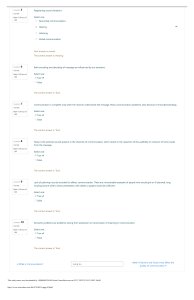

CE6331: Biological Processes Homework 3 Solutions Problem 1 An aerobic biochemical process uses a CSTR w/o recycle. The feed characteristics are as follows: Influent substrate concentration, So = 200 mg/L; half- velocity coefficient, Ks = 50 mg/L; maximum, specific substrate utilization rate, k = 5 g/g- day; yield coefficient, Y = 0.5 g Xa/g substrate consumed; microorganism decay coefficient, b = 0.10 day-1. 1. The process goal is the production of active biomass. Determine the hydraulic retention time that the reactor should be operated in order to maximize the reactor active biomass concentration (Xa). How does this retention time compare with the minimum solids retention time that the system can theoretically be operated? Calculate the solids retention time safety factor. 2. Based on the solids retention time for maximum Xa calculated above, estimate the active biomass concentration (Xa) and the substrate removal efficiency (E, %). SOLUTION Part 1 𝑋! = 𝑆= When /0# /+" "($% ! &%' (eq 1) ()(*+" ()*+" 𝐾, "-+ &(()*+ " ") (eq 2) 𝑑𝑋! $𝑑𝜃 = 0, then Xa = maximum, thus " "($% ! &%' / = /+ % ()*+" " & (eq 3) Substituting for equation 2 in equation 3 and taking derivative of a reciprocal you get /0# /+" &"% ! * = (()*+ Setting " "1 ("-&*) % + [("-&*)+ )$ $ " &(] (eq 4) 𝑑𝑋! $𝑑𝜃 = 0 and substituting values for Y, S0, b, k, Ks, solve for 𝜃" " 𝜃" = 1.6 days The minimum theoretical 𝜃" that the system can be operated at can be calculated as 1 )% ! % 𝜃4567 = % !("-&*)&*1 % (eq 5) 𝜃"#$% = 0.52 days This study source was downloaded by 100000770139657 from CourseHero.com on 03-09-2023 14:04:15 GMT -06:00 https://www.coursehero.com/file/146046420/CE6331-Homework-3-solutionspdf/ The actual retention time for maximum biomass production is higher than the minimum retention time to operate this reactor. Safety factor = )𝜃8567 * 965 𝜃" ' #$% &$# %𝜃" & ( = "-&* (eq 6) [𝜃4567 ]965 = 0.417 days i.e., Safety factor = 1.6/0.417 = 3.84 days. Part 2 Using equation 1 for a retention time of 1.6 days Xa = 77.4 mg/L Using equation 2 for retention time of 1.6 days S = 20.4 mg/L And the removal efficiency (%) is 89.8% This study source was downloaded by 100000770139657 from CourseHero.com on 03-09-2023 14:04:15 GMT -06:00 https://www.coursehero.com/file/146046420/CE6331-Homework-3-solutionspdf/ Problem 2 An activated sludge plant (CSTR w/ recycle) has the following characteristics: Influent substrate concentration, So = 400 mg/L BODL (all soluble); influent VSS, Xvo = 0; effluent substrate concentration, S = 10 mg/L BODL; flow rate, Q = 1000 m3/day; aeration basin volume, V = 200 m3; reactor MLVSS, Xv = 4,280 mg/L; average, steady-state oxygen uptake rate, Oxygen uptake rate (OUR) = 0.3 mg O2/L-min. The biomass viability (i.e., v = Xa/Xv) was measured using the oxygen uptake rate (OUR) technique and found equal to 0.926. An aliquot of mixed liquor was placed in a small reactor, aerated without any exogenous substrate addition (i.e., starvation conditions) and it’s OUR was measured over time resulting in the following data: Time (days) OUR (mg O2/L-min) 0 1 2 3 4 5 6 8 10 0.3 0.274 0.243 0.222 0.203 0.182 0.165 0.135 0.110 By use of the above data, the microorganism decay coefficient (b, day-1) can be estimated if you assume that a constant relationship exists between Xa and OUR, i.e., OUR = a Xa, where a = proportionality constant (g O2/g Xa - min). 1. Estimate b (1/d) by using the above data (Use regression). 2. Calculate the solids retention time for this plant. 3. Calculate the net biodegradable fraction of the viable biomass (fd). SOLUTION '(! ') Part 1 = 𝑏𝑋! (starvation contion) (eq 1) Integrating equation 1 from t=0 to t=t 𝑋! = 𝑋!* 𝑒 +,) (eq 2) Since, OUR= aXa 𝑂𝑈𝑅 = 𝑂𝑈𝑅* 𝑒 +,) (eq 3) thus, the slope of ln(OUR/OUR0) vs t will give us -b This study source was downloaded by 100000770139657 from CourseHero.com on 03-09-2023 14:04:15 GMT -06:00 https://www.coursehero.com/file/146046420/CE6331-Homework-3-solutionspdf/ 0.2 Ln (OUR/OUR0) 0 -0.2 y = -0.1002x + 0.0017 R² = 0.9997 -0.4 -0.6 -0.8 -1 0 2 4 6 8 10 12 Time (days) Therefore, b = 0.1 days Part 2 Xa = vXv Xa = 0.926 (4280 mg/l) = 3963.3 mg/l -$.#!// $% /1/)2# 𝜃" = ,$.#!// 3!/)2' 45.# /1/)2# Biomass in system = Xa * V = 3963.3 mg/l*200m3*1000 l/m3 * 1kg/106mg= 792 kg biomass. All biomass produced should be removed to maintain SRT, Thus, biomass removed = Y*Q*(S0-S) Assuming Y for heterotrophic biomass = 0.5 g VSS/g BODL Biomass removed = 0.5 g VSS/g BODL* 1000 m3/day * 1000 l/m3 *(400 mg BODL/l – 10 mg BODL /l)* 0.001mg BODL/gBODL* 1kg/103g = 195 kg biomass removed/day 𝟕𝟗𝟐 𝒌𝒈 𝜽𝒄 = 𝟏𝟗𝟓 𝒌𝒈/𝒅 = 4.06 days. This study source was downloaded by 100000770139657 from CourseHero.com on 03-09-2023 14:04:15 GMT -06:00 https://www.coursehero.com/file/146046420/CE6331-Homework-3-solutionspdf/ 𝑋@ = 𝑋! (1 + (1 − 𝑓' )𝑏𝜃" Xa = vXv Solving for fd fd = 0.8 Part 3 This study source was downloaded by 100000770139657 from CourseHero.com on 03-09-2023 14:04:15 GMT -06:00 https://www.coursehero.com/file/146046420/CE6331-Homework-3-solutionspdf/ Problem 3 A "three-sludge" biological treatment system (i.e., three suspended-growth reactors in series, each with its own clarifier) is to be designed to remove BOD and nitrogen from a municipal wastewater. Assume each process is "reactor wasted". Stage I: CSTR with recycle for BOD removal (a high-rate, sloppy system) has already been designed. The following data apply to the effluent from stage I: Q = 1.82 x 107 L/day Xa (active organic-carbon users) = 37.4 mg/L Xi (inert biomass) = 12.6 mg/L S (carbonaceous BOD) = 6.3 mg/L Alkalinity = 139 mg/L as CaCO3 NH4+-N = 26.8 mg/L. Stage II: PF with recycle (for nitrification and further BOD removal). Ignore ammonia production and alkalinity change due to the carbonaceous BOD removal in the second stage. Preliminary: The equations for the MLVSS in AS systems as a function of various parameters need to be modified if carbonaceous and nitrogenous oxidations are occurring in the same reactor. Also, modification is required wherever there is an appreciable active organism concentration in the influent to a reactor. Both modifications are required for Stage II, since the problem specifies that Stage I is a high-rate, sloppy system (i.e., additional BOD removal will take place in Stage II and, with a high-rate system for Stage I, the degree of clarification in Clarifier I is rather poor, resulting in significant active carbon-users in the influent stream to Stage II). 𝜃" (𝑋!* + 𝑌(𝑆* − 𝑆)) 𝑋! = (1 + 𝑏𝜃" ) 𝜃 𝜃" 𝑌A (𝑁* − 𝑁) 𝑋A = 𝜃 (1 + 𝑏A 𝜃" ) 𝜃" * 𝑋@ = 𝑋$ + 𝑋! (1 + 0.2𝑏𝜃" ) + 𝑋A (1 + 0.2𝑏A 𝜃" ) 𝜃 Where 𝑋! and 𝑋!* = active, carbon oxidizing bacteria in influent and reactor, respectively 𝑋A = active nitrifier concentration in bioreactor 𝑋$* = inert biomass influent 𝑋@ = total biomass in reactor For Stage II, assume: SRT = 15 days; mean MLVSS =2000 mg/L; Y=0.448gVSS/gBODL; b=0.10day-1; YN =0.34gVSS/gN; bN =0.05day-1 Specify: 1. Reactor volume and hydraulic retention time (assume effluent BODL and ammonia from Stage II are negligibly small from this PF reactor); 2. Xa and XN concentration; 3. Oxygen requirements for both heterotrophs and autotrophs (kg O2/d); 4. Effluent NO3-N concentration; 5. Alkalinity consumed. If addition is required, specify dose and form to maintain a pH = 7. In any event, specify effluent alkalinity for pH = 7 (assume this is an open system and at equilibrium with air at a PCO2 = 10-3.5 atm); This study source was downloaded by 100000770139657 from CourseHero.com on 03-09-2023 14:04:15 GMT -06:00 https://www.coursehero.com/file/146046420/CE6331-Homework-3-solutionspdf/ 6. Excess VSS handled (kg VSS/d, assuming no significant effluent VSS] and waste flow rate (Qw). SOLUTION Part 1 𝜃" 𝑋@ = 𝑋$* + 𝑋! (1 + 0.2𝑏𝜃" ) + 𝑋A (1 + 0.2𝑏A 𝜃" ) 𝜃 𝑋@ = 𝜃" * 𝜃" (𝑋!* + 𝑌(𝑆* − 𝑆)) 𝜃" 𝑌A (𝑁* − 𝑁) (1 + 0.2𝑏𝜃" ) + (1 + 0.2𝑏A 𝜃" ) 𝑋$ + (1 + 𝑏𝜃" ) 𝜃 𝜃 𝜃 (1 + 𝑏A 𝜃" ) 𝑋@ = 𝜃" * (𝑋!* + 𝑌(𝑆* − 𝑆)) 𝑌A (𝑁* − 𝑁) (1 + 0.2𝑏𝜃" ) + (1 + 0.2𝑏A 𝜃" )] [𝑋$ + (1 + 𝑏𝜃" ) (1 + 𝑏A 𝜃" ) 𝜃 assume effluent BODL and ammonia from Stage II are negligibly small from this PF reactor, S=0, N=0 and rearrange to ger 𝜃" * (𝑋!* + 𝑌(𝑆* )) 𝑌A (𝑁* ) (1 + 0.2𝑏𝜃" ) + (1 + 0.2𝑏A 𝜃" )] 𝜃= [𝑋$ + (1 + 𝑏𝜃" ) (1 + 𝑏A 𝜃" ) 𝑋@ Substituting all known values, 𝜽 = 7.1 hours Volume = 5.39 x106 L Part 2: 𝑿𝒂 = 𝑿𝑵 = 𝜽𝒄 (𝑿𝟎 𝒂 )𝒀(𝑺𝟎 &𝑺)) (𝟏)𝒃𝜽𝒄 ) 𝜽 𝜽𝒄 𝒀𝑵 (𝑵𝟎 &𝑵) 𝜽 (𝟏)𝒃𝑵 𝜽𝒄 ) = 815 mg/L = 264 mg/L Part 3: E.GHI MOUR BCD = Q(S* − S) C1 − EJK "#$ (1 + 0.2bMCD θN )F = 76.7 kg/day L "#$ % E.QRI&'$ MOUR OPD = Q(N* − N) C1 − EJK &'$ L% (1 + 0.2bOPD θN )F = 2013 kg/day. Part 4: From class notes, overall stoichiometry of nitrification. • 0.13 moles ammonium oxidation produced 0.125 moles nitrate • Complete oxidation of 26.8 mg-N/l of ammonium would thus result in 25.77 mg-N/L as nitrate This study source was downloaded by 100000770139657 from CourseHero.com on 03-09-2023 14:04:15 GMT -06:00 https://www.coursehero.com/file/146046420/CE6331-Homework-3-solutionspdf/ Part 5: For 1 mg ammonium consumed, 7.14 mg of alkalinity as CaCO3 is consumed (see class notes on nitrification) + + Alkalinity consumed = 26.8 mg NH4 -N /l *7.14 mg alkalinity/1mg NH4 -N = 191.35 mg as CaCO3/L. The influent alkalinity is 139 mg/L as CaCO3. Thus, alkalinity will need to be added. The desired alkalinity at pH 7 in an open system can be calculated as Desired Alkalinity = [HCO3-] + 2[CO32-] + [OH-] – [H+] = 𝐾B 𝐾C( 𝑃8DE 𝐾B 𝐾C( 𝐾CE 𝑃8DE + 2 ∗ + [𝑂𝐻& ] + [H) ] [𝐻) ]E [𝐻) ] PCO2 =10-3.5 atm KH = 10-1.5 mol/L.atm [OH-] = 10-7 [H+] = 10-7 K 𝛼1 = 10-6.37 K 𝛼2 = 10-10.32 Desired alkalinity = 4.27 x 10-5 eq/l = 2.55 mg CaCO3/l Influent alkalinity – Alkalinity consumed + added alkalinity = 2.55 mg CaCO3/L Therefore, added alkalinity = 2.55 + 191.35- 139 = 54.9 ml CaCO3/L Part 6: Excess VSS = Xv*V/θc = 2000 x 5.39x106/15 = 719 kg/day Qw = V/θc = 5.39x106/15 = 3.59*105 L/day. Stage III: PF with recycle (for denitrification, using methanol). Assume: SRT 5 days; MLVSS = 2000 mg/L; [D.O.]o = 0; [NO2-]o = 0 and a covered tank. Specify: 1. Influent flow rate; 2. Methanol dose; 3. Reactor volume and hydraulic retention time; 4. Concentration of active denitrifier population (XD); 5. Effluent alkalinity and excess VSS produced (kg VSS/d). SOLUTION Part 1 Influent flow rate = Stage 2 effluent – Stage 2 waste = 1.82 x 107 L/day - 3.59*105 L/day = 1.78x107 L/day Influent flow rate = 1.78x107 L/day Part 2 This study source was downloaded by 100000770139657 from CourseHero.com on 03-09-2023 14:04:15 GMT -06:00 https://www.coursehero.com/file/146046420/CE6331-Homework-3-solutionspdf/ From class notes (methanol use stoichiometry), 0.1667 moles of methanol required for 0.1561 moles of nitrate. Effluent nitrate concentration for stage 2 is 25.77 mg-N/L = 1.84 mmoles/L. Methanol dose required = 1.84*0.1667/0.1561 * 32.04 mg/mmol = 62.9 mg/L Part 3 From class notes (see table) 0.49 gVSS produced g NO3--N consumed when methanol is electron donor Assuming all nitrate is consumed, The excess VSS produced each day will be = 25.77 mg NO3—N/L * 1.78x107 L/day* 0.49 = 225.77 kg/day The excess VSS must be remove daily to maintain SRT i.e., SRT = XvV/QwXv therefore V = SRT * QwXv / Xv = 5 days * 225.77 kg/day/2000 mg/l*10-6 kg/mg V = 564.4 *103 liters. HRT = V/Q = 564.4 *103 L/1.78x107 L/day = 45 minutes Part 4 For this you will need to estimate yield on methanol. From class notes (see table) – net yield when methanol is electron donor is 0.135 gVSS/g OD. The COD of methanol is 1.5 g O2/g methanol. Therefore, the yield per gram of methanol = 0.2 g VSS/g methanol 𝑋/ = +" (0*! )"(%! &%)) + (()*+" ) F = (GF/(EG∗JK)) K)K.E(JE.M&K)) (()K.KF∗F) = 1610 mg/l Part 5 From class notes (see table), 3.57 grams of alkalinity (as CaCO3) is produced per gram of NO3--N consumed. Thus effluent alkalinity = (input alkalinity to stage 3)+ (alkalinity produced) = (3 )+ (25.77*3.57) = 94.9 mg/L From class notes (see table) 0.49 gVSS produced g NO3--N consumed when methanol is electron donor Assuming all nitrate is consumed, The excess VSS produced each day will be = 25.77 mg NO3—N/L * 1.78x107 L/day* 0.49 = 225.77 kg/day This study source was downloaded by 100000770139657 from CourseHero.com on 03-09-2023 14:04:15 GMT -06:00 https://www.coursehero.com/file/146046420/CE6331-Homework-3-solutionspdf/ Powered by TCPDF (www.tcpdf.org)