsheet and Coding modules, including more refined inference criteria to overcome the issue of discontinuous sampling. Thirdly, the more the time resolution of LCAs narrows down to single product batches, the higher the importance of aggregation and visualization techniques, due to the higher amount of data that must be managed and that could be communicated to the target audience. Additional dashboards may also be developed, such as detailed process flow charts able to show the impacts associated to single unit processes within every production unit. From the LCA developer side, the tool needs to be updated to maintain the compliance with existing standards and LSRs. Moreover, a new function of the tool will be related to contextualize the company performance within a wider framework. In our paper, the dashboard presented in Figure 8 already relates environmental impact reduction targets with the performance of the organization. Future works will be related to linking these targets to global sustainability initiatives. This new function will be conceived exploiting the links between initiatives, which were found by Tsalis et al. [91], who analyzed disclosure topics from GRI and evaluated the quality of information published in sustainability reports with respect to each UN-SDG. Moreover, Henzler et al. [92] developed an SDG-based, topdown approach linking LCA impact categories with SDGs. Sustainability 2022, 14, 3746 25 of 31 Figure 9. Contextualization of the modular LCA tool, synthesized within the grey box, within a wider framework which includes interactions with external entities, to be developed in future works. The acronyms are all introduced in Section 1. Finally, concerning the interaction with the company staff, an interface to guide the user through the selections of environmental labels will be implemented. The outputs of the tool will be refined, too, with the provision of an LCA-based decision support system, as already proposed in the literature [4]. The latter may include normalization and weighting steps across LCIA categories, refined simulations (with respect to the what-if scenarios shown by Figure 8) and optimizations. Accordingly, the Visualization module will be refined in order to allow interaction with the proposed new functions, to propose Sustainability 2022, 14, 3746 26 of 31 environmental impact reduction pathways, to better highlight critical hot-spots within the existing factory and to contextualize the company performance within a wider framework according to global sustainability initiatives. 5. Conclusions The present paper presents a general methodology to develop a modular tool for LCA-based monitoring in industry. The tool allows to modify single datasets while leaving the architecture unchanged. Moreover, the tool connects five independent modules, to provide the functions of primary data retrieval, computation of unitary impacts, LCA data collection and wrangling, LCA data manipulation, LCA results visualization. Due to the independency across modules, either the currently existing modules may be updated, or new ones may be added, without changing the overall architecture. With this structure, the tool allows to handle a high quantity of data delivered by the dynamic LCA, with more than 5 × 105 results handled and visualized, together with different classifications and aggregations. Moreover, it allows the user to flexibly modify LCA datasets (e.g., update unitary impacts, refine the monitored consumptions and productions), by simply interacting with a spreadsheet, without having to deal with coding. We test the tool within the ORI Martin secondary steelmaking plant and we frame the discussion on current and potential outcomes into 3 research questions, which are answered in the following points: • • • RQ1: A dynamic LCA shows how the temporal dynamics of industrial processes affect the variability of LCA results associated to different product batches. In our specific case, while a static LCA would provide the information that Energy and Materials groups constitute the highest contributors to LCA results, the dynamic LCA shows that the variability of results is mostly due to Materials group, rather than Energy. Monthly LCA results show a remarkable variability, up to ±14% around the yearly average value. The higher the time resolution of LCAs, the more variability is likely to be disclosed. RQ2: The unitary impacts computed using different background models and LCIA methods may even differ by one order of magnitude, while a 20% difference of LCA results is found by following the LSRs of the International EPD system and the CFP. RQ3: The high amount of LCA results can be visualized in a tidy way through interactive dashboards, which can visualize a high amount of values by dynamically updating charts depending on the user’s selections.The charts can provide the full complexity of the LCA methodology by allowing the user to navigate results across time, products, LCIA categories and environmental labels, while allowing to zoom into the contributions of specific drivers of environmental impacts and changing the process classifications. The higher the temporal resolution, the higher the amount of data to be managed, which further increases the need of these dashboards. Moreover, through a bi-directional interaction with the Coding module, dashboards can visualize results of prospective what-if scenarios, that can relate targets on environmental performance with efficiency improvement or substitution measures. Our modular tool is foreseen to be integrated within a single automated digital architecture of the organization, to reach the final objective of the Lighthouse project: Developing an automated tool for decision-making support on sustainability policies of the ORI Martin steelmaking company. Supplementary Materials: The supporting information can be downloaded at: https://www.mdpi. com/article/10.3390/su14073746/s1. Author Contributions: Conceptualization, D.R., C.B. and M.A.; Data curation, D.R. and C.B.; Formal analysis, D.R.; Funding acquisition, C.B. and A.B.; Investigation, D.R.; Methodology, D.R., C.B. and M.A.; Project administration, D.R., C.B., M.Z. and A.B.; Resources, D.R., C.B. and M.Z.; Software, D.R.; Supervision, D.R. and C.B.; Validation, D.R.; Visualization, D.R., C.B. and E.A.; Writing—original draft, D.R., C.B. and M.A.; Writing—review & editing, D.R., C.B., M.A. and E.A. All authors have read and agreed to the published version of the manuscript. Sustainability 2022, 14, 3746 27 of 31 Funding: This research was funded by the Lombardy region of Italy and Italian Ministry of Economic Development as part of the “Lighthouse project Steel 4.0”, relating to the development of “flagship plants” in the perspective of industry 4.0 for the steel and metallurgical sector. Data Availability Statement: The used primary data directly represent the production line of ORI Martin S.p.A. in 2018. Due to confidentiality reasons, these data are and will not be publicly available. Part of the collections and calculations of the Spreadsheet module can be found in a partial version which is provided as Supplementary Materials, using fictitious values for the sake of data confidentiality. Moreover, a reproduction of the dashboards information is provided as Supplementary Materials, through GIF files. Conflicts of Interest: The authors declare the following financial interests/personal relationships which may be considered as potential competing interests: M.Z. is the Research and Development manager of ORI Martin Ltd. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results. Abbreviations The following abbreviations are used in this manuscript: CDP CFP EAF EPD ERP GHG GLO GPI GRI GWP HBI ILCD IPCC ISO LCA LCC LCI LCIA LSR PB PCR PEF POFP PU RES RER RQ SbT SDG UI UID UN WSP Carbon Disclosure Project Carbon Footprint Electric Arc Furnace Environmental Product Declaration Enterprise Resource Planning Greenhouse Gas Global General Programme Instructions Global Reporting Initiative Global Warming Potential Hot Briquetted Iron International Life Cycle Data system Intergovernmental Panel on Climate Change International Organization for Standardization Life Cycle Assessment Life Cycle Costing Life Cycle Inventory Life Cycle Impact Assessment Label Specific Rules Planet Boundaries Product Category Rules Product Environmental Footprint Photochemical Ozone Formation Potential Production Unit Renewable Energy Source Rest of Europe Research Question Science-based Target Sustainable Development Goal Unitary Impact Unique Identifier United Nations Water Scarcity Potential Sustainability 2022, 14, 3746 28 of 31 References 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. 29. United Nations. UN SDG: Goal 9. Available online: https://www.un.org/sustainabledevelopment/infrastructureindustrialization/ (accessed on 15 November 2021). Rödger, J.M.; Beier, J.; Schönemann, M.; Schulze, C.; Thiede, S.; Bey, N.; Herrmann, C.; Hauschild, M.Z. Combining Life Cycle Assessment and Manufacturing System Simulation: Evaluating Dynamic Impacts from Renewable Energy Supply on Product-Specific Environmental Footprints. Int. J. Precis. Eng. Manuf.-Green Technol. 2021, 8, 1007–1026 . [CrossRef] Testa, F.; Nucci, B.; Tessitore, S.; Iraldo, F.; Daddi, T. Perceptions on LCA implementation: Evidence from a survey on adopters and nonadopters in Italy. Int. J. Life Cycle Assess. 2016, 21, 1501–1513. [CrossRef] Favi, C.; Germani, M.; Mandolini, M.; Marconi, M. PLANTLCA: A Lifecycle Approach to Map and Characterize Resource Consumptions and Environmental Impacts of Manufacturing Plants. Procedia CIRP 2016, 48, 146–151. [CrossRef] OECD. Aligning Policies for a Low-Carbon Economy; OECD Publishing: Paris, France, 2015; pp. 1–240. [CrossRef] Hauschild, M.Z.; Kara, S.; Røpke, I. Absolute sustainability: Challenges to life cycle engineering. CIRP Ann. 2020, 69, 533–553. [CrossRef] Rockström, J.; Steffen, W.; Noone, K.; Persson, A.; Chapin, F.S.; Lambin, E.F.; Lenton, T.M.; Scheffer, M.; Folke, C.; Schellnhuber, H.J.; et al. A safe operating space for humanity. Nature 2009, 461, 1262. [CrossRef] Moshrefi, S.; Abdoli, S.; Kara, S.; Hauschild, M. Product portfolio analysis towards operationalising science-based targets. Procedia CIRP 2020, 90, 377–382. [CrossRef] Global Reporting Initiative. GRI Website. 2021. Available online: https://www.globalreporting.org/ (accessed on 6 December 2021). Carbon Disclosure Project. CDP Website. 2021. Available online: https://www.cdp.net/en (accessed on 6 December 2021). ISO. Technical Committees. 2021. Available online: https://www.iso.org/technical-committees.html (accessed on 10 December 2021). Heijungs, R.; Suh, S. The Computational Structure of Life Cycle Assessment; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2002; Volume 11. [CrossRef] Roos, S.; Zamani, B.; Sandin, G.; Peters, G.M.; Svanström, M. A life cycle assessment (LCA)-based approach to guiding an industry sector towards sustainability: The case of the Swedish apparel sector. J. Clean. Prod. 2016, 133, 691–700. [CrossRef] Environdec. General Programme Instructions for the International EPD System, 2021. GPI 4.0. Available online: https://www.datocms-assets.com/37502/1617181375-general-programme-instructions-v-4.pdf (accessed on 10 December 2021). Filleti, R.A.; Silva, D.A.; Silva, E.J.; Ometto, A.R. Dynamic system for life cycle inventory and impact assessment of manufacturing processes. Procedia CIRP 2014, 15, 531–536. [CrossRef] Andersson, J.; Grönkvist, S. A comparison of two hydrogen storages in a fossil-free direct reduced iron process. Int. J. Hydrogen Energy 2021, 46, 28657–28674. [CrossRef] Tiruta-Barna, L.; Pigné, Y.; Navarrete Gutiérrez, T.; Benetto, E. Framework and computational tool for the consideration of time dependency in Life Cycle Inventory: Proof of concept. J. Clean. Prod. 2016, 116, 198–206. [CrossRef] Beloin-Saint-Pierre, D.; Albers, A.; Hélias, A.; Tiruta-Barna, L.; Fantke, P.; Levasseur, A.; Benetto, E.; Benoist, A.; Collet, P. Addressing temporal considerations in life cycle assessment. Sci. Total Environ. 2020, 743, 140700. [CrossRef] [PubMed] Collet, P.; Lardon, L.; Steyer, J.P.; Hélias, A. How to take time into account in the inventory step: A selective introduction based on sensitivity analysis. Int. J. Life Cycle Assess. 2014, 19, 320–330. [CrossRef] Sohn, J.; Kalbar, P.; Goldstein, B.; Birkved, M. Defining Temporally Dynamic Life Cycle Assessment: A Review. Integr. Environ. Assess. Manag. 2020, 16, 314–323. [CrossRef] Lueddeckens, S.; Saling, P.; Guenther, E. Temporal issues in life cycle assessment—A systematic review. Int. J. Life Cycle Assess. 2020, 25, 1385–1401. [CrossRef] Corrado, S.; Castellani, V.; Zampori, L.; Sala, S. Systematic analysis of secondary life cycle inventories when modelling agricultural production: A case study for arable crops. J. Clean. Prod. 2018, 172, 3990–4000. [CrossRef] [PubMed] Brondi, C.; Carpanzano, E. A modular framework for the LCA-based simulation of production systems. CIRP J. Manuf. Sci. Technol. 2011, 4, 305–312. [CrossRef] Ferrari, A.M.; Volpi, L.; Settembre-Blundo, D.; García-Muiña, F.E. Dynamic life cycle assessment (LCA) integrating life cycle inventory (LCI) and Enterprise resource planning (ERP) in an industry 4.0 environment. J. Clean. Prod. 2021, 286, 125314. [CrossRef] Hagen, J.; Büth, L.; Haupt, J.; Cerdas, F.; Herrmann, C. Live LCA in learning factories: Real time assessment of product life cycles environmental impacts. Procedia Manuf. 2020, 45, 128–133. [CrossRef] Notarnicola, B.; Sala, S.; Anton, A.; McLaren, S.J.; Saouter, E.; Sonesson, U. The role of life cycle assessment in supporting sustainable agri-food systems: A review of the challenges. J. Clean. Prod. 2017, 140, 399–409. [CrossRef] Diekel, F.; Mikosch, N.; Bach, V.; Finkbeiner, M. Life cycle based comparison of textile ecolabels. Sustainability 2021, 13, 1751. [CrossRef] Del Borghi, A.; Moreschi, L.; Gallo, M. Communication through ecolabels: How discrepancies between the EU PEF and EPD schemes could affect outcome consistency. Int. J. Life Cycle Assess. 2020, 25, 905–920. [CrossRef] Patchell, J. Can the implications of the GHG Protocol’s scope 3 standard be realized? J. Clean. Prod. 2018, 185, 941–958. [CrossRef] Sustainability 2022, 14, 3746 30. 31. 32. 33. 34. 35. 36. 37. 38. 39. 40. 41. 42. 43. 44. 45. 46. 47. 48. 49. 50. 51. 52. 53. 29 of 31 Pecreboom, E.C.; Kleijn, R.; Lemkowitz, S.; Lundie, S. Influence of Inventory Data Sets on Life-Cycle Assessment Results: A Case Study on PVC. J. Ind. Ecol. 1998, 2, 109–130. [CrossRef] Abbate, E.; Rovelli, D.; Andreotti, M.; Brondi, C.; Ballarino, A. Plastic packaging substitution in industry: Variability of LCA due to manufacturing countries. Procedia CIRP 2022, 105, 392–397. [CrossRef] Pauer, E.; Wohner, B.; Tacker, M. The influence of database selection on environmental impact results. Life cycle assessment of packaging using gabi, ecoinvent 3.6, and the environmental footprint database. Sustainability 2020, 12, 9948. [CrossRef] Modahl, I.S.; Askham, C.; Lyng, K.A.; Skjerve-Nielssen, C.; Nereng, G. Comparison of two versions of an EPD, using generic and specific data for the foreground system, and some methodological implications. Int. J. Life Cycle Assess. 2013, 18, 241–251. [CrossRef] UN Environment Programme (UNEP) Life Cycle Initiative. Global LCA Data Access. 2021. Available online: https://www.globallcadataaccess.org/ (accessed on 15 November 2021). Finkbeiner, M. Product environmental footprint—Breakthrough or breakdown for policy implementation of life cycle assessment? Int. J. Life Cycle Assess. 2014, 19, 266–271. [CrossRef] Forster, P.; Ramaswamy, V.; Artaxo, P.; Berntsen, T.; Betts, R.; Fahey, D.W.; Haywood, J.; Lean, J.; Lowe, D.C.; Myhre, G.; et al. Changes in Atmospheric Constituents and in Radiative Forcing. In Climate Change 2007: The Physical Science Basis. Contribution of Working Group I to the Fourth Assessment Report of the Intergovernmental Panel on Climate Change; Solomon, S., Qin, D., Manning, M., Chen, Z., Marquis, M., Averyt, K., Tignor, M., Miller, H., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2007; Chapter 2, p. 212. Myhre, G.; Shindell, D.; Bréon, F.M.; Collins, W.; Fuglestvedt, J.; Huang, J.; Koch, D.; Lamarque, J.F.; Lee, D.; Mendoza, B.; et al. Anthropogenic and natural radiative forcing. In Climate Change 2013 the Physical Science Basis: Working Group I Contribution to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Stocker, T., Qin, D., Plattner, G.K., Tignor, M., Allen, S., Boschung, J., Nauels, A., Xia, Y., Bex, V., Midgley, P., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2013; Chapter 8, p. 731. [CrossRef] Minkov, N.; Schneider, L.; Lehmann, A.; Finkbeiner, M. Type III Environmental Declaration Programmes and harmonization of product category rules: Status quo and practical challenges. J. Clean. Prod. 2015, 94, 235–246. [CrossRef] Galatola, M.; Pant, R. Reply to the editorial “product environmental footprint-breakthrough or breakdown for policy implementation of life cycle assessment?” Written by Prof. Finkbeiner (Int J Life Cycle Assess 19(2):266–271). Int. J. Life Cycle Assess. 2014, 19, 1356–1360. [CrossRef] Durão, V.; Silvestre, J.D.; Mateus, R.; de Brito, J. Assessment and communication of the environmental performance of construction products in Europe: Comparison between PEF and EN 15804 compliant EPD schemes. Resour. Conserv. Recycl. 2020, 156, 104703. [CrossRef] Passer, A.; Lasvaux, S.; Allacker, K.; De Lathauwer, D.; Spirinckx, C.; Wittstock, B.; Kellenberger, D.; Gschösser, F.; Wall, J.; Wallbaum, H. Environmental product declarations entering the building sector: Critical reflections based on 5 to 10 years experience in different European countries. Int. J. Life Cycle Assess. 2015, 20, 1199–1212. [CrossRef] AzariJafari, H.; Guest, G.; Kirchain, R.; Gregory, J.; Amor, B. Towards comparable environmental product declarations of construction materials: Insights from a probabilistic comparative LCA approach. Build. Environ. 2021, 190, 107542. [CrossRef] Manfredi, S.; Allacker, K.; Pelletier, N.; Schau, E.; Chomkhamsri, K.; Pant, R.; Pennington, D. Comparing the European Commission product environmental footprint method with other environmental accounting methods. Int. J. Life Cycle Assess. 2015, 20, 389–404. [CrossRef] Masanet, E.; Chang, Y. Who cares about life cycle assessment?: A survey of 900 prospective life cycle assessment practitioners masanet and chang who cares about LCA? J. Ind. Ecol. 2014, 18, 787–791. [CrossRef] Molina-Murillo, S.A.; Smith, T.M. Exploring the use and impact of LCA-based information in corporate communications. Int. J. Life Cycle Assess. 2009, 14, 184–194. [CrossRef] Cerdas, F.; Kaluza, A.; Erkisi-Arici, S.; Böhme, S.; Herrmann, C. Improved Visualization in LCA Through the Application of Cluster Heat Maps. Procedia CIRP 2017, 61, 732–737. [CrossRef] Otto, H.E.; Mueller, K.G.; Kimura, F. Efficient information visualization in LCA: Approach and examples. Int. J. Life Cycle Assess. 2003, 8, 259–265. [CrossRef] Otto, H.E.; Mueller, K.G.; Kimura, F. Efficient Information Visualization in LCA: Application and Practice. Int. J. Life Cycle Assess. 2004, 9, 2–12. [CrossRef] Raoufi, K.; Taylor, C.; Laurin, L.; Haapala, K.R. Visual communication methods and tools for sustainability performance assessment: Linking academic and industry perspectives. Procedia CIRP 2019, 80, 215–220. [CrossRef] Röck, M.; Hollberg, A.; Habert, G.; Passer, A. LCA and BIM: Visualization of environmental potentials in building construction at early design stages. Build. Environ. 2018, 140, 153–161. [CrossRef] Traverso, M.; Finkbeiner, M.; Jørgensen, A.; Schneider, L. Life Cycle Sustainability Dashboard. J. Ind. Ecol. 2012, 16, 680–688. [CrossRef] Büdel, V.; Fritsch, A.; Oberweis, A. Integrating sustainability into day-to-day business: A tactical management dashboard for O-LCA. In Proceedings of the ACM International Conference Proceeding Series, Bristol, UK, 21–26 June 2020; pp. 56–65. [CrossRef] Camana, D.; Manzardo, A.; Fedele, A.; Toniolo, S. Life Cycle Sustainability Dashboard and Communication Strategies of Scientific Data for Sustainable Development; Elsevier: Amsterdam, The Netherlands, 2021; pp. 135–152. [CrossRef] Sustainability 2022, 14, 3746 54. 55. 56. 57. 58. 59. 60. 61. 62. 63. 64. 65. 66. 67. 68. 69. 70. 71. 72. 73. 74. 75. 76. 77. 78. 79. 80. 81. 30 of 31 Joppa, L.; Luers, A.; Willmott, E.; Friedmann, S.J.; Hamburg, S.P.; Broze, R. Microsoft’s million-tonne CO2 -removal purchase— Lessons for net zero. Nature 2021, 597, 629–632. [CrossRef] Meinrenken, C.J.; Sauerhaft, B.C.; Garvan, A.N.; Lackner, K.S. Combining life cycle assessment with data science to inform portfolio-level value-chain engineering: A Case Study at PepsiCo Inc. J. Ind. Ecol. 2014, 18, 641–651. [CrossRef] Moon, J.M.; Chung, K.S.; Eun, J.H.; Chung, J.S. Life cycle assessment through on-line database linked with various enterprise database systems. Int. J. Life Cycle Assess. 2003, 8, 226–234. [CrossRef] Cerdas, F.; Thiede, S.; Juraschek, M.; Turetskyy, A.; Herrmann, C. Shop-floor Life Cycle Assessment. Procedia CIRP 2017, 61, 393–398. [CrossRef] iPoint-Systems Gmbh. Umberto LCA+. 2021. Available online: https://www.ipoint-systems.com/solutions/lca/ (accessed on 15 November 2021). Backes, J.G.; Suer, J.; Pauliks, N.; Neugebauer, S.; Traverso, M. Life cycle assessment of an integrated steel mill using primary manufacturing data: Actual environmental profile. Sustainability 2021, 13, 3443. [CrossRef] Ma, X.; Ye, L.; Qi, C.; Yang, D.; Shen, X.; Hong, J. Life cycle assessment and water footprint evaluation of crude steel production: A case study in China. J. Environ. Manag. 2018, 224, 10–18. [CrossRef] Wang, P.; Ryberg, M.; Chen, W.; Kara, S.; Hauschild, M. Efficiency stagnation in global steel production urges joint supply- and demand-side mitigation efforts. Nat. Commun. 2021, 13, 1–11.[CrossRef] Wang, P.; Kara, S.; Hauschild, M. Role of manufacturing towards achieving circular economy: The steel case. CIRP Ann. Manuf. Technol. 2018, 67, 21–24. [CrossRef] Pauliuk, S.; Milford, R.; Müller, D.; Allwood, J. The steel scrap age. Environ. Sci. Technol. 2013, 47, 3448–3454. [CrossRef] Norgate, T.; Jahanshahi, S.; Rankin, W. Assessing the environmental impact of metal production processes. J. Clean. Prod. 2007, 15, 838–848. [CrossRef] Oda, J.; Akimoto, K.; Tomoda, T. Long-term global availability of steel scrap. Resour. Conserv. Recycl. 2013, 81, 81–91. [CrossRef] Muslemani, H.; Liang, X.; Kaesehage, K.; Ascui, F.; Wilson, J. Opportunities and challenges for decarbonizing steel production by creating markets for ‘green steel’ products. J. Clean. Prod. 2021, 315, 128127. [CrossRef] Yellishetty, M.; Mudd, G.; Ranjith, P.; Tharumarajah, A. Environmental life-cycle comparisons of steel production and recycling: sustainability issues, problems and prospects. Environ. Sci. Policy 2011, 14, 650–663. [CrossRef] Worldsteel Association Life Cycle Inventory Study. Technical Report December. 2018. Available online: https://worldsteel.org/pu blications/bookshop/life-cycle-inventory-report-2018/?do_download_id=b8a2da11-7173-4575-b5cb-3287f23d7967 (accessed on 15 November 2021). Ekvall, T.; Björklund, A.; Sandin, G.; Jelse, K.; Lagergren, J.; Rydberg, M. Modeling Recycling in Life Cycle Assessment. Final Project Report May. 2020. Available online: https://www.lifecyclecenter.se/wp-content/uploads/2020_05_Modeling-recylingin-life-cycle-assessment-1.pdf (accessed on 15 November 2021). Westfall, L.; Davourie, J.; Ali, M.; McGough, D. Cradle-to-gate life cycle assessment of global manganese alloy production. Int. J. Life Cycle Assess. 2016, 21, 1573–1579. [CrossRef] Bartzas, G.; Komnitsas, K. Life cycle assessment of ferronickel production in Greece. Resour. Conserv. Recycl. 2015, 105, 113–122. [CrossRef] Ecoinvent Association. Ecoinvent Database 3.6, Cut-Off. Available online: https://ecoinvent.org/ (accessed on 15 November 2021). Haque, N.; Norgate, T. Estimation of greenhouse gas emissions from ferroalloy production using life cycle assessment with particular reference to Australia. J. Clean. Prod. 2013, 39, 220–230. [CrossRef] Wei, W.; Samuelsson, P.B.; Tilliander, A.; Gyllenram, R.; Jönsson, P.G. Energy Consumption and Greenhouse Gas Emissions During Ferromolybdenum Production. J. Sustain. Metall. 2020, 6, 103–112. [CrossRef] Chen, B.; Yang, J.X.; Ouyang, Z.Y. Life cycle assessment of internal recycling options of steel slag in Chinese iron and steel industry. J. Iron Steel Res. Int. 2011, 18, 33–40. [CrossRef] Environdec. Impact Indicators and Inventory Indicators. 2022. Available online: https://www.environdec.com/resources/indicators (accessed on 15 November 2021). ISO. BS EN ISO 14067: Greenhouse Gases—Carbon Footprint of Products—Requirements and Guidelines for Quantification and Communication; International Organization for Standardization: Geneva, Switzerland, 2018. World Resources Institute (WRI); World Business Council on Sustainable Development (WBCSD). Product Life Cycle Accounting and Reporting Standard; World Resources Institute: Washington, DC, USA, 2011. Available online: https://ghgprotocol.org/sites/default/files/standards/Product-Life-Cycle-Accounting-Reporting-Standard_041613.pdf (accessed on 15 November 2021) European Industrial Gases Association AISBL. Benchmarking: Air Separation Plants and Indirect CO2 Emissions; European Industrial Gases Association AISBL: Brussels, Belgium, 2010. World Steel Association. CO2 Data Collection. User Guide, Version 10. Technical Report September. 2021. Available online: https://worldsteel.org/wp-content/uploads/CO2-data-collection-user-guide-version-10.pdf (accessed on 15 November 2021). Boulay, A.M.; Bare, J.; Benini, L.; Berger, M.; Lathuillière, M.J.; Manzardo, A.; Margni, M.; Motoshita, M.; Núñez, M.; Pastor, A.V.; et al. The WULCA consensus characterization model for water scarcity footprints: Assessing impacts of water consumption based on available water remaining (AWARE). Int. J. Life Cycle Assess. 2018, 23, 368–378. [CrossRef] Sustainability 2022, 14, 3746 82. 83. 84. 85. 86. 87. 88. 89. 90. 91. 92. 31 of 31 Leiden University. CML-IA Characterisation Factors. 2022. Available online: https://www.universiteitleiden.nl/en/research/ research-output/science/cml-ia-characterisation-factors (accessed on 15 November 2021). Mehmeti, A.; Angelis-Dimakis, A.; Arampatzis, G.; McPhail, S.J.; Ulgiati, S. Life cycle assessment and water footprint of hydrogen production methods: From conventional to emerging technologies. Environments 2018, 5, 24. [CrossRef] Big Room Inc. Ecolabel Index. 2021. Available online: http://www.ecolabelindex.com/ (accessed on 15 November 2021). Toniolo, S.; Mazzi, A.; Simonetto, M.; Zuliani, F.; Scipioni, A. Mapping diffusion of Environmental Product Declarations released by European program operators. Sustain. Prod. Consum. 2019, 17, 85–94. [CrossRef] Strazza, C.; Del Borghi, A.; Magrassi, F.; Gallo, M. Using environmental product declaration as source of data for life cycle assessment: A case study. J. Clean. Prod. 2016, 112, 333–342. [CrossRef] Yu, M.; Robati, M.; Oldfield, P.; Wiedmann, T.; Crawford, R.; Nezhad, A.A.; Carmichael, D. The impact of value engineering on embodied greenhouse gas emissions in the built environment: A hybrid life cycle assessment. Build. Environ. 2020, 168, 106452. [CrossRef] Olinzock, M.A.; Landis, A.E.; Saunders, C.L.; Collinge, W.O.; Jones, A.K.; Schaefer, L.A.; Bilec, M.M. Life cycle assessment use in the North American building community: Summary of findings from a 2011/2012 survey. Int. J. Life Cycle Assess. 2015, 20, 318–331. [CrossRef] Tasaki, T.; Shobatake, K.; Nakajima, K.; Dalhammar, C. International Survey of the Costs of Assessment for Environmental Product Declarations. Procedia CIRP 2017, 61, 727–731. [CrossRef] Ovako Sweden, A.B. EPD of Hot-Rolled Bar Steel Products in Hofors; Environdec: Stockholm, Sweden, 2020. Available online: https://portal.environdec.com/api/api/v1/EPDLibrary/Files/4eb13d9e-f94e-4068-85c1-cf340ed66724/Data (accessed on 15 November 2021). Tsalis, T.A.; Malamateniou, K.E.; Koulouriotis, D.; Nikolaou, I.E. New challenges for corporate sustainability reporting: United Nations’ 2030 Agenda for sustainable development and the sustainable development goals. Corp. Soc. Responsib. Environ. Manag. 2020, 27, 1617–1629. [CrossRef] Henzler, K.; Maier, S.D.; Jäger, M.; Horn, R. SDG-based sustainability assessment methodology for innovations in the field of urban surfaces. Sustainability 2020, 12, 4466. [CrossRef]