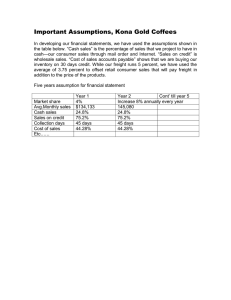

Program: M. Pharm + MBA; Sem II Course/Module: Pharma Supply Chain End to End Order Processing & Fulfilling in Supply Chain Abhinav Agrawal Order Processing :Time needed to complete the activities of order cycle is at the heart of customer service • Why Order processing is gaining importance ? • Order processing activity takes 70 % of the total order cycle across industries. • Cost of labor and materials have risen where as the cost of providing timely and accurate information throughout the supply chain has been dropped dramatically. • There has been increasing efforts to substitute resources with information through Order processing. • These information on order processing has been used to replace inventories, reducing logistic costs. • Increase service levels to the customers. • Use of Technology in logistics is creating a new business domain of Logistic information technology. Order management system. • It represents the principal means by which buyers and sellers communicate information relating to individual orders for a products. • Order management system is one of the most important components of the Overall management information system of the firm. • Effective Order management is crucial for a firm to achieve Operational Efficiency and customer satisfaction. • Effective Order management provides competitive advantage to the firm over the other competitor, as it is necessary for the firm to carry out all activities relating to order management in a timely, accurate and thorough manner to ensure that present and potential customers take a positive view of the consistent and predictable order cycle time and have higher customer satisfaction index. Order Management function. Receive Order. Check Credit. Check availability of Inventory. Modify Order Suspend Order. Enter Order – Manual/Elec tronically. Verify and Check Order for accuracy. Process back orders, if any. Acknowle dge Order receipt. Check Pricing and Promotion. Order Processing system/FLOW. Order preparation. Order Transmittal. Order Entry. Order Filling. Order Status Report. Order Process Flow 1.Order preparation • It refers to the activities of gathering the information needed about the products and services desired for which there is a need to be purchased. • It will involve the following activity at Customer level ( Customer can be any one in the channel – Franchise/Retailer/Wholesaler/ • • • • • • Identifying the appropriate Vendor. Filling the Order form Checking the available stocks. Getting in touch with the sales force for the enquiry. Visiting Product Order site or Corporate web page to know about the product. Gathering the information on the product/ services to be procured on the open market source. • Order Preparation • Technological advances are really changing the Order preparation process. • Use of Product Bar Coding at the Retail/Chemist/Stockist are eliminating the use of manual bin cards or Data entry work. • Scanning the Bar codes for the customer would enable them to know the actual inventories, expiries, reorder level and also the vendor who is best suited for the repurchase. • Human interaction and delays and inaccuracy are avoided and eliminated. • Web based information is the new trend that has increased the customer trust and interaction for providing easy and vast information to the customer before buying. • Products which are regularly used like standard parts for repair and maintenance are generally orders using Web Technology. • EDI – Electronic Data interface is another form of generating order enquiry. Where in the computers of buyers and sellers are connected through electronic Data Interchange. • RFID - Radio Frequency Identification technology ( RFID) is assigned to each inventory items which emits the radio frequency which is integrated to the Customer’s ERP and It can be used to accurately map the information about Qty, locations, manufacturer, price, shelf life and urgency of re-order level. Steps followed in Order Processing/FLOW. 2.Order Transmittal. • It refers to the activities of sending/ transmitting the Order prepared to vendor / service provider. • It involves the transferring the order request form from the place of Origin to the place where Order entry can be handled. • It can be accomplished Manually or Electronically. • Manual order transmittal involves carrying the physical order form or mailing the order form to the entry operator. • Electronic transmittal is more popular and preferred as it • It is instantaneous and flow of order information is fastest. • It reduces the supply chain cost involved in physical resources utilized like Sales man, Paper, travel cost & time. • It is most accurate and does not have scope for any Order information manipulations. • It has high degree of reliability and accuracy. Steps followed in Order Processing/FLOW. 3.Order Entry • It refers to the actual filling of an order for the execution/invoice generation. • It is an essential process as many order details are not there in the order form, such as batch, lot, schemes, pack changes, Rate changes, etc • This process is very greatly impacted by technological improvements, such as bar code, Optical scanners and computerization of processes. • Order entry is would be very crucial in deciding the logistic arrangement as efforts are made to ensure the standard pack size are not sold in loose pack. • Inventory building activity is one of the outcome of the order entry. • Order cycle time can be reduced drastically by automating the entry level interface at the supplier’s and Customer’s end. • Order entry corresponds to • Checking the accuracy of the order information, such as item description, number, quantity, and price. • Check the availability of the requested items. • Preparing back – order or cancellation of documents. • Checking the customer’s credit status. • Transcribing the order information as necessary. • Billing. Example – One Order Portal of Awac. Steps followed in Order Processing/Flow. 4.Order Filling • It refers to the actual filling of an order. • This process involves actual Picking and packing of the Order. • It involves acquiring the items through stock retrieval, production or purchasing. • Packing the items for shipment. • Schedule the shipment for delivery. • Prepare shipping documents. • These activities take parallel with those of order entry., to reduce the processing time. Steps followed in Order Processing/FLoW. 4.Order Filling • The total Order cycle time for individual orders is affected by the setting of order – filling priorities and the associated procedures. • Some priorities rules that may be used are: • First – received first processed. • Shortest processing time order first. • Specified Priority number order first. • Smaller, Less-complicated order first. • Earliest promised delivery date order first. • Orders having the least time before promised delivery date first. Criteria used for selecting particular Rule depends on (i) fairness to all customers. (ii) Identify the important order (iii) Overall speed of processing which can be achieved. Steps followed in Order Processing/FLOW. 5.Order Status Reporting • This activity ensures that customers are kept informed about the order processed, delivery schedule and delays if any in the delivery. • This activity has no impact on the Total customer Order cycle. • It includes the following processes: • Tracing and tracking the order throughout the order cycle. • Communicating with the customer about the status of the orders. Technology is a key enabler in this process. Some Suppliers / Transporters are able to tell the exact location of the orders to the customers at any point of time post dispatch from their ware house. This updates keeps the customer interest and readiness to accept the ordered products and organize payments on time or as per credit norms. It also enables the Customer to reach the Supplier in case of any urgent or change in delivery address or schedule and thus avoid other additional cost for re-routing or delay or return logistics. Technology used in industry to improve order fulfilment. • Technology has reduced the human interface element. It has eradicated the data entry errors. • It has enable the Suppliers and Customers in B2B business to be integrated and enabled the customer to place orders in time and enabled suppliers to replenish the demand in time. • Inventory management due to Electronic Data Interface by integrating suppliers and customer’s software has reduce stock out, excess inventory and reduce inventory carrying cost. • In B2C business too web based order entry has reduced all the lead time and inaccuracies in the process of order flow at supplier’s end and increase order status updation to the end customer. • Use of Optical scanners, Radio Frequency Identification, Electronic data interface and Artificial Intelligence has become phenomenon and it has reduced the lead times in Order preparation, entry ,Order transmittal, filling and also enabled the customer to see online status of the order. • It has enabled the supplier to understand the priority customers to be served based on volumes and business transactions. • It has enabled the company to decide on the locations to open ware house based on order patterns and size as per the online orders patterns. • There has been cost reductions in terms of freight, ware house and human resources. Order Processing Categories. Based on the Customer types the Order processing activity are categorized in to three types Industrial Order Processing. Retail Order Processing. Customer Order Processing. Industrial Order processing. • Involves higher degree of Human Intervention throughout the system. • Activities involved are • Customer’s requests are entered into the order processing system through Sales people. • Sales people are main point of contact for customer. • Institution or Industrial Order received are usually attended by customer service desk at the supplier’s end. • These orders are usually punched or recorded in abbreviated form for product’s name, descriptions and quantities. • The Orders received at customer service desk are processed by Order Clerk/Order processing team who add value by allocating proper product names, Price, Qty and Schemes. • The Sales Manager usually validates the orders for Price and Deadlines. • Once orders are approved by Sales managers they are passed on to the Production site for further processing. • Ex – Orders from Construction houses to Cement Manufacturers Retail Order processing. • It has moderate component of automation throughout the system. • The Retailers are at the intermediate to vendors and customers and have to customize their orders as per customer’s need so automation is not very rampant. • Their order replenishment time has to be very fast from the vendor as they have to serve the customers immediately. • Order processing at retail level is complex with multiple products, segments, vendors and different strength they have to handle to meet the demand. • This very complex nature is suitable to ensure automation takes place at retail order processing. • At Attempt to have Direct to Customers effort where in Ware house can be eliminated. The Process would require Web based / Technology based approach. Retail Order processing. • Activities involved in Warehouse – Direct to Customer process • Customer informs the distributors via EDI the orders incorporating details like which Product, How much and where is it needed. • In Response the Supplier/Distributor informs the customer how much of which product will be executed. ( EDI) • Simultaneously the Distributor informs the logistic service providers to how much and from where they have to pick up the orders for Customer ( EDI) • Suppliers processes the orders and completes the order filling and documentation and keep the order ready for logistic service provider to pick up. • Logistic service providers picks up the goods and ensure proper segregation, marking and bar coding for track and trace till it is delivered to the customer. Customer order processing. • These orders are generated out of direct interaction with the customer or final consumer. • Customer Order processing requires very high level of Customer services. • Companies involved in direct customer order processing are usually faced with a challenge of maintaining highest level of customer service. • This order processing is more complex if the product is easily substitutable. • Usually the Customer order cycle time is the least of all the order processing, It also offers a lower price to the customer as compared to retailers locally. Customer order processing. • Various Steps involved in Customer Order processing : • Customer uses web interface or email or telephone to place the order directly. • Either the Order taker or the Customer enters the orders in a computer terminal or web based order entry form, which than fetches the inventory, price and availability immediately and provided update to the customer about the same and final price to pay. • The customer is given the choice to pay using different payment orders. • Order closed by the customer or Order taker than the information flows to the ware house team for order filling on the same day. • Orders are shipped to the customer by an authorized logistic service provider and If delivery is urgent than a extra delivery charge may be collected. E commerce and Order Processing. E commerce segment in INDIA. • The Indian e-commerce market is expected to grow to US$ 200 billion by 2026 from US$ 38.5 billion as of 2017. • The ongoing digital transformation in the country is expected to increase India’s total internet user base to 829 million by 2021 from 636.73 million in FY19. India’s E-commerce revenue is expected to jump from US$ 39 billion in 2017 to US$ 120 billion in 2020, growing at an annual rate of 51 per cent, the highest in the world. B2B B2C Web based channel order planning • Why Web /Internet based ordering process is getting more acceptance ? • Low cost of initiating and Operating on Web site is one major reason. • Web based Ordering system can help integrate all functions of the SCM and increase the efficiency. • It is an interactive platform to communicate for all parties involved. • Lead times at all levels from Order placement to Order fulfillment can be reduced by more than 30 % or 50 % in some cases. • Real time information and quick response is the key reason, which helps the SCM team to increase efficiency. • Since all Channel members are using the same Data base, there is better transparency in the process and track n trace is better. Other factors affecting order- processing time. Factors which are resulting either speeding up or slowing down of Order processing time are mainly due to Operating Procedures, Customer service policy and Transportation policies. Processing Priorities. Order Batching. Parallel versus Sequential processing. Order Filling accuracy. Lot sizing. Shipment consolidation. FACTORS AFFECTING ORDER PROCESSING TIME. • Processing Priorities. • • • Some firms have limited resources of time, capacity and effort and therefor they may prioritize their customer list as a way of allocating limited resources to more profitable orders. Some firms may have the process of executing first received first process policy. This may not always be beneficial as it may result in longer processing time for premium customers. • Parallel Versus Sequential Processing. • • • Order Processing time can be reduced by closely analyzing and arranging the process or task involved in order processing. Process time can be reduced by carrying out some tasks simultaneously as carrying out all task in sequential manner will take longer time. Order Filling Accuracy. • • Order Processing time can be reduced by reducing the error in the customer order form and at entry level. Errors can be minimized by checking with the customer before invoicing. Factors affecting order processing time. • Order Batching. • Some firms have process of collecting orders from multiple customer and forming a group for batch processing to reduce the processing cost. • It will increase the order processing time and increase the cost of order processing as it will result in collection and accumulation of all customer’s order • It may impact the customer who has placed order first but have to wait till the order to be processed becomes sufficient to qualify for batch size. limited resources of time, capacity and effort and therefor they may prioritize their customer list as a way of allocating limited resources to more profitable orders. • Lot Sizing. • Customer’s Order size will be too large to fulfill from the stocks in hand and rather than waiting , we may choose to fulfill it by sending it in lot. • Customer will receive order in part and will have some of the ordered products at his end and product availability will be better. • Customer response will be good but transport cost will increase. • Tracking of other ordered products / items will be required to be kept till the complete order is fulfilled. Factors affecting order processing time. • Shipment consolidation. • • • • • As batch ordering, one can hold orders which can be accumulated to converted into economical shipment size, to reduce cost of freight. Smaller orders to be clubbed to make a bigger shipment order to achieve economy of cost and space utilization for transportation. Order Processing time will increase but transport cost will reduce. Customer service level will be reduced. Marketing team and customer has to be updated of the consolidation. Logistic information system External function. Logistic information system Internal function. Need for logistic information system. • Need for Logistic information system (LIS) - Major purpose for collecting, retaining and manipulating data within a firm is to make strategic, tactical and operational decision. • There are many enterprises wide information system such as SAP, Oracle, Baan, J. Edwards. • Improved internet access and EDI have made it easier for the customer and supplier to transmit and share information easily and precisely in Supply chain management. • Timely and comprehensive information within the firm and sharing of appropriate information among other channel members have facilitate more efficient logistic operations. • Logistic information system should be capable enough not only to allow information flow between functional departments ( marketing, sales, finance, production, etc) but also allow between the supply chain members ( vendors and customers). • LIS shares information related to sales, shipments, production schedules, stock availability, order status and it enables to reduces the uncertainty for buyers as well as seller. • It is essential to have a limit on how much information firms are willing to share with others. Subsystems of logistic information system. Transport Management System. Order Management System. Ware house management System. Logistic Information System. Order management system (OMS) • This system is more at time of Order placement by the customer, which involves product enquires and order placement. • It is the Front end of the LIS ( logistic information system) • It communicates with the ware house for checking the product availability or checks the Work in progress (WIP) at the production schedule. • It gives the information about the quantity available, locations of the product in the supply network and also the estimated time for delivery. • Once the product availability is accepted by the Customer, the OMS interacts with the company’s finance information system to check the customers status and verify the credit situation. • Once the Order is accepted the OMS will allocate the product to the customer , assign it to the production location, allocate inventory and complete the shipping formality and send the invoice to the customer. Order management system (OMS) • OMS system cannot work in isolation, it has to be merged or integrated with the other information systems. Ex with Transport management system. • OMS at the customer’s end usually works around fulfilling the Order placed. • OMS at the Supplier’s end works around company’s vendor showing their delivery performance, costs, ratings, terms of sales, capabilities and financial strength • OMS usually is very helpful to decide the trends and buying patterns of the customers and decide on process efficiency and reduce cost on inventory carrying and transportations. • OMS data analysis would enable the Organization to decide on the customer’s rating and decide on assigning the service manager based on the buying potential. Warehouse management system ( WMS) • Ware house management system is to be tied up with OMS so that the sales team are aware of the availability of the products for the sales. • It may be integrated with OMS or may not be integrated with OMS, based on the inventory the ware house handles. Ex – FG goods WMS is associated or integrated with OMS where are plant level WMS related to Raw material inventory is not associated with Customer level Order management system. • WMS is associated with the management of product flow through the Logistic management system or network. • Key element of WMS are (i)Receiving (ii) Put Away (iii) inventory Management. (iv) Order processing and retrieving ( v) Shipment preparations. Warehouse management elements. (iii) inventory Management. (i)Receiving (ii) Put Away ( v) Shipment preparations (iv) Order processing and retrieving WMS (ware house management elements) • Receiving : This is the first point of interaction physically for the products with the receiving locations at Ware house. The product characteristics such as Price, Qty, Batch, product code and lot/batch nos are to be checked. Use of RIFD /Scanner / barcoding are rampant at this stage. Product dimension like Weight, packing configurations and storage locations are all decided and updated or cross checked at receiving activity. • Put Away : All material are first to be inspected so they are to be stored at a separate area marked in the ware house. Post updation of the receiving documents the WMS allocated a specific area to be used for stocking / storing the goods received for future retrieval. Multiple batches/lots for the same products received are properly aligned or sequentially stored. WMS (WARE HOUSE MANAGEMENT ELEMENTS) • Inventory Management : At ware house level the inventory management is specially done to avoid loss in terms of products not being allocated or dispatched. Ware house team uses the WMS to electronically transmit the inventory level to procurement team and avoid stock out of regular inventories. They also use the WMS to decide the policy of inventory or stock keeping or quarantine for all the stocks being stored in the ware house. • Order processing and retrieving: It is most valuable aspect of WMS. Recalling or retrieving the products ordered is most time consuming and performance driven. Items are stored using WMS as per the group, segments, division or locations. Some items are picked in loose cases and some in standard cases which takes majority of the time for the packer, so WMS enables this process to be efficiently managed by giving the list of items and locations from where it is to be drawn. Picking rule are also updated in the WMS such as first expiry first out. WMS ( ware house management elements.) • Shipment Preparation: Order packing and Picking in the ware house does not happens for all invoices or orders simultaneously., usually orders are packed based on transport/shipment priority. Which means Order are clubbed for a specific area or destination to best suit the vehicle/ shipment size. WMS helps the ware house team make decision to use the best mode of transport for economy of scales and cost of freight. Loads are labelled using the WMS process to declare the weight, destination, customer and transporter on the packs. In case of Retail the price tags are affixed using the WMS. • WMS process over all helps in labour planning, inventory level planning , space utilization and transport selection. • WMS are linked with OMS and TMS to get best efficiency. Transport management System (TMS) • The system focuses on the inbound and outbound transportation of the firm. • It is an integral part of LIS. • WMS shares the information about product weight, dimension, quantity and destination with the TMS to schedule dispatches. • It’s purpose is to assist in the planning and controlling of the firm’s transportation activity. • It enables the Organization in (i) mode selection (ii)Freight Consolidation (iii) Routing and Scheduling shipments (iv)Claim processing ( v ) tracking shipments (vi)freight bill payments and auditing. TMS- Transport management System. • Mode Selection: Many Organization uses multiple shipment sizes resulting in multiple freight services. Transport choices based on the shipment can vary from package carrier to Ocean Container or rail car load or Truck load. TMS will store factual data on mode, freight rates, shipment time and Estimate time for delivery, Mode availability and service frequency. • Freight consolidation : TMS provide very high input in freight consolidation. Freight rates usually drops with increase in weight or volume. TMS can give real time data on the consolidation and freight cost saving and increase efficiency. TMS- TRANSPORT MANAGEMENT SYSTEM. • Routing and Scheduling shipments: This is more useful if the Vehicle and Fleet is owned by the Supplier. This is very crucial for them from OMS – WMS – the complete flow of order, value, qty, shipment size and customer destination and deadline are all factored and best economical freight mode and shipment methods can be used using TMS. It also factors the distance and time for carrier to cover it and hence delivery schedule and dead line can be decided using TMS. • Claim Process: It is unavoidable that in transportation there cannot be any losses in terms of handling, damages and shortages. TMS also enable the Organisation to process the claims on the transporter and insurance company by collating the complete data on the customer’s invoice, product, qty and value of shortages/damage with out much human interaction. TMS- Transport management System. • Tracking shipments: Information system has played major role in tracking the progress of shipments once they have been transferred to transport carrier. Use of bar code, Radio transmission, global positioning system GPS on the transport vehicles enables the TMS to provide real time information to the customer about their Order. • Freight Bill payment and Audit : TMS can assist the organization in creating a data base of all freight charges and enable them to check the real time information based on destination and load type to arrive at the best rate for the freight to be paid. Company’s Finance dept / Account can fetch details from the TMS to understand the freight or transport service taken and co relate it with the freight service provider’s bill. This can reduce the manual checking and cross checking by the internal audit team. It reduces the post mortem analysis of freight bills since TMS has real time data and bills can be audited online to ascertain the freight cost as per the agreement with the transporter. Logistic information system ( LIS) Input. Output. Database management. LiS – internal operation - input element. • This element of LIS is associated with acquiring input data to facilitate decision making. • Inputs can be received through many sources such as customers,company records, published data, management. • During order entry , data are captured which are used for forecasting and operating decision such as sale volume, location of sales, tax complexity, Order size and inventory. • Similarly while data entry about shipments, transportation cost and deliveries made to customer, freight bills, purchase orders, invoices and credit information, the organization gets critical information to decide on business decision. • External research and survey data too can be integrated to the LIS and business scenario can be understood for external factors. • Predictions of sales, cost, expansions and revenue generation can be provided to company’s personnel using the input data. LiS – internal operation – Data base management. • This element of LIS is associated with converting the data to information. • Converting the data in a useful manner and interfacing the information with decision assisting methods are often the heart of all information system. • Data management involves with decision to selecting the data and retrieving the data as and when required. • Other than retaining data in hard copy it is also stored in soft format on Disc and Servers. • Data maintenance and data retention is very expensive activity as involve compliance to statutory norms and tax authority requirement. • Data processing is also a part of data maintenance, which involves the transactional level entry made in any information system for generation of commercial or transactional documents like PO, Invoice, Tax ledger, Customer ledger. LiS – internal operation – Data base management. • Data Management is decided based on following factors. • • • • How critical information is for the future or present decision making. The frequency of data retrieval. Frequency of data access. Efforts required for creating the data required in the form needed. • Data Analysis is the most sophisticate and newest use made of the information system. It contain algorithms and statistical models to generate probability and expected reports. • Data Analysis has assumed critical importance of late and many business vertical are using the data to guide business houses to make strategic decision for future. Ex – ORG/C MARG…etc LiS – internal operation – Output • Final element of information system is the Output. • Output are generally of several types and forms. • Most Obvious output forms are – REPORTs & FORMS. • Reports generally are (i) Exception reports as that against desired expectations. (ii) Summary reports of cost or performance. • (iii) Status reports on inventory, outstanding, dues, balances etc. • Forms generally are final predesigned forms required for commercial or statutory tax compliances as per set approved formats. Ex invoice, Bill of lading, PO, freight bills, etc.