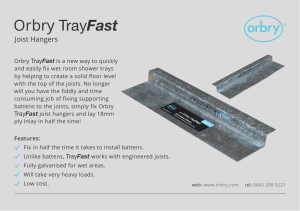

Simpson Strong-Tie Face-Mount Hangers Evaluation Report

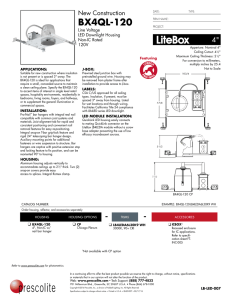

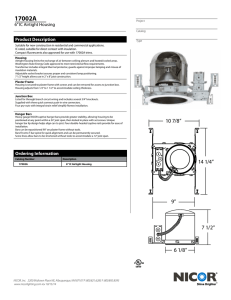

advertisement