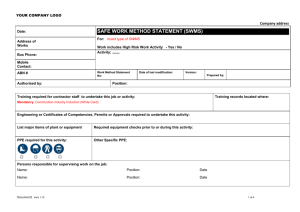

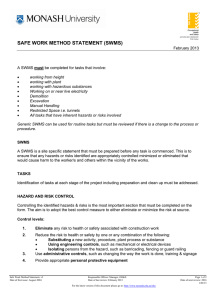

Safe Work Method Statement Use of Master Builders Generic Safe Work Method Statements Disclaimer: The Master Builders Association of Victoria expressly disclaim all and any liability to any person in respect of anything, and of consequence of anything done or omitted to be done by any or such person in reliance, whether wholly or partially on this generic safe work method statement. Rules for the use of Master Builders generic SWMS 1. This generic SWMS is provided as a sample. It is not to be used by a builder or subcontractor for the purpose of managing safety on their projects. It can be used as a template to enable builders and subcontractors to produce their own SWMS. Master Builders have carbon copy pads available for sale to enable builders/subcontractors to produce their own SWMS. 2. Employers intending to use this SWMS as a template for their own SWMS must ensure they consult with their employees, including their Health and Safety Representatives, prior to its introduction. 3. Builders and subcontractors must ensure that their SWMS is relevant to the project at hand. Generic SWMS should not be used unless precautions have been taken to ensure that the document adequately addresses the hazards and risks relevant to each particular project. 4. Builders and subcontractors intending to use this sample SWMS as a template for their own generic SWMS, without making any changes to the detail, must ensure that they adhere to and implement all of the relevant risk controls. 5. The range of generic SWMS provided by Master Builders are not sufficiently broad enough to cover “all” hazards or risks encountered by builders and subcontractors. It does not cover the full list of requirements for which SWMS are specifically required under the OHS Construction Regulations. It is important that the builder or subcontractor undertake their own hazard identification and risk control process relevant for each particular task. It is highly recommended that persons who are responsible for preparing and reviewing SWMS undertake training so as to understand the process of identifying and controlling risks in the workplace. Remember : Each Safe Work Method Statement should be site specific. Include all workers in the development of the Safe Work Method Statement. All workers should sign off to verify that they understand all the requirements of this Safe Work Method Statement. NOTE : Work must be performed in accordance with this SWMS. This SWMS must be kept and be available for inspection until the high risk construction work to which this SWMS relates is completed. If the SWMS is revised, all versions should be kept. If a notifiable incident occurs in relation to the high risk construction work in this SWMS, the SWMS must be kept for at least 2 years from the date of the notifiable incident. (PCBU Name, ABN, Office Address and Phone) Principal Contractor (PC) Works Manager: Contact phone: Date SWMS provided to PC: (Name, ABN, Office Address) Work activity: Scaffolding - general High risk construction work involves : Risk of a person falling more than 2 metres Work on or near energised electrical installations or services Work on or near chemical, fuel or refrigerant lines Work in an area with movement of powered mobile plant Temporary load-bearing support for structural alterations or repairs Work in areas with artificial extremes of temperature Tilt-up or precast concrete elements Use of explosives Work on or near pressurised gas mains or piping Likely to involve disturbing asbestos Work on, in or adjacent to a road, railway, shipping lane or other traffic corridor in use by traffic other than pedestrians Work in or near water or other liquid that involves a risk of drowning Work in or near a shaft or trench deeper than 1.5 m or a tunnel Work in or near a confined space Diving work Demolition of load-bearing structure Work in an area that may have a contaminated or flammable atmosphere Work on a telecommunication tower Have workers been consulted about the SWMS? Note: Consultation with Health and Safety Representatives (HSRs) should be undertaken where there is a HSR at a workplace Person/s responsible for ensuring compliance with SWMS: Workplace location: YES NO Date SWMS received: What measures are in place to ensure compliance with the SWMS? Person responsible for reviewing SWMS control measures: Date SWMS received by reviewer: How will the SWMS control measures be reviewed? Review date: Reviewer’s signature: What are the tasks involved? What are the hazards and risks? What are the control measures? List the work tasks in a logical order. Identify the hazards and risks that may cause harm to workers or the public. Describe what will be done to control the risk. What will you do to make the activity as safe as possible? 1. Poor communication with employees and Principal Contractor. Nominate Supervisor / Foreman to liaise with Principal Contractor. Inadequate training. A scaffold that is in excess of 4.0 metres high must be erected, altered and /or dismantled by a qualified scaffolder. Training to be provided to the person/s erecting, altering and / or dismantling of scaffold regardless of its height. General planning. Incorrect selection of equipment. A risk assessment is to be carried out in order for the selection of the correct tools and equipment to be used for the job. Unstable base out. Unstable ground and erosion 2. Delivery of materials to site. Overloading scaffold. Identify what type of work is to be carried out on the scaffold and select the type of scaffold to be used i.e. light, medium or heavy duty. Serious injury from moving plant or vehicle. Co-ordinate with site management to unload materials in designated storage area. Struck by load falling from forklift. Load must be secured to ensure no materials fall from the load when being transported. Traffic accident. Forklift driver must hold appropriate ticket operate. Manual handling. 3. Moving materials to work area by crane, where applicable. Determine if ground can support the weight of the intended scaffold. Struck by crane moving materials. Struck by falling object. If unloaded by hand, ensure correct manual handling techniques are used. No load over 20kg to be lifted by one person, trolleys and wheelbarrows to be used to move materials, ensure materials are secure when transported. Qualified and competent person to operate crane. Qualified dogman / rigger to load and unload materials by the crane. Crane driver to have constant communication with dogman / rigger. Current test certificate is to be available for all lifting gear and crane. If unloading by hand, ensure correct manual handling techniques are used. No load over 20kg to be lifted by one person. Trolleys and wheelbarrows are to be used to move materials. Unsecure materials are to be made secure when scaffold is to be transported. Scaffold failure due to mix components being used. All scaffold materials to be visually inspected to ensure components match and have no damage. Damage components may fall. All damage and/or mis-matched components MUST NOT be used and are to be removed from site. Crushing injury from stacked materials falling or spilling over. Visually inspect materials to ensure they are stacked correctly before untying and/or cutting straps. Cuts and abrasions. Wear suitable gloves to avoid cuts and abrasions. Eye injury. Wear approved safety eyewear when cutting straps. Manual handling. Correct manual handling techniques are to be used. Unstable ground. Determine if ground can support the weight of the intended scaffold. Injury to other trades. Remove all trades from the area where the scaffold is to be erected and barricade off area. Fall from heights. Always follow the correct erection sequence as per the Australian Standard AS/NZS 4576: Guidelines for Scaffolding. Follow fall protection guidelines for scaffolding. All temporary working platforms to be fully decked. Manual handling. 4. 5. 6. Visual inspection of equipment. Sorting components for erection. Erecting scaffold. All lap boards to be secured. Unauthorised access. Incomplete scaffold signs to be posted and scaffold to be barricaded. Manual handling. Correct manual handling techniques are to be used. 7. Working near powerlines. Proximity of overhead power cables – electrocution, electric shock. Check with site management and the local power supply Authority of the hazard involved by the overhead power supply (if applicable). 8. Tying the scaffold to the building or structure. Scaffold collapse. Confirm with the Principal Contractor that the building and/or structure can support the scaffold being tied off. Building and/or structure failure. Object or materials fall from heights. Area below the scaffold is to be barricaded off with signage posted ‘MEN WORKING ABOVE’. If scaffold is hoarded or screened, the mechanical engineer’s ‘signoff’ is required. Electrocution. All electrical equipment to be tagged and checked for current period by a licensed electrician. Lacerations and cuts. All guarding to be left in place on electric saw. Ensure no trades are working in the vicinity of flying debris from the electric saw. Extension leads to be elevated on insulated hooks / stands. All electrical equipment to be tested and tagged and checked for current period by a licensed electrician. Eye and hearing damage. Eye protection and hearing protection to be worn. 10. Handover of scaffold. Personal injury and / or property damage due to scaffold being used prior to it being completed. Scaffold to be inspected and the Handover Certificate provided to the Principal Contractor and the scaffold provider’s management prior to the removal of the ‘SCAFFOLD INCOMPLETE’ signage. 11. Training. Incorrect procedure being used. All workers involved are to read and ‘sign-off’ on the requirements of this SWMS as to having understood its contents. 9. Cutting timber boards. Electrocution. Name of Worker/s Worker signature/s Date SWMS received by workers PLEASE NOTE: It may be necessary to use more than one page to complete an adequate safe work method statement (SWMS).