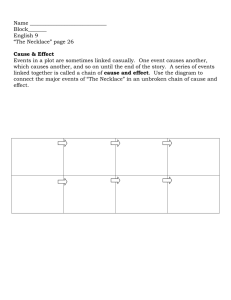

Thermal Processing/Heat Treatment of Steel Lecture 9 Heat Treatment Fundamentals It is an operation or combination of operations involving heating a metal or alloy in its solid state to a certain temperature holding it there for some times, and cooling it to the room temperature at a predetermined rate to obtain desired properties. All basic heat-treating processes for steels involve the transformation of austenite. the nature and appearance of these transformation products determine the physical and mechanical properties of heat treated steels. 2 Humayun Kabir, Dept of MME, BUET Heating Period Holding Heating steel to above critical temperature range (A3 or Acm) in order to form single-phase austenite. Rate of heating is usually less important than other factors, except for [1] highly stressed materials, or [2] thick-sectioned materials. Temperature Usually slow heating rate is preferable. 3 Humayun Kabir, Dept of MME, BUET Time Holding / Soaking Period Holding Holding at the austenitizing temperature for complete homogenization of structure. Usually 1 hour per inch section is enough for holding. Temperature Time 4 Humayun Kabir, Dept of MME, BUET Cooling Period Cooling rate determines the nature of transformation products of austenite. Depending on cooling rate, common heat treatment of steels are classified as: [1] annealing [2] normalizing [3] hardening 5 Humayun Kabir, Dept of MME, BUET Annealing of Steels Annealing is a heat treatment process that consists of heating to and holding at a suitable temperature followed by cooling slowly through the transformation range preferably in the furnace, primarily for the softening of metallic materials. Generally, in plain carbon steels, full annealing (commonly known as annealing) produces ferrite-pearlite structures. Purposes of annealing: 6 May be to refine grain Inducing ductility, toughness, softness Relieve residual stresses Improving electrical and magnetic properties In some cases to improving machinability Humayun Kabir, Dept of MME, BUET 1.Full Annealing Heating and holding steels to austenitizing temperature, and then cooling very slowly through the transformation range preferably in the furnace. Improves ductility utilized in low- and medium-carbon steels that will be machined or will experience extensive plastic deformation during a forming operation. 7 Humayun Kabir, Dept of MME, BUET 2.Stress Relief Annealing Heating and holding steels to below lower critical temperature, and then cooling to room temperature (sub-critical annealing). Relieve residual stresses due to heavy machining/grinding or other coldworking processes, non-uniform cooling (during weld/casting), and phase transformations. Distortion and warpage may result if these residual stresses are not removed. 8 Humayun Kabir, Dept of MME, BUET 3.Process Annealing Similar to stress relief annealing. Process annealing is a heat treatment that is used to negate the effects of cold work. i.e; to soften and increase the ductility of a previously strain-hardened metal. It is commonly utilized during fabrication procedures that require extensive plastic deformation, to allow a continuation of deformation without fracture or excessive energy consumption. Structure refined by a process of recovery and recrystallization. Ordinarily a fine-grained microstructure is desired Designed to restore ductility of steels between processing steps and facilitate further cold working. 9 Humayun Kabir, Dept of MME, BUET 4.Spheroidizing Annealing Make very soft steels for good machining (for hypereutectoid steels). Prolonged heating breaks pearlite and cementite network and spheroids of cementite in ferrite matrix forms. Both sub-critical and inter-critical annealing practices are used. 10 Prolonged heating at a temp. just below the lower critical temp. Heating and cooling alternately between temperatures that are just above and just below the lower critical line. Heating to a temperature above the lower critical line and then either cooling very slowly in the furnace or holding at a temperature just below the lower critical line. Humayun Kabir, Dept of MME, BUET 4.Spheroidizing Annealing The spheroidized structure is desirable when minimum hardness, maximum ductility or maximum machinability is important. Low carbon steels are seldom spheroidized for machining because in the spheroidized condition they are excessively soft and gummy. The cutting tool will tend to push the material rather than cut it. 11 Humayun Kabir, Dept of MME, BUET Temperature Range 12 Humayun Kabir, Dept of MME, BUET Annealing of Hypoeutectoid Steels Since cooling is very slow, annealing comes closest to follow the iron – iron carbide equilibrium diagram AUSTENITE austenite 910C (c) A3 FERRITE + AUSTENITE Temperature (b) ferrite pearlite 723 C A1 0.80 Pearlite Austenite FERRITE + PEARLITE (a) 13 0.2 wt.% C Humayun Kabir, Dept of MME, BUET (d) Annealing of Hyper-eutectoid Steels Refinement of the grain size of hypereutectoid steel will occur about 30°C (50°F) above the lower-critical-temperature (A1) line. Heating above this temperature will coarsen the austenitic grains, which, on cooling, will transform to large pearlitic areas. The microstructure of annealed hypereutectoid steel will consist of coarse lamellar pearlite areas surrounded by a network of proeutectoid cementite. Because this excess cementite network is brittle and tends to be a plane of weakness, annealing should never be a final heat treatment for hypereutectoid steels. The presence of a thick, hard, grain boundary will also result in poor 14 Humayun Kabir, Dept of MME, BUET machinability. A careful estimation of the proportions of pearlite and/or ferrite present in an annealed steel can be used to determine the approximate carbon content of the steel: Wt.% C = (0.80) x (%Pearlite area) + (0.008) x (%Ferrite area) Wt.% C = (0.80) x (%Pearlite area) + (6.67) x (%Cementite area) An approximate tensile strength of a hypoeutectoid steel can also be determined in a similar manner: Approx. Tensile Strength, psi = (120,000) x (%Pearlite area) + (40,000) x (%Ferrite area) Tensile strength of hypereutectoid steels can not be estimated similarly, since their strengths are determined by the cementite network only. Humayun Kabir, Dept of MME, BUET Problem Microstructure of an annealed steel sample is found to contain 25% ferrite area and 75% pearlite area. Identify the steel and determine its approximate tensile strength. Wt.% C in steel = (0.8) 0.75 + (0.008) 0.25 = 0.602 % Since the carbon content is less than 0.80, the eutectoid composition, the sample is a hypoeutectoid steel. Approx. Tensile Strength = (120,000) 0.75 + (40,000) 0.25 psi = 100,000 psi Humayun Kabir, Dept of MME, BUET Thermal Processing/Heat Treatment of Steel Lecture 10 Normalizing is done by heating the steel approximately 55°C above the upper critical (A3 and Acm), followed by cooling to room temperature in still air. The main purpose of normalizing heat treatment is to produce harder and stronger steel than full annealing. Other Purposes of normalizing Modifying and refining cast dendritic structure Refining grains and homogenising the structure Inducing toughness Improving machinability Humayun Kabir, Dept of MME, BUET Temperature Range 3 Humayun Kabir, Dept of MME, BUET Normalizing produces a more harder and stronger steel than full annealing (due to a faster cooling rate). ❑ Thus, normalizing is often used as a final heat treatment (whereas annealing cannot!!). The initial cementite network is required to be dissolved completely into austenite. ❑ For this reason, both hypo- and hypereutectoid steels are always heated to complete austenite region. Humayun Kabir, Dept of MME, BUET Effect of Faster Cooling Rate Cooling rate is no longer under equilibrium conditions Iron – iron carbide phase cannot be used to predict the proportions of pearlite and proeutectoid constituents (ferrite or cementite) Approximate carbon content cannot be determined knowing the proportions of pearlite and proeutectoid constituents (ferrite or cementite) There is less time for the formation of proeutectoid constituents There will be less ferrite/cementite and more pearlite Reduces the continuity of cementite network Sometimes, formation of proeutectoid constituents is suppressed altogether Hypereutectoid steels show increased strength (due to lesser cementite) Humayun Kabir, Dept of MME, BUET Effect of Faster Cooling Rate Austenite transformation condition is changed The austenite transformation temperature is decreased; the faster the cooling rate, the lower the temperature of austenite transformation The eutectoid point is shifted towards lower C content for hypoeutectoid steels and towards higher C content for hypereutectoid steels Cementite Ferrite Fineness of pearlite is increased(Fine-grained pearlitic steels are tougher than coarse-grained ones) The soft ferrite is held close by the hard cementite plates Stiffness of ferrite is increased (so it will not yield as easily) Thus, the hardness is increased ANNEALED coarse lamellar pearlite NORMALISED medium lamellar pearlite To conclude, normalising produces a finer and more abundant pearlite structure than is obtained by annealing, which results in a harder and stronger steel Humayun Kabir, Dept of MME, BUET Effect of carbon and heat treatment on properties of plaincarbon steels Under slow or moderate cooling rates ❑ ❑ C atoms are able to diffuse out of the austenite structure The iron atoms then moves slightly to become b.c.c (body centered cubic) This gamma to alpha transformation is a diffusion controlled process, which requires slow cooling Growth Nucleation & (Time Dependent) With a still further increase in cooling rate: ❑ ❑ ❑ Insufficient time is allowed for C atoms to diffuse out of austenite solution C atoms remained trapped inside austenite The structure cannot become b.c.c. (Austenite cannot transforms into ferrite). # The resultant structure is called Martensite. Humayun Kabir, Dept of MME, BUET Hardening is done by heating the steel approximately to ❑ 50 C above the upper critical temperatures (A3 line) (for hypeutectoid steels). ❑ 50 C above the lower critical temperatures (A3,1 line) (for hypereutectoid steels) followed by drastic cooling to room temperature. Purposes of hardening: to improve hardness to improve wear resistance Humayun Kabir, Dept of MME, BUET What happens during hardening? If cooling rate is very fast (as in during water quenching): ❑ austenite cannot transforms into ferrite due to insufficient time is given for C atoms to diffuse out of austenite. ❑ most of the C atoms remain trapped in austenite to distort the structure; (Although some movement of iron atoms takes place). The c-axis becomes elongated and the cubic structure is transformed into a tetragonal structure. ❑ a supersaturated solid solution of C atoms trapped in a body-centred tetragonal (BCT) structure is formed. ❑ this structure is called MARTENSITE. Humayun Kabir, Dept of MME, BUET What happens during hardening? Structure of martensite (BCT) where the vertical axis is slightly expanded because of the trapped carbon atoms Humayun Kabir, Dept of MME, BUET What happens during hardening? The highly distorted lattice structure is the prime reason for the high hardness of martensite . The basic aim of most hardening operations is to obtain 100% full martensitic structure. The minimum cooling rate that is required to produce a full martensitic structure(avoid the formation of any of the softer products of transformation) is called the critical cooling rate (CCR). Since atoms of martensite (BCT) are less densely packed than in austenite (FCC), an expansion occurs during this transformation. Humayun Kabir, Dept of MME, BUET What happens during hardening? This expansion during the formation of martensite produces high localized stresses which result in plastic deformation of the matrix. After drastic cooling (quenching), Martensite appears microscopically as needle or acicular structure, sometimes described as a pile of straw. In most steels, the martensitic structure appears vague and unresolvable. In high-carbon alloys where the background is retained austenite, the acicular structure of martensite is more clearly defined. Humayun Kabir, Dept of MME, BUET What does martensite look like? Martensite needles (black) in retained austenite (white background) Humayun Kabir, Dept of MME, BUET Characteristics of martensitic transformation Diffusionless (time independent) transformation. ❑ Small volume of austenite suddenly changes its crystal structure into martensite by a combination of two shearing actions; No change in chemical composition. (athermal transformation, not isothermal transformation!!) ❑ Transformation depends upon the decrease in temperature; start at MS temperature, ends at MF temperature. Temperature Transformation proceeds only during cooling ❑ The amount of martensite formed with decreasing temperature is not linear. Humayun Kabir, Dept of MME, BUET MS MF Per cent Martensite Characteristics of martensitic transformation The start of martensite transformation cannot be suppressed. ❑ MS or MF temperature cannot be changed by changing cooling rate. ❑ MS temperature is a function of composition only. ❑ Martensite transformation never completes; there is always some retained austenite in the structure. Ms(°F)= 1000-(650 x %C) - (70 x %Mn) - (35 x %Ni) - (70 x %Cr) - (50 x %Mo) Humayun Kabir, Dept of MME, BUET Characteristics of martensitic transformation Martensite is a metastable structure. ❑ It will change into a stable ferrite (BCC), if given the opportunity. Need sufficient carbon to obtain extreme hardness. ❑ The max. hardness obtainable from a steel depends on the C content only. ❑ 60 Rockwell C @ 0.4%C and then start to level off ❑ ❑ 65 Rockwell C @ 0.8 %C. The leveling off is due to the greater tendency to retain asutenite in high carbon steels . Humayun Kabir, Dept of MME, BUET Thermal Processing/Heat Treatment of Steel Lecture 11 Formation of a full martensitic structure is desirable in order to have the maximum hardness. But we can’t always produce martensite throughout an entire part. ➢ The part geometry, ➢ alloy content/composition and influence the formation of martensite. ➢ quenching medium Hardenability is a term that is used to describe the ability of an alloy to be hardened by the formation of martensite as a result of a given heat treatment i.e; the ability of steel to form a full martensitic structure throughout the part is called hardenability. (Not to be confused with hardness!!) Humayun Kabir, Dept of MME, BUET Hardenability of Steels Hardenability is not “hardness,” which is the resistance to indentation; Rather, hardenability is a qualitative measure of the rate at which hardness drops off with distance into the interior of a specimen as a result of diminished martensite content. A steel alloy that has a high hardenability is one that hardens, or forms martensite, not only at the surface but to a large degree throughout the entire interior. The most widely used methods of determining hardenability is the end quench hardenability test or the Jominy test. 3 Humayun Kabir, Dept of MME, BUET Hardenability of Steels The Jominy End- Quench Test: ❖ With this procedure, except for alloy composition, all factors that may influence the depth to which a piece hardens (i.e., specimen size and shape, and quenching treatment) are maintained constant. ❖ A cylindrical specimen 25.4 mm (1.0 in.) in diameter and 100 mm (4 in.) long is austenitized at a prescribed temperature for a prescribed time. ❖ After removal from the furnace, it is quickly mounted in a fixture as diagrammed in Figure 11.11a. ❖ The lower end is quenched by a jet of water of specified flow rate and temperature. Thus, the cooling rate is a maximum at the quenched end and diminishes with position from this point along the length of the specimen. 4 Humayun Kabir, Dept of MME, BUET Hardenability of Steels 5 Humayun Kabir, Dept of MME, BUET Hardenability of Steels The Jominy End- Quench Test: ❖ After the piece has cooled to room temperature, shallow flats 0.4 mm (0.015 in.) deep are ground along the specimen length and Rockwell hardness measurements are made for the first 50 mm (2 in.) along each flat (Figure 11.11b); ❖ for the first 12.8 mm hardness readings are taken at 1.6-mm intervals, and for the remaining 38.4 mm, every 3.2 mm. A hardenability curve is produced when hardness is plotted as a function of position from the quenched end. 6 Humayun Kabir, Dept of MME, BUET Hardenability Curve ❖ The quenched end is cooled most rapidly and exhibits the maximum hardness; 100% martensite is the product at this position for most steels. ❖ Cooling rate decreases with distance from the quenched end, and the hardness also decreases. ❖ Thus, a steel that is highly hardenable will retain large hardness values for relatively long distances; a steel with low hardenability will not. ❖ With diminishing cooling rate, more time is allowed for carbon diffusion and the formation of a greater proportion of the softer pearlite, which may be mixed with martensite and bainite. 7 Humayun Kabir, Dept of MME, BUET Hardenability Curve 8 Humayun Kabir, Dept of MME, BUET Quenching medium Severity of cooling medium influences the cooling rate. Air slow cooling rate low hardness Oil moderate cooling rate moderate hardness Water fast cooling rate high hardness Part geometry Thicker the sample, more variation in the cooling rate between the centre and surface of the sample. Centre slow cooling rate low hardness Surface faster cooling rate high hardness Alloy Content Addition of alloying elements slows down the diffusion process, thereby making it easier for the steel to form martensite. Humayun Kabir, Dept of MME, BUET In the as-quenched condition, martensite, in addition to being very hard, is too brittle for most applications. The formation of martensite also leaves high residual stresses in the steel. any internal stresses that may have been introduced during quenching have also a weakening effect. Toughness (ft-lb) Hardness (RC) 100 80 Hardness 60 40 20 0 0 200 400 600 800 Tempering Temperature (C) Tempering is done almost immediately after hardening to relieve residual stresses and to improve ductility and toughness. The increase in ductility is attained at the sacrifice of some hardness or strength. Humayun Kabir, Dept of MME, BUET In tempering, the hardened steel is heated and held to a temperature (which is below the lower critical) for a specified time period, and then cooled to room temperature. The selection of heating temperature depends upon desired properties. Normally, tempering is carried out at temperatures between 250 and 650°C (480 and 1200°F); internal stresses, however, may be relieved at temperatures as low as 200°C (390°F). This tempering heat treatment allows, by diffusional processes, the formation of tempered martensite, according to the reaction martensite (BCT, single phase) tempered martensite (α + Fe3C phases ) where the single-phase BCT martensite, which is supersaturated with carbon, transforms to the tempered martensite, composed of the stable ferrite and cementite phases. Humayun Kabir, Dept of MME, BUET What happens during tempering? During tempering, the excess carbon atoms, trapped in martensite, gradually come out as extremely fine cementite particles and the metastable BCT martensite transforms into stable BCC ferrite. The resulting microstructure of tempered martensite consists of extremely small and uniformly dispersed cementite particles embedded within a continuous ferrite matrix. Humayun Kabir, Dept of MME, BUET In general, over the broad range of tempering temperatures, hardness decreases and toughness increases as the tempering temperature is increased. This is true if toughness is measured by reduction of area in a tensile test. However, this is not entirely true if the notched bar such as Izod or Charpy impact test is used as a measure of toughness. Most steels actually show a decrease in notched-bar toughness when tempered between 400°F and 800 °F, even though the piece at the same time loses hardness and strength. The reason for this decrease in toughness is not fully understood. Humayun Kabir, Dept of MME, BUET Humayun Kabir, Dept of MME, BUET The tempering range of 400 to 800°F is a dividing line between applications that require high hardness and those requiring high toughness. If the principal desired property is hardness or wear resistance, the part is tempered below 400° F If the primary requirement is toughness, the part is tempered above 800°F Humayun Kabir, Dept of MME, BUET Humayun Kabir, Dept of MME, BUET Surface Hardening of Steel Lecture 12 Numerous industrial applications require a hard, wear-resisting surface (called the case), and a relatively soft, tough inside (called the core). Examples: roll, camshaft, gears, etc. Such a combination of properties of the same sample is impossible in any ordinary HT method (such as annealing/normalizing/hardening). Consequently, several special heat treatment processes have been developed, called surface heat treatment or case hardening. 1. 2. 3. 4. 5. Carburizing Nitriding Cyaniding and carbonitriding Flame hardening Induction hardening Transmission Gears/Shafts Humayun Kabir, Dept of MME, BUET In this method, the carbon content of the surface of the steel is increased. Since the objective of case hardening is to produce a hard case and a tough core, the first consideration is to select steel capable of producing a tough core. Thus, the steel should have low carbon (less than ~ 0.20%) content (unable to produce martensite). When the carbon content of the surface is raised, it becomes hardenable during subsequent heat treatment. 3 Humayun Kabir, Dept of MME, BUET During carburizing, steel is heated to an austenitizing temperature (usually about 925°C/1700°F) Presence of suitable carbon medium, where C diffuses into the steel surface Therefore, a surface layer of high carbon (about 1.2% C) is built up. Since the core is of low carbon content, the carbon atoms trying to reach equilibrium will begin to diffuse inward. After diffusion has taken place for the required time, depending on the desired case depth, the sample is removed from the furnace and cooled. 4 Humayun Kabir, Dept of MME, BUET If the part is furnace cooled and examined microscopically, the carbon gradient will be visible in the gradual change of the structure. Core direction from the Surface Surface Fig. 1: Structure of 0.2% carbon steel pack carburized at 925 C for 6 h and furnace cooled. 5 Humayun Kabir, Dept of MME, BUET In carburizing, low-carbon steel is placed in an atmosphere that contains substantial amounts of carbon monoxide. Hence, the following reaction takes placeFe + 2CO = Fe(C) +CO2 The carburization reaction is reversible and proceeds to the left, removing carbon from the surface layer. Thus, in the presence of CO2 gas in the atmosphere, the removal of carbon, known as decarburization, occurs. Fig. 2: Decarburized ferrite layer on the surface of a high-carbon annealed steel. 6 Humayun Kabir, Dept of MME, BUET Other decarburization reactions are Fe (C) + H2O = Fe + CO + H2 Fe (C) + O2 = Fe + CO2 As a result, the surface will be depleted in carbon and will not transform into martensite on subsequent hardening. Decarburization can be prevented by using a suitable endothermic gas mixture (about 40% N2, 40% H2, and 20% CO prepared by reacting hydrocarbon gas with air) to protect the surface of the steel from oxygen, carbon dioxide, and water vapor. 7 Humayun Kabir, Dept of MME, BUET Pack carburizing (using solid carburizing materials) Parts are packed in a closed container (Heat resistant) with a mixture of hard coke/charcoal and barium/sodium/calcium carbonate (used as an energizer). Carbon cannot diffuse into steel directly. It reacts with oxygen first to form CO, then reacts with steel. Mixtures in the form of coarse particles or lumps are used so that sufficient air is trapped to form CO after sealing the container. A typical reaction is: BaCO3 = BaO + CO2 ; CaCO3 = CaO + CO2 Na2CO3 = NaO + CO2 ; CO2 + C = CO Fe + 2CO Fe (C) + CO2. ; The commercial carburizing compound consists of hardwood charcoal, coke, and about 20 percent of barium carbonate as an energizer. 8 Humayun Kabir, Dept of MME, BUET Gas carburizing (using suitable hydrocarbon gases). Parts heated in methane, propane, natural gas, or vaporized fluid hydrocarbon atmosphere, along with a carrier gas.Typical reaction: CH4 + Fe Fe(C) + H2 CH4 = Catomic + H2 Catomic +Fe Fe(C) + H2 CO2 + C = CO Fe + 2CO Fe (C) + CO2 Liquid carburizing (using fused baths of carburizing salts). Parts are placed in a bath of fused salts containing sodium cyanide and alkaline earth salts (also known as a bath of molten cyanide). Salts react with cyanide to form alkaline earth metal cyanide, which reacts with iron.Typical reactions: 2 NaCN + BaCl2 =2 NaCl + Ba(CN)2 Ba(CN)2 + Fe Fe(C) + BaCN2. 9 Humayun Kabir, Dept of MME, BUET The heat treatment of carburized steel is complex because of the variation of carbon content that occurs in one piece of steel. If steel is cooled slowly after carburizing from the carburized temperature, the surface hardness will be low since the structure will effectively be that of annealed high-carbon steel, Fig.1. Since steel is carburized in the austenite region, direct quenching from the carburized temperature will harden the case and core if the cooling rate exceeds Critical Cooling Rate (CCR). Direct quenching of coarse-grained steels often leads to brittleness and distortion, so this treatment should only be applied to fine-grained steels. 10 Humayun Kabir, Dept of MME, BUET The heat treatment given to carburized steel depends on (1) the carburizing temperature used, (2) the composition of the core and case, and (3) the purpose for which the part is intended or the properties that must be obtained to meet the specifications. When a carburized part is hardened, the case will appear as a light martensite zone followed by a darker transition zone. The effective case (or hard case) is measured from the outer edge to the middle of the dark zone. From the nature of the carbon gradient, the hard case contains a portion above 0.40 percent carbon and approximately equal to two-thirds of the total case. The distance from the surface to the point where hardness level HRC 50 or a carbon content of about 0.4 weight percent. 11 Humayun Kabir, Dept of MME, BUET Cases containing carbon and nitrogen are produced in liquid salt baths (cyaniding) or by the use of gas atmosphere (carbo-nitriding). N imparts inherent hardness by forming hard nitride compounds, and increased C content makes the steel surface hardenable during quenching. Cyaniding is closely related to carburizing. Liquid carburizing may be distinguished from cyaniding by the character and composition of the case produced. The cyanide case is higher in nitrogen and lower in carbon; the reverse is true of liquid carburized cases. The heating temperature is about 760 – 875 °C (1400-1600˚F), generally lower than that used in carburizing. Exposure time is shorter, resulting in thinner cases (up to 0.01 inch for cyaniding and up to 0.03 inch for carbo-nitriding). 12 Humayun Kabir, Dept of MME, BUET The case usually contains about 0.5 – 0.8 % C (carbon content is lower than that produced by carburizing) and 0.5 % N. The proportion of nitrogen and carbon in the case produced by a cyanide bath depends on the bath’s composition and temperature (prominent). Typical bath composition is: 30% sodium cyanide, 40% sodium carbonate, and 30% sodium chloride. General reactions to take place: 2NaCN + 2O2 = Na2CO3 + CO + 2N 2CO = CO2 + C 2NaCN + O2 = 2NaCNO NaCN + CO2 = NaCNO + CO 3NaCNO = NaCN + Na2CO3 + C + 2N 13 Humayun Kabir, Dept of MME, BUET Carbonitriding is a modification of gas carburizing Adding anhydrous ammonia gas to the furnace atmosphere causes both C and N to be absorbed simultaneously by the steel surface at the carbonitriding temperature. Actually, carbonitriding is a modification of carburizing, and the name “nitrocarburizing” is more descriptive. Although a wide variety of gas mixtures are used, the typical composition is 15 % anhydrous ammonia (provides nitrogen to the surface), 5 % natural gas (enriching gas and is the primary source of the carbon added to the surface), 80 % carrier (mixture of N2, H2, and CO; endothermic) gas. The heating temperature range is 650 – 885 °C, lower than those used for gas carburizing. Case depth rarely exceeds 0.02 in (due to lower heating temperatures). 14 Humayun Kabir, Dept of MME, BUET This is a process for case hardening of alloy steel in an atmosphere consisting of a mixture in suitable proportions of ammonia gas and dissociated ammonia. The effectiveness of the process depends on the formation of nitrides in the steel by the reaction of nitrogen with certain alloying elements. Although at suitable temperatures and with the proper atmospheres, all steels can form iron nitrides; The best results are obtained in steels containing one or more of the major nitride-forming alloying elements like Al, Cr, or Mo. The parts to nitride are placed in an airtight container through which the nitriding atmosphere is supplied continuously while the temperature is raised and held between 925˚F (496˚C) and 1050˚F (565˚C). 15 Humayun Kabir, Dept of MME, BUET The nitriding cycle is quite long, depending upon the case depth desired. A 60h-cycle will give a case depth of approximately 0.024 inches at 975˚F (524˚C). A nitride case consists of two distinct zones. In the outer zone, the nitride-forming elements, including iron, have been converted to nitrides. This layer is known as the white layer. In the zone beneath this white layer, alloy nitrides only have been precipitated. The white layer is brittle and tends to chip or spall from the surface if it has a thickness over 0.0005 inches. Thicker white layers must be removed by grinding after nitriding. 16 Humayun Kabir, Dept of MME, BUET Since nitriding is performed at relatively low temperatures and no quenching (and tempering) is required, distortion is reduced to a minimum. However, some growth does occur due to the increase in volume of the case. This growth is constant and predictable for a given part and cycle, so in most cases, parts may be machined very close to the final dimensions before nitriding. This is an advantage of nitriding over carburizing. Some complex parts that cannot be case hardened satisfactorily by carburizing have been nitrided without difficulty. 17 Humayun Kabir, Dept of MME, BUET Wear resistance is an outstanding characteristic of the nitride case and is responsible for its selection in most applications. The hardness of a nitride case is unaffected by heating to temperatures below the original nitriding temperature. Fatigue resistance is also an important advantage. Although it is sometimes indicated that nitriding improves the corrosion resistance of steel, this is true only if the white layer is not removed. 18 Humayun Kabir, Dept of MME, BUET Disadvantages of nitriding include 1. the long cycles usually required, 2. the brittle case, 3. the use of special alloy steels if maximum hardness is to be obtained, 4. the cost of ammonia atmosphere, and 5. the technical control required. 19 Humayun Kabir, Dept of MME, BUET