Process Engineering II Tutorial: Fluid Mechanics Problems

advertisement

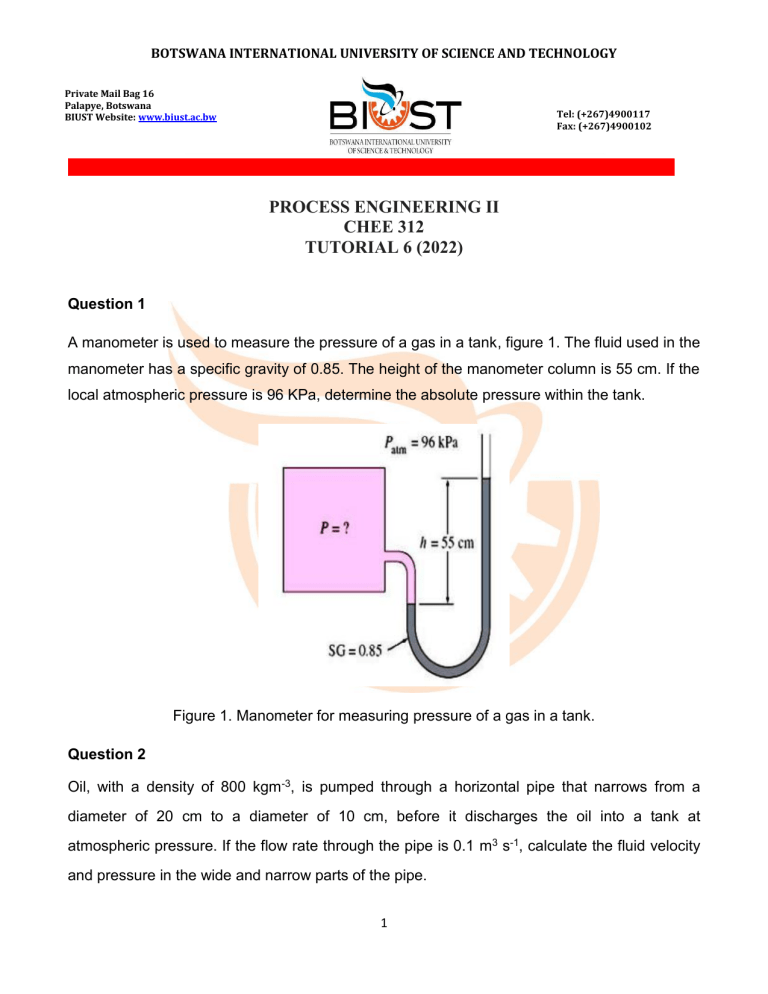

BOTSWANA INTERNATIONAL UNIVERSITY OF SCIENCE AND TECHNOLOGY Private Mail Bag 16 Palapye, Botswana BIUST Website: www.biust.ac.bw Tel: (+267)4900117 Fax: (+267)4900102 PROCESS ENGINEERING II CHEE 312 TUTORIAL 6 (2022) Question 1 A manometer is used to measure the pressure of a gas in a tank, figure 1. The fluid used in the manometer has a specific gravity of 0.85. The height of the manometer column is 55 cm. If the local atmospheric pressure is 96 KPa, determine the absolute pressure within the tank. Figure 1. Manometer for measuring pressure of a gas in a tank. Question 2 Oil, with a density of 800 kgm-3, is pumped through a horizontal pipe that narrows from a diameter of 20 cm to a diameter of 10 cm, before it discharges the oil into a tank at atmospheric pressure. If the flow rate through the pipe is 0.1 m3 s-1, calculate the fluid velocity and pressure in the wide and narrow parts of the pipe. 1 BOTSWANA INTERNATIONAL UNIVERSITY OF SCIENCE AND TECHNOLOGY Question 3 As shown in figure 2, a pipe of cross sectional area 0.01m2 and total length of 5.5m is used for siphoning water from a tank. The discharge from the siphon is 1m below the level of the water in the tank. At its highest point, the pipe rises 1.5 m above the level in the tank. Assume there is no friction in the pipe. i. Calculate the water velocity in the pipe. ii. Calculate the lowest pressure (gauge) in the pipe, and where does it occur? Figure 2. Siphon for draining a tank. Question 4 Oil is pumped into an open tank through a 800 m steel pipe with inside diameter of 500 mm. The roughness (𝜀) of the pipe is 0.0009m. The pipe contains some fittings as shown in the table 1. The pressure at A = 25 KPa (gauge) and the flow rate is 0.2 m3/s. The kinematic viscosity of the oil is 5.16 x 10-6 m2/s and its density is 861 Kg/m3. The tank is 25 m higher than the pump. Calculate the head of the pump. 2 BOTSWANA INTERNATIONAL UNIVERSITY OF SCIENCE AND TECHNOLOGY Table 1. Pipe fittings Fittings or valves Number of fittings or valves Le/D values Standard elbow 90o 4 35 Standard elbow 45o 3 16 Ball valve 5 13 Gate valve 2 25 3