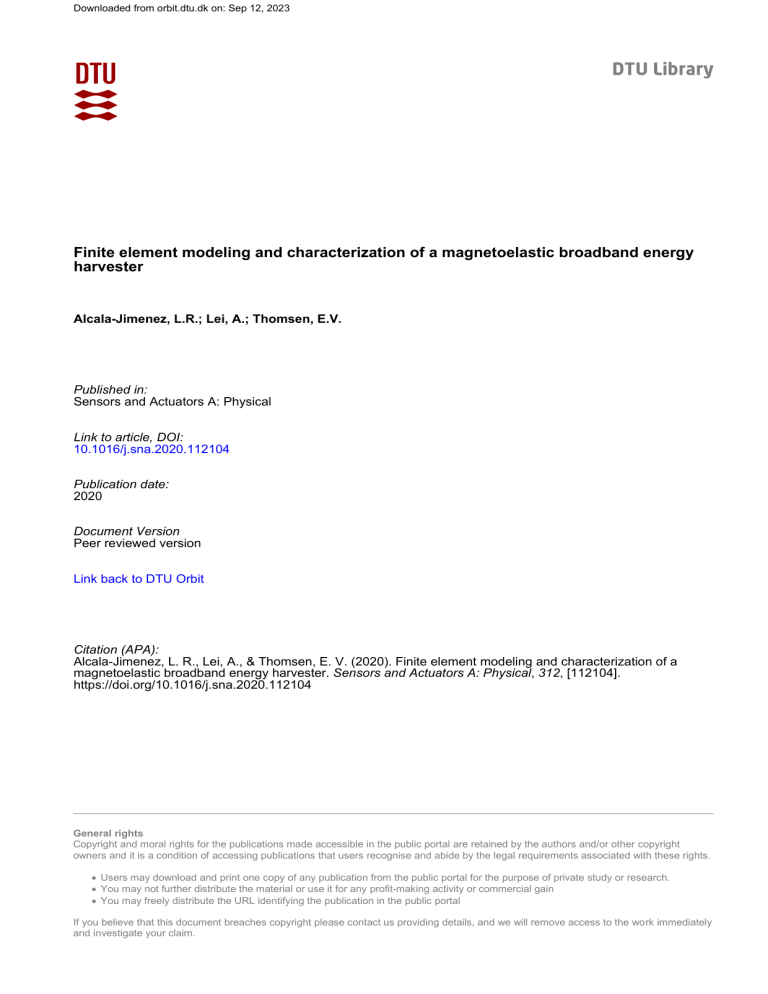

Downloaded from orbit.dtu.dk on: Sep 12, 2023 Finite element modeling and characterization of a magnetoelastic broadband energy harvester Alcala-Jimenez, L.R.; Lei, A.; Thomsen, E.V. Published in: Sensors and Actuators A: Physical Link to article, DOI: 10.1016/j.sna.2020.112104 Publication date: 2020 Document Version Peer reviewed version Link back to DTU Orbit Citation (APA): Alcala-Jimenez, L. R., Lei, A., & Thomsen, E. V. (2020). Finite element modeling and characterization of a magnetoelastic broadband energy harvester. Sensors and Actuators A: Physical, 312, [112104]. https://doi.org/10.1016/j.sna.2020.112104 General rights Copyright and moral rights for the publications made accessible in the public portal are retained by the authors and/or other copyright owners and it is a condition of accessing publications that users recognise and abide by the legal requirements associated with these rights. Users may download and print one copy of any publication from the public portal for the purpose of private study or research. You may not further distribute the material or use it for any profit-making activity or commercial gain You may freely distribute the URL identifying the publication in the public portal If you believe that this document breaches copyright please contact us providing details, and we will remove access to the work immediately and investigate your claim. Journal Pre-proof Finite Element Modeling and Characterization of a Magnetoelastic Broadband Energy Harvester L.R. Alcala-Jimenez, A. Lei, E.V. Thomsen PII: S0924-4247(20)30463-5 DOI: https://doi.org/10.1016/j.sna.2020.112104 Reference: SNA 112104 To appear in: Sensors and Actuators: A. Physical Received Date: 28 March 2020 Revised Date: 8 May 2020 Accepted Date: 23 May 2020 Please cite this article as: L.R. Alcala-Jimenez, A. Lei, E.V. Thomsen, Finite Element Modeling and Characterization of a Magnetoelastic Broadband Energy Harvester, <![CDATA[Sensors & Actuators: A. Physical]]> (2020), doi: https://doi.org/ This is a PDF file of an article that has undergone enhancements after acceptance, such as the addition of a cover page and metadata, and formatting for readability, but it is not yet the definitive version of record. This version will undergo additional copyediting, typesetting and review before it is published in its final form, but we are providing this version to give early visibility of the article. Please note that, during the production process, errors may be discovered which could affect the content, and all legal disclaimers that apply to the journal pertain. © 2020 Published by Elsevier. Finite Element Modeling and Characterization of a Magnetoelastic Broadband Energy Harvester L. R. Alcala-Jimenez, A. Lei and E. V. Thomsen Department of Micro- and Nanotechnology, DTU Nanotech, Technical University of Denmark, Building 345E, DK-2800 Kgs. Lyngby, Denmark Abstract re -p ro of Piezoelectric-based vibration energy harvesters have been extensively developed to the end of replacing low-power batteries. However, matching the frequency of the ambient vibration is not always possible and to broaden the frequency response of the harvesters, di↵erent proof-of-concept devices have been developed. This work presents a miniaturized device intended for magnetoelastic broadband vibration energy harvesting. The device consists of a silicon beam where ferromagnetic foils act as proof mass and interacts with an external pair of permanent magnets. The interaction is first simulated using a Finite Element Method (FEM) model for di↵erent distances between the magnets and beam (a) and between the magnets (b). This is done for both an attractive and a repulsive magnet configuration and the calculation is performed for a set of a and b values. Both spring softening and hardening e↵ects are observed for the two magnet configurations. The attractive configuration has a monostable potential energy landscape with an associated spring softening for a large range of a and b values which makes this configuration very usefull for energy harvesting applications. The attractive configuration is experimentally investigated by impedance measurements. These measurements are performed for a 2 [400 µm, 2500 µm] and b 2 [320 µm, 3140 µm] and a region that allows for broadband harvesting is found experimentally. Compared to the linear case the largest spring softening e↵ect yielded a decrease in the e↵ective spring constant of 74%, a decrease in the resonant frequency of 49%, and the coupling coefficient was increased with a factor of 2.6. lP Keywords: MEMS, Energy harvester, FEM, Piezoelectric, Magnetoelastic, Broad bandwidth. 1. Introduction 15 20 ur na 10 The demands on power sources limit the applicability of wireless miniature sensor systems for use in o↵-the-grid applications where it is difficult or impossible to change batteries. Two of the main requirements for miniatur- 30 ized systems used as power sources are physical dimensions in the millimeter-scale range and long lifetime. Conventional batteries imply continuous and sometimes expensive replacement cost. Furthermore, they impose a limit on system miniaturization. This means that for some applications a replacement for conventional batteries must 35 be found. Vibration energy harvesters (VEHs), which can harvest energy from ambient vibrations and convert it into electrical energy automatically, have become a promising alternative for a range of applications. There are three main approaches to harvesting energy from vibrations, 40 which involve the use of either electrostatic [1–6], electromagnetic [7, 8] or piezoelectric [9–19] principles. As a general rule, the main challenge in vibrational energy harvesting is that the maximum system performance is achieved when the resonant frequency of the VEH matches the ex- 45 ternal vibration source. The key parameters for VEHs are the output power and the frequency bandwidth. The output power can be increased by optimizing the coupling Jo 5 25 Preprint submitted to Sensors & Actuators: A. Physical factor, the design or the energy conversion scheme. Most of the available published material presents studies of systems under resonant excitation. However, most ambient vibration sources have a frequency shift over time [20]. For that reason, either continuously tuning the resonant frequency using for example passive or active methods [15, 21] or widening the frequency bandwidth of the VEHs has become of utmost importance before their practical implementation. The frequency bandwidth of the VEH can be increased using non-linear e↵ects [22–26]. These non-linear e↵ects can be introduced by using permanent magnets and ferro electric materials [22–24], for example by having a ferromagnetic cantilever and one or more permanent magnets located close to the cantilever [22, 23, 27]. This will e↵ectively change the potential energy landscape. Due to dimensional constraints, the magnetoelastic method is more suitable for small systems than the approach where several harvesters operate in parallel [28]. Piezoelectric-based VEHs have attracted much attention because it is feasible to produce them in millimeterscale whilst having large power densities [29, 30]. They typically consist of a cantilever structure with piezoelectric layers on top. For such a device, the non-linear e↵ect May 5, 2020 a) N S S N Attractive b) N S N S Table 1: Dimensional and material parameters used for the simulations. Repulsive Device parameters Beam length, l Beam thickness, h Beam width Foil length, lf Foil thickness, hf Foil width Magnet length, lm Magnet thickness, hm Magnet width Magnetization, Mmag Si Young modulus Foil relative permeability =1 mm = 1 mm = 6.5 mm = 3.25 mm Fe Si = 150 m c) 60 65 70 75 lP can be accomplished by externally implementing a magnetic set-up and adding ferromagnetic material to the tip 90 of the cantilever, as illustrated in Fig. 1. Commonly, the external magnetic set-up consists of either one or a pair of magnets. It has previously been demonstrated that the latter one leads to increased generated power when compared to the former set-up [31]. Therefore, the two-magnet 95 configuration shown in Fig. 1 will be studied in this work. A similar, however much larger system, has been previously studied [32]. It consisted of a beam with a length of about 11 cm placed vertically and two cylindrical magnets. In that work, an analytical model was developed. There, the force acting on the cantilever beam was directly calculated from an expression of the magnetic field. However,100 the method presented in that study does not directly apply to smaller system dimensions where tiny square magnets are used. A numerical study of a non-linear oscillator for broadband energy harvesting was presented by [33]. Nonetheless, the study did not consider any external mag-105 netic setup, therefore lacking any dimensional analysis. On the other hand, it has been found that for a given set-up, like the one under study in this work, the parameters that determine whether the cantilever presents a softening effect or a bi-stable behavior are the distance between the110 magnets and the tip of the cantilever, a, and the distance between the magnets, b [15, 16, 34]. The position of the magnets with respect to the cantilever beam is illustrated in Fig. 1. When a pair of magnets is used they can be positioned in either an attractive magnetic configuration, Fig.115 ur na 55 85 Jo 50 80 1a, or a repulsive magnetic configuration, Fig. 1b. As a consequence, it becomes of utmost importance to find the dimensional parameters, a and b, that allows for a VEH that presents a softening e↵ect. The aim of this work is to find the positions of the magnets, a and b, that lead to a VEH having a softening effect. These positions are found by studying the potential energy of the system using finite element calculations. Experiments are performed to validate the proposed device. Since one of the requirements for powering wireless sensor systems, as described previously, is dimensions in the millimeter-scale range, the focus of this study is on small-size cantilevers with lateral dimensions no longer than 10 mm. The article is organized as follows: First, the simulation methods used are explained. Secondly, the experimental methods are presented, together with a fabrication process description. Thirdly, the simulation results are presented followed by the experimental findings. Finally, the article ends with conclusions. re Figure 1: Side-view of the vibrational energy harvester system showing how the two magnets are placed and a definition of the magnet configurations studied in this work. a) Shows the two magnets placed in an attractive magnetic configuration. b) The two magnets are placed in a repulsive magnetic configuration. c) The energy harvester consists of a silicon cantilever beam with integrated iron foils acting as proof mass. The magnets are placed in the attractive magnetic configuration. ro of Fe -p = 40 m Values 6.5 mm 40 µm 6 mm 3.25 mm 150 µm 6 mm 1 mm 1 mm 5.5 mm 750 kA/m 150 GPa µr = 4000 2 2. Simulation Methods The system studied in this work is depicted in Fig. 1 and relevant dimensions are given in Tab. 1. It consists of a silicon cantilever beam with a pair of iron foils attached on either side and two external neodymium magnets. The two magnets can be placed in either an attractive or a repulsive magnetic configuration as shown in Fig. 1a and Fig. 1b, respectively. The materials used in the simulations are silicon for the cantilever structure, with a length of l = 6.5 mm, see Tab. 1; neodymium for the external magnets, which are modeled as squares with a constant magnetization of Mmag = 750 kA/m; and iron for the ferromagnetic foils, which are modeled as hysteresis free magnetic soft materials with a magnetic relative permeability of µr = 4000. FEM studies were performed using COMSOL multiphysics 5.2 [35] combining the Solid Mechanics and the Magnetic Fields modules. Each simulation was divided 125 130 contacts to the electrodes, Fig. 2b. To analyze the nonlinear response of the system, a pair of NdFeB magnets, obtained from Supermagnete [36], were mounted on a positioner in the attractive magnetic configuration, Fig. 2c. In order to have a precise control over the positioning of the magnets in the three spatial dimensions, a XYZ 300 TR stage model from Quater Research and Development was used, Fig. 2a. The distance between the magnets and the beam, a, and the distance between the magnets, b, were measured by using a Dino-Lite edge digital microscope model AZ7915MZTL together with the DinoCapture 2.0 software [37]. The distance between the magnets and the cantilever, a, was varied by moving the stage controlling the position of the magnets. The distance between the magnets, b, was varied using spacers made out of brass. ro of 120 into two steps. The first step was a calculation performed170 in the mechanical domain. A uniformly distributed input force was applied on the whole cantilever structure and the position of the center of mass for the cantilever was found. The next step was a calculation in the magnetic domain where the magnetic force on the iron foils mounted on the175 beam was found. The position of the cantilever found in the mechanical domain was fixed during this calculation, i.e. the total force as function of cantilever deflection could be determined. These steps were repeated for di↵erent input forces, from which the potential energy as a function180 of deflection was calculated. This procedure was then repeated for di↵erent positions, a and b, of the magnets. The e↵ective spring constant, ke↵ , and the linear spring constant, k0 , were calculated from the total force as the negative of the derivative of the force with respect to po-185 sition. 4. Simulation Results 150 155 160 165 re lP 145 ur na 140 The piezo electric energy harvesters were fabricated by standard silicon micro- and nano fabrication methods us-190 ing a (100) oriented n-type Si substrate with a resistivity of 0.0015 ⌦cm. This very low resistivity allows the silicon substrate to be used as a bottom electrode for the piezoelectric material. The process proceeds as follows: First, a 3000 nm thick oxide layer was grown on both195 sides of the wafer. Holes were opened in the oxide using lithography and HF etching, and KOH etching was used to define a plate. After stripping the masking layer, the cantilever’s anchoring point was rounded at the corner to increase the mechanical robustness of the energy200 harvester. This was done by growing a 1000 nm wet oxide layer at 1100 C, which rounds the sharp corner obtained after KOH etching. The oxide was then removed in HF. The piezo electric material and top and bottom electrodes were deposited by evaporation and sputtering205 of Pt/AlN/Pt/Ti with thickness of 50 nm/400 nm/120 nm, and 10 nm, respectively. Lithography and wet etching were used to define the geometry of the piezoeletric layer and the electrodes. Once this was done the cantilever was released from the plate using a STS ICP Advanced Silicon210 Etcher system and photoresist as masking material. After stripping the photoresist the energy harvesters were diced out using a Disco Automatic dicing saw, model DAD321. Finally, ferromagnetic foils were glued on both sides of the beam using a pick-and-place operation. 215 The magnetoelastic behaviour of the cantilevers was studied using impedance spectroscopy. The experimental set-up is shown schematically in Fig. 2. The impedance measurements were performed using an Agilent E4990A Impedance Analyzer equipped with an Agilent 4294A220 impedance probe, Fig. 2a. The impedance measurements were performed using a test signal level (AC) of 50 mV. The cantilever was mounted on a sample holder having pogo pins to both secure the beam and provide electrical Jo 135 The results obtained from the simulation study, explained in Section 2, are described in the this section. Fig. 3 shows the calculated potential energy landscapes for the linear configuration and three magnetoelastic cases (a = 1000 µm, a = 564 µm and, a = 200 µm, respectively) where the magnets are mounted in the attractive configuration, and extracted results are summarized in Tab. 2 . In all cases, the distance between the magnets was b = 500 µm. The dashed curve in Fig. 3 corresponds to the linear case, for which a spring constant k0 = 120.7 N/m was found. For the longest distance between magnets and cantilever tip, that is for a = 1000 µm, a monostable landscape was found. The e↵ective spring constant for this case is ke↵ = 90.8 N/m, i.e. compared to the linear case a spring softening has occurred. The black curve in Fig. 3 represents the results obtained for a distance a = 564 µm, which leads to a rather ”flat” potential energy landscape around zero deflection. The e↵ective spring constant corresponding to zero deflection is 2.2 N/m. Compared to the linear case a significant spring softening e↵ect has taken place. Such a flat region in the potential energy landscape is attractive seen from a broadband energy harvesting perspective. Finally, when the magnets are positioned at a = 200 µm, a bistable potential energy landscape was obtained, i.e. two stable positions, located at deflections of ±399 µm, are found. The e↵ective spring constants corresponding to the local potential energy minima are, based on symmetry, expected to be the same and the calculated value is 434.3 N/m. For zero deflection the e↵ective spring constant becomes negative and a value of 439.6 N/m is found. The potential energy landscape for a repulsive magnet configuration having b = 500 µm is shown on Fig. 4. The figure shows the potential energy as function of deflection for the linear system (i.e. without magnets) and for three magnetoelastic cases: monostable (a = 1000 µm), flat potential (a = 384 µm), and a bistable system (a = 200 µm). -p 3. Experimental methods 3 Impedance probe Impedance probe Microscope Stage for beam Magnets Microscope Beam holder Stage for magnets a) ro of Beam holder b) c) ur na lP re -p Figure 2: Experimental set-up used for characterizing the electrical properties of the energy harvesters. a) The cantilever beam is placed in a sample holder which can be moved by the stage for the beam. The impedance probe is connected to the two electrodes of the energy harvester. The magnets are placed in a fixture attached to the stage for the magnets. The distance between the magnets and the beam, a, can be varied using the two stages. b) Details of the experimental set-up used for the electrical characterization showing the sample holder with integrated pogo-pins securing the beam to the sample holder. One pogo-pin is used to contact the top electrode of the harvester allowing impedance measurements to be performed. The microscope used for measuring distances is shown as well. c) Holder for the magnets with the rectangular magnets located at the center of the fixture. The distance between the magnets, b, can be adjusted by placing brass spacers between the two magnets. Table 2: E↵ective spring constants, ke↵ , and the location, xmin , of the minimum in potential energy for selected potential energy landscapes. The results are for di↵erent values of the beam to magnet distance, a, as indicated in the table. The distance between the magnets is b = 500 µm Jo for all cases considered. Results for both a repulsive and an attractive configuration of the magnets are shown together with the results obtained for the linear configuration (i.e. without the magnets). Linear Repulsive Attractive Parameter Unit Bistable Bistable Flat Monostable Bistable Bistable Flat Monostable ke↵ N/m 120.7 281.6 -268.7 4.3 136.6 434.3 -439.6 2.2 90.8 a µm 200 200 384 1000 200 200 564 1000 xmin µm 0 ±311 0 0 0 ±399 0 0 0 4 Attractive configuration, b=500 m 25 Linear (without magnets) Monostable, a=1000 m Flat, a=564 m Bistable, a=200 m 20 Repulsive configuration, b=500 m 30 Linear (without magnets) Monostable, a=1000 m Flat, a=384 m Bistable, a=200 m 25 10 5 0 -5 -10 -15 -800 -600 -400 -200 0 200 400 600 20 15 10 5 0 800 Deflection ( m) -5 -800 Figure 3: Potential energy as function of deflection for the linear system (i.e. without magnets) and for three magnetoelastic cases: monostable (a = 1000 µm), flat potential (a = 564 µm), and a bistable system (a = 200 µm). The simulation was performed for an attractive magnet configuration. The distance between the magnets was b = 500 µm for all cases considered. 240 245 250 255 0 200 400 600 800 -p re For this configuration the monostable case shows a spring hardening where the e↵ective spring constant is increased to 136.6 N/m, i.e. slightly higher than for the linear case where the spring constant is 120.7 N/m. For the flat potential energy landscape the e↵ective spring constant is 4.3 N/m corresponding to a significant spring softening. Finally, the bistable potential energy landscape has its minima located at deflections of ±311 µm and the e↵ective spring constant is 281.6 N/m. Both the attractive and repulsive magnet configurations lead to flat potential energy landscapes for certain values of a. In order to find a range of magnet positions that lead to a flat potential energy landscape a sweep over both the a and b parameters was performed and the effective spring constant for zero deflection was calculated. The results are shown in Fig. 5, where the normalized effective spring constant, ke↵ /k0 , is plotted as function of a and b for an attractive magnet configuration. The contour line for ke↵ /k0 = 0 determines the contour between the monostable and bistable cases. The sign and value of the normalized e↵ective spring constant at zero deflection can be used to classify the system. Spring hardening occurs for ke↵ /k0 > 1, spring softening occurs for 0 < ke↵ /k0 < 1, flat potential occurs for ke↵ /k0 = 0, and bistable behavior occurs for ke↵ /k0 < 0. The contour plot of the normalized e↵ective spring constant, Fig. 5, shows three distinct regions named I, II and III. Both regions I and II present monostable potential energy landscapes with spring softening and spring hardening e↵ects taking place, respectively. Region III corresponds to a bistable regime. For the attractive configura- lP 235 -200 Figure 4: Potential energy as function of deflection for the linear system (i.e. without magnets) and for three magnetoelastic cases: monostable (a = 1000 µm), flat potential (a = 384 µm), and a bistable system (a = 200 µm). The simulation was performed for a repulsive magnet configuration. The distance between the magnets was b = 500 µm for all cases considered. ur na 230 -400 Deflection ( m) I: Monostable, softening III: Bistable Jo 225 -600 ro of Potential energy ( J) Potential energy ( J) 15 II: Monostable, hardening Figure 5: Contour plot of the normalized e↵ective spring constant, ke↵ /k0 , evaluated at zero deflection and for di↵erent a and b values associated to the attractive magnet configuration. 5 1800 I: Monostable, softening Attractive, monostable 1600 Attractive, bistable 1400 Repulsive, monostable b, [ m] 1200 III: Bistable Repulsive, bistable 1000 800 600 400 200 0 0 100 200 300 400 500 ro of II: Monostable, hardening 600 a, [ m] Figure 7: The plot shows matching values of the magnet separation parameters, a and b, for which ke↵ /k0 = 0. The two curves correspond to the repulsive (blue) and attractive (red) magnet configuration, respectively. Figure 6: Contour plot of the normalized e↵ective spring constant, ke↵ /k0 , evaluated at zero deflection and for di↵erent a and b values associated to the repulsive magnet configuration. -p 5. Experimental results The same study was performed for the repulsive magnet290 configuration, resulting in the contour plot shown in Fig. 6. For this configuration region II is more pronounced and extends over a larger range of a and b values. lP 260 285 The static simulations performed in this study allow to determine the potential energy landscapes. Once this315 has been determined a dynamic study of the performance of the energy harvester can be performed using Duffing’s equation as described in refs. [33, 38], among others. 275 Jo 270 ur na 280 In order to more easily compare both configurations, 295 the contour lines for ke↵ /k0 = 0 from Fig. 5 and Fig. 6 are plotted in Fig. 7. Both configurations have regions where bistable and monostable behaviour occur. For the repulsive configuration configuration of the magnets the shift between the bistable and monostable regions occurs 300 in most cases for smaller values of a and b compared to the attractive magnet configuration. From a practical point of view both configurations have a set of a and b values leading to flat potential energy landscapes and they can be realistically obtained during assembly of the energy har305 vesting system. Comparing the attractive, Fig. 5, and the repulsive magnet configurations, Fig. 6, it is observed that the attractive configuration leads to a more simple e↵ective spring constant landscape as the iso-lines are more vertical and the region where spring softening takes place 310 (Region I) is larger. Therefore, the attractive configuration of the magnets is expected to be easier to implement in practice and is therefore investigated experimentally. 265 To experimentally investigate the potential energy landscape for the attractive configuration of the magnets, impedance measurements were performed for di↵erent positions of the magnets, i.e. for di↵erent a and b values, using the measurement set-up described in Section 3. As an example of the results obtained the impedance spectra measured for b = 420 µm are presented in Figs. 8, 9, and 10. A typical impedance measurement is shown in Fig. 8 where both the measured impedance magnitude and phase are plotted as function of the frequency, and in the measurements the position of the magnets were (a, b) = (1000 µm, 420 µm). The resonant frequency, fr , for a given set of a and b values was obtained from the minimum in the impedance magnitude and a value of fr = 158 Hz was found. Fig. 9 shows the impedance magnitude for a range of a values corresponding to the data points shown in Fig. 10. From Fig. 9 it is apparent that not only the impedance magnitude at the resonant frequency changes, but all spectra shift towards higher impedance magnitudes. This is due to the electrical capacitance of the AlN layer, whose associated impedance scales inversely with respect to frequency. The resonant frequency corresponding to each a value was found from the impedance magnitude measurements presented in Fig. 9. Fig. 10 shows the resonant frequencies, impedance magnitudes and maximum phases at resonance, which were obtained for b = 420 µm and for di↵erent values of a. For large values of a the measured resonant frequency, f0 = 240.8 Hz, corresponds to the natural resonant frequency of the beam, i.e. the magnetic force is not strong enough at that distance to influence the dynamics of the beam. At a distance of about a = 3 mm a small shift re tion, region I extends to most of the values associated to a and b, while region II only occurs for small values. 6 -78 240 -80 230 -82 220 -84 210 -86 200 -88 190 155 156 157 158 159 160 161 260 220 -90 162 Frequency [Hz] ! = 5900&m 180 160 335 340 345 350 ! = 700 &m 140 120 ! = 600 &m 60 150 ! = 500 &m -5 = 240.8 Hz ! = 400 &m 80 200 250 300 350 400 450 500 550 Frequency [Hz] Figure 9: Impedance magnitude associated to the measurements used to create the data shown in Fig. 10. The distance between the magnets was b = 420 µm and each curve corresponds to a di↵erent value of the beam to magnet distance, a. lP re -p in the measured parameters is observed, indicating that a spring softening e↵ect takes place. The minimum in resonant frequency, fmin , is obtained at a = 1 mm, where the resonant frequency has decreased to fmin = 158 Hz which corresponds to a decrease in frequency of 34% compared to the resonant frequency of the linear device. For smaller values of a the resonant frequency begins to increase and for a < 0.8 mm a spring hardening e↵ect occurs. The softening and hardening e↵ects observed are in overall agreement with the simulation results presented in Fig. 5, where first a spring softening and then a spring hardening e↵ect is obtained for b = 420 µm as a decreases in value. However, the exact value of a where these e↵ects are introduced di↵er most probably due to uncertainties in the magnetization. The main results from an analysis of the impedance spectra measured for a range of b values are shown in Tab. 3. The values of amin , which correspond to the lowest resonant frequency found for each b value, are also listed in Tab. 3. The relative spring constant, kr , is calculated from the measured resonant frequency as kr /k0 = (fr /f0 )2 where k0 is the natural spring constant of the beam. These values are also shown in Tab. 3. The coupling coefficient 2 2 is calculated for each case as KSYS = (fmax /fmin 1)(1/2) , where fmax represents the antiresonant frequency associated to each case, i.e. the frequency for which the maximum value in impedance magnitude is found. As seen from Tab. 3, the coupling coefficient, KSYS , increases for each optimal positioning of the magnets with respect to the linear case, KSYS,lin , which indicates a widening of the separation between the resonant and antiresonant frequencies. These higher coupling coefficients lead to higher power output, as described in [39]. The largest reduction ur na 330 ! = 800 &m Jo 325 ! = 1250 &m 200 100 Figure 8: Impedance magnitude (red, left y-axis) and phase (blue, right y-axis) measured for a magnet position that leads to a spring softening e↵ect. The measurement was performed for (a, b) = (1000 µm, 420 µm), which corresponds to the lowest resonant frequency, fr = 158 Hz, obtained in Fig. 10, where b is fixed to 420 µm. 320 ! = 1000 &m, -min = 158 Hz 240 ro of 250 Impedance magnitude [k ] -76 Phase [°] Impedance magnitude [k ] 260 Figure 10: Plot of the impedance magnitude (red, left y-axis) at the resonant frequency, the resonant frequency (blue, right y-axis), and maximum phase (black) for a range of a values. For the experiment the separation distance between the magnets was b = 420 µm. 7 Table 3: Main results from the experimental study. Minimum resonant frequencies, fmin , measured for a range of b values. The a value, for which the minimum in the resonant frequency was found, amin , is listed in the second column. The experiment was performed for an attractive configuration of the magnets. The maximum reduction in resonant frequency compared to the natural resonant frequency of the beam was 49%. ✓0 [ ] -63.1 -63.1 -62.7 -64.0 -64.5 -63.0 -62.2 -63.9 -64.2 -62.6 -63.3 ± 0.8 fmin [Hz] 169.5 157.9 177.3 198.5 182.6 158.9 129.2 173.2 122.2 122.8 – ✓min [ ] -76.5 -76.1 -74.4 -75.3 -78.5 -74.1 -75.9 -72.5 -74.5 -74.2 – in resonant frequency, compared to the natural resonant frequency of the beam, was 49%. This value was found for a position where a = 550 µm and b = 2950 µm. For this position the spring constant showed a decrease by 74% and the coupling coefficient increased by a factor of 2.6 compared to the linear device. For this case, the phase angle was ✓min = 74.5 , i.e. a decrease of of 10.2 compared to the linear device where the phase was ✓0 = 64.2 . Fig. 11 shows a contour plot of the relative spring constant, kr /k0 , for a 2 [400 µm, 2500 µm] and b 2 [320 µm, 3140 µm]. The experimental results presented in Fig. 11 show the two distinct regions, I and III, that are also visible in Fig. 5, i.e. the softening region for the monostable case and the hardening region corresponding to the bistable regime. Spring softening is seen for a large range of a and b values, which is in good agreement with the findings shown in Fig. 5. As explained previously in this study, once a bistable regime is obtained a hardening e↵ect occurs and the beam bends towards one of the magnets. These measurements demonstrate that experimentally it is possible to find positions leading to a significant spring softening, which is attractive seen from an energy harvesting point of view. fmin /f0 – 0.704 0.656 0.736 0.825 0.759 0.660 0.536 0.720 0.508 0.510 – KSYS,lin [%] 7.3 7.4 7.5 7.5 7.5 7.3 7.2 7.5 7.5 7.3 7.4 ± 0.1 re 360 f0 [Hz] 240.9 240.8 240.7 240.7 240.7 240.7 240.8 240.6 240.6 240.7 240.7 ± 0.1 380 385 b [mm] lP 6. Conclusion ur na 375 kr /k0 – 0.49 0.43 0.54 0.68 0.58 0.44 0.29 0.52 0.26 0.26 – 6 0.5 0.6 0.8 0.7 !" = 0.9 !# 5.5 5 2.5 2 5 1.5 4 3 1 4.5 4 I: Monostable, softening 3.5 3 0.9 2.5 1 0.6 2 2 0.7 1.5 0.8 1 6 0.5 0.5 0.5 1 1.5 2 2.5 a [mm] Jo 370 KSYS /KSYS,lin – 2.01 2.15 1.79 1.65 2.12 2.03 2.67 1.75 2.60 2.69 – 3 III: Bistable - hardening 365 KSYS [%] 14.7 15.8 13.4 12.4 16.0 14.9 19.3 13.1 19.6 19.6 – -p 355 amin [µm] 1004 1000 1250 1050 1250 1100 800 700 550 400 – ro of b [µm] 320 420 520 910 1170 1870 2270 2790 2950 3140 – A cantilever-based structure intended for broadband magnetoelastic vibrational energy harvesting was presented. The device was made using silicon micro fabrication techniques. Ferromagnetic foils were placed on either side of the beam and served both as proof mass and to provide interaction with an external pair of permanent magnets such that a magnetoelastic behavior is obtained. FEM simulations were performed for two di↵erent magnet configurations: repulsive and attractive, with sweeps over di↵erent a and b values. Both the repulsive and attractive magnetic configurations showed regions that allowed for a spring softening e↵ect. These regions can Figure 11: Contour plot of the measured normalized spring constant, kr /k0 , for di↵erent a and b values. This was measured using the attractive magnet configuration. 8 400 405 References 425 430 435 440 445 450 re lP 420 ur na 415 [1] Y. Tada, Experimental characteristics of electret generator, using polymer film electrets, Japanese Journal of Applied Physics 31 (3R) (1992) 846. [2] S. Roundy, P. K. Wright, J. Rabaey, A study of low level vi-485 brations as a power source for wireless sensor nodes, Computer Communications 26 (11) (2003) 1131–1144. [3] S. Boisseau, G. Despesse, T. Ricart, E. Defay, A. Sylvestre, Cantilever-based electret energy harvesters, Smart Materials and Structures 20 (10) (2011) 105013. 490 [4] A. H. Ramini, Q. M. Hennawi, M. I. Younis, Theoretical and experimental investigation of the nonlinear behavior of an electrostatically actuated in-plane MEMS arch, Journal of Microelectromechanical Systems 25 (3) (2016) 570–578. [5] A. H. Ramini, A. Z. Hajjaj, M. I. Younis, Tunable resonators for495 nonlinear modal interactions, Scientific reports 6 (2016) 34717. [6] A. Ramini, N. Alcheikh, S. Ilyas, M. I. Younis, Efficient primary and parametric resonance excitation of bistable resonators, AIP Advances 6 (9) (2016) 095307. [7] M. El-Hami, P. Glynne-Jones, N. White, M. Hill, S. Beeby,500 E. James, A. Brown, J. Ross, Design and fabrication of a new vibration-based electromechanical power generator, Sensors and Actuators A: Physical 92 (1) (2001) 335–342. [8] S. P. Beeby, R. Torah, M. Tudor, P. Glynne-Jones, T. O’Donnell, C. Saha, S. Roy, A micro electromagnetic genera-505 tor for vibration energy harvesting, Journal of Micromechanics and Microengineering 17 (7) (2007) 1257. [9] R. Elfrink, T. Kamel, M. Goedbloed, S. Matova, D. Hohlfeld, R. Van Schaijk, R. Vullers, Vibration energy harvesting with aluminum nitride-based piezoelectric devices, in: Proceedings510 of the PowerMEMS Workshop, Sendai, 2008, pp. 249–52. [10] A. Erturk, D. J. Inman, An experimentally validated bimorph cantilever model for piezoelectric energy harvesting from base excitations, Smart Materials and Structures 18 (2) (2009) 025009. 515 [11] S. Priya, Advances in energy harvesting using low profile piezoelectric transducers, Journal of Electroceramics 19 (1) (2007) 167–184. [12] E. Iborra, J. Olivares, M. Clement, L. Vergara, A. Sanz-Hervás, J. Sangrador, Piezoelectric properties and residual stress of520 sputtered AlN thin films for MEMS applications, Sensors and Actuators A: Physical 115 (2) (2004) 501–507. Jo 410 480 ro of 395 [13] P. Wang, H. Du, S. Shen, M. Zhang, B. Liu, Deposition, characterization and optimization of zinc oxide thin film for piezoelectric cantilevers, Applied Surface Science 258 (24) (2012) 9510– 9517. [14] G. Shan, D. F. Wang, J. Song, Y. Fu, X. Yang, A springassisted adaptive bistable energy harvester for high output in low-excitation, Microsystem Technologies 24 (9) (2018) 3579– 3588. [15] T. Yildirim, M. H. Ghayesh, T. Searle, W. Li, G. Alici, A parametrically broadband nonlinear energy harvester, Journal of Energy Resources Technology 139 (3) (2017) 032001. [16] A. Ibrahim, S. Towfighian, M. I. Younis, Dynamics of transition regime in bistable vibration energy harvesters, Journal of Vibration and Acoustics 139 (5) (2017) 051008. [17] A. Ibrahim, S. Towfighian, M. Younis, Q. Su, Magnetoelastic beam with extended polymer for low frequency vibration energy harvesting, in: Smart Materials and Nondestructive Evaluation for Energy Systems 2016, Vol. 9806, International Society for Optics and Photonics, 2016, p. 98060B. [18] Y. Li, D. Yin, X. Cheng, J. Chen, A. Zhou, X. Ji, Y. Li, Vibration energy harvesting with piezoelectric ceramics working in d33 mode by using a spring-mass-spring oscillator, Journal of Applied Physics 127 (6) (2020) 064104. [19] N. Gupta, A. Ray, A. Naugarhiya, A. Gupta, Design and optimization of mems piezoelectric cantilever for vibration energy harvesting application, in: Advances in VLSI, Communication, and Signal Processing, Springer, 2020, pp. 655–662. [20] D. Zhu, M. J. Tudor, S. P. Beeby, Strategies for increasing the operating frequency range of vibration energy harvesters: a review, Measurement Science and Technology 21 (2) (2009) 022001. [21] S. Roundy, Y. Zhang, Toward self-tuning adaptive vibration based micro-generators, Proceedings of Spie–the International Society for Optical Engineering 5649 (1) (2005) 373–384. [22] M. Ferrari, M. Bau, M. Guizzetti, V. Ferrari, A single-magnet nonlinear piezoelectric converter for enhanced energy harvesting from random vibrations, Sensors and Actuators A: Physical 172 (1) (2011) 287–292. [23] M. Ferrari, V. Ferrari, M. Guizzetti, B. Andò, S. Baglio, C. Trigona, Improved energy harvesting from wideband vibrations by nonlinear piezoelectric converters, Sensors and Actuators A: Physical 162 (2) (2010) 425–431. [24] F. Cottone, H. Vocca, L. Gammaitoni, Nonlinear energy harvesting, Physical Review Letters 102 (8) (2009) 080601. [25] R. Ramlan, M. Brennan, B. Mace, I. Kovacic, Potential benefits of a non-linear sti↵ness in an energy harvesting device, Nonlinear Dynamics 59 (4) (2010) 545–558. [26] J. Kim, P. Dorin, K.-W. Wang, Vibration energy harvesting enhancement exploiting magnetically coupled bistable and linear harvesters, Smart Materials and Structures (forthcoming) (2020). URL http://iopscience.iop.org/10.1088/1361-665X/ab809a [27] J.-T. Lin, B. Lee, B. Alphenaar, The magnetic coupling of a piezoelectric cantilever for enhanced energy harvesting efficiency, Smart Materials and Structures 19 (4) (2010) 045012. [28] R. B. MacCurdy, T. Reissman, E. Garcia, Energy management of multi-component power harvesting systems, in: The 15th International Symposium on: Smart Structures and Materials & Nondestructive Evaluation and Health Monitoring, International Society for Optics and Photonics, 2008, pp. 692809– 692809. [29] P.-h. Wang, S.-w. Shi, H.-j. Du, Fabrication and performance of ZnO piezoelectric cantilever for vibration energy harvesting, in: Piezoelectricity, Acoustic Waves, and Device Applications (SPAWDA), 2015 Symposium on, IEEE, 2015, pp. 147–151. [30] S.-C. Lin, W.-J. Wu, Fabrication of PZT MEMS energy harvester based on silicon and stainless-steel substrates utilizing an aerosol deposition method, Journal of Micromechanics and Microengineering 23 (12) (2013) 125028. [31] A. Lei, E. V. Thomsen, Wideband piezomagnetoelastic vibration energy harvesting, in: Journal of Physics: Conference Se- -p 390 be obtained using realistic positions of the magnets relative to the cantilever beam, i.e. positions that can be obtained experimentally. The contour plot of the e↵ective spring constant for the attractive magnetic configuration,455 compared to the repulsive configuration, showed a larger set of magnet positions where spring softening was observed. Therefore, the attractive configuration was investigated experimentally by impedance spectroscopy. The460 experiments were performed for a 2 [400 µm, 2500 µm] and b 2 [320 µm, 3140 µm]. The results obtained were in overall agreement with the simulations and both spring softening and hardening e↵ects were observed. Compared to the465 linear case, the spring softening e↵ect led to a significant increase in the coupling coefficient, which was increased with a factor of between 1.75 to 2.69 compared to the linear case. Together with this, the largest spring softening470 e↵ect that was observed lead to a decrease in resonant frequency of 49% and a decrease in the e↵ective spring constant of 74%. The largest e↵ects are observed for b values around 3 mm and a values in the range of 400 µm to475 800 µm. 9 ro of -p 545 re 540 lP 535 ur na 530 Jo 525 ries, Vol. 557, IOP Publishing, 2014, p. 012121. [32] J. I. Tam, P. Holmes, Revisiting a magneto-elastic strange attractor, Journal of Sound and Vibration 333 (6) (2014) 1767– 1780. [33] G. Sebald, H. Kuwano, D. Guyomar, B. Ducharne, Simulation of a Duffing oscillator for broadband piezoelectric energy harvesting, Smart Materials and Structures 20 (7) (2011) 075022. [34] L. Tang, Y. Yang, C. K. Soh, Toward broadband vibrationbased energy harvesting, Journal of Intelligent Material Systems and Structures 21 (18) (2010) 1867–1897. [35] COMSOL, Inc., 100 District Avenue Burlington, MA 01803, COMSOL Multiphysics 5.2 User’s Manual (2015). URL http://www.comsol.com [36] Supermagnete, Webcraft GmbH, Industriepark 206, 78244 Gottmadingen, Germany. [link]. URL http://www.supermagnete.de [37] AnMo Electronics Corporation, Inc., 17F, No. 97, Sec. 4, ChongHsin Rd., Sanchong Dist., New Taipei City, 241 Taiwan, DinoCapture User’s Manual (2017). URL http://www.dino-lite.com [38] A. Erturk, D. Inman, Broadband piezoelectric power generation on high-energy orbits of the bistable Duffing oscillator with electromechanical coupling, Journal of Sound and Vibration 330 (10) (2011) 2339–2353. [39] A. Lei, R. Xu, L. M. Borregaard, M. Guizzetti, O. Hansen, E. V. Thomsen, Impedance based characterization of a high-coupled screen printed pzt thick film unimorph energy harvester, Journal of Microelectromechanical Systems 23 (4) (2014) 842–854. 10