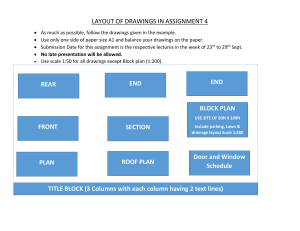

Discipline of Mechanical Engineering, UKZN Design Methods: ENME2DM, H2 Design Assignment 2023 Design of a Thin-film Blade Coater Assessment Objectives • • • • • Assess students’ ability to conduct independent learning. Assess students’ ability to plan and track a simple project Assess students’ ability to synthesize mechanical components and systems. Assess students’ ability to produce production drawings, i.e., orthographic projections, assembly drawings, exploded assemblies. Assess students’ ability to apply knowledge and theory from lectures and prior courses to a mechanical design. Design Task The aim of this project is to design a desktop thin-film blade coater actuated by a lead screw mechanism, similar to the images shown above. The design consists of a stationary flat plate upon which a thin film of liquid solution is applied using a blade mounted on a lead screw. The lead screw serves to actuate the blade to spread the solution across the flat plate. The lead screw is connected to a stepper motor. This method is often used to manufacture thin films of piezoelectric materials and capacitors. You are required to produce a complete mechanical design such that your design blueprints can be given to a general fabrication engineering workshop for manufacturing. You are allowed to select Commercial Off-The-Shelf (COTS) components to complete your design. A complete set of CAD drawings for all components must be submitted. Manufacturing drawings must be produced for all parts requiring machining. COTS components do not require manufacturing drawings but must be represented in assembly drawings (i.e., an approximate 3-D model would be suitable). The engineering specifications of COTS components must be presented, together with the supplier’s details, stock numbers and cost. Engineering management forms part of any engineering project. Included in this assignment, it is necessary to show evidence of satisfactory engineering management of your project. The required evidence is a Gantt chart showing the planned timing of your activities as well as your progress as you completed the assignment. You must include a Burndown chart of you task/work hours for your assignment. Please include these in the appropriate section. Page 1 of 6 Customer Specifications The coater must be designed to produce films of thickness of 5 μm. It can be assumed that the thickness of the film is independent of velocity (i.e. high viscosity). The design must be capable of producing a minimum film area of 210 mm x 297 mm and operate at a traverse speed 0-50 mm/s. This speed must be used to determine the required torque from the speed-torque curve of an appropriate stepper motor. The equation below indicates how linear speed can be converted to rpm. 𝑚𝑚 𝐿𝑖𝑛𝑒𝑎𝑟 𝑠𝑝𝑒𝑒𝑑 ( 𝑠 ) 𝑁 (𝑟𝑝𝑚) = × 60 𝐿𝑒𝑎𝑑 (𝑚𝑚) To simplify the design, students do not need to consider the heating of the base plate. Students may assume the control subsystem is a standalone unit connected only to the Stepper Motor. The design of the control components is not required. All stepper motors must have a step angle of 1.8°. Due consideration must be given to safety, cost, and availability of off the shelf components. Additive manufacturing techniques may not be used, e.g., 3D Printing, when designing components to be manufactured. As part of the design, students are required to verify the load that can be applied by the blade using the torque and dimensions of the lead screw. Each group has been allocated specific lead screw dimensions which must be used in the design. Details available on Learn2023. Assignment Sections Abstract – 0.5 page (Max) Introduction – 0.5 page (Max) Design Specifications – 1 page (Max) Material Selection – 0.5 page (Max) Selection of COTS components – 1 page (Max) Discussion – 1 page (Max) Conclusion – 0.5 page (Max) References – 1 page (Max) Appendix A: Project Management – 2 pages (Max) Appendix B: Calculations – 3 pages (Max) Appendix C: CAD Drawings – Unlimited Digital copies of the report are to be submitted on the Learn2023 platform. Do not exceed the length guidelines! The report and drawings need only possess sufficient information such that the complete fabrication of the thin-film blade coater can take place, i.e., purchase parts and materials, machine components and final assembly. Project Management The report must consist of the following project management evidence, placed in Appendix A: • A Gantt Chart. • A Burndown Chart. Page 2 of 6 The charts may be produced in Microsoft Excel and copied over into the report. The methods for producing these types of charts is a self-study component of course and will not be covered in lectures. Calculations All calculations must be typed using an appropriate equation editor and placed in Appendix B. Calculation results must be cross-referenced in the relevant written sections of the report. The report must consist of the following essential calculations: • Power screw calculations (torque, efficiency, bearing stress, thread shear stress, etc.). • The relevant joint fastener calculations. Additional calculations may be performed as necessary, provided that the prescribed page limit is not exceeded. Drawings The drawings must be produced according to ISO standard CAD and placed in Appendix C. A numbering system must be applied to the drawings, which will allow individual drawings to be crossreferenced in the relevant written sections of the report. COTS components do not require part drawings but must be represented in assembly drawings (i.e., an approximate 3-D model would be suitable). The following drawings must be included: • all component drawings for parts that are not commercially available such that the design can be completely fabricated in an engineering workshop; • a minimum of one exploded view drawing, either of a subassembly or the final assembly, with a bill of materials/parts table; • a minimum of one standard assembly drawing (not in exploded view), of the entire machine, with a bill of materials/parts table. Note that all part drawings are required to be in first angle orthographic projection. Design Blueprints - Acceptance Criteria • • • • • • • • All sections of the Learn template to be completed satisfactorily, otherwise reject. All calculations completed satisfactorily (min number, correctness), otherwise reject. All drawings completed satisfactorily (min number, quality), otherwise reject. All project management evidence presented satisfactorily, otherwise reject. The design blueprints will be rejected if the quality and quantity of the drawings are insufficient such that design cannot be completely manufactured with the information provided. The design blueprints will be rejected if the system cannot be reasonably manufactured using existing technologies (i.e., parts have features that are too costly or unreasonable to manufacture and assemble). The design blueprints will be rejected if the system will not function correctly. Report will receive an immediate mark of zero if no drawings are presented. Marks & ECSA Outcomes The following ECSA outcomes are assessed by means of this assignment: GA 1 (Problem solving) at developmental level GA 3 (Engineering Design) at developmental level GA 5 (Engineering methods, skills, and tools, including IT) at developmental level GA 11(Engineering Management) at developmental level This assignment will be assessed out of 100 marks and constitutes 20 % of the final course mark. Students who have obtained below 50 % or have not met all of the acceptance criteria will be required to resubmit their work. Page 3 of 6 Online Submission: The completed reports and drawings must be submitted by 11:59 PM on 18 September 2023. Reports must be uploaded in PDF format to the submission portal on Learn2023. No late or emailed submissions will be accepted under any circumstances. Reports, appendices and drawings must be consolidated into a single .pdf file. Instructions on preparation of the final pdf to follow. Murphy’s Law: Your computer will crash, the printer will stop working, your flash drive will be stolen and Learn2023 will begin to malfunction on 18 September 2023. You have sufficient time to complete this assignment, plan ahead! Groups • Exactly two members are required per group. • Ensure that you have registered your group on Learn by 12:00 on Friday 03 August 2023. • Persons who do not register their groups will be randomly allocated to a group. • Absolutely no changes to groups are allowed after 03 August 2023. Questions and Answers • Students should first perform independent learning and research to determine answers to questions. The purpose of the assignment is to encourage independent learning and research! • Assignment questions must be posted on the Learn “Questions and Answers” forum. DO NOT EMAIL questions about the assignment. Preparation of .pdf reports • Use the “save as .pdf” option in Microsoft word to save the body of the report as a .pdf file. • Most CAD packages have to option to “print to .pdf”. Use this option to generate .pdf files for each of your drawings. • If these options do not work for you, try the following free software: o http://www.dopdf.com/ o http://www.cutepdf.com/ o http://www.primopdf.com/ • The following websites provide a free service for merging .pdf documents into a single file: o http://pdfjoiner.com/ o http://combinepdf.com/ o https://www.pdfjoin.com/ • The following free software is also available for merging .pdf documents: o http://www.pdfmate.com/free-pdf-merger.html • Do not print your report/drawings and then scan to .pdf. This will prevent Turnitin from processing the document and will be seen as an effort to hide plagiarism. Referencing All references must be formatted according to IEEE style. See the following website for a short guide: http://www.ijssst.info/info/IEEE-Citation-StyleGuide.pdf. At least 5 of the references must include peer reviewed sources such as books, journals, or conference papers. Formatting Headings – As per Template Subheadings – As per Template Paragraphs – Calibri, 11-point, 1.15 line spacing, justified Tables and Table Titles – Calibri, 9 point Figures and Figure Titles – Calibri, 9 point Page Size – A4, Margins 2.54 cm on all sides Page 4 of 6 Figures The report should not contain any figures or diagrams except for the official CAD drawings and the project management charts. Student Responsibilities • It is the responsibility of the student to make sure that work is submitted as per the stated deadline. • It is the responsibility of the student to prepare questions relating to the assignment and post to the Q&A Forum. • It is the responsibility of the student to make sure that all work submitted for assessments are free of plagiarism. • It is the responsibility of the student to make sure that his/her designs are original and not created by copying YouTube tutorials or any other source. Marking Rubric Assessment Criteria Max Student Marks Mark 1. Professional and technical communication • • • • How well is the report written? Are there grammatical errors, has the student used slang or colloquial language? Is there inconsistent formatting and formatting errors? Are the references properly documented according to IEEE or Harvard standards? 10 2. Engineering Management (GA 11) • • • • • • Has the student presented a Gantt chart? Is there evidence of appropriate project planning? Is the Gantt chart realistic of the time spent on the project? Is there evidence of tracking progress as the assignment progressed? Is there a Burndown chart? 10 3. Design Specifications • • • Has the student presented a comprehensive set of design specifications? Has the student developed suitable, additional specifications over and above the basic customer specifications? Do the specifications provide sufficient information for a potential customer? 10 3. Use of Engineering Theory – Material Selection • • • • • Have appropriate materials been selected for various components? Has the material selection been supported with sufficient engineering justification? Have the selected materials been specified using the official numbers and specifiers? Have material suppliers been identified? Have materials been selected with due consideration of available and preferred stock sizes? 10 Page 5 of 6 4. Selection of COTS Components • • • • Have all necessary COTS components been selected to complete the design? Has the selection of COTS components been supported with sufficient engineering justification? Have COTS suppliers been identified? Have stock numbers, quantity and cost been presented? 10 5. Design Calculations • • 10 Have all necessary calculations been completed satisfactorily? Is there evidence that the calculations supported and informed the design decisions? 6. Drawings – Completeness of the Design • • • Is it evident that the design is complete and not missing any components for its correct functioning? Have a sufficient number of drawings been provided to completely manufacture the system? Have the minimum numbers and types of drawings been provided as per the question paper? 15 7. Drawings – Quality • • • • • • • • • • Have the drawings been done in an appropriate CAD package? Are the drawings of an acceptable standard? Do the drawings have an appropriate scale? Are the drawings complete with annotations and dimensions? Is the dimensioning logical and easily interpreted for manufacturing? Are there missing dimensions, centre lines and annotations? Do the assembly drawings contain detailed Bill of Materials/Parts? Do the drawings contain unnecessary views? Have the thread and gears been represented according to standard? Do the drawings reflect tolerances and machining symbols? 15 8. Drawings – Manufacturability & Assembly • • • • Can the parts that have been designed be manufactured with conventional technologies? Can the parts be assembled in reality to complete the system? How easily can the parts be manufactured? How easily can the parts be assembled? Total 10 100 Page 6 of 6