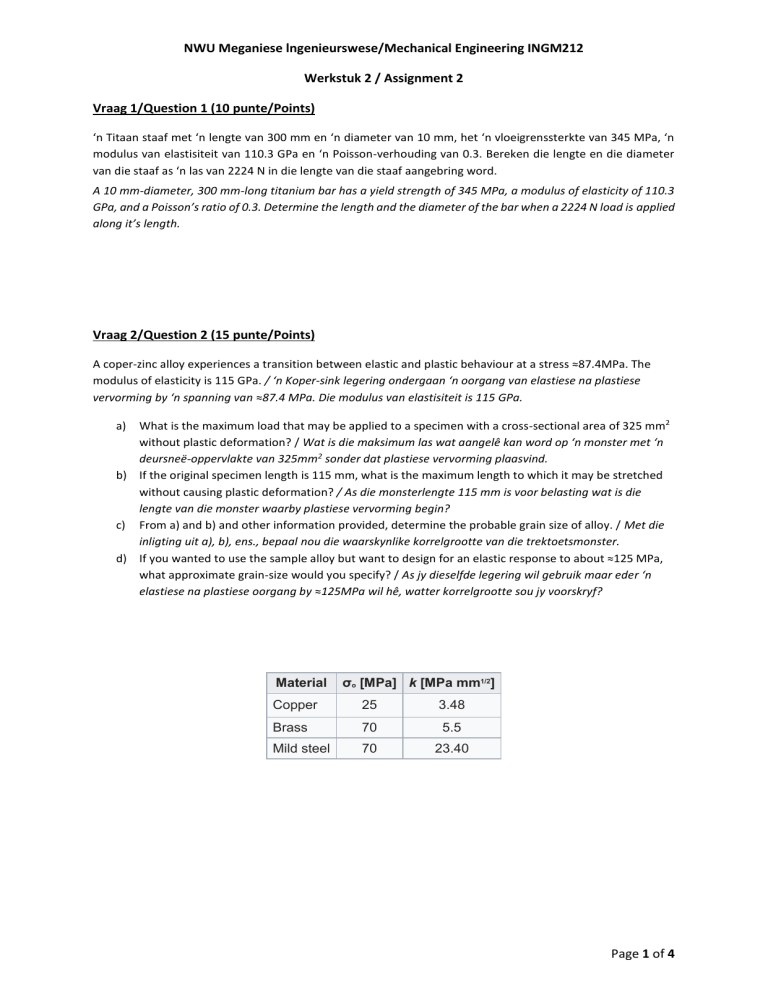

NWU Meganiese lngenieurswese/Mechanical Engineering INGM212 Werkstuk 2 / Assignment 2 Vraag 1/Question 1 (10 punte/Points) ‘n Titaan staaf met ‘n lengte van 300 mm en ‘n diameter van 10 mm, het ‘n vloeigrenssterkte van 345 MPa, ‘n modulus van elastisiteit van 110.3 GPa en ‘n Poisson-verhouding van 0.3. Bereken die lengte en die diameter van die staaf as ‘n las van 2224 N in die lengte van die staaf aangebring word. A 10 mm-diameter, 300 mm-long titanium bar has a yield strength of 345 MPa, a modulus of elasticity of 110.3 GPa, and a Poisson’s ratio of 0.3. Determine the length and the diameter of the bar when a 2224 N load is applied along it’s length. Vraag 2/Question 2 (15 punte/Points) A coper-zinc alloy experiences a transition between elastic and plastic behaviour at a stress ≈87.4MPa. The modulus of elasticity is 115 GPa. / ‘n Koper-sink legering ondergaan ‘n oorgang van elastiese na plastiese vervorming by ‘n spanning van ≈87.4 MPa. Die modulus van elastisiteit is 115 GPa. What is the maximum load that may be applied to a specimen with a cross-sectional area of 325 mm2 without plastic deformation? / Wat is die maksimum las wat aangelê kan word op ‘n monster met ‘n deursneë-oppervlakte van 325mm2 sonder dat plastiese vervorming plaasvind. b) If the original specimen length is 115 mm, what is the maximum length to which it may be stretched without causing plastic deformation? / As die monsterlengte 115 mm is voor belasting wat is die lengte van die monster waarby plastiese vervorming begin? c) From a) and b) and other information provided, determine the probable grain size of alloy. / Met die inligting uit a), b), ens., bepaal nou die waarskynlike korrelgrootte van die trektoetsmonster. d) If you wanted to use the sample alloy but want to design for an elastic response to about ≈125 MPa, what approximate grain-size would you specify? / As jy dieselfde legering wil gebruik maar eder ‘n elastiese na plastiese oorgang by ≈125MPa wil hê, watter korrelgrootte sou jy voorskryf? a) Material σo [MPa] k [MPa mm1/2] Copper 25 3.48 Brass 70 5.5 Mild steel 70 23.40 Page 1 of 4 Sien my Excel sheet Vraag 3/Question 3 (15 punte/Points) Consider an alloy containing 70 % Ni and 30 wt % Cu (See Fig. 10-15, Askeland). Assume equilibrium conditions. / Beskou ‘n legering bestaande uit 70 % Ni en 30 % Cu (Sien Fig. 10-15, Askeland). Aanvaar dat ekwilibrium kondisies geld. a. b. c. d. e. f. g. Which phases are present at 1450C? / Watter fases is teenwoordig by 1450oC? At 1450oC how much of each element is present? / By 1450oC, hoeveel van elke element is teenwoordig? Which phases are present at 1350C? / Watter fases is teenwoordig by 1350oC? At 1350oC how much of each element is present? / By 1450oC, hoeveel van elke element is teenwoordig? Which phases are present at 1300C? / Watter fases is teenwoordig by 1300oC? At 1300oC how much of each element is present? / By 1300oC, hoeveel van elke element is teenwoordig? Sketch the microstructure of the alloy at each of these temperatures by using circular microscopic fields. / Skets die mikrostruktuur wat by elk van die temperature teenwoordig sal wees. a. b. c. d. Liquid phase consisting of a complete solution of Ni and Cu ≈70% Ni and ≈30% Cu Liquid phase + α (alpha) ≈77% Liquid and ≈23% α (could be included in answers, not a must), in the liquid phase ≈40% Cu and ≈60% will be present, in the solid phase 27% Cu and 73% Ni will be present (there might be slight deviations due to errors made by using visual methods on the diagram) Solid phase consisting of 70% Ni and 30% Cu e. Page 2 of 4 Vraag 4/Question 4 (15 punte/Points) Stel geskite isotermiese hitte-behandeling, insluitende temperatuur en tyd, voor om die volgende te verkry: a. ‘n isotermies-uitgeloeide 1050 staal met ‘n hardheid van HRC 23; b. ‘n isotermies-uitgeloeide 10110 staal met ‘n hardheid van HRC 40; c. ‘n isotermies-uitgeloeide 1050 staal met ‘n hardheid van HRC 30; d. ‘n austemperde 1050 staal met ‘n hardheid van HRC 40; e. ‘n austemperde 1050 staal met ‘n hardheid van HRC 50. Recommend appropriate isothermal heat treatments to obtain the following including appropriate temperatures and times: a. an isothermally annealed 1050 steel with a hardness of HRC 23; b. an isothermally annealed 10110 steel with a hardness of HRC 40; c. an isothermally annealed 1050 steel with a hardness of HRC 30; d. an austempered 1050 steel with a hardness of HRC 40, e. an austempered 1050 steel with a hardness of HRC 50. Your answer should take the following format, e.g.,/U antwoord moet op die volgende wyse aangebied word, bv: a. Austenitize/Austenitiseer to/by …………. C Cool/Quench to …………. C and hold for…… s;Koelaf/blus tot by ………………… en hou vir …..s Cool to ………………………. temperature/Koelaf tot ……………………….. temperatuur. Antwoord: f. Austenitise to ≈820C Quench to 600C and hold for more than 10 s; Cool to room temperature. g. Austenitise to ≈900C Quench to ≈640C and hold for more than 10 s; Cool to room temperature; h. Austenitise to ≈820C Quench to 500C and hold for more than 10 s; Cool to room temperature. i. Austenitise to 820C Quench to ≈300C and hold for more than 1000 s; Cool to room temperature. Page 3 of 4 j. Austenitise to ≈820C Quench to 330C and hold for more than 10000 s; Cool to room temperature. Vraag 5/Question 5 (15 punte/Points) A part produced from a low-alloy 0.2% steel has a microstructure containing ferrite, pearlite, bainite, and martensite after quenching to room temperature. a. Write down the cooling rate achieved b. What microstructure would be obtained if we used a SAE 1080 steel? c. What microstructure would be obtained if we used a SAE 4340 steel? ‘n Onderdeel word vervaardig van ‘n lae-legeer staal met 0.2% C en dit het ‘n mikrostruktuur bestaande uit ferriet, perliet, bainiet en martensiet na afblussing tot by kamertemperatuur. a. Wat was die afkoeltempo? b. Waaruit sou die mikrostruktuur bestaan het as ‘n SAE/AISI 1080 staal gebruik was? c. Waaruit sou die mikrostruktuur bestaan het as ‘n SAE/AISI 4340 staal gebruik was? Antwoord: a. Tussen 10 and 20C/s b. Fyn perliet/Fine pearlite. c. Martensiet Vraag 6/Question 6 (15 punte/Points) Veronderstel dat ‘n 2”-as (50.8mm in diameter) vervaardig moet word sodat dit ‘n hardheid van minstens 50HRC op ½” (12.7 mm) onder die oppervlak van daarvan het. Daar moet van “stil-olie” afblussing gebruik gemaak word tydens hitte-behandeling omdat vorige ondervinding getoon het dat waterafblussing maklik kraking te weeg bring. Watter tipe staal moet gebruik word? Suppose that a simple shaft 2” (50.8 mm) in diameter needs to be produced with a hardness of at least 50 HRC to ½ in (12.7 mm) beneath the surface. Still-oil quenching needs to be employed for hardening, since experience have shown that a watrer quench can easily leed to cracking in the steels that can be considered. Which steel should be used? Antwoord: SAE/AISI 4340, 8640 Vraag 7/Question 7 (15 punte/Points) Voltooi die volgende table tov tempearatuur (C) waarby die proses uitgevoer word: Complete the following table with respect to the temperature (C) at which the process is best carried out: A1 Temperatuur(T)/Temperature(T) A3 of Acm T Vol Uitgloei T/Full Annealing T Normaliseer T/Normalising T Prosesuitloei T/Process annealing T Spheroïdisering T/Spheroidising T AISI/SAE1035 727C 790C 820C 845C 557 - 647C - AISI/SAE1015 727C 880C 757C 935C 697C Page 4 of 4