Architectural Graphic Standards [Student Edition] by Keith E. Hedges (editor-in-chief) (z-lib.org)

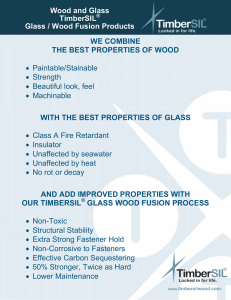

advertisement

![Architectural Graphic Standards [Student Edition] by Keith E. Hedges (editor-in-chief) (z-lib.org)](http://s2.studylib.net/store/data/026356797_1-1fa4dc122bcabe3e99cb9fc3d117e92a-768x994.png)