DeltaV Advanced Unit Management Software Data Sheet

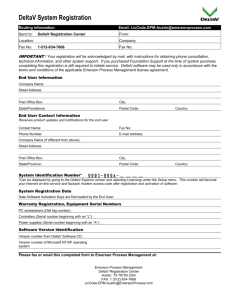

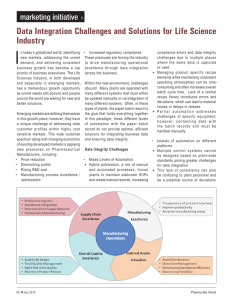

advertisement