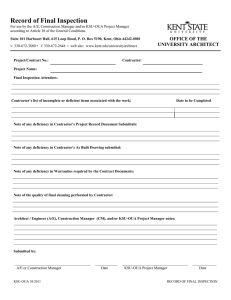

TESTING AND COMMISSIONING PROCEDURE FOR MV PANEL EPCC MS CNG PROJECT - GROBOGAN Company PT ENERGASINDO HEKSA KARYA EPCC CONTRACTOR PT GLOBALINDO - PT AEMCO KSO 0 Rev. Number Document No. GB-AEMCO-EPCC-QC-005 Authorized QC Dept. Issued Date 1 JU 2023 Issued for approval Description QC Officer Prepared By Project Manager Approved By PT. GLOBALINDO - PT AEMCO KSO QC Officer Reviewed By Project Manager Approved By PT. ENERGASINDO HEKSA KARYA Table of Content 1. Introduction .................................................................................................................................................... 3 2. Objectives of the Testing and Commissioning Works ....................................................................................3 3. Scope of the Testing and Commissioning Works ............................................................................................3 3.1.Tests and Inspections during Construction ...........................................................................................3 3.2. Statutory Test and Inspection .............................................................................................................3 3.3. Functional Performance Tests .............................................................................................................4 3.4.Documentation and Deliverables ......................................................................................................... 4 4. Refference Documents, Codes, and Standards .............................................................................................. 5 5. Test Rquirements ............................................................................................................................................ 5 5.1. Safety Guidelines .............................................................................................................5 5.2. Responsibility and Qualified Personnel ............................................................................................... 5 5.3. Tools Required .............................................................................................................5 6. Procedures ...................................................................................................................................................... 6 6.1. Design and visual check ....................................................................................................................... 6 6.2. Mechanical operation tests ................................................................................................................. 6 6.3. Test of auxiliary electrical .................................................................................................................... 6 6.4. Test on auxiliary and control circuits ................................................................................................... 6 6.6. Measurement of the insulation resistance ..........................................................................................7 7. ANNEX ............................................................................................................................................................. 7 1. Introduction The procedures stated in this Testing and Commissioning (T&C) Procedure cover the activities in preliminary tests and inspections, functional performance tests and the commissioning of newly completed installations. This procedure is applied by contractors in the MS CNG Grobogan project. This T&C Procedure is also intended to lay down the minimum testing and commissioning requirements to be carried out by Electrical Contractor on a new Medium Voltage Cubicle Switchboard Installation upon completion. 2. Objectives of the Testing and Commissioning Works The objectives of the T&C works are:(i) To verify proper functioning of the equipment/system after installation; (ii) To verify that the performance of the installed equipment/systems meet with the specified design intent and statutory requirements, if any, through a series of tests, measurements and adjustments; and (iii) To capture and record performance data of the whole installation as the baseline for future operation and maintenance. 3. Scope of the Testing and Commissioning Works 3.1. Tests and Inspections during Construction The purpose of these tests is to ensure that all components and systems are in a satisfactory and safe condition before start up. Preliminary adjustment and setting of equipment at this stage shall also be carried out at the same time to pave way for the coming functional performance tests. Before carrying out any test, the Electrical Contractor shall ensure that the Installations comply with all relevant statutory requirements and regulations. The T&C works shall also comply with all site safety regulatory requirements currently in force. 3.2. Statutory Test and Inspection The Electrical Contractor shall carry out tests for the Installations to meet statutory requirements as specified in the Specification. After the proper testing and commissioning of the Installations, the Electrical Contractor shall notify the appropriate authority as specified in the Specification, through the Project Owner at the completion of the Installations and its readiness for inspection and testing. The Electrical Contractor shall arrange for the necessary inspections and tests as required by the Authority. 3.3. Functional Performance Tests The purpose of functional performance tests is to demonstrate that the Installations can meet the functional and performance requirements as specified in the Specification. Some of the tests may need to be carried out under the supervision of the supplier according to the provisions of the Specifications. Any performance deficiencies revealed during the functional performance tests must be evaluated to determine the cause. After completion of the necessary corrective measures, the Electrical Contractor shall repeat the tests. If any test cannot be completed because of circumstances that are beyond the control of the Electrical Contractor, it shall be properly documented and reported to the Project Owner, who shall then liaise with the relevant parties to resolve the situation. The Contractor shall resume his testing work immediately upon the attainment of a suitable testing environment. 3.4. Documentation and Deliverables The Electrical Contractor shall submit his proposed T&C procedures to get Project Owner for approval. All inspection and T&C results shall be recorded by the Electrical Contractor in the appropriate test record forms. A complete set of these forms can be found in Annex of this document. Data recorded in other formats may also be acceptable subject to prior approval of the Project Owner. Upon completion of all the required T&C works, the Electrical Contractor shall complete and sign the testing and commissioning certificate to the effect that the agreed T&C works have been duly carried out. Functional test reports covering all measured data, data sheets, and a comprehensive summary describing the operation of the system at the time of the functional tests shall be prepared and submitted to the Project Owner. Deviations in performance from the Specification or the design intent should be recorded, with a description and analysis included. Where required in the Specification, the Electrical Contractor shall conduct a final evaluation of the performance of the Installations, the results of which shall be included in the commissioning report. The Electrical Contractor shall sign work completion certificate(s) and issue to the Project Owner after completion of the Installations or any work subsequent to repair, alteration or addition to an existing installation. This should be done before the installations are energized. 4. Refference Documents, Codes, and Standards EHK-GBA-0323-10501-ELC-DW-011 SNI 0225:2011 IEC 60038 IEC 62271 IEC 60060 IEC 60694 5. General Arrangement Drawing and Wiring Termination for MV Panel Standar Nasional Indonesia. Persyaratan Umum Instalasi Listrik 2011 IEC Standard Voltages High Voltage Switchgear and Controlgear High Voltage Test Techniques Common Specification for High Voltage Switchgear and Controlgear Test Rquirements 5.1. Safety Guidelines (a) (b) (c) (d) (e) (f) (g) 5.2. Responsibility and Qualified Personnel (a) (b) (c) 5.3. Always follow the project safety plan and policy Safety sign, safety warning, and safe boundary must be arranged prior to the every test sequence Always assume that any exposed conductor and electrical equipment are live or energized during the T&C Do Not cross the test boundaries when the T&C is being carried out. Visitors are advised not to wear loose clothing, necklaces or rings around fingers which may impair safety as it can be a hazard during the mechanical and electrical test. Refrain from wearing any high platform footwear to prevent any injuries from tripping when on the factory floor. Refrain from using mobile phones or any other personal electrical devices when the electrical test is being conducted. Quality Control is responsible for conducting the Test and issue of Test. Project owner and Third Party Inspector will witness the test. Only qualified personnel can perform the tests Only authorized person may engaged in this T&C Tools Required (a) (b) Continuity tester Grounding/earth tester 6. Procedures 6.1. Design and visual check The switchgear shall be checked to verify its compliance with the purchase specification. The specification should be verified consist of : (a) Type of designation (b) Rating (c) Dimension (d) Phisical Fitness (e) Completeness (f) Tightnes of busbar fixing 6.2. Mechanical operation tests Operation test are made to ensure that switching devices and removable parts comply with operating conditions and the mechanical interlock work properly. Each switching device and removable part shall be tested 5 times in each direction. Additional noted that these operation are tested in no voltage supply. 6.3. Test of auxiliary electrical The electrical, pneumatic and other interlocks together with control devices having a predetermined sequence of operation shall be tested 5 times in succession in the intended conditions of use and operation and with the most unfavourable limit values of auxiliary supply. During the test no adjustment shall be made. The test are considered to be satisfactory if the auxiliary devices have operated properly, if they are in good operating condition after the tests and if the effort to operate them is practically the same before and after tests. 6.4. Test on auxiliary and control circuits Inspection of auxiliary and control circuits, and verification of conformity to the circuit diagram and wiring diagrams (a) visual check of the nature of the material, quality of assembly, installation & the coating. (b) inspection of interlock, locks etc. (c) check the property mounting of component of auxiliary and control circuit also the property connection & sufficiently wiring space. (d) check the property routing of conductor and cables. (e) to ensure that no mechanical damage can occur to conductors and cables due to the promixity of sharp edges or heating elements, or to the movement of moving parts. (f) verify the identification of component, terminal, cables and wiring (if applicable). (g) check the conformity of auxiliary and control circuits to the diagram/drawings (h) check the technical data provided by manufacturer (for example: number of free auxiliary) contact and the class of each one, number, type and capacity of contact other than auxiliary and control contact, electrical power of shunt trip etc) A functional test of all low-voltage circuits shall be made to verify the proper functioning of auxiliary and control circuit in conjuction with the other parts of the switchgear such as : (a) Current Transformer (b) Voltage Transformer (c) Switching device (DS, CB, LBS exct) (d) Metering Component (A-Meter, V-Meter, Watt & VAR meter, Energymeter, ect) 6.6. Measurement of the insulation resistance Megger test is made to measure insulation between phases and each phase to ground. For Main circuit of MV switchgear, the megger tension shall not exceed 10 kV dc with duration maximum of 5 seconds 7. ANNEX EPC-04 EPC-20 INSPECTION FOR MV PANEL TEST FOR MV SWITCHGEAR EPC-04 Date Page Doc. No: of QC-EPC-04- INSPECTION FOR MV PANEL Project no : Project : MS CNG GROBOGAN Erection by. : PT GLOBALINDO-AEMCO KSO Equipment Tag Number : Weather : Manufacture : Temperature : Rated Voltage : Product S/N : Reference drawing : Equipment Title : RESULT OK NOK ITEM TO CHECK 1 Visual & dimensional 2 Board assembly and bolting 3 Busbars bolted connection 4 Fuse ratings and gauge rings 5 Cable glands, clamping and termination 6 Tag & wire number 7 Check grounding connections 8 Check rating and capacity of CT, PT. 9 The relays have complete final setting 10 Insulation resistance measurement 11 Mechanical operation test 12 Mechanical and functional operation test for protection & relay 13 FAT Report DATE ACCEPT SIGN REMARKS 14 Remarks : Contractor Inspector PT Globalindo - Aemco KSO PT Sertco Quality Project Owner PT Energasindo Heksa Karya Name Signature Date QC QPCC MS CNG - 04 - Page 1 of 1 EPC-20 Doc. QC-EPC-20- TEST FOR MV SWITCHGEAR Date Page of Project no : Project : MS CNG GROBOGAN Erection by. : PT GLOBALINDO-AEMCO KSO Inspection Item : MV Switchgear Weather : Manufacturer : Schneider Date of Inspection : Reference drawing : MV SWITCHGEAR DATA CUBICLE SERIAL NUMBER DESCRIPTION CUBICLE TYPE CI-2022-W12-4-0006 INCOMING IM CI-2022-W11-4-0032 OUTGOING QM TAG NUMBER VISUAL INSPECTION CHECK ITEM ACCEPTANCE CRITERIA Name plate panel As per project documents Name plate CB As per project documents Name plate CT As per project documents Name plate VT As per project documents Label & sticker on panel As per project documents PANEL NO. INCOMING OUTGOING WIRING AND INSTALLATION CHECK ITEM Component layout ACCEPTANCE CRITERIA As per project documents Wire size As per project documents Panel arrangement INSPECTION OUTGOING RESULT As per schematic Wire colour Wiring tighness INCOMING No loose As per project documents Insulation Resistance R-N > 25 MW S-N > 25 MW T-N > 25 MW R-S > 25 MW R-T > 25 MW S-T > 25 MW MECHANICAL TEST CHECK ITEM Interlocking MV Door with ACCEPTANCE CRITERIA INSPECTION INCOMING OUTGOING MV door can be opened when the earthing switch close QC QPCC MS CNG - 20 - Page 1 of 2 EPC-20 Page Doc. QC-EPC-20- TEST FOR MV SWITCHGEAR Date of Project no : earthing switch Not possible to open the MV door when the earthing switch open Interlocking DS with earthing switch Not possible to close Disconnecting Switch when the earthing switch in close condition ELECTRICAL OPERATION TEST CHECK ITEM INSPECTION INCOMING OUTGOING ACCEPTANCE CRITERIA DS close manually DS can close manually properly DS open manually DS can open manually properly Heater function Heater in a good operational condition Thermostat function Thermostat can operate according to given temperature Trip function DS can close when receive trip signal FINAL RESULT Contractor Inspector Project Owner PT Globalindo - Aemco KSO PT Sertco Quality PT Energasindo Heksa Karya Name Signature Date QC QPCC MS CNG - 20 - Page 2 of 2