Strategic Capacity Planning: Operations Management Summary

advertisement

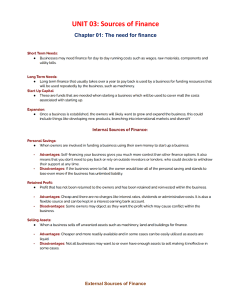

Chapter 5 of "Operations Management" (14th ed.) by William J. Stevenson, published by McGraw-Hill, focuses on Strategic Capacity Planning. The chapter emphasizes the importance of efficiently managing a company's capacity to meet long-term demand. The goal of strategic capacity planning is to achieve a match between the long-term supply capabilities of an organization and the predicted level of long-term demand. The key questions in capacity planning are the following: 1. What kind of capacity is needed? 2. How much is needed to match demand? 3. When is it needed? Here is a summary of the key takeaways: Capacity Measurement: To effectively plan for capacity, it's crucial to measure it accurately. Capacity refers to the maximum output a system can achieve in a given period. This measurement serves as a baseline for further analysis. Consideration of Factors: Capacity planning must take into account various factors, including demand patterns, market trends, and potential disruptions. A thorough understanding of these factors is essential to make informed decisions. Demand Forecasting: Accurate forecasting of future demand is a cornerstone of capacity planning. Organizations need to analyze historical data, market research, and other relevant information to predict demand accurately. Bottleneck Identification: Identifying bottlenecks in the production process is vital. Bottlenecks are points in the system where capacity is limited and can slow down the entire operation. Addressing bottlenecks is key to improving overall efficiency. Continuous Improvement: Strategic capacity planning involves continuous improvement efforts. It's not a one-time task but an ongoing process. Companies should engage all stakeholders in identifying areas for improvement and implementing changes. Product Design Quality: Quality in product design is essential. Companies should aim to build quality into the design phase, ensuring that products are easy to manufacture and assemble. This approach reduces the likelihood of defects and rework. Balanced Workload: Implementing a balanced system where workloads are evenly distributed among workstations is crucial. This helps match cycle time (the time available to produce an item) with takt time (the rate at which customers demand products). Process Quality Improvement: Quality improvement efforts should focus on defect prevention, automation, and the use of visual signals like Andon and Jidoka for quality control. Preventing defects at the source is more cost-effective than detecting and fixing them later. Planning and Control Strategies: Strategies for capacity planning and control include level loading (maintaining a consistent production rate), pull systems (producing based on customer demand), cultivating close supplier relationships, and preventive maintenance to keep equipment in optimal condition. Value Stream Mapping: Value stream mapping is a valuable visual tool for analyzing and optimizing material and information flows within the organization. It helps identify areas of waste and inefficiency. In summary, Chapter 5 of "Operations Management" underscores the importance of strategic capacity planning in achieving efficient operations. It highlights the need for accurate measurement, forecasting, continuous improvement, product design quality, and effective planning and control strategies to meet long-term demand effectively.