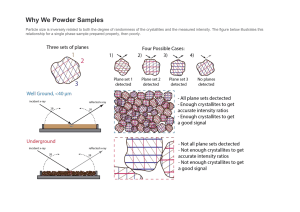

See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/235937736 Corrosion behaviour of 316L stainless steel in PTA slurry Article in Corrosion Engineering Science and Technology · November 2012 DOI: 10.1179/1743278212Y.0000000059 CITATIONS READS 2 1,382 4 authors, including: Junlei Tang Institute for Carbon Neutrality & School of Chemistry and Chemical Engineering Southwest Petroleum University 83 PUBLICATIONS 941 CITATIONS SEE PROFILE Some of the authors of this publication are also working on these related projects: Coatings View project Corrosion inhibitors for CO2 corrosion in oil and gas production View project All content following this page was uploaded by Junlei Tang on 03 April 2016. The user has requested enhancement of the downloaded file. Corrosion behaviour of 316L stainless steel in PTA slurry P. F. Ju, Y. Zuo*, J. L. Tang and Y. M. Tang The corrosion behaviour of 316L stainless steel (SS) in acetic–10% formic acid mixture containing Br2 and in simulated purified terephthalic acid (PTA) slurry was investigated to understand the corrosion mechanism of 316L SS in the drying process of PTA slurry. The results show that in acetic–10% formic acid mixture containing Br2, the corrosion rate of 316L SS increases with the increase in Br2 concentration and temperature. In the PTA slurry, the corrosion rate of 316L SS changes in a parabolic form with an increase in the solid/liquid ratio of the slurry. The slurry has the strongest corrosivity when the solid/liquid ratio of the slurry reaches ,6?25. In a half dry–half wet PTA slurry, when the 316L steel surface remained at a suitable temperature to avoid continuous liquid film on the surface, the corrosion rate of the steel will be greatly reduced. Keywords: Stainless steel, Acetic acid, Corrosion, PTA, Solid/liquid ratio Introduction The polyester industry has been developing rapidly in recent years. As the main raw material of polyester, purified terephthalic acid (PTA) is in great demand.1 In the PTA process, paraxylene is oxidised to terephthalic acid. Manganese acetate and cobalt acetate are used as catalysts, tetrabromoethane is used as accelerator and acetic acid is the dissolvent.2 Hence, acetic acid containing Br2 is the primary solution in PTA slurry, which is strongly corrosive to stainless steel equipments. During the drying process of PTA slurry, the solvent is gradually evaporated in the dryer. It is frequently observed in practical industries that the middle part of the dryer was most severely corroded, which indicates a relationship between the solid/liquid ratio of the PTA slurry and the corrosion rate. The corrosion behaviour of stainless steel in acetic acid with or without halide ions has been reported by many authors.3–9 However, a few researches were focused on the corrosion behaviour of stainless steel in PTA slurry, which is important to industrial production. In this research, the corrosion behaviour of 316L stainless steel (SS) in the simulated drying process of PTA slurry was studied. The effects of the solid/liquid ratio of the slurry and temperature on the corrosion behaviour of 316L SS were investigated. Experimental The studied material was 316L SS with the following chemical composition (wt-%): Fe–0?75Si–2?00Mn– 0?045P–2?28Mo–17?14Cr–12?58Ni–0?030C–0?030S. The School of Materials Science and Engineering, Beijing University of chemical Technology, Beijing 100029, China *Corresponding author, email zuoy@mail.buct.edu.cn ß 2013 Institute of Materials, Minerals and Mining Published by Maney on behalf of the Institute Received 7 June 2012; accepted 17 September 2012 DOI 10.1179/1743278212Y.0000000059 sample surface was abraded with abrasive papers up to no. 1000 and then was degreased with acetone. The corrosion rate of 316L SS in boiling 90 wt-% acetic plus 10 wt-% formic acid mixture containing 400 ppm Br2 was measured by weight loss test. The addition of formic acid was to accelerate the corrosion rate. The PTA slurry was composed of 150 mL PTA and 60 mL acetic/formic acid mixture containing 400 ppm Br2. Figure 1 shows the schematic diagram simulating the PTA slurry drying process. The solution was evaporated from the slurry at 105uC and collected by a measuring cylinder; therefore, by measuring the evaporated volume, the solid/liquid ratio of the slurry can be calculated (Table 1). The solid/liquid ratio was calculated by dividing the purified terephthalic volume by the rest acetic/formic acid mixture in the slurry. After the solid/liquid ratio of the slurry reached the required value, a vertical reflux condensation tube was connected with the flask to keep the solid/liquid ratio of the slurry stable. The specimens were immersed in slurries with different solid/liquid ratios for 72 h at 105uC. Scanning electron and optical microscopes were used to observe the surface of the specimens after immersion. A special experimental equipment was designed to study the influence of the steel surface temperature on the corrosion behaviour in PTA slurry, as shown in Fig. 2. The container was made of 316L SS. A 316L SS specimen, which has the same size as the container bottom, it was put closely at the bottom and sealed with polytetrafluoroethylene. Then, PTA slurry was added in the container, and the whole container was heated to 150uC by an oil bath. Three other 316L SS specimens were immersed in the middle part of the slurry. The temperature of the middle part of the slurry was 105uC, as measured by a thermometer. To keep the solid/liquid ratio of the slurry stable, the acetic/formic acid mixture containing 400 ppm Br2 was added into the slurry at the rate of 40 mL h21, as the slurry was evaporated during Corrosion Engineering, Science and Technology 2013 VOL 48 NO 3 207 Ju et al. Corrosion behaviour of 316L stainless steel in PTA slurry 1 Schematic diagram simulating PTA slurry drying process the testing process. During the test, the Br2 concentration of PTA slurry may increase gradually due to the solution evaporation; however, the results on the influence of surface temperature on corrosion rate would not be influenced. 1: container made of 316L SS; 2: 316L specimen at container bottom; 3: 316L specimens immersed in middle part of PTA slurry; 4: constant temperature oil bathing; 5: mechanical stirring; 6: solution replenish; 7: flowing regulator 2 Schematic diagram of experiment facility to study influence of temperature on corrosion behaviour of 316L SS in PTA slurry Results and discussion Corrosion behaviour of 316L SS in boiling acetic and formic acid mixture Figure 3 shows the corrosion rate of 316L SS in boiling acetic and formic acid mixture containing different Br2 concentrations at 105uC. According to Fig. 3, the corrosion rate increases as the Br2 concentration increases. The corrosion resistance of stainless steels is dependent on the passive film on the surface. In boiling acetic and formic acid mixture, which is a reducing medium, the passive film is not stable, and Br2 ions would adsorb on the surface defects10 and damage the passive film. Figure 4 shows the morphology of the 316L samples after immersion in boiling acetic and formic acid mixture containing 400 ppm Br2. It can be seen that the corrosion morphology of 316L SS in the medium is mainly uniform with some shallow pits, which is in accordance with a previous report.11 3 Relationship between corrosion rate of 316L SS and Br2 concentration in boiling acetic and formic acid mixture Effect of temperature on corrosion rate of 316L steel in acetic/formic acid mixture containing Br2 The conductivity of non-aqueous acetic acid increases rapidly with increasing temperature. On the other hand, at higher temperature, more Hz tends to ionise from acetic acid, which accelerates the dissolve rate of stainless steel.11 In addition, the porosity of the passive film increases with temperature, which can accelerate the permeation of Br2 in the passive film.12 Figure 5 shows the corrosion rate of 316L SS in the acetic/10% formic acid mixture containing 10 ppm Br2 at different temperatures. As shown in Fig. 5, the corrosion rate rises as the temperature increases. Sekine4 reported that the corrosion of 430 SS in aqueous formic and acetic acid systems is determined by the solution conductivity. Table 1 Corrosion rate of 316L SS at different PTA humidities Volume of evaporated solution from PTA slurry/mL Volume of rest solution in PTA slurry/mL Solid/liquid ratio/a.u. Corrosion rate/g m22 h21 208 Corrosion Engineering, Science and Technology 0 60 2.50 0.05 2013 VOL 12 48 3.12 0.18 48 20 40 3.75 0.25 NO 3 25 35 4.28 0.41 30 30 5.00 0.50 36 24 6.25 0.52 42 18 8.33 0.48 48 12 12.5 0.43 54 6 25.0 0.22 Ju et al. Corrosion behaviour of 316L stainless steel in PTA slurry 4 Corrosion morphology of 316L SS after immersed in boiling acetic and formic acid mixture containing 400 ppm Br2 (10 wt-% formic acid) 5 Relationship between corrosion rate of 316L SS and temperature of acetic and formic acid mixture containing 10 ppm Br2 Corrosion behaviour of 316L SS in PTA slurry at different solid/liquid ratios Table 1 and Figure 6 show the corrosion rate of 316L SS in PTA slurry with different solid/liquid ratios. The solid/liquid ratio was calculated from the evaporated solution volume. It is seen that as the solid/liquid ratio of the PTA slurry increases from the initial value to ,6?25, the corrosion rate rises quickly until a peak value. After the peak value, the corrosion rate decreases as the solid/liquid ratio increases. The colour of the initial acetic/formic mixture containing Br2 was orange yellow, while the evaporated solution was colourless and transparent. When AgNO3 was added in the two solutions, different results were observed. In the initial solution, white and yellow precipitation was produced, and the solution turned colourless and transparent, which is due to the reaction 6 Relationship between corrosion rate of 316L SS and solid/liquid ratio of PTA slurry between Br2 in the solution and AgNO3, while in the evaporated solution, white precipitation was produced, and the solution remained colourless. The white precipitation is due to AgAc, which is insoluble in HAc. This experiment confirms that the evaporated solution did not contain Br2; hence, during the heating process, Br2 in the rest of the PTA slurry was concentrated. This may explain the increase in the corrosion rate with the increased solid/ liquid ratio. When the solid/liquid ratio exceeds a critical value (,6?25 in Fig. 6), the liquid film on steel surface would turn thinner and discontinuous, which leads to decreased corrosion rate, although the Br2 concentration is at high levels. From the above results, the corrosion phenomenon in a PTA slurry dryer may be explained. At the initial section, the temperature of the PTA slurry is low, and the corrosion is low. As the slurry is put forward in the dryer and heated, both the slurry temperature and Table 2 Corrosion behaviour of 316L SS in PTA slurry at different temperatures Specimen immersion situation Immersion time/h Corrosion rate/g m22 h21 Corrosion phenomenon 316L SS at the bottom (150uC) 316L SS in the slurry (105uC) 316L SS in the slurry (105uC) 316L SS in the slurry near the solution supply (105uC) 72 72 72 72 8.3361024 0.1372 0.1075 0.6655 Glossy and slightly corroded Rugged and severely corroded Rugged and severely corroded Rugged and severely corroded Corrosion Engineering, Science and Technology 2013 VOL 48 NO 3 209 Ju et al. Corrosion behaviour of 316L stainless steel in PTA slurry a specimen at container bottom (150uC); b specimen in middle part of slurry (105uC) 7 Morphology of 316L SS specimens after immersion in PTA slurry at different locations the Br2 concentration increase, and the corrosivity of the slurry increases. However, with the drying process going on, the slurry gradually turns to solid PTA, and corrosion decreases again. Therefore, at the middle section of the drying process, the slurry shows the most severe corrosivity to the stainless steel dryer. Influence of 316L SS surface temperature on corrosion rate in PTA slurry Table 2 shows the measured corrosion rates of 316L SS specimens in PTA slurry at different temperatures. It is seen that the corrosion rate of the specimen at the container bottom, which remained 150uC during the test, is only 8?3361024 g m22 h21, three orders of magnitude lower than that of the specimens in the middle part of the slurry. The surface morphology of the specimens after immersion is shown in Fig. 7. The specimen at 150uC was only slightly corroded and the surface remained smooth, while for the specimens immersed in the slurry, where the temperature was only 105uC, the corrosion rate was obviously higher. The highest corrosion rate was observed for the specimen located near the solution supply (Fig. 2). The above results may be explained as follows: corrosion reactions as electrochemical processes depend on the presence of the electrolyte on the surface. In the solid/liquid mixed slurry, when the surface temperature of the specimen is high enough, the liquid film on the surface may be evaporated quickly. Hence, corrosion is greatly decreased. While for the other specimens in the middle part of the slurry, because the specimen surface is heated by the PTA slurry, the liquid film would be always present on the surface, resulting in a continued corrosion reaction. The above results show that in a half dry–half wet PTA slurry, if the 316L steel surface remained at a high temperature to avoid continuous liquid film on the surface, the corrosion rate of the steel may be reduced. 210 Corrosion Engineering, Science and Technology 2013 VOL 48 Conclusions 1. In acetic/10% formic acid mixture containing Br2, the corrosion rate of 316L SS increases with the increases in Br2 concentration and temperature. 2. In PTA slurry, the corrosion rate of 316L SS shows a parabolic relationship to the solid/liquid ratio of the slurry. The slurry has the strongest corrosivity when the solid/liquid ratio of the slurry reaches ,6?25. 3. In a half dry half wet PTA slurry, if the 316L steel surface remained at a high temperature to avoid continuous liquid film on the surface, the corrosion rate of the steel may be greatly reduced. Acknowledgement The authors are grateful to the National Natural Science Foundation of China (contract no. 51210001) for support to this work. References 1. G. R. Pophali, R. Khan, R. S. Dhodapkar, T. Nandy and S. Devotta: J. Environ. Manage., 2007, 85, 1024–1033. 2. S. Q. Mu, H. Y. Su, T. Jia and Y. Gu: J. Chu. Comput. Chem. Eng., 2004, 28, 2219–2231. 3. I. Sekine, S. Hatakeyama and Y. Nakazawa: Corros. Sci., 1987, 27, 275–288. 4. I. Sekine, S. Hatakeyama and Y. Nakazawa: Electrochim. Acta, 1987, 32, 915–920. 5. I. Sekine and K. Senoo: Corros. Sci. 1984, 24, 439–448. 6. I. Sekine, T. Kawase, M. Kobayashi and M. Yuasa: Corros. Sci., 1991, 32, 815–825. 7. T. Alan, R. Mary Ryan, W. Anthony and S. Q. Zhou: Corros. Sci., 2003, 45, 1051–1072. 8. M. A. Veloz and G. González: Electrochim. Acta, 2002, 48, 135–144. 9. X. Q. Cheng, X. G. Li and C. F. Dong: Int. J. Miner. Metall. Mater., 2009, 16, 170–176. 10. T. Suter and H. Bohni: Electrochim. Acta, 1997, 42, 3275–3280. 11. G. Q. Liu, Z. Y. Zhu and W. Ke: Corros. Sci. Prot. Technol., 2000, 12, 296–299. 12. W. Bogaerts, A. van Hanute and M. J. Brabers: ‘Localized corrosion’, 31; 1981, Houston, TX, NACE. NO 3 Copyright of Corrosion Engineering, Science & Technology is the property of Maney Publishing and its content may not be copied or emailed to multiple sites or posted to a listserv without the copyright holder's express written permission. However, users may print, download, or email articles for individual use. View publication stats