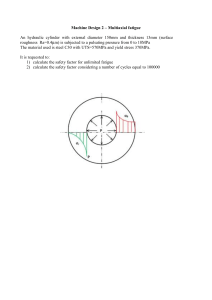

APPENDIX W HIGH CYCLE FATIGUE ASSESMENT OF PIPING SYSTEMS (Draft 3/25/09) W300 Application This appendix addresses the fatigue evaluation of B31.3 piping subjected to cyclic loadings when the total number of significant stress cycles due to all causes exceeds 100,000. A significant stress cycle is defined as a cycle with a computed stress range greater than 41.4 Mpa (6.0 ksi). The allowable displacement stress range requirements of 302, using the computed stress range in accordance with 319, provides an acceptable method of evaluating piping systems for fatigue when the number of significant stress cycles is less than 100,000. The piping cyclic loadings may be due to thermal expansion, anchor motion, vibration, inertial loads, wave motion or other sources. Fatigue due to pressure cycling is not addressed in this appendix but must be considered in design. The methodology in ASME BPV Section VIII Division 2 may be applied to address pressure cycling. The design, fabrication, examination and testing requirements of this Appendix are in addition to the requirements of Chapters I through IX. W301 Nomenclature CF = Welded Joint Fatigue Curve Coefficient, SI (US) CME = Conversion factor, = 1.0 for stress in MPa and = 6.8948 for stress in Ksi dt = Fatigue damage due to thermal stress with constant amplitude dw = Fatigue damage due to wave stress with variable amplitude E= Modulus of elasticity for the displacement cycle under consideration MPa (Ksi) Ea = Modulus of elasticity at ambient temperature MPa (Ksi) fI = Fatigue Improvement Factor from ASME BPV Section VIII Division 2 fE = Environmental Correction Factor (See Table W302.2) fMT = Material Temperature Correction Factor Γ= Gamma Function h= Weibull stress range shape distribution parameter k= fatigue strength thickness exponent Ld = Piping Cyclic Design Life (Years) Lw = Design Storm Period of Occurrence (Years) m = Welded Joint Fatigue Curve Exponent Ni = cycles for condition i q= Weibull stress range scale distribution parameter which can be expressed in terms of stress range Saw = Allowable maximum probable stress range during Nw wave cycles MPa (ksi) SEi = computed displacement stress range for condition i corresponding to cycles Ni, MPa (ksi) TE = Effective component thickness at weld joint, mm (in) _ T = component nominal thickness at weld joint, mm (in) SEW = Computed maximum stress range due to wave motion MPa (ksi) Nw = Design Storm Wave height associated cycles Nd = Design number of pipe stress cycles Ni = number of cycles for loading condition, i. Nti = allowable number of cycles for loading condition, i. Vo = average zero-crossing frequency (hz) W302 Design for Fatigue The fatigue design procedure in this appendix addresses two types of cyclic loading: Fatigue loading where the loading spectrum may be reduced to a series of stress range – cycle pairs and fatigue loading where the loading spectrum may be represented by a two parameter Weibull distribution. Fatigue damage is the summation based on the linear damage rule. The fatigue design analysis methodology in this appendix is based on the following general requirements: a) In the absence of more directly applicable data the stress intensification factors shown in Appendix D for elbows, bends and B16.9 tees may be used. The stress intensification factors for other components are the responsibility of the designer and their validity documented in the engineering design. b) Integral construction is recommended. Fabricated components such as unreinforced branch connections, pad reinforced branch connections, and miter elbows are not recommended. c) The maximum stress range from all sources of loadings shall not exceed the displacement stress range requirements of 302.3.5 with f = 1.0. d) The maximum longitudinal stress due to pressure, weight and inertial forces due to wave loading shall meet the requirements of 302.3.6. W302.1 Fatigue damage due to Cyclic Stress Range from other than Wave Motion The maximum stress range SE shall be computed in accordance with 319 and meet the allowable displacement stress range requirements of 302.3.5 with f=1.0. The stress range – cycle pairs (SEi, Ni) shall be established from a stress – cycle histogram by the Rainflow method of ASME BPV Section VIII Division 2 Annex 5.B. Fatigue damage shall be computed as follows. Allowable Fatigue Cycles for load case i: f Nti = I fE f MT CF S T k Ei E m (W-1) Where, E Ea fI = 1.0 unless otherwise documented in the engineering design. fMT = _ for T ≤ 16 mm (0.625 in.) TE = T for 16 mm (0.625 in.) < T < 150 mm (6 in.) TE = 150 mm (6 in.) for T ≥ 150 mm (6 in.) TE = 16 mm (0.625 in.) _ _ _ Fatigue Damage due to Displacement Loadings: dt := Ni N ti Where dt must be less than 1.0. (W-2) Table W302.1 Fatigue Material Coefficients CF (SI) (US) m Ferritic and Stainless 14137 (999.1) 3.13 Steels Aluminum 2303 (162.8) 3.61 SI units include SEi (MPa) and TE (mm) in equation W-1 US units include SEi (Ksi) and TE (in) in equation W-1 k .222 .222 In the absence of more directly applicable data the values of fE, for the affect of the environment on the fatigue life of carbon steel piping at temperatures less than 200F, provided in Table W302.2 may be used. The values of fE for other materials shall be specified and the basis documented in the engineering design. Table W302.2Environmental Fatigue Factors for Carbon Steel Piping, T≤200F Environment fE Air 1.0 Seawater with Cathodic Protection 2.51 Seawater with free corrosion 3.0 W302.2 Fatigue damage due to Cyclic Stress Range from Wave Motion This paragraph addresses variable amplitude random loadings where the long term stress range distribution may be represented by a two-parameter Weibull distribution. The specific requirements are written for wave loadings for applications such as floating offshore platforms, however the methodology may be applied to other applications where the Weibull distribution applies. When designing for wave motion the design sea state shall be specified by the owner. The sea state shall be characterized by a two parameter wave-scatter diagram of significant wave height and zero upcrossing period. The stress range is assumed proportional to wave height and the Weibull stress range shape distribution parameter and average zero crossing frequency determined from the data. The long term stress range distribution may be represented by a two-parameter Weibull distribution as follows: S F: = exp( - EW q q: = S aw In ( N w ) 1 h h ) (W-3) (W-4) Where, F = probability for exceeding the stress range SEW exp(x) = ex The design fatigue curve is represented by a single equation of the form given by eq. (W-1): Allowable Fatigue Damage for variable Wave Loadings: dw = 1-dt (W-5) Design Storm Wave height associated cycles: Nw = 33.54·106·VoLw (W-6) Design number of pipe stress cycles Nd = 33.54·106·VoLd (W-7) The maximum probable stress range shall be determined from the maximum probable wave height based on a two parameter Weibull model. The maximum probable wave height (or maximum probable stress range) will be exceeded on the average once every Nw design wave cycles. Allowable maximum probable stress range during Nw wave cycles: 1 1 Saw = C ME 1 d w a m In( N w ) h 1 N d (1 mh ) m (W-8) Where, f a= I fE f CF MT k T E m (W-9) The computed maximum stress range, SEW is assumed to be proportional to the maximum probable wave height (trough to peak). The stress range shall be computed in accordance with 319 from the imposed displacements created by the maximum probable wave height and shall not exceed the allowable maximum probable stress range, Saw. W302.2.1 Design Parameters This Appendix does not prescribe specific values for h, Vo, Lw, or Ld. These design parameters shall be specified by the owner and/or regulatory authority as applicable. The values for h and Vo are determined by statistical data based on the specific Sea Environment. The design life of the piping, Ld, and the design maximum probable wave height based on the design storm period of occurrence, Lw, shall be based on the intended life of the piping and acceptable risk. In the absence of more applicable data for the specific Sea site the following typical values may be used. h = 1.0 V0 = .159 Hz LD = 20 years Lw, = 100 years. W302.3 Alternative Analysis Methods The fatigue analysis method presented in W302.2 is based on a two parameter weibull model for a design fatigue curve with a single linear slope on a log-log stress-cycles plot and a single sea state. With the owner’s approval, the designer may apply more applicable data or more rigorous analysis method for fatigue of piping. The applicable parameters (eg. CF, m, etc.) for materials other than the materials covered in Table W302.1 shall be as specified in the engineering design. The fatigue analysis methodology of ASME BPV Section VIII Division 2 may be used for piping as an alternative to the methodology of this Appendix. W305 Fluid Service Requirements If SE > .8 Sa or SEW > .8 Saw the requirements for severe cyclic service in Chapters I through IX apply, in addition to the requirements of this Appendix, except that pipe designed in accordance with this Appendix shall meet the requirements of 305.2.3 and lap joint flanges are not permitted. W323 Materials The impact test exemptions of Fig. 323.2.2B are not permitted. W328 Fabrication All circumferential girth welds in piping greater than 1 1/2 NPS shall be full penetration _ butt welds. If the offset at the circumferential butt weld exceeds the lesser of .1 T or 1/8 in (3mm) an additional stress concentration factor shall be applied. W341 Examination All longitudinal welds shall be full penetration butt welds and subjected to 100% radiography per para. 344.5.1 and Table 341.3.2. The extent of radiographic examination of circumferential butt welds shall be as follows: 1. ASME Class 150 through Class 600: 10% of the welds shall be subjected 100% radiography and 20% of the welds shall be subjected to Liquid Penetrant (LP) or Magnetic Particle (MP) examination. 2. ASME Class 900 through Class 1500: 20% of the welds shall be subjected 100% radiography and 100% LP or MP 3. ASME Class 2500 through API 10K: 100% radiography and 100% LP or MP 4. The requirements of W305 apply when applicable. In addition to the above requirements, 100% radiographic examination is required for the following conditions, regardless of pressure rating: 1. All circumferential butt welds, in other than Category D Fluid Service, made in the field. 2. All circumferential butt welds within 10 meters from personnel accommodations. 3. All circumferential butt welds requiring Post Weld Heat Treatment. 4. All circumferential butt welds, in other than Category D Fluid Service, not accessible for in service inspection and examination. W341 Pressure Testing Pressure testing of the system shall be in accordance with the requirements of para. 347 except the test duration for hydrostatic testing, which shall be a minimum of one hour after the test pressure has been adequately stabilized. BACKGROUND High cycle fatigue evaluation of offshore piping systems has been performed by the DNV methodology. The stress – cycle S-N curve for welded construction used in the DNV method has a slope of – 1/3 and agrees with approaches used in Europe. The slope of the welded component fatigue curve also agrees with the Structural Stress Approach in paragraph 5.5.5 of the 2007 Edition of the ASME BPV Code Section VIII Division 2. However the Markl correlation used by the B31 Codes has a slope of – 1/5 and may be non-conservative relative to the other approaches at high cycles. The problem is to bring high cycle fatigue into B31.3, recognizing the long successful history of the Markl approach for displacement stress analysis. The stress intensification factors in Appendix D were also determined using Markl. Comparing fatigue curves shows that the Markl correlation is conservative at low cycles, where the typical piping system operates. The approach used in this appendix is to defer to the traditional B31.3 approach for the conventional displacement stress analysis and the Structural Stress approach for high cycle fatigue. The coefficients and factors agree with the Div. 2 Structural Stress approach based on the following definition of terms: CF = I1/mss C I1/mss = 1.221 (If the stress range is all membrane, Rb,k = 0, the most conservative assumption. If it is all bending, Rb,k = 1 and I1/mss = 1.3308) m = 1/h Using the -3σ correlation for coefficient C C (SI) (US) 11578 (818.3) Ferritic and Stainless Steels Aluminum 1886 (133.3) SI units include SEi (MPa) and TE (mm) US units include SEi (Ksi) and TE (in) CF (SI) (US) 14137 (999.1) 2303 (162.8) The environmental factors, fE, are based on the DNV document. The 100,000 cycle limit for the base code was based on discussion on the Paulin Research report at the spring 2008 B31 MDC meeting. The concerns with the base code are the construction details allowed and the known inaccuracies in the SIF’s. A comparison of C.S. design curves DNV F3, Div. 2 Structural Stress (-3σ), and B31.3 for two assumptions on SL using SH = SC = 20 Ksi is shown in the figure below. Design Curves: Div 2 Structural Stress, DNV, B31.3 Air Data, t = 32mm (1.26") Stress Amplitude (ksi) 1000 100 Div 2 Str Stress DNV F3 B31.3 SL=0 B31.3 SL=.5SH 10 1 1.00E+02 1.00E+03 1.00E+04 1.00E+05 1.00E+06 Cycles, N 1.00E+07 1.00E+08 1.00E+09 1.00E+10