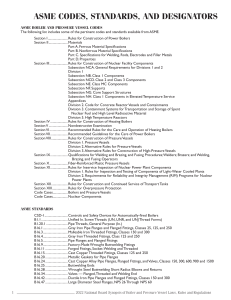

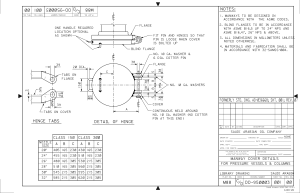

8/19/23, 8:11 PM Pipe Flanges and Flanged Fittings - ASME B16.5 [PDF] - PDFYAR - Engineering Notes, Documents & Lectures PDFYAR - Engineering Notes, Documents & Lectures Search for... Pipe Flanges And Flanged Fittings – ASME B16.5 [PDF] August 19, 2023 ASME B16.5 – Pipe Flanges And Flanged Fittings: A Comprehensive Guide The American Society of Mechanical Engineers (ASME) has been a driving force behind the standardization of engineering practices in various industries for over a century. One of the fundamental aspects of fluid handling systems is the connection between pipes and equipment. This connection is made possible through pipe flanges and flanged fittings. ASME B16.5, titled “Pipe Flanges and Flanged Fittings,” is a pivotal standard governing these components. In this comprehensive guide, we’ll delve into the world of ASME B16.5, exploring its significance, key provisions, and practical applications. Download ASME B16.5 https://pdfyar.com/pipe-flanges-and-flanged-fittings-asme-b16-5-pdf/ 1/6 8/19/23, 8:11 PM Pipe Flanges and Flanged Fittings - ASME B16.5 [PDF] - PDFYAR - Engineering Notes, Documents & Lectures Download ASME B16.5 PDF Understanding The Role Of Pipe Flanges And Flanged Fittings 1.1. Connecting The Dots: The Importance Of Flanges In any system involving the transport of fluids or gases, the seamless connection between pipes, valves, pumps, and other equipment is paramount. Pipe flanges serve as the critical link in this network. They provide a reliable means to join pipes and equipment, facilitating fluid flow, control, and maintenance. 1.2. Versatility And Ubiquity One of the remarkable aspects of pipe flanges is their versatility. They are employed across diverse industries, including petrochemical, oil and gas, manufacturing, pharmaceuticals, and more. Whether it’s a simple water supply system or a complex chemical processing plant, you’ll find flanges at work. ASME B16.5: The Backbone Of Flanged Connections 2.1. What Is ASME B16.5? ASME B16.5 is a widely recognized standard that sets forth the dimensions, materials, tolerances, and testing procedures for pipe flanges and flanged fittings. It falls under the umbrella of ASME’s Boiler and Pressure Vessel Code (BPVC), specifically in Section VIII, Division 1. This standard is not just a piece of paper; it’s the foundation upon which countless industrial systems are built. 2.2. Historical Significance ASME B16.5 has a rich history dating back to the early 20th century when the need for standardization in the emerging industrial landscape became evident. Over the years, this standard has evolved to accommodate changes in technology, materials, and industrial practices. Navigating ASME B16.5: Key Provisions And Insights 3.1. Flange Types And Facing https://pdfyar.com/pipe-flanges-and-flanged-fittings-asme-b16-5-pdf/ 3/6 8/19/23, 8:11 PM Pipe Flanges and Flanged Fittings - ASME B16.5 [PDF] - PDFYAR - Engineering Notes, Documents & Lectures The standard classifies flanges into various types, each with its unique features and applications. Common types include welding neck, slip-on, socket welding, blind, lap joint, and threaded. Additionally, ASME B16.5 defines facing dimensions, which are crucial for achieving a proper seal between flanges. 3.2. Dimensions And Tolerances ASME B16.5 provides precise dimensions for flanges, ensuring compatibility and interchangeability. This includes flange diameters, bolt hole sizes, and flange thicknesses. The standard also establishes tolerances to guarantee consistency in manufacturing. 3.3. Materials And Pressure-Temperature Ratings Selecting the right materials for flanges is essential for safety and performance. ASME B16.5 outlines the acceptable materials for different service conditions, taking into account pressure and temperature ratings. These ratings are essential for determining the appropriate flange class for a given application. 3.4. Bolting And Gaskets Flange connections are secured by bolts, and gaskets provide the necessary sealing. ASME B16.5 offers guidelines on bolt sizes, materials, and torque values. It also discusses gasket types, materials, and dimensions, helping engineers make informed choices. 3.5. Testing And Inspection Quality control is integral to ensuring the reliability of flanged connections. The standard outlines the procedures for testing and inspecting flanges, including methods for detecting defects and verifying compliance. Practical Applications And Industry Relevance 4.1. Oil And Gas Sector In the oil and gas industry, where safety and reliability are paramount, ASME B16.5 flanges play a pivotal role. They connect pipelines, valves, and pressure vessels, allowing for the transport of hydrocarbons from extraction sites to refineries and distribution networks. https://pdfyar.com/pipe-flanges-and-flanged-fittings-asme-b16-5-pdf/ 4/6 8/19/23, 8:11 PM Pipe Flanges and Flanged Fittings - ASME B16.5 [PDF] - PDFYAR - Engineering Notes, Documents & Lectures 4.2. Chemical Processing Chemical processing plants rely on ASME B16.5 flanges to handle a wide range of corrosive and hazardous materials. Flanged connections enable the safe transfer of chemicals while facilitating routine maintenance and equipment changes. 4.3. Power Generation Power plants, whether coal, gas, or nuclear, rely on ASME B16.5 flanged fittings to manage steam, water, and other fluids. These fittings ensure the integrity of critical systems and allow for efficient power generation. 4.4. Water Treatment In municipal and industrial water treatment facilities, flanges are used to connect pipes, pumps, and filtration systems. ASME B16.5 standards ensure that water treatment processes are consistent and reliable. Challenges And Future Trends 5.1. Material Advancements As industries evolve, so do the materials used in flange construction. Innovations in metallurgy and composite materials continue to offer opportunities for improved performance, corrosion resistance, and cost-effectiveness. 5.2. Digitalization And Simulation Modern engineering practices leverage digital tools and simulations to optimize flange designs and predict behavior under various conditions. This trend enhances efficiency and safety in flanged connections. 5.3. Sustainability Sustainable practices in manufacturing and materials selection are gaining prominence. Engineers and manufacturers are exploring eco-friendly alternatives without compromising performance. Conclusion: The Enduring Legacy Of ASME B16.5 https://pdfyar.com/pipe-flanges-and-flanged-fittings-asme-b16-5-pdf/ 5/6 8/19/23, 8:11 PM Pipe Flanges and Flanged Fittings - ASME B16.5 [PDF] - PDFYAR - Engineering Notes, Documents & Lectures ASME B16.5, with its rich history and enduring relevance, remains a cornerstone in the world of engineering and industrial fluid systems. From securing pipelines in the oil fields to ensuring the safety of chemical reactors, its impact is felt across Tags: ASME STANDARDS Leave A Reply Logged in as Zahid1078. Edit your profile. Log out? Required fields are marked * Comment * Post Comment Neve | Powered by WordPress https://pdfyar.com/pipe-flanges-and-flanged-fittings-asme-b16-5-pdf/ 6/6