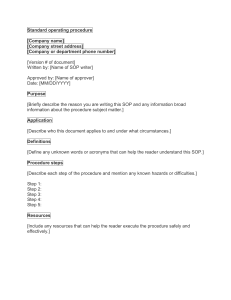

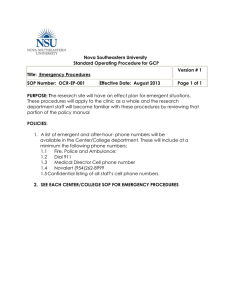

Americas HUB June, 2023 Classification: Internal Why Continuous Improvement? “Practice the philosophy of continuous improvement. Get a little bit better every single day.” Brian Tracy "We're focused on providing innovations in software, driving the continuous improvement for a much better experience, and there's a lot going on here that speaks to this decade and what's going to happen in this decade. We can kind of sum it up in terms of saying, "Yes, you can.”" Bill Gates Classification: Internal “Without continual growth and progress, such words as improvement, achievement, and success have no meaning.” Benjamin Franklin “Improve quality and you’ll automatically improve productivity” W. Edwards Deming Why Continuous Improvement? Some benefits of having CI in an organization are: • Increased efficiency and productivity • Improved employee engagement and relationships • Reduced waste • Reduced costs • Improved customer satisfaction • Reduced cycle times • Increased innovation • Fosters organizational resilience • Staying ahead of the competition! Classification: Internal Meet the Team Farheen Mahmud Head of Americas Hub José Sebastián López Continuous Improvement Lead Andrés Jaramillo Continuous Improvement Manager Classification: Internal TBH Operational Excellence Manager TBH Continuous Improvement Business Partner (Performance management, BCP ) TBH Continuous Improvement Business Partner (Performance Management, Standardization) Team Expertise Lean Management Six Sigma Project Management Agile Maersk Improvement Model DAMCO’s OPEX Classification: Internal Understanding the terms • Lean Management: • Focuses in reducing or eliminating waste from the business process, which in turn results in reduced costs in storage, transportation, and overproduction. • Six Sigma : • Focuses in achieving breakthrough profitability by reducing process variation and eliminating causes of mistakes • Agile: • Way of working in which collective input is preferred in order to deliver faster high-quality value outcomes, that improve customer satisfaction • Maersk improvement Model • Maersk’s own continuous improvement methodology, that got the best from the industry leading methodologies (such as Lean Management and Six Sigma). • DAMCO’s OPEX • Continuous improvement program used by DAMCO (with roots in lean management) that focuses on working smart to improve productivity, quality and reliability to provide a more robust service to our customers. Key components are: behavior, communication, transparency, coaching, empowerment and structure. Classification: Internal Example of a living Continuous Improvement culture Classification: Internal First steps of America’s Hub CI • Americas Hub is a new-born entity, so we will startexpected at culture and journey ahead level 1, building solid foundations for Continuous Improvement. • Focus right now is on building our organization by bringing in the right talent and setting teams up. As soon as the organization is in place, focus will be to organize (and document) our ways of work. • Once ways of work are organized, focus will shift to standardize and optimize such ways of work, leveraging from our CI toolkit =). Classification: Internal Capable Predicta ble Managed Structur ed We are here! IV. Creating capable processes * Process statistical control * Advanced analytics III. Creating stable and efficient processes * Long-term projects focused on waste and variation reduction * Process quality assessment II. Creating a Continuous Improvement Culture * Maersk Operating System * Gembas, kaizen events (quick wins) * Visual Management (KPIs / Dashboards) I. Creating a Solid Foundation * Organized work environment * Process knowledge base in place * CI Mindset (& Maersk values) establishment For the next part of this training, we will go over some CI tools that will be of use for our current stage. But first, we’ll make a little team dynamic! Classification: Internal Dynamic – “Ribbons” • Form teams of 5 to 8 persons • Each team will receive a ribbon • Each person of each team must grab by the hand to form a circle. The ribbon must be placed in the connection of two hands • The dynamic consist in making the ribbon go through the whole circle, but nobody is allowed to break the circle. If the circle is broken, the team must return the ribbon to its initial place and start all over again. • The team that manages to complete the movement of the ribbon faster wins. Classification: Internal Reflection time! Classification: Internal Role Charter Classification: Internal Meeting Guidelines Before the meeting During the meeting After the meeting •Do you even need a meeting? •Invite only the right stakeholders •Define the purpose, prepare an agenda and share these with anticipation •Assign the correct duration. (i.e., can we cover the meeting purpose in 45 mins instead of using 1 complete hour?) •Start on time and finish on time (time consciousness) •Moderate the time of each section of the agenda (designate a time-keeper?, review pending issues offline?) •Set ground rules (cellphones allowed? Email checking allowed?) •Capture agreements and actions (designate a notetaker?) •Meeting wrap-up. Confirm next steps. •Send the MOM (Minutes of the meeting). Make sure actions have a welldefined owner and a deadline •Follow up on the actions. Classification: Internal MOS MOS (Maersk Operational System), is a meeting that supports how we manage our business, in line with our strategic plans. From strategy to execution in frontline, different types of MOS are described below MOS Quarterly/Bi-annually/Anually Monthly Weekly Flow Short-term strategic planning Performance Management Execution Purpose Revisiting our targets and strategies plus cascade direction to team on changes Taking stock on plan and outlook for delivering on plan Addressing specific obstacles. Operational challenges. Direction Downstream Upstream Circular Meetings Strategy sign off RoFo targets Product strategies Functional strategies Region/Area Business Performance Area Area to Region OPR Region to CEO Cascade Functional strategies Product strategies and targets (Product Direction) Product Alignment & Enablement Global Product to Local Product Global Product Global Product to CEO Team Performance Operational status Challenges / support needed Aligning on priorities for coming week and cascade of Leadership priorities |14 Classification: Internal Process Map A process map is usually a diagram that depicts each of the steps of a process. Its purpose is to offer a simplified view of a process to help to easily explain it and also it enables its analysis to see how such process can be improved. Below you may see some basic building blocks of process maps: A GEMBA walk is one of the best alternatives to understand a process, to later document it in a process map. Some •Observe important to action remember about the points process in and ask questions that allow you to understand it, as if you were GEMBAs are: going to perform it •Engage people who are involved in the process, to make sure you get the inputs. •Define the process scope. Where it begins and where it ends. •Make sure to have a separate section in which you write the ‘process gaps’ or ‘pain points’ that are brought to the table. •Make sure to map the process as it is and not as you think it should be. (there will be time to map a TO BE process map later!) No Service call registration Classification: Internal Situation or Problem Diagnosis Resource allocation Yes Solution Execution Customer Satisfied? Case closing Process Map (Example) Classification: Internal SOP/IOP What is? It is used… How is it used? Classification: Internal • A simple visual and written description of the safest, highest quality, and most efficient way agreed to perform a particular process or task (steps). • If current processes are non standardized and operator specific • In order to set up Best Practice sharing • Use a standard template • By simplifying process flows through observing and noting the minutest possible details SOP/IOP (Guidelines to Create) 1 2 Preparation • Familiarize yourself with the process • Identify key steps and draw an SOP skeleton Develop Draft 3 • Outline process steps • Describe the main activities • Develop a draft SOP. Worth using a template Pilot and Amend 4 5 Validate Train and Share • Select relevant frontline staff and test SOP • Validate SOP through subject matter experts • SOP included in training material • Capture feedback and amend where appropriate • Road test SOP as needed • Sign-off from the manager responsible 6 Maintain • Staff updates SOPs as needed • Upload to SOP library • Share SOPs near workstations of the relevant staff Standard Points • SOP skeleton developed • Staff creates SOP • SOPs piloted and refined • SOPs thoroughly road-tested • Management signs off Classification: Internal • SOPs in library • SOPs updated continuously SOP/IOP (Example) Classification: Internal Reflection time! Classification: Internal Any Questions? Classification: Internal