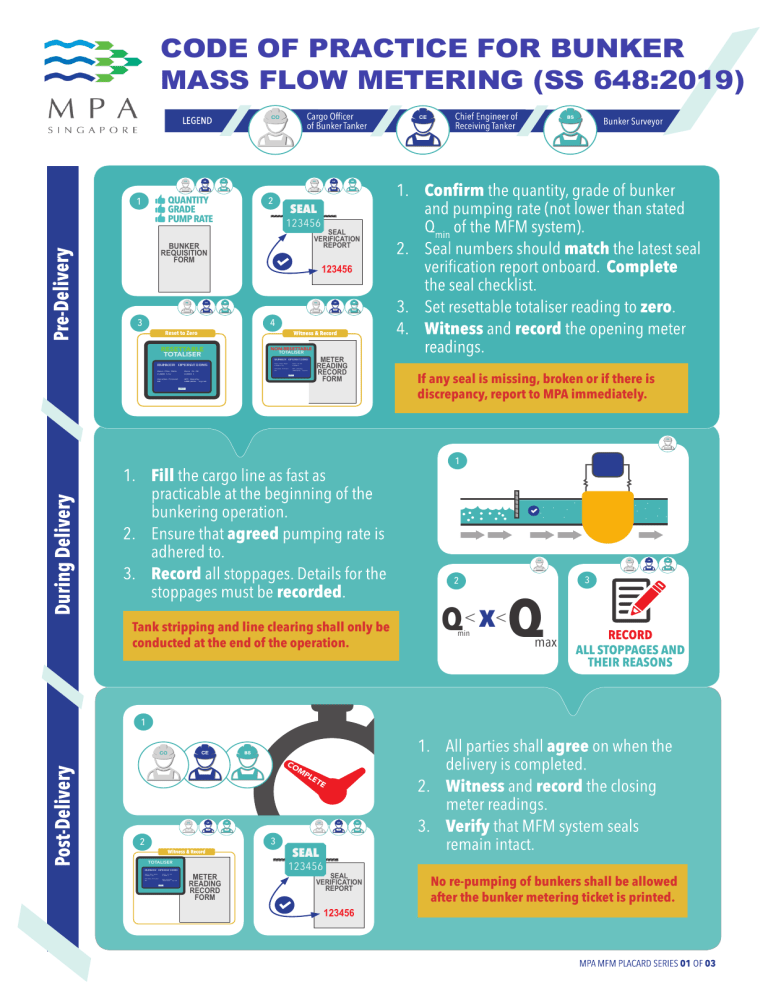

CODE OF PRACTICE FOR BUNKER 0$66)/2:0(7(5,1* 66 648:2019) QUANTITY GRADE PUMP RATE 1 2 SEAL 123456 SEAL VERIFICATION REPORT BUNKER REQUISITION FORM 123456 4 3 Reset to Zero RESETTABLE TOTALISER BUNKER OPERATIONS Mass Flow Rate 0.0000 t/hr Aeration Present NO Mass In Air 0.0000 t NON-RESETTABLE TOTALISER BUNKER OPERATIONS Mass In Air 0.0000 t Mass Flow Rate 0.0000 t/hr Aeration Present NO API Density 1006.6351 kg/m3 EXIT API Density 1006.6351 kg/m3 METER READING RECORD FORM EXIT If any seal is missing, broken or if there is discrepancy, report to MPA immediately. 1 2 Tank stripping and line clearing shall only be conducted at the end of the operation. Q< x< min 3 Q max 1 CO M 3 2 TOTALISER BUNKER OPERATIONS Mass Flow Rate 0.0000 t/hr Aeration Present NO Mass In Air 0.0000 t API Density 1006.6351 kg/m3 EXIT METER READING RECORD FORM PL ET E SEAL 123456 SEAL VERIFICATION REPORT 123456 No re-pumping of bunkers shall be allowed after the bunker metering ticket is printed. Cargo Officer (CO) shall do the following Chief Engineer (CE) shall do the following 1. 1. 2. 2. 3. Invite CE and BS to re-witness meter totaliser readings. Provide assistance for CE & BS to check documentation, seals and piping system. Raise a Note of Protest if dispute remains unresolved. 3. 4. 5. 6. Re-witness meter totaliser readings. Re-check and verify all seals in seal verification report are intact. Confirm that no modification from piping diagram was made. Obtain and examine relevant pages of bunker tanker meter totaliser log. Obtain and examine certificates and documents listed in clause 10.7.4 of SS648. Raise a Note of Protest if dispute remains unresolved. Bunker Surveyor (BS) shall do the following 1. Assist CE in the dispute management procedure as listed above. 2. Witness all procedures. 3. Record all relevant details, findings and observations in a statement of fact. MPA HOTLINE FOR QUANTITY DISPUTES DURING BUNKERING OPERATIONS 1800 - BUNKERS (1800-2865377) QUALITY DISPUTES • Lodge a complaint in writing to bunker supplier within 30 days after bunker delivery. • Lodge a copy of the complaint and BDN with the “Executive Director, Singapore Shipping Association” AND “Bunker Services Department, Maritime and Port Authority of Singapore”. QUANTITY DISPUTE: REPORT TO RELEVANT PARTY WITHIN 14 DAYS QUALITY DISPUTE: REPORT TO RELEVANT PARTY WITHIN 30 DAYS MASS FLOW METERING BEST PRACTICES BE FIRM F I R M Flow Rate (Qmin < X < Qmax) Inspect the seals before and after the bunker delivery. Reset the totaliser before the bunker operation and print out the Bunker Metering Ticket (BMT). Match the delivered quantity figure indicated on the BMT with the BDN. Flow Rate Inspect Seals Reset Totaliser Match Records Q x Reset to Zero SEAL 123456 BUNKER OPERATIONS Mass Flow Rate 0.0000 t/hr < min Aeration Present NO < SEAL VERIFICATION REPORT 2. Calibration range is indicated on the stamping plate of the meter. The meter calibration certificate is available onboard the bunker tanker upon request. API Density 1006.6351 kg/m3 Print Bunker Metering Ticket Bunker Metering Ticket 123456 max Flowrate for delivery shall be within the calibrated flow range of the MFM (Qmin< X < Qmax). Mass In Air 0.0000 t EXIT Q 1. Bunker Delivery Note (BDN) RESETTABLE TOTALISER 1. All seals have a unique serial number issued by Authorised Verifier. 1. Always ensure that the resettable totaliser is set to zero prior to delivery. 2. Match the seal numbers with the seal verification report. 2. 3. Ensure that the seals are intact and the blanks/flanges are tamper-free before and after the operation. Record the readings of the nonresettable totalisers before and after the operation. 1. Fill in all relevant and applicable fields of the BDN. 2. CO and CE to endorse and stamp all cancellation and amendments on BDN. MPA MFM PLACARD SERIES 03 OF 03 BUNKERING 101 MPA SINGAPORE SINGAPORE STANDARD 648:2019 SAMPLING PROCEDURES (KEY STEPS) Chief Engineer should check and ensure that SS648's sampling procedures are carried out. SAMPLING E)u�;___I l=l=I SAMPLING CONTAINER 1 Inspect sampling equipment and Ensure sampling container is clean. 4 Ensure sampling starts simultaneously with the bunkering operation. 5 6 7 1 O Confirm that the seals of both the sampling container and the needle valve are not tampered with. 2 Seal sampling container. Seal needle valve at the commencement of bunkering. Record needle valve seal number in the Meter Reading Record Form Check continuous drip sample is taken throughout bunkering operation. 11 Shake or Stir the sampling container to promote homogeneity. 12 Pour the sample into 4 (or 5 if a testing lab is engaged) sample bottles making 3 or 4 passes to fill each bottle in turn. SAMPLE LABEL � CARGO OFFICER !z: •• =5 fa • � I; a. z i!!i • • 8 9 Record sampling container seal number in the Meter Reading Record Form and Bunker Surveyor's sampling document (If engaged). Adjust needle valve if necessary. Reseal needle valve, if adjusted, and Record the new seal number in the sampling document. 13 Tighten sample bottle cap on sample bottle neck. 14 Seal the sample bottles with uniquely numbered security seals through the aperture on the cap and the opposite aperture on the bottle. BON CHIEF ENGINEER �. 15 Record the seal numbers in the sample labels. 16 Check the sample labels for complete information. 3 �� i§ � 17 Paste the sample labels on the sample bottles in the presence of both parties. 18 Sign the sample labels. 19 Record the seal numbers in the Bunker Delivery Note (BON). DO NOT SIGN ANY SAMPLE LABELS PRIOR TO THE COMPLETION OF THE BUNKERING AND SAMPLING OPERATIONS. DO NOT SIGN EXTRA SAMPLE LABELS. AN ADDITIONAL SAMPLE SHALL BE COLLECTED FOR THE TESTING LABORATORY, IF ENGAGED, MAKING IT A TOTAL OF 5 SAMPLES FOR THE OPERATION. RECORDING OF THE SAMPLE SEAL NUMBERS IN THE BON IS IMPORTANT. FAILURE TO DO SO, THE AUTHENTICITY OF THE SAMPLE CANNOT BE VERIFIED. COUNTER SEALS, IF USED, SHALL BE RECORDED IN THE SAMPLE LABELS AND BON. © Maritime and Port Authority of Singapore (June 2022) ===- SINGAPORE STANDARD 648:2019 �G�O � BUNKERING 101 BUNKER SAMPLE COLLECTION (5 SAMPLES) Otte For MARPOL BUNKER SURVEYOR '3111•� Otte For Vessel's uel Quality restittg Progra11t11te � HIEF INEER �-- CARGO O�FICER � © Maritime and Port Authority of Singapore (June 2022) SINGAPORE STANDARD SS600 – PROCEDURES AND REQUIREMENTS FOR BUNKER DELIVERY Chief Engineer should check and ensure that SS600’s pre-delivery conference and documentation procedures are carried out. KEY STEPS Opening Tank Gauging CE CO Chief Engineer Cargo Officer Delivery Procedures CE 0 Cargo Tank CE C Cargo Tank 0 Cargo Tank C Cargo Tank CO Bunker Tanker Bunker Tanker 1 Check the barge stock movement log book’s recorded quantity prior to barge measurements and to bunkering. 2 3 4 Witness and Confirm the opening tank gauging and cargo temperature readings of all cargo tanks. Line-clearing method (if any) should be addressed during the pre-bunker conference and shall only be carried out at the end of the pumping operations. 5 Bunkering operation shall commence only after confirmation by the Chief Engineer that the pre-delivery requirements are completed and the bunker hose(s) is/ are properly connected. Ensure that the agreed pumping rate is adhered by the bunker tanker within safe operating practices. The agreed pumping rate should not be exceeded unless requested and endorsed by the Chief Engineer. 6 The bunker residue content in the delivery hose(s) shall be drained back into the bunker tanker before the final gauging is taken. No re-pumping of bunkers shall be allowed, and post delivery checks and documentation shall commence. 7 Chief Engineer must be informed that a preliminary sounding must be taken on the receiving vessel before stripping. Closing Tank Gauging CE C 0 Cargo Tank Verification of Delivery Quantity Cargo Tank CO CE BDN 123 TGC FORM Bunker Tanker CO 8 Witness and Confirm the closing tank gauging and cargo temperature readings of all cargo tanks. MPA HOTLINE FOR ON-SITE ASSISTANCE DURING BUNKERING OPERATIONS: 1800 - BUNKERS (1800-2865377) 9 Complete and Sign the Tank Gauging/Calculation Form. Calculate the delivered quantity. 10 Delivered quantity shall be based on the bunker tanker’s tank gauging and calculations as witnessed by both Cargo Officer and Chief Engineer. 11 Complete, Sign and Stamp on the Bunker Delivery Note. +65 6221 1742)