The Energv Balance for Chemical Reactors

322

0 3 NA

4 4NA

.44N

A

. f

f

f

N'-' _____o �

______

.J

L

L

'_-'

__

�

�oR

726

738�oR

874n 'R

830 'R

Q

2 x 1 05 BTU/hr

h�

1

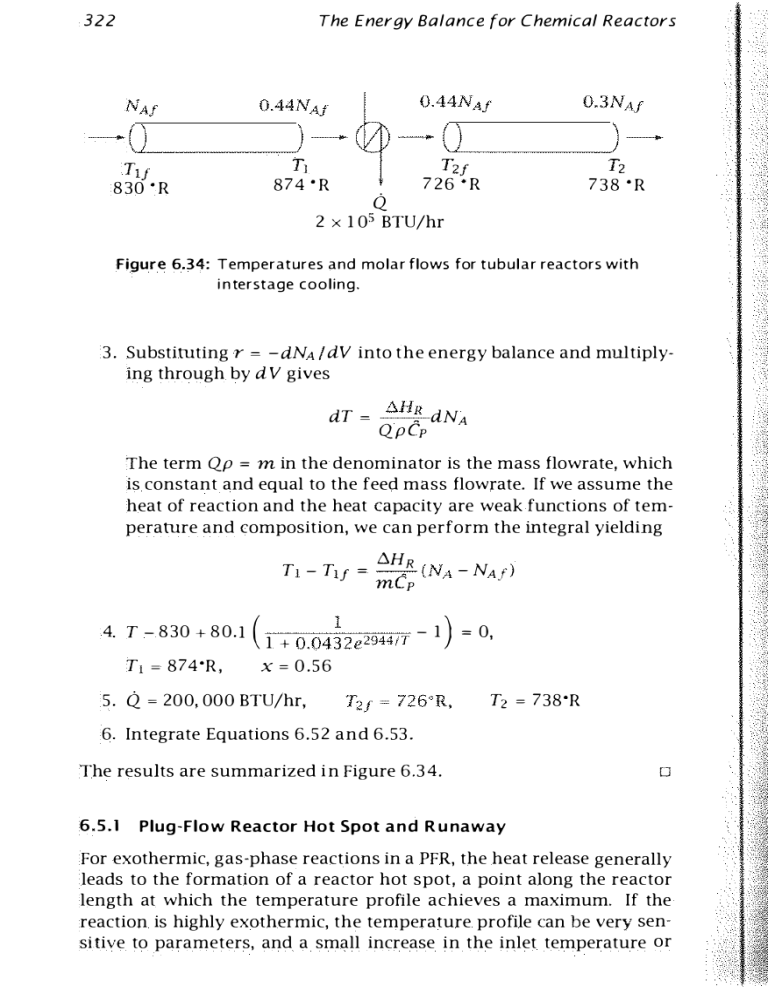

Figure 6.34: Temperatures and molar flows for tubular reactors with

i n terstage cooling.

3.

-dNA ldV into the energy balance and mUltiply­

dV gives

Substituting r =

ing through by

Qp m

dT =

t.H�

Qp Cp

dNA

=

The term

in the denominator is the mass flowrate, which

is constant and equal to the feed mass flowrate. If we assume the

heat of reaction and the heat capacity are weak functions of tem­

perature and composition, we can perform the integral yielding

Tl - Tl

t.HR

-.

- (NA - NAjl

f mep

=

4. T - 830 + 80.1 ( 1 + 0 .04�2 e 2944IT - 1 ) = 0,

Tl = 874'R, x = 0.56

5. Q 200, 000 BTU/hr,

T2 = 738'R

6. Integrate Equations 6.52 and 6.53.

The results are summarized in Figure 6.34.

=

6.5.1

[J

Plug-Flow Reactor Hot Spot a n d R u naway

For exothermic, gas-phase reactions in a PFR, the heat release generally

leads to the formation of a reactor hot spot, a point along the reactor

length at which the temperature profile achieves a maximum. If the

reaction is highly exothermic, the temperature profile can be very sen­

sitive to parameters, and a small increase in the inlet temperature or

6.5 The Plug·Flow Reactor

323

reactant feed concentration, for example, can lead to large changes in

the temperattne profile. sudden, large increase in the reactor temper,

ature due to a small change in feed conditions is known as reactor run·

away. Reactor runaway is highly dangerous, and operating conditions

are normally chosen to keep reactors far from the runaway condition.

The following example, oxidation of o·xylene to phthalic anhydride,

illustrates the PFR hotspot and reactor nmaway.

A

Example 6.5: Oxidation of o-xylene to phthalic anhydride

The gas-phase oxidation of o-xylene to phthalic anhydride

is highly exothermic. The reaction is carried out in PFR tube bundles

with molten salt circulating as the heat transfer fluid [ 10]. The a-xylene

is mixed with air before entering the PFR. The reaction rate is limited

by maintaining a low concentration of hydrocarbon in the feed. The

mole fraction of o-xylene is less than 2%.

Under these conditions, the large excess of oxygen leads to a pseudo­

first-order rate expression

in whlch ex is the a-xylene concentration. The operating pressure is at­

mospheric. Calculate the temperature and o-xylene composition pro­

files. The kinetic parameters are adapted from Van Welsenaere and

Froment and given in Table 6 . 5 [26].

Solution

Ifwe assume constant thermochemical properties, an ideal gas mixture,

and express the mole and energy balances in terms of reactor length,

The Energy Balance for Chemical Reactors

324

Parameter

Value

1922.6

625

625

1.0

1.5

0.0125

0.992

0.373

0.019

1.3636 x 104

- 1 .361 X 1 03

2.6371 x 10-3

km

Ta

Tm

Pf

1

tp

R

UO

Yxj

EIR

t:.HR

Qp

Table 6.5:

Units

1

s

K

K

atm

m

m

kJ/kg K

kJ/m2 s K

K

kJjkmol

kg/s

PFR operating conditions and parameters for o·xylene ex·

ample.

we obtain

dNx

dz

=

dT

dz

=

-

A Cr

-f3r + y ( Ta - T)

Nx

RT N

r = k .f..

in which

y=

2rrRUO

•

Qp Cp

and the total molar flow is constant and equal to the feed molar flow

because of the stoichiometry. Figure 6.35 shows the molar flow of 0xylene versus reactor length for several values of the feed temperature.

The corresponding temperature profile is shown in Figure 6.36. We see

a hotspot in the reactor for each feed temperature. Notice the hotspot

temperature increases and moves down the tube as we increase the

feed temperature. Finally, notice if we increase the feed temperature

above ahout 6 3 1 K, the temperature spikes quickly to a large value and

all of the o-xylene is converted by z = 0 . 6 m, which is a classic example

of reactor runaway. To avoid this reactor runaway, we must maintain

the feed temperature below a safe value. This safe value obviously also

depends on how well we can control the composition and temperature

in the feed stream. Tighter control allows us to operate safely at higher

325

6.5 The Plug-Flow Reactor

0.001 6

0.0014

0.0012

'iii'

J

Z

0.001

0.0008

615

0.0006

625

0.0004

6

0.0002

3'71---1--

0

0.2

0

OA

1

0.8

0.6

1 .2

].4

z (m)

Figure

Molar flow of o-xylene versus reactor length for differ­

ent feed temperatures.

6.35:

740

720

700

T(K)

625

680

660

615

640

620

600

0

OA

0.2

0.6

0.8

1

1.2

1A

z (m)

Figure

6.36:

Reactor temperature versus length for different feed

temperatures.

The Energy Balance for Chemical Reactors

326

Ta ( 0 )

=

T(O)

-

-

-

-

Catalyst bed where

reaction occu

rs

Ta W

=

TaJ - - - - - - - - Products

Feed

Pre eate

Reactants

h r

Figure 6.37: Autothermal plug-flow reactor; the heat released by the

exothermic reaction is used to preheat the feed,

feed

temperatures

the producti

on rate.and feed a-xylene mole fractions, which increases

Ianreactor

many applinletictatiemperat

ons, ituires necessary

toghheatreactia feed

ster.eamIf thetoreacti

achieoven

havi

n

g

a

hi

o

n

rat

c, iwentegrathaveiothen. Thepossiessenti

bility taol liodwerea isthtoe reactor

oper­

atialrelsneoased

giscostexotbybyhtermi

heat

use

t

h

e

heat

h

e

react

i

o

n

t

o

heat

the

feed

stream.

As

a

si

m

pl

e

exam­

the gheaturatiionnteigrats known

ion scheme

depiothctedermalin

Fiplplgeuureg·offlot6.hwi3s7reactconcept,

[IJ. oThir. sTheconsi

reactorreactderconfi

as

an

aut

o

r

system

i

s

an

annul

a

r

l

U

be.

The

feed

passes

thel.outTheer regifeedonthenandenters

is heatedthe ithrough

contact

wiotn,h

thewhichoth isthrough

reactor

wal

n

ner

react

i

o

n

regi

fil ed with the catalyst, and flows countercurrently to the feed

0

6.5.2

The Autothermal Plug-Flow Reactor

327

6.5 The Plug-Flow Reactor

stream. The heat released due to reaction in the inner region is used

to heat the feed in the outer region. When the reactor is operating at

steady state, no external heat is required to preheat the feed. Of course,

during the reactor start up, external heat must be supplied to ignite the

reactor.

Although recycle of energy can offer greatly lower operating costs,

the dynamics and contrnl of these reactors may be complex. We next

examine an ammonia synthesis example to show that multiple steady

states are possible. Ammonia synthesis is also interestingbecause of

its large impact on the early development of the chemical engineering

discipline. Quoting Aftalion {2, p. 1 0 1 ]

While physicists and chemists were linking u p t o understand

the structure of matter and giving birth to physical chem­

istry, another discipline was emerging, particularly in the

United States, at the beginning of the twentieth century, that

of chemical engineering

it was undoubtedly the synthesis

of ammonia hy BASF, successfully achieved in 1 9 1 3 in Op­

pau, which forged the linking of chemistry with physics and

engineering as it required knowledge in areas of analysis,

equllibrium reactions, high pressures, catalysis, resistance

of materials. and design of large-scale apparatus.

. . .

Example 6.6: Ammonia synthesis

Calculate the steady-state conversion for the synthesis o f ammonia us­

ing the autothermal process shown in Figure 6.37 [25]. A rate expres­

sion for the reaction

(6.5 4)

over an iron catalyst at 300 atm pressure is suggested by Temkin [ 2 1 ]

r

= LdRT

[

P3 /2

K 2 (1. /N II

P,4

_

PA

pH3! 2

]

(6. 5 5 )

in which PN , PH , PA are the partial pressures o f nitrogen, hydrogen, and

ammonia, respectively, and K is the equilibrium constant for the reac­

tion forming one mole of ammonia. For illustration, we assume the

thermochemical properties are constant and the gases form an ideal­

gas mixture. More accurate thermochemical properties and a more ac­

curate equation of state do not affect the fundameutal behavior pre­

dicted by the reactor model.

The Energy Balance for Chemical Reactors

328

The steady-state material balance for the ammonia is

dNA

= RA = 2 r

dV

NA ( O ) = NAJ

and the other molar flows are calculated from

NN = NNJ - 1/2(NA - NAJ)

NH = NHJ - 3/2 (NA - NAJ)

If we assume an ideal gas in this temperature and pressure range, the

volumetric flowTate is given b y

The energy balance for the reactor i s the usual

Qp Cp

�

dT

= - 6.HR r + q

dV

(6.56)

in which q is the heat transfer laking place between the reacting fluid

and the cold feed

q

= � UO ( Ta - T)

R

The material balances for the feed-heating section are simple be­

cause reaction does not take place without the catalyst. Without reac­

tion, the molar flow of all species are constant and equal to their feed

values and the energy balance for tbe feed-heating section is

�

dTa

= .

dVa -q

Ta (O) TaJ

Q aPa C Pa

(6. 5 7)

=

in which the subscript a represents the fluid in the feed-heating section.

Notice the heat terms are of opposite signs in Equations 6 . 5 7 and 6.56.

If we assume the fluid properties do not change Significantly over the

temperature range of interest, and switch the direction of integration

in Equation 6.57 using dVa = - dV, we obtain

, dTa .

�

Q p Cp

dV q

Ta ( VR ) TaJ

�

(6.58)

(6.59)

6.5

329

The Plug-Flow Reactor

Parameter

Value

e----- p

Units

atm

:lOO

Qo

Ac

l

Tar

y � ---QpCp

f3 LlHR;1'

�

2rrRU"

QpCp

LlC-

0.1 6

1

12

323

rn"/s

0.5

11m

m2

m

K

-2.342

- 1 .2 x 104

7.794 x 101 1

k_lO

2 x 104

E_1/R

-

"

cal/mol

4250

LlW

m2 s K/mol

cal/mol

K

Table 6.6: Parameter values for Example 6.6; heat of reaction and

mixture heat capacity assumed constant.

700 r---,----,--r---,--,

600

500

400

T(K)

300

A

c

B

200

1 00

300

400

500

600

700

800

900

Ta ( O ) (K)

Figure

6.38:

Coolant temperature at reactor outlet versus temper­

ature at reactor inlet, To. (l) versus Ta ( 0 ) ; intersec­

tion with coolant feed tem perature T/-lf i n dicates three

steady-state solutions (A,S,C).

1000

The Energy Balance for Chemical Reactors

330

1000

900

800

T(K)

T

C

700

Ta

600

B

-- __

sao

--

Ta

400

300 L-----L-----�--�--�

a

8

10

6

2

4

12

A T, Ta

z (m)

Figure 6.39: Reactor and coolant temperature profiles versus reac­

tor length; lower (Al, unstable middle (B), and upper (Cl

steady states.

0.2 5 ,.----,----...,.---,.----,----.

....----,

0.2

0.! 5

c

a.!

B

0.05

- - - - - - - - - - - - - - - - - - ­

----- -�

A

2

Figure

6.40:

4

6

z (m)

8

10

Ammonia mole fraction versus reactor length; lower (A),

unstable m i d d le (B), and upper eCl steady states.

12

jj/

6.6 Summary and Notation

Finally we require a boundary condition for the reactor energy balance,

which we have from the fact that the heating fluid enters the reactor

at z = 0, T ( O)

=

Ta (O)· Combining these balances and boundary con­

ditions and converting to reactor length in place of volume gives the

model

dNA 2

AC r

dz

dT

= -fJr + y ( Ta - T)

dz

dT"

y ( T" - T)

dz

=

NA ( O )

T ( O)

=

=

NAJ

Ta (O) -

'

(6.60)

=

in which

Equation 6.60 is a boundary-value problem, rather than an initial-value

problem, because Ta is specified at the exit of the reactor. A simple

solution strategy is to guess the reactor iniet temperature, solve the

model to the exit of tbe reactor, and then compare the computed feed

preheat temperature to the specified value TaJ. This strategy is known

as a shooting method. We guess the missing values required to pro­

duce an initial-value problem. We solve the initial-value problem, and

then iterate on the guessed values until we match the specified bound­

ary conditions. We will see more about boundary-value problems and

shooting methods when we treat diffusion in Chapter 7.

SolUtion

Figure 6.38 shows the results for the parameter values listed in Ta­

ble 6.6, which are based on those used by van Heerden [ 2 5 ] . For given

values of Ta (O), we solve the initial-value problem, Equation 6.60, and

plot the resulting Ta (VR) as the solid line in Figure 6.38. The inter­

section of that line with the feed temperature TaJ

3 2 3 K indicates a

steady-state solution. Notice three steady-state solutions are indicated

in Figure 6.38 for these values of parameters. The profiles in the reac­

tor for these three steady states are shown in Figures 6.39 and 6.40. It

=

is lmportant to operate at the upper steady state so that a reasonably

0

large production of ammonia is achieved.

332

The Energy Balance for Chemical Reactors

Neglect kinetic and potential energies

dt � Q + W; + Wb

dU

.

.

.

(6.6 1 )

Neglect shaft work

(6.62)

(6.63)

Single phase

(6.64)

(6.65)

a. Incompressihle-fluid or constant-pressure reactor

(6.66)

h. Constant-volume reactor

h.l Constant-volume reactor, ideal gas

(6.68)

Table

6.6

6.7:

Energy balances for the batch reactor.

Sum mary

Tables 6.7-6.10 summarize the important energy balances for the batch,

continuous-stirred-tank, semi-batch, and plug-flow reactors. In con­

trast to the material balance, which is reasonably straightforward, choos­

ing the proper energy balance requires some care. It is unwise to se­

lect an energy balance from a book without carefully considering the

assumptions that have been made in the derivation of that particular