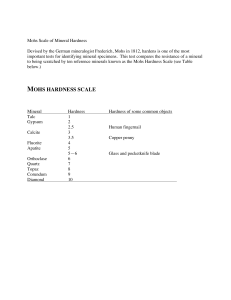

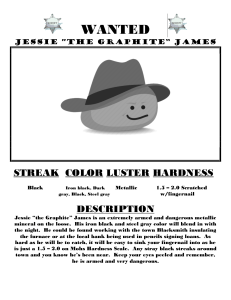

January 31, 2023 Group 6 Moises Menjivar - Manager Katherine Nguyen - Recorder Felice Peluso - Operator Lab Design Section A Group 6: Intro to Materials Properties 1. Please list the materials and provide a description of the procedure you used for each experiment. Density Description: According to the Archimedes Principle, a body submerged in a fluid experiences a buoyant force (𝐹𝑏) equal to the weight of the displaced fluid (𝑊𝑓). It also states that the 𝑊𝑓 is equal to the difference between the weight of a sample in air / dry weight (𝑊𝑠) and the apparent weight of the sample when submerged in fluid / wet weight (𝑊𝑤). Procedure: A balance will be used to measure the dry (𝑚𝑠) and wet (𝑚𝑤) mass. Remember that weight (𝑊) is simply mass (𝑚) times gravity (g). Using a scale, we first measured the dry mass of our samples, which can be seen in the chart below. Afterwards, Felice put a hook onto the scale, which he then placed a beaker of water on top of. A little bucket is added onto the hook, and the scale is zeroed at this point. We then measured the wet mass of our samples in this bucket. Material Mass in Air (g) Mass in Water (g) Steel 120.16 95.80 Aluminum 42.15 21.40 Copper 136.61 110.90 Brass 129.24 104.60 Acrylic 18.27 1.43 Nylon 18.07 1.25 PVC 14.28 -1.24 Sinker 1: Bi 53.29 44.60 Sinker 2: Sn 37.11 29.60 Sinker 3: CC 43.11 34.55 After measuring the masses, both dry and wet, calculate the density ratios, which will give us the density of the material. Material Mass of Water (g) (𝑊𝑠 − 𝑊𝑤) Density of Material (g/ml) 𝑊 𝑠 ( 𝑊 −𝑊 ) 𝑠 𝑤 Steel 24.36 4.9327 Aluminum 20.75 2.0313 Copper 25.71 5.3135 Brass 24.64 5.2451 Acrylic 16.84 1.0849 Nylon 16.82 1.0743 PVC 15.52 .92010 Sinker 1: Bi 8.69 6.1323 Sinker 2: Sn 7.51 4.9414 Sinker 3: CC 8.56 5.0362 Mohs Hardness Description: Mohs Hardness scale was a method created back in the 1800’s within the mineralogy community. Using this scale, the community was able to measure the softest materials, with metallic bonds or even weaker van der Waals bonds, and even the hardest minerals with small atoms, packed tightly together with strong covalent bonds. The hardness of these materials can be tested through scratching. The Mohs Hardness Scale, starting with talc at 1 and ending with diamond at 10, is universally used around the world as a way of distinguishing minerals and materials. We were given 5 materials in this procedure, as shown below: Procedure: We were provided a scratch kit with 4 picks of different hardness levels. Felice used the picks to scratch the samples in order to determine their hardnesses, which is then recorded below. X - scratched Hardness 4 5 6 7 8 9 Brass X X X X X X Steel X X X X X X X X X X X X X X X X X X X X X Aluminum PMMA Glass 2 3 X 2. Include a table of experimentally determined densities for the various materials you studied along with standard values reported in textbooks, EduPack software or any other reliable materials database which describe the "standard" densities for these various materials. You should discuss the precision with which you can make density measurements in this laboratory and adhere to that precision in your reporting. Material Determined Density (g/ml) Standard Density (g/ml) Steel 4.9327 7.85 Aluminum 2.0313 2.7 Copper 5.3135 8.96 Brass 5.2451 8.5 Acrylic 1.0849 1.051 Nylon 1.0743 1.440 PVC .92010 1.330 Sinker 1: Bi 6.1323 9.87 Sinker 2: Sn 4.9414 7.26 Sinker 3: CC 5.0362 3. Using the density property chart from CES EduPack, report the range of densities for the following groups of materials: Material Type Density Range (kg/m^3) Metals and Alloys 4000+ Polymers 1000-3000 Ceramics (technical and non-technical) 2000-4000 Foams 0-1000 4. Calculate the weight percentage of Sn and Bi in the composite sinker 5. Include a table which ranks (in increasing order) the Mohs hardness of the various materials tested in this lab and include the average hardness and uncertainty for each material. Material Average Hardness Aluminum 3 Brass 4 Steel 4 Uncertainty PMMA 5 Glass 6 Through the procedures done on the five materials, the average hardness was lowest on aluminum but highest on glass. Through our experiment, we did not experience any uncertainty as after our first pick in each of the 5 materials, the following picks left scratches as well. Therefore, uncertainty could no be calculated due to not experiencing lower picks scratching compared to higher picks not scratching. 6. Please compare two of the materials you examined in the experiment in terms of how the type of bonding and/or structure relates to their density or hardness. Two materials used in today's lab were steel and glass. Steel was found to be one of the denser materials, though it had a hardness of about 4. Glass, however, was the strongest in terms of hardness from our samples. Steel has metallic bonding, which would explain why it's less hard than glass, which is a polymer and has ionic bonds. Steel was one of the denser materials since the elements that make up it's chemical structure are also somewhat heavier than most other materials, meaning higher molecular mass and therefore higher density. Sources used: Densities of Metals and Elements Table (engineersedge.com) Density of Steel (amesweb.info) What is the density nylon? - Reimagining Education Bismuth - Density - Bi (periodic-table.org)