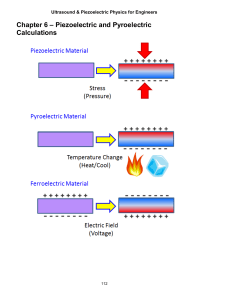

Perovskite lead-free piezoelectric ceramics Cite as: J. Appl. Phys. 127, 190901 (2020); https://doi.org/10.1063/5.0006261 Submitted: 05 March 2020 • Accepted: 26 April 2020 • Published Online: 15 May 2020 Jiagang Wu ARTICLES YOU MAY BE INTERESTED IN A comprehensive review on piezoelectric energy harvesting technology: Materials, mechanisms, and applications Applied Physics Reviews 5, 041306 (2018); https://doi.org/10.1063/1.5074184 Next generation ferroelectric materials for semiconductor process integration and their applications Journal of Applied Physics 129, 100901 (2021); https://doi.org/10.1063/5.0037617 Electrostrictive effect in ferroelectrics: An alternative approach to improve piezoelectricity Applied Physics Reviews 1, 011103 (2014); https://doi.org/10.1063/1.4861260 J. Appl. Phys. 127, 190901 (2020); https://doi.org/10.1063/5.0006261 © 2020 Author(s). 127, 190901 Journal of Applied Physics PERSPECTIVE scitation.org/journal/jap Perovskite lead-free piezoelectric ceramics Cite as: J. Appl. Phys. 127, 190901 (2020); doi: 10.1063/5.0006261 Submitted: 5 March 2020 · Accepted: 26 April 2020 · Published Online: 15 May 2020 View Online Export Citation CrossMark Jiagang Wua) AFFILIATIONS Department of Materials Science, Sichuan University, Chengdu 610065, China a) Author to whom correspondence should be addressed: wujiagang0208@163.com and msewujg@scu.edu.cn ABSTRACT The ability of piezoelectric devices to convert mechanical energy to electrical energy and vice versa has inspired remarkable growth in research on piezoelectric materials. However, based on the Restriction of Hazardous Substances legislation, it is necessary to eliminate the lead from currently used piezoelectric ceramics. Together with the increasing market share and improved performance of lead-free piezoelectrics, this growing recognition that the use of lead should be limited in piezoelectric materials has promoted the development of lead-free piezoelectric ceramics. Some devices with excellent performance based on lead-free piezoelectric ceramics have been reported, and their applications are expected to increase in the near future. This perspective provides an overview of key advances related to the structures and properties of lead-free piezoelectrics, including (K,Na)NbO3, BaTiO3, Bi0.5Na0.5TiO3, and BiFeO3. Future prospects are also discussed based on the performances of lead-free piezoelectric materials investigated to date. Published under license by AIP Publishing. https://doi.org/10.1063/5.0006261 I. INTRODUCTION Since the discovery of quartz crystal in 1880, piezoelectric materials have attracted considerable attention. As classical functional materials, piezoelectric ceramics can realize the conversion between mechanical and electrical energies, allowing them to be applied in electronic devices.1,2 For a long time, the dominant piezoelectric ceramic in commercial applications has been lead– zirconate–titanate [Pb(Zr,Ti)O3, PZT], which was discovered by Jaffe et al. in 1954.3 Based on substantial development efforts, PZT-based ceramics have become common due to their excellent electrical properties and good stability resulting from the formation of a morphotropic phase boundary (MPB).4 The global market value of piezoelectric devices was estimated to be ∼$25.1 billion in 2019 and is expected to continue to increase at an annual growth rate of ∼6.2% over the next five years.5 Although PZT-based ceramics are commercially applied, toxic lead is released into the environment during their preparation and disposal. Consequently, the European Union implemented the Restriction of Hazardous Substances legislation, which set a mandatory standard that prohibits the use of lead-based piezoelectric materials in future electronic devices. Such stricter environmental, health, and safety regulations contributed to the expansion of the market for lead-free piezoceramics and promoted their development. As shown in Fig. 1, lead-free piezoelectric ceramics mainly include potassium sodium niobate [(K,Na)NbO3, KNN], barium titanate (BaTiO3, BT), J. Appl. Phys. 127, 190901 (2020); doi: 10.1063/5.0006261 Published under license by AIP Publishing. bismuth sodium titanate [(Bi,Na)TiO3, BNT], and bismuth ferrite (BiFeO3, BFO). Since the early 2000s, the development and commercialization of lead-free piezoelectric ceramics have attracted growing interest because of environmental and public health concerns.6–8 For example, the successful construction of phase boundaries was found to generate an enhanced piezoelectric coefficient in lead-free piezoelectric ceramics (Fig. 1), resulting in a technological breakthrough in electronic devices.6–8 In addition to the continuous investigation of piezoelectricity and electronic devices, new research hotspots [e.g., high-power energy storage and the electrocaloric effect (ECE)] have also emerged.9,10 As shown in Fig. 2, based on the statistical data of publications since 2004, the growth rate in research of lead-free piezoelectric ceramics has been witnessed. Some lead-free piezoelectric ceramics are currently applied in electronic devices; the global market value for these ceramics reached ∼$172 million in 2019 and is expected to increase to ∼$443 million by 2024 with an annual growth rate of ∼20.8%.5 This perspective discusses the current development efforts and potentially promising topics related to lead-free piezoelectric ceramics, thereby providing useful references and insight for the future development of these materials. II. PROSPECT AND CHALLENGE A. K0.5Na0.5NbO3 (KNN) KNN materials, which were discovered in the 1960s, are potential candidates for piezoelectric devices because of their 127, 190901-1 Journal of Applied Physics PERSPECTIVE scitation.org/journal/jap FIG. 1. Development of typical piezoelectric materials as well as the advance in piezoelectric properties in lead-free piezoelectric ceramics. outstanding electrical properties and high Curie temperature (TC).2,7,11,12 Some strategies have been utilized to enhance the piezoelectricity of KNN, including phase-boundary formation, grain texturing, and domain engineering.2,7 Chemical modification can be used to adjust the material properties by constructing phase FIG. 2. Published papers of lead-free piezoelectric materials from 2004 to 2019 years with keywords including lead-free and piezoelectric ceramics, all data from Web of Science. J. Appl. Phys. 127, 190901 (2020); doi: 10.1063/5.0006261 Published under license by AIP Publishing. boundaries [rhombohedral–orthorhombic (R–O) and orthorhombic–tetragonal (O–T) boundaries]. However, improvements in d33 (100–416 pC/N) remained limited before 2013.13,14 Subsequently, the creation of a new phase boundary between the rhombohedral and tetragonal phases (R–T) resulted in larger d33 values (490–570 pC/N).15–20 In particular, an ultrahigh d33 (650 ± 20 pC/N) was achieved in 2019 by introducing relaxor behavior in addition to the new phase boundary.21 Currently, the introduction of new phase boundaries is the best way to realize large d33 values in KNN-based ceramics. The main strategy for constructing new phase boundaries involves increasing the R–O phase transition temperature (TR–O) to room temperature via doping R additives while simultaneously decreasing the O–T phase transition temperature (TO–T) to room temperature via doping T additives; in this way, new phase boundaries (i.e., R–T or R–O–T) can be established [Fig. 3(a)].2,6,7,12 After the introduction of the new phase boundary, the nanoscale domains and increased domain wall density facilitate domain switching under an external electric field, thereby promoting the piezoelectric effect [Fig. 3(b)].16–18,21 Recently, we found that the relaxor behavior located at the new R–O–T boundary can further enhance d33,21 and the largest d33 realized [Fig. 3(c)] is superior to those of reported nontextured (R–O and O–T) materials and some typical PZT materials [Fig. 3(d)]. Although the introduction of phase boundaries improves the piezoelectric property, the polymorphic 127, 190901-2 Journal of Applied Physics PERSPECTIVE scitation.org/journal/jap FIG. 3. Property development of KNN-based ceramics: (a) new phase boundary design, (b) physical mechanism.16–18,21 Reproduced with permission from Adv. Mater. 28, 8519 (2016). Copyright 2016 Wiley. Reproduced with permission from J. Am. Chem. Soc. 138, 15459 (2016). Copyright 2016 American Chemical Society. Reproduced with permission from Energy Environ. Sci. 10, 528 (2017). Copyright 2017 Royal Society of Chemistry. Reproduced with permission from J. Am. Chem. Soc. 141, 13987 (2019). Copyright 2019 American Chemical Society. (c) Piezoelectricity development history, (d) piezoelectric vs TC, temperature stability of (e) d33 and (f ) d*33,14,18,20–25 (g) electrocaloric effect, (h) energy storage, and (i) Qm. phase-boundary (PPB) characteristics of the phase boundaries inevitably result in the poor temperature stability of the piezoelectric properties [Figs. 3(e)–3(f)]. The temperature stability of d33* can be improved to some extent by strategies including phase engineering, diffuse phase transitions, domain engineering, and chemical modification [Fig. 3(f)].14,18,22–24 However, the poor temperature stability of d33 cannot be solved till now [Fig. 3(e)].25–27 In addition to the piezoelectric effect, other electrical properties including ECE and energy-storage properties have also been considered in KNN-based ceramics. Its ECE can be increased from 0.48 to 1.9 K via chemical modification; an enhanced ΔT of 3.33 K (345 K) has been observed in nanocrystalline ceramics, and a negative ECE was found [Fig. 3(g)].28,29 A large recovered energy-storage density (Wrec ∼ 4.08 J/cm3) was also achieved by composition modification [Fig. 3(h)].30 “Hard” KNN-based ceramics with good properties are difficult to find because good mechanical quality factors (Qm) are always paired with poor d33 values [Fig. 3(i)].31–33 Some challenges still remain in the development of KNN-based ceramics, including bottlenecks in preparation technology, unbalanced development of electrical properties, and gaps between the properties of the ceramics and device requirements (Fig. 4). Regarding the preparation process, KNN-based ceramics J. Appl. Phys. 127, 190901 (2020); doi: 10.1063/5.0006261 Published under license by AIP Publishing. easily absorb moisture because potassium is highly reactive. Furthermore, the electrical properties of KNN-based ceramics are very sensitive to some technological parameters (e.g., calcining temperature, sintering temperature, and poling process), and the volatility of potassium and sodium during the preparation process results in decreased densification. Regarding the unbalanced development of electrical properties, the enhancement in piezoelectricity is typically associated with poor temperature stability, decreased TC, or low Qm. In addition, little attention has been paid to other electrical parameters [e.g., the electromechanical coupling coefficient (k33, kt), d31, mechanical behavior, and conductivity]. Finally, to meet the requirements of different electronic devices, the properties of the ceramic, including properties other than piezoelectricity, should be comprehensively considered. Even if the piezoelectric constant is comparable to those of most PZT-based ceramics, highperformance materials comparable to Pb(Mg1/3Nb2/3)O3–PbTiO3 (PMN–PT) are still lacking. In addition, it remains necessary to further explore the relationships among chemical modification, phase-boundary construction, and domain engineering along with the corresponding physical mechanisms. Meanwhile, the investigation of the temperature stability of the piezoelectric effect and particularly the piezoelectric constant should be continued. Some physical 127, 190901-3 Journal of Applied Physics PERSPECTIVE scitation.org/journal/jap FIG. 4. Issues and challenges of KNN-based materials. mechanisms involved in piezoelectricity require further illumination, including the relationships between structure (crystal structure, domain structure, and defect structure) and performance (piezoelectric, strain, dielectric, and ferroelectric behavior) under different external fields (electric field, temperature field, etc.); the effects of key modifying elements (antimony, bismuth, etc.) on the piezoelectric performance; and the service behavior and failure mechanisms of electronic devices. B. BaTiO3 (BT) In the past, the overall piezoelectric properties of BT were inferior to those of lead-based PZT materials; thus, BT has mainly been used as a dielectric material. Pure BT ceramic produced using the conventional solid-state reaction method has a d33 of ∼190 pC/N.34 Since 2009, researchers have focused on manipulating the phase boundary of BT via ion substitution. A large d33 of 620 pC/N was realized in Ba(Zr0.2Ti0.8)O3–x(Ba0.7Ca0.3)TiO3 ceramics through R–T phase boundary starting a cubic (C)–T–R tricritical point in 2009 [Figs. 5(a)–5(b)].35 Many subsequent studies focused on the physical/structural origin in high piezoelectricity and phase structure modification.36–47 Nevertheless, because of the intrinsic characteristics of the polymorphic phase transition, it remains difficult to realize a real MPB with vertical phase boundaries along the composition axis in lead-based systems. The piezoelectric response of most ceramics rapidly decreases when the composition or temperature deviates from the area of the phase boundary [Fig. 5(b)]. Regarding the physical origin of high piezoelectricity, the nearly vanishing polarization anisotropy at the tricritical point is thought to facilitate the polarization rotation between the R and T phases [Fig. 5(c)].35–37 On the other hand, the phase components about the R–T boundary are controversial. Some reports have suggested the existence of an J. Appl. Phys. 127, 190901 (2020); doi: 10.1063/5.0006261 Published under license by AIP Publishing. intermediate O phase in R–T, while other researchers have proposed that the alleged R–T is actually an O–T phase transition next to a weak R–O phase transition [Fig. 5(a)].40–47 The convergence of the R–O and O–T phase boundaries or the presence of an intermediate O phase would strongly influence the piezoelectric properties [Fig. 5(d)].36,40–49 In addition, the miniaturized domain size and hierarchical domain configuration greatly decrease the domain wall energy and thus facilitate the polarization rotation, thereby resulting in excellent piezoelectric properties [Fig. 5(e)].47 Subsequently, similar systems [Ba(Sn0.12Ti0.88)O3–x (Ba0.7Ca0.3)TiO338 and Ba(Hf0.2Ti0.8)O3–x(Ba0.7Ca0.3)TiO339] were designed to achieve high piezoelectric performance. In 2018, we designed the new (1 – x)Ba(Ti0.89Sn0.11)O3–x (Ba0.7Ca0.3)TiO3 (BTS0.11–xBCT) ceramic37 and employed a new phase-boundary engineering scheme by constructing a broad phase-boundary region with close and successive R–O and O–T polymorphic phase transitions starting from a quadruple critical point (C–R–O–T). The R–O and O–T phase transitions stretched out from the quadruple critical point and were approximately parallel to the composition axis [Fig. 5(f)]. In this region, we achieved a large d33 of >700 pC/N along with high d33 values of >600 pC/N within a wide composition range [Fig. 5(g)]. This ceramic also exhibits an improved temperature stability with d33 > 600 pC/N owing to the broad region of phase coexistence. The physical origin of these properties was determined to be the ultralow energy barriers in the broad phase-boundary region close to the quadruple critical point with extremely weak polarization anisotropy [Fig. 5(h)]. The structural origin was identified as the intimate coexistence of the R, O, and T ferroelectric phases inside nanodomains and the gradual polarization rotation between these phases, as determined via phasefield simulation [Fig. 5(i)] and atomic-resolution polarization mapping [Fig. 5( j)]; these phenomena facilitate polarization/domain 127, 190901-4 Journal of Applied Physics PERSPECTIVE scitation.org/journal/jap FIG. 5. Phase diagram of (a) (1 – x)Ba(Zr0.2Ti0.8)O3–x(Ba0.7Ca0.3)TiO3 (BTZ–xBCT)35 and (f ) (1 – x)Ba(Ti0.89Sn0.11)O3–x(Ba0.7Ca0.3)TiO3 (BTS0.11–xBCT) ceramics.37 Reproduced with permission from Phys. Rev. Lett. 103, 257602 (2009). Copyright 2009 American Physical Society. Reproduced with permission from J. Am. Chem. Soc. 140, 15252 (2018). Copyright 2018 American Chemical Society. Comparison of d33 and Pr for (b) BTZ–xBCT and (g) BTS0.11–xBCT. (c) Landaus free energy surface and free energy barrier along the polarization rotation between R and T phases at tricritical point.35 Reproduced with permission from Phys. Rev. Lett. 103, 257602 (2009). Copyright 2009, American Physical Society. (d) Effects analysis of O phase cluster on polarization rotation48 and (e) hierarchical domain morphologies in BTZ-0.5BCT.47 Reproduced with permission from Nat. Commun. 8, 15944 (2017). Copyright 2017 Springer Nature. Reproduced from Appl. Phys. Lett. 105, 032903 (2014) , with the permission of AIP Publishing LLLC. (h) Free-energy profiles for BTS0.11–xBCT at quasiquadruple point. (i) 2D projection of phase-field simulation for R, O, and T phases coexistence in BTS0.11–xBCT (x = 0−0.2). ( j) STEM polarization mapping images showing gradual polarization rotation from R to T and from O to R in BTS0.11–0.18BCT.37 Reproduced with permission from J. Am. Chem. Soc. 140, 15252 (2018). Copyright 2018 American Chemical Society. rotation and thus result in a large d33 value. The above work provides a new strategy for designing phase boundaries involving broad, multiphase convergence zones to simultaneously optimize piezoelectricity and stability. The improved piezoelectric properties of BT ceramics are based on the decrease in TC (usually <100 °C) and the increase in sintering temperature [>1400 °C; Fig. 6(a)]. A low TC and narrow R–(O)–T region result in poor temperature stability in both d33 and d33*. Hence, it is difficult to apply BT-based ceramics with a working temperature exceeding 100 °C. On the other hand, a high d33 of >550 pC/N can be maintained by constructing broad and successive phase boundaries, even for low TC [∼60 °C; Fig. 6(b)].2,36 Another way to enhance the temperature stability is to maintain a high TC J. Appl. Phys. 127, 190901 (2020); doi: 10.1063/5.0006261 Published under license by AIP Publishing. when forming the phase boundary [Fig. 6(c)].9,50,51 A high TC can be useful to optimize the temperature stability of d33* [Fig. 6(d)], although its ability to enhance the temperature stability of d33 is weak [Fig. 6(e)].50 Therefore, forming a phase boundary to maximize the piezoelectricity while simultaneously maintaining a high TC should be the optimal strategy. It is desirable or necessary to decrease the sintering temperature for industrial production. However, the sintering temperature for high-performance BT-based ceramics is as high as 1450–1500 °C. The sintering temperature can be decreased to 1300–1400 °C after doping with additives (e.g., Li2O, Li2CO3, CuO, ZnO, CeO2, HfO2, Ga2O3, and BiFeO3).2,36 Unfortunately, although these sintering additives can reduce the sintering temperature, they will inevitably 127, 190901-5 Journal of Applied Physics PERSPECTIVE scitation.org/journal/jap FIG. 6. Temperature dependence of εr, d33, and d33* (under 30 kV/cm) for the optimized compositions of (a) BTZ-0.5BCT,35,46 (b) BTS0.11–0.18BCT,37 and (c) BT–0.1CT– 0.075BZH0.550 ceramics with different phase components and Curie temperature. Comparison of temperature stability of (d) d33* and (e) d33 for BT-based ceramics. (f ) d33 distribution as a function of sintering temperature for BT-based ceramics.2,36 All low-temperature sintering was performed after introducing sintering aids. (h) Electrocaloric adiabatic temperature change ΔT as a function of ΔT for BT-based ceramics with low Curie temperature.52 (h) Comparison of Wrec for BT-based ceramics and Q33 for leadfree electrostrictors.2,53,54 result in the degradation of the piezoelectric property [Fig. 6(f)]. Therefore, it is urgent to identify new and economical lowtemperature sintering techniques. BT can also be considered as an excellent electrocaloric material due to its low TC and relatively high spontaneous polarization. ECE refers to the change in adiabatic temperature (ΔT) or isothermal entropy in a polar material under an electric field (ΔE), where the maximum ΔT is reached in the vicinity of TC. The TC peak can be shifted to near room temperature via chemical substitution, and a strong ECE of ΔT = 0.2–1.0 K and ΔT/ΔE = 0.2–0.5 K·m/MV can be achieved near room temperature under low electric fields of ≤40 kV/cm [Fig. 6(g)].2,52 In addition, a high Wrec of ∼1.0–4.5 J/cm3 can be achieved under 90–340 kV/cm [Fig. 6(h)].2 At present, the typical strategy to enhance Wrec is the addition of Bi-based compounds or the preparation of fine-grained ceramics to obtain low-hysteresis ferroelectric loops and improve the breakdown strength. A large electrostrictive coefficient Q33 of ∼0.06–0.07 m4/C2, which is superior to those of other lead-free materials (Q33 < 0.047 m4/C2) along with Pb-based ceramics and crystals (Q33 = 0.015–0.037 m4/C2),2 has also been achieved through chemical modification [Fig. 6(h)].2,53,54 The next steps required for the piezoelectric applications of BT-based ceramics can be summarized as follows: further improve the piezoelectric properties, increase the Curie temperature and optimize the temperature stability, and reduce the sintering temperature. Reconciling the tradeoffs among piezoelectric properties, Curie temperature, and sintering temperature to achieve their simultaneous improvement remains a challenge. The updated phase boundary J. Appl. Phys. 127, 190901 (2020); doi: 10.1063/5.0006261 Published under license by AIP Publishing. strategy, the design of new material systems, and the optimization of the ceramic preparation techniques may represent steps toward the development of applicable BT-based ceramics. For electrocaloric, energy-storage, and electrostrictive applications, multilayer ceramic structures and cofired techniques with metal electrodes should be explored in conjunction with efforts to optimize the material properties and reveal the corresponding mechanisms. C. Bi0.5Na0.5TiO3 (BNT) BNT, which was first discovered in 1960, has rhombohedral symmetry.6 Because of the large remnant polarization (Pr = 38 μC/cm2 ), BNT-based ferroelectrics have attracted considerable attention.6 However, the high conductivity and large coercive field of BNT make the poling of pure BNT ceramics difficult, leading to undesirable d33 values (73–95 pC/N). 6 Chemical modification can promote piezoelectric behavior, and some progress has been made in terms of d33.6 However, the existence of the depolarization temperature Td hinders practical applications and represents the critical bottleneck restricting the further development of this material.6 For poled BNT samples, Td can be traced back to the transition from the ferroelectric to the relaxor state (Td slightly precedes Tf−r), which is derived from the thermal fluctuations of oriented domains induced by the structural R3c-to-P4bm transition.55,56 The calculated Born effective charges show that the polarization of BNT is dominated not only by the displacement of Ti4+, as in normal displacive ferroelectrics, but also 127, 190901-6 Journal of Applied Physics PERSPECTIVE scitation.org/journal/jap FIG. 7. Present status and prospect of relaxor Bi0.5Na0.5TiO3-based ferroelectrics: (a) unit cell distortion caused by the local A-site cations displacement also contributes to the polarization of BNT. (b) Schematic illustrations for the assemblage of distinct octahedral tiltings with nanodomains along [111]pc and [110]pc directions, respectively. Black represents the nontilted octahedra, and cyan, red, and yellow represent the three variants of in-phase tilted octahedra, while green represents the antiphase ones. The gradient colors represent the continuous octahedral tiltings. (c) The figurative evolution images of initial polar entities during the E-field loading, unloading and timerelaxation process. The suppressed large-sized bulks under high E-field is given to illustrate the percolation limit. (d) E-field vs temperature phase diagram of (1−y)[Bi0.5 (Na0.82−xK0.18Lix)0.5]−ySrTiO3 ceramics with x = 0.10 and y = 0.05. by the displacement of local A-site cations.57 In the ideal ordered lattice structure of BNT, the discrepancies between the Bi3+–O–Ti and Na+–O–Ti bonds (hybridization between Bi 6p and O 2p orbitals) cause the intermediate oxygen anions to be displaced toward the Na position; thus, octahedral tilting is expected [ Fig. 7(a)]. Although the lack of an enthalpic driving force for A-site cation ordering may be counterintuitive due to the differences in the sizes and formal charges of Na+ and Bi3+, BNT does not possess any of the combinations of structural and chemical features known to induce A-site cation ordering in perovskites.6 In reality, Bi3+ and Na+ share different local environments, leading to the local inhomogeneity of symmetry [long-range-correlated R3c and short-range-correlated P4bm; Fig. 7(b)]. Taking the above-mentioned relaxor nature of BNT [Fig. 7(c)] into consideration, it is easier to understand the enhanced d33, Chemical modification can increase the ergodicity of BNT [see the metastable state provided in Fig. 7(d)], leading to an increased dielectric response and finally to an enhanced piezoelectric response. However, modifying d33 by increasing the ergodicity of BNT can directly decrease Td [Fig. 8(a)] due to the inverse relationship between d33 and 1/Td [d33 ∝ 1/Td; Fig. 8(b)]. We previously reported BNT-based complex oxides with both large d33 J. Appl. Phys. 127, 190901 (2020); doi: 10.1063/5.0006261 Published under license by AIP Publishing. (232 ± 5 pC/N) and high Td (188 °C) based on a combination of compositional selection and rapid quenching in liquid nitrogen from ultrahigh temperature. In situ characterization indicated that the superior performance (d33 = 232–281 pC/N) is retained in a wide working temperature range (T = 25 °C–185 °C), which may even meet practical requirements to a certain degree. In addition to enhancing d33, increasing the ergodicity also provides the possibility of obtaining a large electrostrain. A large electrostrain of ∼0.45%–0.70% accompanied by a decrease in Td was reported under a high electric field;6 this electrostrain is comparable or even superior to those of lead-based ceramics. Extensive attention has been paid to the modification of electrostrain and the corresponding structural mechanism.6,58 In addition to the widely accepted E-field-induced state transitions from the relaxor state to the ferroelectric state, several complementary physical mechanisms (e.g., remnant ferroelectric domains, nanoscale ferroelectric/relaxor composites, and core–shell structures) have also been proposed to further explain the origin of the ultrahigh electrostrain.6 Note here that the growth and degradation of the inherent polar clusters during the E-field loading and unloading process should be responsible for the electrostrain, which can be traced back to the local symmetry, grain size, defects, and 127, 190901-7 Journal of Applied Physics PERSPECTIVE scitation.org/journal/jap FIG. 8. (a) General illustration of the destruction and reconstruction process of A–O interactions in BNT. (b) Simultaneously enhanced d33 and Td by quenching treatment, which from the general d33 ∝ (1/Td) trend. The data are compiled from the reported review literature.6 (c) Electrostrain of some representative high-performance ferroelectric families against their d33*. All the data are compiled from the reported review literatures.6 (d) General conceptual PNRs growth model utilized to explain the excellent energy-storage properties in BNT.61 Reproduced with permission from J. Mater. Chem. A 7, 3971 (2019). Copyright 2019 Royal Society of Chemistry. other critical factors.59 Based on composition engineering and subtle criticality confinement, we obtained a large recoverable electrostrain (S > 0.7%, realizing Srem modulation without Spol sacrifice) with reduced hysteresis [Fig. 8(c)], and the electrostrain remained at a high level (<2% variation) after 105 fatigue cycles.60 This demonstrates that structural regulations are an effective way to modify the electrostrain behavior. However, the complexities involved in determining the intrinsic structural information make it difficult to further enhance electrostrain via structural regulation. Therefore, to better guide the design of high-performance and deformable structural materials, additional high-resolution in situ structural studies are needed. Despite the achievement of enhanced piezoelectricity (including the small-field and large-field signals), the design of materials to induce the critical metastable state based on R–T symmetries has reached a bottleneck; this is why no major piezoelectric advances (d33 ≤ 271 pC/N, S < 1%) have been reported in recent years. Considering the relaxor nature and great ferroelectric potential (Pmax) of BNT-based ceramics, the promising energy-storage and electrocaloric performances are attracting more and more attention. Among potential systems, relaxor BNT-based ferroelectrics exhibit superior energy-storage performance due to the large Pmax (>50 μC/cm2).61,62 During studies aimed at obtaining large electrostrain, researchers observed pinched P–E loops, inspiring further investigations of energy-storage properties. Through chemical J. Appl. Phys. 127, 190901 (2020); doi: 10.1063/5.0006261 Published under license by AIP Publishing. modification followed by hot-pressed sintering, we obtained enhanced energy-storage performance (Wrec ∼ 2.42 J cm−3 under a low electric field of E = 143 kV cm−1) along with excellent fatigue and thermal stability (variation in Wrec ≤ 0.047% after 105 cycles and Wrec > 2 J cm−3 over 25–175 °C). In 2019, a superior Wrec (7.02 J cm−3) was realized [Fig. 8(d)],62 further confirming our assumptions and directing future work aimed at further increasing dielectric breakdown strength (DBS).61 According to previous reports, the substitution of suitable ions and the constructed polyploid system provide the driving force for the increased ergodicity, and achieving pinched and linearlike P–E loops is the first step toward enhancing the energy-storage potential. Sintering additives and improved experimental processes are useful tools for enhancing DBS and can thus be expected to improve the energy-storage performance. In addition to the excellent energy-storage performance, some interesting observations regarding the electrocaloric performance should also be considered. First-principles simulations indicated that ferroelectrics with multiple symmetry transitions can exhibit large ECEs, both positive and negative, under the influence of large electric fields, and the symmetry transition below TC can also exhibit ECE.63–65 The occurrence of depolarization behavior can also result in a large change in entropy, leading to a considerable ECE.63–65 The high Td of pure BNT (∼190 °C) results in inferior room-temperature ECE. During studies aimed at obtaining large 127, 190901-8 Journal of Applied Physics electrostrain, different methods have been applied to decrease Td and thus enhance the room-temperature ECE. However, few investigations have focused on the ECE properties of BNT-based ceramics, and excellent reports on ECE properties are even fewer. For normal ferroelectrics with first-order phase transitions, strong ECE can only be realized in a narrow temperature range in the vicinity of the ferroelectric–paraelectric phase transition.63–65 In this case, relaxor ferroelectric ceramics with broad and diffuse phase transitions are preferred due to their wide working temperature region. Therefore, in addition to seeking strong ECE, tuning the working temperature region is another potential direction for future work focused on electrocaloric cooling. It is worth noting here that a strong room-temperature ECE with temperature-insensitive stability can hardly be found in BNT-based ceramics. Even worse, an opposite ECE (namely, a negative ECE) is often observed,63–65 indicating that BNT-based ceramics can absorb heat (refrigeration effect) under applied fields. In BNT-based ceramics with rhombohedral symmetry, Qm values of 500–1000 can be obtained by doping with acceptors (Mn, Fe, or Co cations) with enhanced Td values.66 Despite the relatively high Qm values, “hard” BNT-based ceramics exhibit inferior d33 values (<100 pC/N) and dielectric responses (εr < 400), greatly restricting their practical applications in high-power piezoelectric applications. The tuning of electrical properties (i.e., piezoelectric, electrostrain, energy-storage, and electrocaloric properties) via chemical modification and processing improvements is briefly discussed here. Importantly, the relationships between Td and multiple properties are also established, and the inherent mechanisms are discussed in detail to better understand the enhanced electrical behavior. Currently, it is accepted that chemical modification can promote multiple properties, as evidenced by enhancements in piezoelectricity (d33 ∼ 271 pC/N), electrostrain (S > 0.70%, d33* ∼ 1400 pm/V), and recoverable energy-storage density (Wrec = 7.02 J⋅cm−3) along with the promising but still unimplemented electrocaloric behavior. Despite the reported achievements, some problems remain, including the following: (1) the evolutions of the symmetries are still controversial, and it is difficult to link the macroscopic electrical properties with the microscopic evolutions of lattice symmetries; (2) the origin of the depolarization process is not completely clear, and the unavoidable Td hinders real piezoelectric applications; (3) it is difficult to achieve large electrostrain with low hysteresis and low driving E-field, which are necessary for the design of deformable structural devices; (4) it is not clear how to further increase DBS for energy storage; and (5) it is not clear how to obtain large roomtemperature ECE in a wide temperature region. Therefore, before BNT-based materials can be used in practical applications, these above key issues should be addressed. D. BiFeO3 (BFO) BFO is the only single-phase multiferroic material with both magnetic and ferroelectric order at room temperature.8 Although most studies have focused on BFO thin films due to their notable properties such as large ferroelectricity, charged domain walls, and ferroelectric photovoltaic effect,67 BFO ceramics are attracting considerable attention because of improvements in ceramic preparation techniques and the discovery of new properties of BFO ceramics.68 J. Appl. Phys. 127, 190901 (2020); doi: 10.1063/5.0006261 Published under license by AIP Publishing. PERSPECTIVE scitation.org/journal/jap In particular, the phase-boundary-based regulation of the electrical properties of BFO ceramics has become a hot research topic in recent years. 1. Piezoelectricity Composition modification can drive the formation of phase boundaries to promote piezoelectricity. Figures 9(a1) and 9(a2) show the composition dependence of d33 in two classical ceramic systems: Bi1 − xSmxFeO369 and (1 − x)BiFeO3–xBaTiO3.70 A large d33 of 37.2 pC/N is observed in Bi0.88Sm0.12FeO3 ceramic because of the polar-to-polar (R3C/Pna21) phase boundary,67 and 0.7BiFeO3–0.3BaTiO3 ceramic with coexisting R and pseudocubic (Pc) phases exhibits a large d33 of 134 pC/N.70 d33 can be further enhanced by composition modification and/or new processing techniques [Fig. 9(a3)].8 A large d33 of 50 pC/N was obtained in Sm–La codoped BFO ceramic,71 and both a large d33 (405 pC/N) and high TC (450 °C) were obtained in Ga-modified BFO–BTO ceramic because of the formation of the R–T phase boundary and the quenching process.72 Although the introduction of a phase boundary can improve the piezoelectric properties, the intrinsic features of BFO ceramics remain controversial, leading to debates surrounding the structural origin and physical mechanism of the enhanced properties. For instance, the local structure analysis of 0.6BFO–0.4BTO based on the pair distribution function from synchrotron X-ray analysis showed that the local symmetry is rhombohedral (R3C) rather than cubic.73 However, high-energy synchrotron X-ray powder diffraction revealed that the local structure of the ferroelectric cubic phase of (1 − x)BFO–xBTO ceramics is monoclinic with type MA in the Cm space group.74 Therefore, more effort needs to be devoted to elucidating the structure and characteristics of the phase boundary in the future. 2. Ferroelectricity Several strategies have been proposed to modulate the ferroelectricity. As shown in Fig. 9(b1), ions including Dy, Sm, La, and Nd can effectively improve the ferroelectric response based on the longrange macroscale ferroelectric domains and/or phase boundaries.75,76 In addition to composition modification, quenching can enhance both the piezoelectricity and theferroelectricity.72,77 As shown in Fig. 9(b2), the linear P–E loops of slowly cooled samples can be transformed into the saturated P–E loops of air-quenched samples.77 Other strategies including field cycling78 and mechanochemical activation synthesis79 can also improve the ferroelectric properties, resulting in saturated P–E loops with large polarization. However, compared to thin films and single crystals, the ferroelectricity of BFO-based ceramics still lags far behind. Thus, the further enhancement of ferroelectricity is a critical problem to be addressed in the future. 3. Energy storage Among lead-free piezo/ferroelectrics, BFO materials are recognized as one of the most promising alternatives in the field of energy storage due to their large polarization. A large Wrec of 70 J/cm3 was achieved in BiFeO3–SrTiO3 (BF–ST) thin films through domain engineering,80 and a higher Wrec of 112 J/cm3 127, 190901-9 Journal of Applied Physics PERSPECTIVE scitation.org/journal/jap FIG. 9. Electrical properties of BFO-based ceramics. (a1)–(a3) piezoelectricity of BFO-based ceramics.8,69,70 Reproduced from J. Appl. Phys. 119, 064104 (2016), with the permission of AIP Publishing LLC. Reproduced with permission from J. Am. Ceram. Soc. 96, 3163 (2013). Copyright 2013 Wiley. (b1) and (b2) composition dependence of P–E loops and PFM images.75,76 Reproduced with permission from Mater. Des. 120, 83 (2017). Copyright 2017 Elsevier. Reproduced with permission from Adv. Funct. Mater. 29, 1806399 (2019). Copyright 2019 Wiley. P–E loops and TEM images with quenching treatment.77 Reproduced from Appl. Phys. Lett. 109, 202902 (2016), with the permission of AIP Publishing LLC. (c) Energy storage of multilayers.83 Reproduced with permission from Energy Environ. Sci. 12, 582 (2019). Copyright 2019 Royal Society of Chemistry. (d1) and (d2) Strain response as a function of electric cycling and temperature.85,86 Reproduced with permission from J. Mater. Chem. C. 5, 9528 (2017). Copyright 2017 Royal Society of Chemistry. Reproduced with permission from Scr. Mater. 155, 11 (2018). Copyright 2018 Elsevier. together with a high energy efficiency (η) of 80% was obtained in BiFeO3–BaTiO3–SrTiO3 (BF–BT–ST) thin film.81 Tape casting has become a popular method to fabricate multilayer ceramics with improved energy storage properties. For example, high Wrec (6.74 J/cm3) and η (77%) values were obtained in a Nd-substituted BF–BT multilayer ceramic,82 and a high discharge energy density (W = 10.5 J/cm3) and efficiency (η = 77%) were achieved in a BiFeO3–BaTiO3–Nd(Zn0.5Zr0.5)O3 (BF–BT–NZZ) multilayer ceramic by constructing an electrically rather than chemically homogeneous microstructure [Fig. 9(c)].83 In 2019, a large Wrec (8.12 J/cm3), high η (90%), and excellent thermal stability were simultaneously obtained in BF–BT–NN ceramic based on the significant improvement in DBS via nanodomain engineering.84 Thus, increasing DBS plays a critical role in improving the energy storage density. 4. Strain response The strain in piezoelectric materials has extensive applications in actuators. A large peak-to-peak strain (Spp) of 0.66% with a strain memory effect has been reported in defective BFO ceramics J. Appl. Phys. 127, 190901 (2020); doi: 10.1063/5.0006261 Published under license by AIP Publishing. [Fig. 9(d1)].85 One advantage of BFO-based ceramics is that the strain value does not decrease with increasing temperature, similar to PZT [Fig. 9(d2)].86 In addition to improving the strain response, the corresponding physical mechanism has received considerable attention. A switching strain of 0.3% (Spp) can be obtained in Sm-doped BFO ceramic with a morphotropic phase-boundary region featuring polar, antipolar, and nonpolar phases. The enhanced strain in this case arises from dual mechanisms: ferroelectric/ferroelastic domain switching and the E-field-induced phase transition from antipolar Pbam and nonpolar Pnma to polar R3c [Fig. 10(a)].87 Compared to ion-substituted BFO ceramics, BF–BT and/or BF–PT solid solutions have a much stronger strain response due to the coexistence of R and pseudocubic phases. For example, a high strain of 0.4% was reported in BF–BT ceramics doped with Bi(Mg2/3Nb1/3)O3 or (Ba0.8Ca0.2)ZrO3.88,89 Although the physical mechanisms underlying the enhanced properties remain debated, the in situ high-energy X-ray diffraction analysis of core–shell-structured BF–BT ceramics under electric field did not indicate any phase transition [Fig. 10(b)], suggesting that the strain originates from a combination of non-180° domain switching and the associated lattice deformation.90 However, these mechanisms cannot explain why the electric field induces 127, 190901-10 Journal of Applied Physics PERSPECTIVE scitation.org/journal/jap FIG. 10. (a) Phase diagram, S–E curves, and XRD patterns of the Sm-doped BFO ceramics.87 J. Walker et al., Sci. Rep. 6, 19630 (2016); licensed under a Creative Commons Attribution (CC BY) license. (b) In situ XRD results of BF–BT ceramics with slow-cooled and quenched treatment.90 I. Calisir et al., J. Mater. Chem. C 7, 10218 (2019); licensed under a Creative Commons Attribution 3.0 unported license. domain transformation from nanoscale domains to long-range macroscale domains, as indicated by transmission electron microscopy.91 Therefore, the structural origins underlying the strain enhancement require further clarification. The maximum strain value of 1.3% was reported in a pseudoternary BF–PT–LF ceramic. This high strain is attributed to a combination of large spontaneous lattice strain, domain miniaturization, the low-symmetry ferroelectric phase, and large non-180° domain switching.92 However, in situ X-ray diffraction revealed that the strain in BF–PT–BKT ceramics arises from the electric field-induced phase transition together with dominant intrinsic lattice strain and weak extrinsic domain switching.93 These results indicate that BFO-based ceramics have rich structural features and good potential in actuator applications. Based on the research progress in BFO-based ceramics, this material system shows great potential in terms of piezoelectricity, ferroelectricity, energy storage, and strain response. Some new functions of BFO-based ceramics have gradually emerged, giving this material system new vitality. Future studies should focus on achieving breakthroughs in electrical properties and conducting in-depth structural analyses that reveal the relationships among composition J. Appl. Phys. 127, 190901 (2020); doi: 10.1063/5.0006261 Published under license by AIP Publishing. modification, phase-boundary construction, and electrical properties. The rich structural characteristics of BFO-based ceramics both create challenges and provide great potential for the further optimization of electrical properties. Some new effects have been found in the lead-free piezoelectric materials discussed above. External fields including electric field and temperature can be used to modulate the electrical properties of piezoelectric materials. In addition, the optical control of nanoscale properties would constitute a new paradigm in nextgeneration logic devices.94–101 For example, the variation in the polarization angle of a coherent light source can effectively modulate the motion of ferroelectric domain walls in BaTiO3 single crystals.94 Unlike the electrically switchable nature of polarization, the noncontact control of ferroelectric domain walls by light has some potential applications in ferroelectric random access memory devices and in the remote control of piezoelectric actuators.94,95 In particular, the discovery of the reversible optical control of macroscopic polarization and/or intrinsic capacitance facilitates the practical application of photostimulated ferroelectric devices.96,97 Since the manipulation of ferroelectric order by light has become a hot research topic in 127, 190901-11 Journal of Applied Physics modern solid-state physics, light-induced domain motion/switching has also been reported in other lead-free ferro/piezoelectric materials.98–101 For example, Alexe et al. found that ferroelectric polarization in BFO thin films can be fully controlled by tailoring the photocurrent direction, providing guidance for the design of novel optoferroic devices for data storage and sensing.98 The optoelectric control of ferroelectric domains can also boost photovoltaic output in (K0.49Na0.49Ba0.02)(Nb0.99Ni0.01)O2.995 ceramics.99 These recent advances related to nanoscale properties provide versatile opportunities for next-generation nanoelectronic devices, which may become a research hotspot in the near future. As a result, researchers should explore the new effects of these lead-free piezoelectric materials under different external fields or multiple fields. III. SUMMARY In the fields of sensors, actuators, and ultrasonic devices, piezoelectric ceramics based on lead-free KNN, BNT, and BT have been partially applied because of the quick improvement in the performances of lead-free piezoceramics. For larger-scale applications, good comprehensive performance and stability must be achieved. However, the development of lead-free piezoelectric materials faces a major hurdle since most lead-free piezoelectric materials involve temperature-dependent phase boundaries or the called “morphotropic phase boundary (MPB),” resulting in insufficient piezoelectric properties. Therefore, obtaining the real MPB is still necessary to realize high performance along with stability; at a minimum, the temperature stability of the electrical properties should be improved. In terms of temperature stability, BFO- and KNN-based ceramics are the most promising lead-free piezoelectrics for practical applications. The comprehensive performance in terms of the electrical parameters of these ceramics should be improved. For “hard” lead-free piezoelectrics, it is difficult to realize high Qm and high d33. The corresponding physical mechanisms need to be revealed to guide the development of “hard” lead-free piezoelectrics. For energy storage, improving the density is very important. In addition to the electrical parameters, the manufacturing processes (e.g., multilayer and three-dimensional printing processes) of these lead-free piezoelectrics should be considered along with other properties (e.g., mechanical behavior). Domain wall nanoelectronics represent a potential paradigm for next-generation ferroelectric devices. Stricter environmental, health, and safety regulations aimed at limiting the use of lead worldwide are critical. ACKNOWLEDGMENTS The author wishes to acknowledge funding support from the National Natural Science Foundation of China (NSFC Nos. 51972215 and 51722208) and the Key Technologies Research and Development Program of Sichuan Province (No. 2018JY0007). DATA AVAILABILITY The data that support the findings of this study are available from the corresponding author upon reasonable request. J. Appl. Phys. 127, 190901 (2020); doi: 10.1063/5.0006261 Published under license by AIP Publishing. PERSPECTIVE scitation.org/journal/jap REFERENCES 1 B. Jaffe, W. R. Cook, and H. Jaffe, Piezoelectric Ceramics (Academic, New York, 1971). 2 J. G. Wu, Advances in Lead-free Piezoelectric Materials (Springer, New York, 2018). 3 B. Jaffe, R. S. Roth, and S. Marzullo, J. Appl. Phys. 25, 809 (1954). 4 D. Damjanovic, J. Am. Ceram. Soc. 88, 2663 (2005). 5 Lead-Free Piezoelectric Ceramics Technologies and Global Opportunities (NAN063A), BCC Research, 2019. 6 T. Zheng, J. G. Wu, D. Q. Xiao, and J. G. Zhu, Prog. Mater. Sci. 98, 552 (2018). 7 J. G. Wu, D. Q. Xiao, and J. G. Zhu, Chem. Rev. 115, 2559 (2015). 8 J. G. Wu, Z. Fan, D. Q. Xiao, J. G. Zhu, and J. Wang, Prog. Mater. Sci. 84, 335 (2016). 9 L. Yang, X. Kong, F. Li, H. Hao, Z. Cheng, H. Liu, J. Li, and S. Zhang, Prog. Mater. Sci. 102, 72 (2019). 10 J. F. Scott, Annu. Rev. Mater. Res. 41, 229 (2011). 11 N. Zhang, T. Zheng, and J. G. Wu, ACS Omega 5, 3099 (2020). 12 X. Lv, J. G. Zhu, D. Q. Xiao, X. X. Zhang, and J. G. Wu, Chem. Soc. Rev. 49, 671 (2020). 13 R. Z. Zuo, J. Fu, D. Lv, and Y. Liu, J. Am. Ceram. Soc. 93, 2783 (2010). 14 Y. Saito, H. Takao, T. Tani, T. Nonoyama, K. Takatori, T. Homma, T. Nagaya, and M. Nakamura, Nature 432, 84 (2004). 15 X. P. Wang, J. G. Wu, D. Q. Xiao, J. G. Zhu, X. J. Cheng, T. Zheng, and X. J. Wang, J. Am. Chem. Soc. 136, 2905 (2014). 16 K. Xu, J. Li, X. Lv, J. G. Wu, X. X. Zhang, D. Q. Xiao, and J. G. Zhu, Adv. Mater. 28, 8519 (2016). 17 B. Wu, H. J. Wu, J. G. Wu, D. Q. Xiao, J. G. Zhu, and S. J. Pennycook, J. Am. Chem. Soc. 138, 15459 (2016). 18 T. Zheng, H. J. Wu, Y. Yuan, X. Lv, Q. Li, T. L. Men, C. L. Zhao, D. Q. Xiao, J. G. Wu, K. Wang, J. F. Li, Y. L. Gu, J. G. Zhu, and S. J. Pennycook, Energy Environ. Sci. 10, 528 (2017). 19 F. Rubio-Marcos, R. López-Juárez, R. E. Rojas-Hernandez, A. D. Campo, N. Razo-Pérez, and J. F. Fernandez, ACS Appl. Mater. Interfaces 7, 23080 (2015). 20 F. Rubio-Marcos, J. F. Fernandez, D. A. Ochoa, J. E. García, R. E. Rojas-Hernandez, M. Castro, and L. Ramajo, J. Eur. Ceram. Soc. 37, 3501 (2017). 21 H. Tao, H. J. Wu, Y. Liu, Y. Zhang, J. G. Wu, F. Li, X. Lyu, C. L. Zhao, D. Q. Xiao, J. G. Zhu, and S. J. Pennycook, J. Am. Chem. Soc. 141, 13987 (2019). 22 T. Zheng, W. J. Wu, J. Wu, J. G. Zhu, and D. Q. Xiao, J. Mater. Chem. C 4, 9779 (2016). 23 H. Tao, C. L. Zhao, R. Zhang, and J. G. Wu, J. Alloy. Compd. 795, 401 (2019). 24 M. H. Zhang, K. Wang, Y. J. Du, G. Dai, W. Sun, G. Li, D. Hu, H. Z. Thong, C. L. Zhao, X. Q. Xi, Z. X. Yue, and J. F. Li, J. Am. Chem. Soc. 139, 3889 (2017). 25 F. Li, Z. Xu, X. Y. Wei, and X. Yao, J. Electroceram. 24, 294 (2010). 26 R. P. Wang, K. Wang, F. Z. Yao, J. F. Li, F. H. Schader, K. G. Webber, W. Jo, and J. Rödel, J. Am. Ceram. Soc. 98, 2177 (2015). 27 K. Wang, F. Z. Yao, W. Jo, D. Gobeljic, V. V. Shvartsman, D. C. Lupascu, J. F. Li, and J. Rödel, Adv. Funct. Mater. 23, 4079 (2013). 28 R. Kumar and S. Singh, Sci. Rep. 8, 3186 (2018). 29 R. Kumar, A. Kumar, and S. Singh, ACS Appl. Electron. Mater. 1, 454 (2019). 30 T. Q. Shao, H. L. Du, H. Ma, S. B. Qu, J. Wang, J. F. Wang, X. Y. Wei, and Z. Xu, J. Mater. Chem. A 5, 554 (2017). 31 D. M. Lin, K. W. Kwok, and H. L. W. Chan, J. Phys. D Appl. Phys. 41, 045401 (2008). 32 M. Matsubara, K. Kikuta, and S. Hirano, J. Appl. Phys. 97, 114105 (2005). 33 S. L. Yang, C. C. Tsai, Y. C. Liou, and C. S. Hong, J. Am. Ceram. Soc. 95, 1011 (2012). 34 R. Bechmann, J. Acoust. Soc. Am. 28, 347 (1956). 35 W. F. Liu and X. B. Ren, Phys. Rev. Lett. 103, 257602 (2009). 127, 190901-12 Journal of Applied Physics 36 M. Acosta, N. Novak, V. Rojas, S. Patel, R. Vaish, J. Koruza, G. A. Rossetti, and J. Rödel, Appl. Phys. Rev. 4, 041305 (2017). 37 C. L. Zhao, H. J. Wu, F. Li, Y. Cai, Y. Zhang, D. Song, J. G. Wu, X. Lyu, J. Yin, D. Q. Xiao, J. G. Zhu, and S. J. Pennycook, J. Am. Chem. Soc. 140, 15252 (2018). 38 D. Z. Xue, Y. M. Zhou, H. X. Bao, J. H. Gao, C. Zhou, and X. B. Ren, Appl. Phys. Lett. 99, 122901 (2011). 39 C. Zhou, W. F. Liu, D. Z. Xue, X. B. Ren, H. X. Bao, J. H. Gao, and L. X. Zhang, Appl. Phys. Lett. 100, 222910 (2012). 40 Y. G. Yao, C. Zhou, D. C. Lv, D. Wang, H. J. Wu, Y. D. Yang, and X. B. Ren, Europhys. Lett. 98, 27008 (2012). 41 L. F. Zhu, B. P. Zhang, L. Zhao, and J. F. Li, J. Mater. Chem. C 2, 4764 (2014). 42 D. S. Keeble, F. Benabdallah, P. A. Thomas, M. Maglione, and J. Kreisel, Appl. Phys. Lett. 102, 092903 (2013). 43 F. Cordero, F. Craciun, M. Dinescu, N. Scarisoreanu, C. Galassi, W. Schranz, and V. Soprunyuk, Appl. Phys. Lett. 105, 232904 (2014). 44 L. Zhang, M. Zhang, L. Wang, C. Zhou, Z. Zhang, Y. G. Yao, L. X. Zhang, D. Z. Xue, X. J. Lou, and X. B. Ren, Appl. Phys. Lett. 105, 162908 (2014). 45 Y. Tian, X. Chao, L. Jin, L. Wei, P. Liang, and Z. Yang, Appl. Phys. Lett. 104, 112901 (2014). 46 M. Acosta, N. Novak, W. Jo, and J. Rödel, Acta. Mater. 80, 48 (2014). 47 S. Lu, Z. Xu, S. Su, and R. Z. Zuo, Appl. Phys. Lett. 105, 032903 (2014). 48 Y. Nahas, A. Akbarzadeh, S. Prokhorenko, S. Prosandeev, R. Walter, I. Kornev, J. Íñiguez, and L. Bellaiche, Nat. Commun. 8, 15944 (2017). 49 M. Acosta, N. Khakpash, T. Someya, N. Novak, W. Jo, H. Nagata, G. A. Rossetti, and J. Rödel, Phys. Rev. B 91, 104108 (2015). 50 C. L. Zhao, B. Wu, H. C. Thong, and J. G. Wu, J. Eur. Ceram. Soc. 38, 5411 (2018). 51 C. L. Zhao, B. Wu, and J. G. Wu, J. Am. Ceram. Soc. 102, 3477 (2019). 52 C. L. Zhao, J. Yang, Y. L. Huang, X. H. Hao, and J. G. Wu, J. Mater. Chem. A 7, 25526 (2019). 53 Y. L. Huang, C. L. Zhao, J. Yin, X. Lv, J. Ma, and J. G. Wu, J. Mater. Chem. A 7, 17366 (2019). 54 Y. L. Huang, C. L. Zhao, and J. G. Wu, Adv. Electron. Mater. 4, 1800075 (2018). 55 W. Jo, R. Dittmer, M. Acosta, J. Zang, C. Groh, E. Sapper, and J. Rödel, J. Electroceram. 29, 71 (2012). 56 J. Yin, H. Tao, G. Liu, and J. G. Wu, J. Am. Ceram. Soc. 103, 1881 (2020). 57 B. Jiang, T. Grande, and S. M. Selbach, Chem. Mater. 29, 4244 (2017). 58 J. Yin, C. L. Zhao, Y. X. Zhang, and J. G. Wu, Acta Mater. 147, 70 (2018). 59 J. Yin, G. Liu, C. L. Zhao, Y. L. Huang, Z. Li, X. Zhang, K. Wang, and J. G. Wu, J. Mater. Chem. A 7, 13658 (2019). 60 J. Yin, G. Liu, X. Lv, Y. X. Zhang, C. L. Zhao, B. Wu, X. Zhang, and J. G. Wu, J. Mater. Chem. A 7, 5391 (2019). 61 H. Qi and R. Zuo, J. Mater. Chem. A 7, 3971 (2019). 62 J. Yin, Y. Zhang, X. Lv, and J. G. Wu, J. Mater. Chem. A 6, 9823 (2018). 63 Y. Bai, G. Zheng, and S. Shi, Mater. Res. Bull. 46, 1866 (2011). 64 I. Ponomareva and S. Lisenkov, Phys. Rev. Lett. 108, 167604 (2012). 65 X. Zheng, G. Zheng, Z. Lin, and Z. Jiang, J. Electroceram. 28, 20 (2012). 66 J. F. Li, K. Wang, F. Zhu, L. Cheng, and F. Yao. J. Am. Ceram. Soc. 96, 3677 (2013). 67 L. W. Martin and A. M. Rappe, Nat. Rev. Mater. 2, 16087 (2016). 68 T. Rojac, A. Bencan, B. Malic, G. Tutuncu, J. L. Jones, J. E. Daniels, and D. Damjanovic, J. Am. Ceram. Soc. 97, 1993 (2014). 69 X. X. Shi, X. Q. Liu, and X. M. Chen, J. Appl. Phys. 119, 064104 (2016). 70 Y. X. Wei, X. T. Wang, J. T. Zhu, X. L. Wang, and J. J. Jia, J. Am. Ceram. Soc. 96, 3163 (2013). 71 T. Zheng and J. G. Wu, J. Mater. Chem. C 3, 3684 (2015). 72 M. H. Lee, D. J. Kim, J. S. Park, S. W. Kim, T. K. Song, M. H. Kim, W. J. Kim, D. Do, and I. K. Jeong, Adv. Mater. 27, 6976 (2015). J. Appl. Phys. 127, 190901 (2020); doi: 10.1063/5.0006261 Published under license by AIP Publishing. PERSPECTIVE scitation.org/journal/jap 73 Y. Yoneda, K. Yoshii, S. Kohara, S. Kitagawa, and S. Mori, Jpn. J. Appl. Phys. 47, 7590 (2008). 74 A. Singh, C. Moriyoshi, Y. Kuroiwa, and D. Pandey, Phys. Rev. B 88, 024113 (2013). 75 H. Tao, J. Lv, R. Zhang, R. Xiang, and J. G. Wu, Mater. Des. 120, 83 (2017). 76 J. Chen, B. Xu, X. Q. Liu, T. T. Gao, L. Bellaiche, and X. M. Chen, Adv. Funct. Mater. 29, 1806399 (2019). 77 D. S. Kim, C. I. Cheon, S. S. Lee, and J. S. Kim, Appl. Phys. Lett. 109, 202902 (2016). 78 L. Wang, R. H. Liang, Z. Y. Zhou, N. T. Liu, and X. L. Dong, J. Am. Ceram. Soc. 102, 4670 (2019). 79 J. Walker, P. Bryant, V. Kurusingal, C. Sorrell, D. Kuscer, G. Drazic, A. Bencan, V. Nagarajan, and T. Rojac, Acta Mater. 83, 149 (2015). 80 H. Pan, J. Ma, J. Ma, Q. H. Zhang, X. Z. Liu, B. Guan, L. Gu, X. Zhang, Y. J. Zhang, L. L. Li, Y. Shen, Y. H. Lin, and C. W. Nan, Nat. Commun. 9, 1813 (2018). 81 H. Pan, F. Li, Y. Liu, Q. H. Zhang, M. Wang, S. Lan, Y. P. Zheng, J. Ma, L. Gu, Y. Shen, P. Yu, S. J. Zhang, L. Q. Chen, Y. H. Lin, and C. W. Nan, Science 365, 578 (2019). 82 D. W. Wang, Z. M. Fan, D. Zhou, A. Khesro, S. Murakami, A. Feteira, Q. Zhao, X. L. Tan, and I. M. Reaney, J. Mater. Chem. A 6, 4133 (2018). 83 G. Wang, J. L. Li, X. Zhang, Z. M. Fan, F. Yang, A. Feteira, D. Zhou, D. C. Sinclair, T. Ma, X. L. Tan, D. W. Wang, and I. M. Reaney, Energy Environ. Sci. 12, 582 (2019). 84 H. Qi, A. Xie, A. Tian, and R. Z. Zuo, Adv. Energy Mater. 10(6), 1903338 (2019). 85 J. Lv, W. W. Gao, J. Li, T. Li, C. Long, X. J. Lou, and J. G. Wu, J. Mater. Chem. C 5, 9528 (2017). 86 T. Zheng, C. L. Zhao, J. G. Wu, K. Wang, and J. F. Li, Scr. Mater. 155, 11 (2018). 87 J. Walker, H. Simons, D. O. Alikin, A. P. Turygin, V. Y. Shur, A. L. Kholkin, H. Ursic, A. Bencan, B. Malic, V. Nagarajan, and T. Rojac, Sci. Rep. 6, 19630 (2016). 88 S. Murakami, D. W. Wang, A. Mostaed, A. Khesro, A. Feteira, D. C. Sinclair, Z. M. Fan, X. L. Tan, and I. M. Reaney, J. Am. Ceram. Soc. 101, 5428 (2018). 89 X. Liu, J. W. Zhai, and B. Shen, J. Mater. Chem. C 7, 5122 (2019). 90 I. Calisir, A. K. Kleppe, A. Feteira, and D. A. Hall, J. Mater. Chem. C 7, 10218 (2019). 91 S. O. Leontsev and R. E. Eitel, J. Mater. Res. 26, 9 (2011). 92 B. Narayan, J. S. Malhotra, R. Pandey, K. Yaddanapudi, P. Nukala, B. Dkhil, A. Senyshyn, and R. Ranjan, Nat. Mater. 17, 427 (2018). 93 Y. Z. Li, Y. Chen, Z. B. Zhang, A. Kleppe, and D. A. Hall, Acta Mater. 168, 411 (2019). 94 F. Rubio-Marcos, A. D. Campo, P. Marchet, and J. F. Fernández, Nat. Commun. 6, 6594 (2015). 95 F. Rubio-Marcos, D. Páez-Margarit, D. A. Ochoa, A. D. Campo, J. F. Fernández, and J. E. García, ACS Appl. Mater. Interfaces 11, 13921 (2019). 96 F. Rubio-Marcos, D. A. Ochoa, A. D. Campo, M. A. García, G. R. Castro, J. F. Fernández, and J. E. García, Nat. Photonics 12, 29 (2018). 97 D. Páez-Margarit, F. Rubio-Marcos, D. A. Ochoa, A. D. Campo, J. F. Fernández, and J. E. García, ACS Appl. Mater. Interfaces 10, 21804 (2018). 98 M. M. Yang and M. Alexe, Adv. Mater. 30, 1704908 (2018). 99 Y. Bai, G. Vats, J. Seidel, H. Jantunen, and J. Juuti, Adv. Mater. 30, 1803821 (2018). 100 F. Rubio-Marcos, A. D. Campo, R. E. Rojas-Hernandez, M. O. Ramírez, R. Parra, R. U. Ichikawa, L. A. Ramajo, L. E. Bausá, and J. F. Fernándeza, Nanoscale 10, 705 (2018). 101 G. Vats, Y. Bai, D. Zhang, J. Juuti, and J. Seidel, Adv. Opt. Mater. 7, 1800858 (2019). 127, 190901-13