Sous vide processing for food quality enhancement - A review

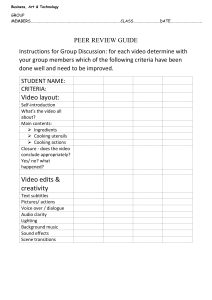

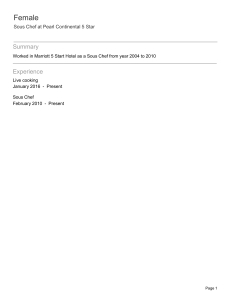

advertisement

Food and Humanity 1 (2023) 543–552 Contents lists available at ScienceDirect Food and Humanity journal homepage: www.editorialmanager.com/foohum/journal_overview.html Sous vide processing for food quality enhancement: A review Poornima Singha,b, Zainab Sultana, Vinay Kumar Pandeya,c, , Rahul Singha, ⁎ a b c ⁎⁎ ]] ]] ]]]]]] Department of Bioengineering, Integral University, Lucknow, Uttar Pradesh, India Faculty of Engineering and Technology, Mahatma Gandhi Chitrakoot Gramodaya Vishwavidyalaya, Chitrakoot, Madhya Pradesh, India Department of Biotechnology, Axis Institute of Higher Education, Kanpur, Uttar Pradesh, India A R T I C L E I N F O Keywords: Sous vide Vacuum Pathogens Seafoods Meat products A B S T R A C T As customer preferences shift, innovative food processing procedures that have little influence on food quality (prevent loss of nutrients, volatiles, and moisture content) and ensure microbiological safety are being developed. A recent innovation called Sous vide (SV) evenly distributes heat by cooking food in vacuum packaging at precise temperatures. An overview of the state of the science for using SV methods for food processing and preservation is provided below. In contrast to traditional thermal food processing methods, the SV method increases the quality of the food, nutritional content, and storage life while destroying microorganisms (Salmonella, Clostridium, and many more). The majority of the time, SV cooks food at the range of 60–100 °C generally for 1–7 h. Microbiological pathogens such as parasites and vegetative and spore types of bacteria cannot be completely erased even though it works well for processing and preparing food. The nutritional, and sensory characteristics of food are only minimally impacted by integrating the process with other non-thermal methods (High-pressure processing and microwave cooking,), and spore-forming microbe inactivation can be improved. In addition to investigating the method of operation of SV technology, the difficulties associated with its adoption in the food business are examined. This review looks at the possibilities, applications, and effects of the SV technique on spore-forming microorganisms and spore inactivation. The discussion and debate presented may serve as a starting point for additional study and actual applications of this food manufacturing system. 1. Introduction The professional cooking technique known as sous-vide often referred to as the vacuum cooking technique, has applications in the catering, home, food industry, and molecular gastronomy (Zavadlav et al., 2020). On the one side, sous-vide has long been regarded as the world's best-kept culinary secret, it was developed in response to rising consumer demand for processed meals that tasted "fresh-like" and were of high quality (nutritional and sensory characteristics) (Aguilera, 2018; Zavadlav et al., 2020). The phrase "sous-vide" means "under vacuum" and refers to a technique in which raw or partially cooked food is placed in a plastic bag or pouch, kept in vacuum condition, and cooked for a prolonged time in a water bath at 60–100 °C (usually from 1 to 7 h) (Kilibarda et al., 2018a). For some foods (meat and meat products), this could take up to 48 h or longer. By using this technique, naturally derived juiciness can be preserved without overcooking. The heat used during sous vide processing may be sufficient to denature specific proteins, changing their structure and characteristics and, ultimately, the quality of the meat. The connective tissue proteins, mostly collagen, ⁎ ⁎⁎ contract and solubilize, the myofibrillar proteins, primarily myosin and actin, shrink transversely and longitudinally, and the sarcoplasmic proteins aggregate and gel. According to researchers, the degree and type of denaturation, contraction, and expansion of meat proteins mostly rely on the rate of heat transmission, temperature, and time. The shrinking of myofibrils, which occurs at a linear rate up to 80 °C, causes the quickest alterations in the proteins of meat between 35 and 40 °C (Aguilera, 2018). Sarcoplasmic proteins begin to aggregate and gel at temperatures of about 40 °C and reach their peak around 60 °C. Meat softness rises while cooking at 60–70 °C due to collagen solubilization and a decrease in interfiber adhesion. At temperatures about 60 °C, the collagen fibers start to contract; at temperatures above 65 °C, they contract more intensively, shattering the triple-stranded helix structure and turning the collagen fibers into haphazard coils that are soluble in water, which increases tenderness. With an increase in temperature, collagen denaturation grows exponentially (Kilibarda et al., 2018a). It has been observed that sous vide cooking at low temperatures for an extended period of time, 58–75 °C for 6.5–24 h, can soften tough meat and dissolve collagen (Aguilera, 2018; Onyeaka et al., 2022). In Corresponding author at: Department of Bioengineering, Integral University, Lucknow, Uttar Pradesh, India. Corresponding author. E-mail addresses: vinaypandey794@gmail.com (V.K. Pandey), rahulsingh.jnu@gmail.com (R. Singh). https://doi.org/10.1016/j.foohum.2023.06.028 Received 9 January 2023; Received in revised form 8 May 2023; Accepted 23 June 2023 2949-8244/© 2023 Elsevier B.V. All rights reserved. P. Singh, Z. Sultan, V.K. Pandey et al. Food and Humanity 1 (2023) 543–552 addition to its numerous benefits, sous-vide cooking provides customers with premium-quality prepared food at minimal operating and equipment costs as compared to high-pressure processing, ultrasound processing, and ozonation (Onyeaka et al., 2022; Aguilera, 2018; Zavadlav et al., 2020). Based on the intensity of the applied heat treatment, sousvide products can be divided into different types- Low-temperature sous vide and high-temperature sous vide. For example, the low temperature and long cooking method (LTLT) produce food products with beneficial properties such as enhanced delicacy and preferable mouthfeel, reduction in lipid oxidation, improved flavour and aroma, and reduced delicacy losses, which results in prolonged shelf life, reduced flavour losses (due to vacuum packaging), and improved colour and visual appeal as the volatiles and textural properties are deteriorated by high temperature. Even though the fact that there is no need for chemicals or preservatives when food is cooked sous-vide, certain nutrients (such as proteins) are changed to improve functionality (Zavadlav et al., 2020; Karki et al., 2022). Regardless of whether it is intended for restaurants or home usage, food is promptly cooled once it has reached the ideal intended textural characteristics, and the internal temperature and is then kept chilled or frozen until it is time to serve to prevent microbial growth and preserve the texture (Choi et al., 2018), (Zavadlav et al., 2020). It is necessary to optimize the heat treatment settings in order to successfully inactivate pathogenic E. coli germs in meat, according to the researchers, who believe that a heat treatment temperature of 71 °C may not be sufficient. Despite this, some pathogenic Escherichia coli, such as the isolate of E. coli AW 1.7 from beef, have been discovered to be heat resistant, raising concerns regarding the method's efficacy in inactivating pathogens during the processing of beef (Karki et al., 2022). However, the impact of heat on E. coli depends on the strain's variability as well as the characteristics of the food formulations, such as the salt and water activity levels. It is important to be aware that heat causes changes in E. coli cells, especially in the DNA, ribosomes, and cytoplasm of the cells as well as the membrane. Foods including meat, milk, vegetables, seafood, and eggs are contaminated by these germs (Smith, 2020). For this culinary technique, microbial safety assessment is crucial, so it's crucial to understand how such treatments affect microorganisms to assess the products' safety. The components are first cooked at mild temperatures after being vacuum-sealed in a bag. In addition to reducing the danger of bacterial contamination, these preserving techniques can prevent the growth of anaerobes in food throughout storage due to temperature pressure combination. As a result, cooked food can be kept for longer in storage and cool down quickly after cooking. The cooking duration and temperature may also be precisely regulated. Foods have excellent flavor because vacuum-sealed packaging effectively transfers heat while limiting oxidation, loss of volatile ingredients, and moisture (Aguilera, 2018). According to several studies, viruses (such as rotavirus Norwalk virus, and hepatitis viruses) present in sous-vide foods when are present in sous-vide foods when they are consumed come from raw ingredients since they survive cooking (Choi et al., 2018; Aguilera, 2018; Zavadlav et al., 2020). In addition to lessening the detrimental effects of cooking on nutrients (such as proteins, lipids, and vitamins), precisely controlled temperature and duration also boost total polyphenols and antioxidant activity and enhance the overall texture and color of food (Kilibarda et al., 2018a). Here, we thoroughly examine the impacts of sous-vide techniques, a novel cooking technique, on food safety, nutritional value, and eating quality, as well as potential causes. The purpose of the current research was to evaluate cutting-edge and useful sous-vide methods for producing wholesome, premium food while considering safety. ingredients for cooking using the sous vide method, the same procedures as with the conventional cook-chill method must be followed. The SV is a particular cooking method that involves cooking food in evacuated, vacuum-sealed containers (Choi et al., 2018; Smith, 2020). SV cooking, which entails pre-packaging meals in plastic containers or bags, creating a vacuum, and then preparing food inside the bags at controlled pasteurization temperatures, is a crucial step in this procedure. To guarantee that the best sensory and nutritional qualities are produced and kept, the method is often used by professional chefs at low temperatures of 50–65 °C. Other temperatures used in SV vary from 50° to 75°C for processing meat, fish, and shellfish, and are maintained for several hours or even days. Vegetables are processed at high temperatures of 90–100 °C for a short period of time. The following steps shown in Fig. 1 are included in the basic sous vide system (PilavtepeCelik et al., 2014). Preparation-Before cooking, the raw components are prepared by performing operations including washing, trimming, peeling, seasoning, and others, depending on their origins. At this point, a conventional strategy, such as the typical cook-chill approach, can be used (Smith, 2020). Pre-cooking-Since the food is warmed up inside a plastic container during the sous vide process rather than being heated directly, it may be necessary to pre-brown some products using conventional cooking methods. Additionally, some vegetables must be blanched (i.e. 88 ± 99 ℃), and prior to packaging to stop the browning of the product and some strong flavors must be imitated (Smith, 2020; Gazzala, 2004). Vacuum packaging-It is placing cooked food into specialized plastic bags or pouches that are airtight and allow efficient heat transfer. These plastic multi-laminate materials, which are used to manufacture the bags and pouches, have great resistance to heat and gas leakage. Aluminum, ethylene vinyl alcohol, polyethylene (PE), and polyamide plastic laminating bag were suggested for sous vide processing because of their low oxygen permeability and lack of harmful effects on color. An especially made vacuum chamber with a pump is used to create a vacuum after the food has been filled into the container. The pack is quickly thermally sealed after that to prevent vacuum loss. The most crucial step in sous vide is vacuum packaging, so the bag's residual air content needs to be effectively reduced (Karki et al., 2022). Pasteurization-Depending on the special qualities of the food to be cooked, the packed food is pasteurized for a predetermined period of time at a predetermined temperature. This step can be completed in a steam composite oven or a water bath. One of the most crucial stages in this process to produce highly flavorful, tender food is sous vide processing, which can be accomplished with the later unit's ability to control temperature more precisely (Smith, 2020). Service-It is possible to serve sous vide-cooked food right away or to take chilled (0–3 °C), pre-packaged, unpasteurized food packs out of the chill store and pasteurize them right away before serving (Karki et al., 2022). Quick cooling-Within 90 min, the packed pasteurized foods are refrigerated to a temperature between 1° and 3° An ice-cold water bath (direct chilling) is the equipment used for this stage. It is both more affordable and effective than blast chilling, which is generally used in traditional cook-chill processes. Cold storage-Before use, chilled storage at 0 °C should be maintained for a while. A continuous temperature recorder, an alert system for when the actual storage temperature deviates from the predetermined set levels, and a digital real-time logging data logger of storage conditions are all required for chilled storage. In this case, the food is stored in airtight containers, which slows down the rate of microbial degradation and other potential chemical changes while also preventing the growth of aerobic bacteria. Regeneration-This entails reheating and maintaining the food item. According to the conventional cook-chill technique, the dish must be reheated to at least 70 °C in the center. For this purpose, a variety of re- 2. Sous vide (SV) processing A variation of the traditional cook-chill catering approach is sous vide. With this system, food that has been vacuum-sealed in multiplelaminate plastics is cooked. In order to prepare the food and raw 544 P. Singh, Z. Sultan, V.K. Pandey et al. Food and Humanity 1 (2023) 543–552 Fig 1. Steps involved in sous-vide processing of food. heating techniques can be used, such as heating the food in a water bath or a steam oven while it is still under vacuum, or heating the food on either the stovetop or the interior of the oven and placed in a heatresistant dish. The use of microwaves, where the bag is perforated and heated, is the more popular method of reheating food. Normal microwaves should not be used, though, as they might not evenly reheat food unless the product can be heated in only 30 min of being removed from the cold store. The time allowed between reheating and service is no more than five minutes (Kilibarda et al., 2018a; Smith, 2020; Gazzala, 2004). processing pulses, fruits, vegetables, meat, and meat products, which are discussed below and shown in Fig. 2. 3.1. Sous vide in meat and meat products The use of low-heat processing methods, Recently, there has been a lot of interest in using techniques like SV technology to enhance the quality of dishes that contain meat as shown in Fig. 2. The appropriate mix of time and temperature factors in SV cooking is critical to the meat's water-holding ability, textural qualities, and juiciness. The researchers found that compared to chicken breast treated at a single temperature of 60 °C, chicken breast treated at two temperatures (50–60 °C) had better textural properties, lower cooking losses, tolerable redness values, and lower lipid degradation levels due to the role of endogenous enzymes like cathepsins (Gazzala, 2004). On the week of storage, SV-cooked shrimp retained their distinct fresh seaweed aroma, but conventionally cooked shrimp lost their freshness aroma following vacuum packaging. Heating at temperatures above 70 °C is thought to assist define the characteristic of volatile aromatic constituents in mature meat, but SV at temperatures below 50–60 °C does not result in a nice, cooked meat flavor (Kilibarda et al., 2018a; Choi et al., 2018). Meat contains around 20% protein, 75% water, and 5% fat and other ingredients. Heat is used to alter (or denature) these proteins when we cook. Temperature and, to a lesser extent, time determine which proteins get denatured and how much. Many categorize the proteins into three groups: connective tissue (10–15%), sarcoplasmic (30–34%), and myofibrillar (50–55%). The connective tissue proteins (mostly collagen) and myofibrillar proteins (primarily 3. Sous vide application in food Because it provides better accuracy and consistency, better control over doneness, a safe level of microbial decrease at lower temperatures, and more texture options than conventional cooking methods, SV cooking is a valuable tool in today's kitchen. Additionally, vacuumized packaging improves heat transfer, reduces the loss of food nutrients to the cooking environment, decreases the possibility of recontamination and lengthens the food's life span, and decreases flavors due to deterioration and unique color than conventional processing (Zavadlav et al., 2020). When cooking, precise temperature control enables you to benefit from both quick and gradual changes: The maximum temperature that food achieves determines fast changes, such as doneness; slow changes, which often take hours to days, allow you to tenderize tough portions of meat that would typically be cooked while keeping medium-rare doneness (Aguilera, 2018). The sous vide method is very useful in 545 P. Singh, Z. Sultan, V.K. Pandey et al. Food and Humanity 1 (2023) 543–552 Fig 2. A schematic representation of the application of sous-vide with advantages. characteristics like color tone, softness, chewiness, and overall quality, the sensory quality of chicken breast flesh that had been cooked sous vide was higher. According to Gil et al., (Gil et al., 2022), musculus semitendinosus and longissimus thoracis samples were taken from beef half-carcasses for the investigation. 2 h of sous vide cooking at 65 °C after conventional food preparation in water at 95 °C until the piece's internal temperature attained 65 °C. The experiment was conducted following two and twentyone days of cold storage. Instruments were used to evaluate the textural parameters (texture profile analysis), color, and sensory aspects of meat. Meat that had been kept for 21 days performed better in terms of physicochemical and sensory analysis than meat that had been tested 48 h after death (Przybylski et al., 2021; Gil et al., 2022). The study also found that sous vide heat treatment had a good effect on textural metrics and sensory qualities, as well as variations in the production of quality attributes amongst muscles (Kilibarda et al., 2018a). This study investigates the effects of a novel three-step sous-vide (SV) process on bacterial growth and variety, as well as the relationship between these factors and product storage life. Vacuum-packed naturally infected steaks were sequentially cooked at 39 °C (60 min), 49 °C (60 min), and 59 °C (4 h), then stored at 1.5 and 2 °C for 28 days, with comparative SV at 59 °C for 4 h. After incubation at 39 or 49 °C, none of the seven indicator bacteria examined grew; microbial diversity was also impacted. Both SV techniques lowered bacterial burden by up to 6 log units. On the 28th, the odor of all steaks remained good. Pseudomonas, rather than Lactobacilli, unexpectedly predominated the microflora on steaks cooked using either SV method during storage. This was most likely caused by the psychrotrophic bacteria's resistance to heat and/or the temperature change lag phase (Przybylski et al., 2021; Hasani et al., 2022). In summary, the three-step SV did not encourage bacterial growth or reduce the amount of time cooked foods could be stored. myosin and actin) constrict when heated, whereas the sarcoplasmic proteins expand (Karki et al., 2022). Muscle fibers contract transversely and longitudinally, sarcoplasmic proteins gel and clump, and connective tissues contract and solubilize when heated. For quick changes, muscle fibers start to contract at 35–40 °C, and shrinkage rises almost linearly with temperature until it reaches 80 °C. Sarcoplasmic protein aggregation and gelation start at around 40 °C and end at about 60 °C. Around 60 °C, connective tissues begin to contract, but at 65 °C/150°F, they contract more forcefully. Through the gradual changes' breakdown of collagen into gelatin and reduction of interfiber adhesion, tenderness is primarily increased (Smith, 2020). These rapid variations give rise to the misconception that the greatest temperature at which meat is considered to be cooked—50 °C/ 125°F for rare, 55 °C for medium-rare, 60 °C for medium, and 70 °C and above for well done—determines the degree of doneness. The color of two comparable slices may differ, despite the fact that they will both be similarly plump and juicy when cooked to the same internal temperature. Meat cooked at 55 °C for 90 min up to 48 h and note how the meat cooked for 48 h is noticeably paler than the meat cooked for 3 h. The color of meat cooked to the same temperature depends on how quickly it reaches that temperature and how long it is held at that temperature. The faster it comes up to temperature, the redder it is. the longer it is held at a particular temperature, the paler it is (Hasani et al., 2022). Furthermore, compared to the one-step sous vide technique, the two-step SV method showed a significantly higher total soluble protein of the chicken breast. For inactivating the main pathogens of interest (C. perfringens and L. monocytogenes) in vegetative cells, based on pasteurization values, the twostep sous vide technique was just as secure as the one-step sous vide technique (Hasani et al., 2022; Gazzala, 2004). According to Przybylski et al. (2021), the study was done to analyze the impact of the thermal treatment method, namely the sous-vide method, on the sensory attributes of poultry meat, along with the process's efficiency in terms of technological quality. The cooking yield of poultry meat using the sous-vide method was higher than the usual way of cooking in water. The flesh was also determined to be more delicate and redder and less yellow. In terms of 3.2. Sous vide in vegetables The International Fresh-cut Produce Association defines minimally processed produce as "any fresh food or any combined effect that has 546 P. Singh, Z. Sultan, V.K. Pandey et al. Food and Humanity 1 (2023) 543–552 been physically changed from its native incarnation but remains in a fresh state" (IFPA). SV is distinguished from minimally processed produce by this. The preparation of minimally processed vegetables includes a number of methods other than cooking; these methods include eating the vegetables raw. Additionally, these foods don't need special preparations before eating (Garrett, 1999; Zavadlav et al., 2020). On the other hand, vegetables that have been sous-vide processed, even at a low temperature, are not minimally processed because they are no longer "fresh."Various procedures are used to process the raw veggies, including sorting, chopping, peeling, washing, cutting, blanching, and pre-cooking (Iborra-Bernad et al., 2014; Guillén et al., 2017; Amoroso et al., 2019). Convectively heated foods are heated to the appropriate temperature, typically at the set temperature, with the length of holding being the sole consideration. The time required to cook and chill food to optimum temperatures, however, is as crucial (Gazzala, 2004). The difficult part of preparing veggies is defining the right circumstances to keep their good quality. After cooking, vegetables are quickly cooled down to below 3.3 °C (in no more than 2 h), at which point the product's temperature should be maintained throughout storage and distribution (Aguilera, 2018; Iborra-Bernad et al., 2014). Various vegetables have been researched for the use of sous-vide technology, but not fruits. Although chefs occasionally boil pears and apples until they are soft, fruits are typically eaten raw. Compared to other traditional methods like boiling, steaming, or microwaving, The reduced oxygen content in the pack will generally tend to sustain the nutritional value and sensory qualities of vegetables (Iborra-Bernad et al., 2014; Guillén et al., 2017; Kosewski et al., 2018; Gonnella et al., 2018; Amoroso et al., 2019). These methods of processing vegetables result in a loss of nutrients because heat damages the cellular walls, allowing nutrients and water to flow out. As the temperature rises, the rate of chlorophyll degradation rises, as does the rate of color degradation (Gonnella et al., 2018). Vegetable cellular membranes are largely left unchanged during the sous-vide process, and the food is made delicate by solubilizing the pectin that maintains the cells together (Sila et al., 2006). It is also seen that cell separation or debonding can result in the weakening of intermediate lamellae when linking texture to the structure. This results in a mealy or dry texture because the cells are not split and so do not release intracellular contents when eaten (Guillén et al., 2017; Kosewski et al., 2018; Gonnella et al., 2018). In terms of physicochemical qualities, water activity, and pH are essentially identical to raw vegetables after processing, most likely due to the absence of chemicals. Even the addition of salt as a flavor enhancer does not affect the product's water activity (Carlin, 2014). dos Reis et al. (2015), found that compared to fresh samples, after being cooked sous-vide, the pH of the inflorescences of both cauliflower and broccoli decreased by half a point (90 ℃, 20 min). The most likely cause of this is cellular wall ruptures that released interior acids. The weight reduction of processed vegetable food items may be reduced via sous-vide treatment. According to Gonnella et al. (2018), the weight loss of asparagus spears after the sous-vide process (80 ℃, 15 min) was 2.1%. When vegetables are cooked sous-vide, they seem to retain their phenolic chemicals better than when they are boiled or steam-cooked using conventional techniques. Compared to carotenoids, this was most likely because of these substances' limited capacity for oxidation in vacuum settings (Chiavaro et al., 2012). Regarding this, Martnez-Hernández et al (Martínez-Hernández et al., 2013)., found that when compared to raw vegetables, kailan-hybrid cauliflower cooked sous-vide (90 ℃, 15 min) had a slight improvement (less than 1.4 times) in phenolic content. Furthermore, Sacha inchi kernels SV cooked at 100 ℃ for approx. 2 h showed a 5% increase in total phenolic content, according to Štěrbová et al (Štěrbová et al., 2017). In addition, Carrot slices with a modest increase in phenolic content due to sous-vide preservation (less than 5% compared to raw samples) as compared to the conventional method. The researchers suggested that the quality of Sacha inchi kernels during food preparation can be considerably influenced by heating technique and enough time. As a result of the production of novel compounds, roasting Sacha inchi kernels, particularly at 190 ℃ for 35 min and honey roasting at 170 ℃ for 30 min, has a good impact on boosting TPC. The tocopherols held up rather well during the boiling operations, but roasting is when they are most likely to degrade. The loss of tocopherols was offset by a rise in TPC, therefore thermal processing had no effect on the Sacha inchi kernels' ability to scavenge radicals. The values of the tested parameters were least affected by the sous-vide method. From this vantage point, it appears to be a fairly gentle way of preparing Sacha inchi kernels. Last but not least, more study is required to determine whether sous-vide processing alters the vegetable matrix, that is, whether this method of preparation results in phytochemical constituents that are more readily bioaccessible—that is, more readily released from the matrix and absorbed in the intestinal system—and useful for physiological functions (bioavailability) (Banerjee & Verma, 2015). 3.3. Sous vide in seafoods The development of various process technologies, such as minimal cooking techniques is the outcome of efforts in fishery products processing to ensure healthy and premium-quality products as the demand for naturally occurring and minimally processed efficient seafood items grows (Banerjee & Verma, 2015). Marine organisms contain long-chain fatty acids, highly digestible proteins, non-protein nitrogen molecules, fiber, taurine, sterol, and pigments. They also contain elements that are absent from creatures that live on the ground (Hosomi et al., 2012). However, due to the high concentration of polyunsaturated fatty acids in marine organisms' muscle lipids, which makes them very susceptible to oxidation, improper handling and processing can quickly cause these substances to lose their sensory and nutritional qualities, leading to rancidity and the development of off-flavors (Banerjee & Verma, 2015; Choi et al., 2018). The most popular techniques used to process vegetables (e.g., stewing, roasting, microwaving, boiling, and steaming) Fabari (Fabbri & Crosby, 2016), could also be employed in seafood processing (Barbosa et al., 2018; Pilavtepe-Celik et al., 2014). On the other hand, cooking promotes several unfavorable physicochemical processes, the most damaging of which are lipid oxidation and hemeprotein denaturation (Kristinova et al., 2014). When vegetables, meat, or seafood are prepared at higher temperatures, water-soluble nutrients, such as vitamins and minerals, are frequently lost because of evaporation and as exudates depart the food. This contains phytochemicals and antioxidants, which are crucial for the health of immunity (Puertollano et al., 2011). Some proteins that are water-soluble may also be lost during the cooking process. As a result, Wan et al (Wan et al., 2019)., suggested that sous-vide cooking might be employed as a healthier alternative because it was shown to help retain the quality of slices from the largemouth bass. However, careful monitoring of operational technological parameters is essential to protect nutritional and sensory performance during the thermal treatment of marine organisms. Heat and cooking time have been shown to affect lipid oxidation in seafood products (Cropotova et al., 2019). The membrane gaps in fish muscles are also altered by a range of metabolic processes, protein aggregations, and conformations that are brought on by higher temperatures (Wan et al., 2019). By employing improved process parameters during the sous-vide preparation of wild salmon, Głuchowski et al. (2019), were able to achieve a comparable level of cooked fish flavor and aroma without noticeably deteriorating texture. Vacuum treatment, however, can be used to reduce lipid damage during the heating process as well as to separate oxygen and prevent metabolic processes that require oxygen (Głuchowski et al., 2019). According to Dominguez-Hernandez et al (Dominguez-Hernandez et al., 2018)., low-temperature long-time cooking (LTLT) had a number of benefits over conventional high-temperature cooking (Singh et al., 2016; Cropotova et al., 2019)., reducing the heat-related degradation of 547 P. Singh, Z. Sultan, V.K. Pandey et al. Food and Humanity 1 (2023) 543–552 proteins, lipids, and nutrient-rich fluid (Singh et al., 2016). Preparing and cooking squid and octopus using SV technology is one of the most difficult tasks today, as both are not always of consistent quality (Mo et al., 2020). In squid and octopus, like abalone and clam, cooking should be done gently to avoid the muscle tissue from toughening. Cephalopods retain their structure when cooked sous-vide at a moderate temperature. Prior to sous-vide thermal treatment, cephalopods can be completely vacuumed inside the container due to their strong muscles and firmness. The connective tissue structure that resides just below the skin and is said to be resistant to autolytic processes has likely changed as a result of rigidity. The collagen concentration in seafood has a strong correlation with muscle hardness, making squids particularly challenging to prepare (Singh et al., 2016; Mo et al., 2020). The majority of techniques call for either rapid frying or low and slow roasting, both of which can still cause the meal to become harder to chew. According to researchers, in order to become more delicate and maintain a succulent structure, the mantle from cephalopods like Sepia officinalis and Loligo forbesii has to be heated for a very brief period of time at low temperatures (50–60 C). Squid-cooked sous-vide at low temperatures may have a tender, melt-in-your-mouth feel (DominguezHernandez et al., 2018). On the other hand, sous-vide cooking at higher temperatures promotes protein denaturation and coagulation of sarcoplasmic proteins on the surface, which also drastically changes color (Głuchowski et al., 2019). Cuttlefish must be tenderized before cooking because it is challenging to prepare because it turns tough or rubbery when cooked. The use of sous-vide technology has the advantage of preventing the meat from shrinking and tenderizing the meat, resulting in meals that are soft and succulent. Additionally, aromatics are not lost when a plastic sheet and a vacuum seal are used. This study suggests that, when compared to conventional processing techniques, SV treatment at reduced temperatures can suppress bacterial development while improving nutritional quality (Singh et al., 2016; Mo et al., 2020). 4. Effect of sous vide on microorganisms The ability of processing technology to stop the growth of microbial spores and bacteria that form spores is what determines the safety of the food. As a result, the primary objective for food preservation and shelflife extension remains the prevention of degradation and food-borne microbes (Kilibarda et al., 2018b). Microbial contamination is the root cause of food spoilage, outbreaks of foodborne illness, and product failure. Food contamination by microorganisms has resulted in millions of dollars’ worth of packaged food recalls worldwide. In order to effectively and efficiently manage, the impact of microbes on food, preservatives, and techniques are crucial. Analysis In this situation, it is critical to assess the SV technique's potential to eliminate spore-forming microbes and spores, enhance food safety, and lengthen shelf life shown in table 2. The lowtemperature range used in SV technology has been criticized for being insufficient to ensure microbial food safety as a preserving strategy (Kilibarda et al., 2018a). 4.1. Effect on bacteria Numerous studies have suggested that the microorganisms found in the finished sous vide foods are most likely caused by bacteria that were present in the raw materials and survived throughout processing. The microbes of concern in sous vide foods are classified into four types. E. coli, Vibrio, Salmonella, Campylobacter, and Staphylococcus aureus are examples of vegetative bacteria that cannot grow at cold temperatures. The first category also includes other bacterial species (Onyeaka et al., 2022; Kilibarda et al., 2018b; Hart et al., 2022). Pasteurization primarily inactivates these germs. Listeria monocytogenes, Yersinia, and Aeromonas are examples of vegetative bacteria that can thrive and reproduce at refrigerated temperatures. Contrary to vegetative bacterial cells, Bacillus and Clostridium spores frequently resist different safety risks are presented by food preservatives and preservation methods to producers and processing businesses. Due to their ability to produce spores and toxins, they are considered a significant pathogen in heattreated foods and are sensitive to pH levels above 4.4 (Kilibarda et al., 2018a; Onyeaka et al., 2022). Unexpectedly, the shelf-life recommendation is only 10 days, unless the storage environment is below 2.5 °C, in which case the storage period shouldn't exceed 90 days. In contrast to other techniques, the SV method preserves the nutritional value and organoleptic qualities of the food without allowing nonproteolytic bacteria spores to grow and produce neurotoxins (Onyeaka et al., 2022). This is due to SV's shelf-life and storage temperature (Kilibarda et al., 2018b). It has been asserted that SV vacuumed packs comprise some remaining oxygen, but not enough to prevent Bacillus and Clostridium, at pH 4.2–4.4 which are frequently found in packaged foods, from reproducing and growing. Bacillus and Clostridium spores may or may not recover and grow after being damaged by the high temperatures produced by SV (Hart et al., 2022). Under favorable conditions, the germination of microspores in food may result in food contamination, deterioration, and disease outbreaks. Microorganisms called spores have an innately specific conformation that enables them to tolerate and withstand harsh environmental conditions like high temperatures, radiation, and toxic substances (Tehri et al., 2018). SV, well-known for its low heat treatment requirements, might be adequate for vegetative cells but ineffective for killing off L. monocytogenes, C. botulinum, and B. cereus bacterial spores, which are regarded as serious microbiological risks (Cabo et al., 2009; Cosansu & Juneja, 2018). Between 77 and 94 °C, an SV-processed meal had a 3-log decrease in B. cereus counts, decreasing from 0.5 to 1.0 logs. This shows that spores regerminated at 10 °C in a day (Miguel-Garcia et al., 2009). However, when paired with other treatments or used as an adjuvant strategy, SV has been demonstrated to be effective in inhibiting microbial spores and inhibiting spore germination/outgrowth. The combination of pediocin and nisin inhibited the growth of Bacillus subtilis in 3.4. Sous vide in pulses Pulses or grain legumes are dicotyledonous pods of plants in the family Leguminosae that are grown primarily for human consumption and harvested for dry grain. The edible seeds of some legumes, such as different types of beans, and lentils, are known as pulses. Pulses are abundant in essential amino acids, plant-based protein, carbohydrates, and dietary fiber, as well as the right levels of vitamins and minerals. The study conducted by Kirse et al., (Ķirse et al., 2017), was to determine the effects of high-pressure processing (700 MPa/20 °C/10 min) and To determine consumer acceptance of processed pulse spreads after 22 days of storage, to assess the nutritional properties of cowpea and maple pea spreads after processing and 2 months of storage at 5 °C temperature, and to assess the nutritional coverage of pulse spreads in comparison to reference intake for adults and adolescents, sous vide treatment (80 °C/15 min) was used. The ingredients for pulse spreads included cooked pulse seeds, citric acid, salt, oil, and spice. Under vacuum, pulse spreads were properly sealed. Standard techniques were used to establish the nutritional composition, and a 5-point hedonic scale was employed to gauge overall acceptance. The results imply that high-pressure processing has no impact on the general acceptance of pulse products when compared with the untreated specimen and sous vide pulse spreads. The goal of Kirse et al., (Kirse et al., 2016), the study was to create creative pulse spreads using various pulses grown in Europe and evaluate the spreads' sensory quality both before and after SV cooking. Two varieties of pulse spreads, a conventional (control) spread and a spread with spices, were made from cowpeas and maple peas. The SV treatment had no effect on consumers' preferences for cowpea and maple pea spreads, according to consumer hedonic analysis. New pulse spreads could be SV treated to lengthen their shelf life and preserve their sensory quality for a minimum of 22 days. The effect of SV in different commodities is shown in table 1. 548 P. Singh, Z. Sultan, V.K. Pandey et al. Food and Humanity 1 (2023) 543–552 Table 1 Application of Sous-vide processing in different food products. Food Treatment Analysis Reference Cauliflower, Brussel sprouts, and Broccoli 45 min at 90 ℃ (cauliflowers and broccoli)50 min at 90 ℃ (Brussels sprouts)Traditional cooking time: 10 min (cauliflowers and broccoli) or 15 min (other vegetables) (Brussels sprouts)Cooking time: 7 min at 100 °C. (Kirse et al., 2016) -Cauliflower, Brussel sprouts, and Broccoli -Cauliflowers and broccoli can be sous-vide cooked at 90 °C for 45 min or 90 °C for 50 min. (Brussels sprouts)Cauliflowers and broccoli are traditionally cooked for 10 min in unsalted water or for 15 min in salted water (Brussels sprouts)Storage: 21 °C for 0, 48, and 120 h for steam cooking; 100 °C for 7 min for storage. Asparagus spears Boiling: 99.0 ± 1.0 °C for 5 minutesSteaming: 99.0 ± 1.0 °C for 6 minutesMicrowaving conventionally: 2450 MHz, 900 W, 1.5 minSous-vide cooking: 99.0 ± 1.0 °C for 5 minutesSous-vide: 80 °C for 15 minutesMicrowave time: 1.5 min, 2450 MHz, 900 W Pumpkin Cooking with a 0.2% salt addition:8 min of boiling in water12 minutes of steaming at 95°CMicrowave—2450 MHz, 10 minutesSous-vide—90 °C, 30 min Tomato powder Sous-vide cooking for 4 h at 60 ◦C Salmon Par-roasting at 300 ◦C (3 min) Sous-vide at 80 ◦C (43 min) Pirarucu Sous-vide at 60 ◦C(9.48 min) Lobster High-Pressure Processing (HPP): 150 MPa/350 MPa (10 min) at 4 ◦C Sous-vide at 65 ◦C (10 min) -Low-temperature SV cooking had not affected the vegetables' microbiological safety or quality.-In contrast to uncooked vegetable samples, cooked veggies had greater GLS concentrations.-Six of the nine discovered glucosinolates (glucoiberin, glucoraphanin, progoitrin,gluconapin, 4-metoxyglucobrassicin, and glucobrassicin) were found in larger concentrations in SV broccoli than in typically cooked broccoli.- SV preparation of Romanesco-style cauliflower and Brussels sprouts resulted in greater GLS losses than conventional cooking.-A sophisticated technique for preparing broccoli for consumption is SV cooking. -SV proved to be the best favorable in terms of pcoumaric, caffeic, and gallic acid stability.-In both raw and thermally processed vegetables, there was discovered to be a strong positive correlation between antioxidant activity and total phenolic components.Regarding the preservation of the phenolic component in Brassica vegetables, the SV technique is thought to be the best thermal approach. Microwave produced the greatest change in weight, dry weight increase, and overall colour difference compared to unprocessed samples- All cooking techniques were deemed to be sensory-acceptable, but sous vide-microwave cooking garnered the most favour.-Sous vide- microwave preserves the nutritional quality and colour attributes better than other cooking methods.- When compared to unprocessed samples, Sous vide- microwave samples had a 42% increase in violaxanthin level.- The cooking procedures had no statistically significant effect on rutin levels.Sous videmicrowave was discovered to be the best way for preserving asparagus stalks. -Ascorbic acid was lost during all cooking processes by about 50% when compared to raw samples.- The total flavonoids' decline (30.27%) was most significantly impacted by the sous-vide cooking technique.- The richest concentrations of anthocyanins and carotenoids were found in microwaved samples, whereas the lowest concentrations of both pigments—reductions of 54.37% and 50.0%, respectively—were found in sousvide samples.- The total polyphenol content was lowered from 49.68% to 64.94% across all cooking techniques.-Microwaved pumpkins demonstrated the greatest sensory adaptability, Boiling, steaming, and sous-vide cooking come next. -Following the SV cooking of tomato powder, losses for L-ascorbic acid (20.35%), lycopene (10.93%), and total phenol content (15.98%) were calculated.-After being sous-vided, tomato powder had an Amadori component concentration that was roughly 2.2 times higher than it had been before.-The results of all four tests showed that tomato powder that had been sousvide treated had higher levels of antioxidants than untreated samples.- The cooking procedures had no statistically significant effect on rutin levels.-The most effective method for preserving asparagus stalks was found to be SV-MW. -On days 18, 22, and 25, the existence of Enterobacteria was discovered, however, it was always below the minimum detection level.-Salmon kept at 2 C for up to 25 days had it’s Enterobacteria growth effectively slowed down thanks to SV cooking.-Based on the sensory investigation, the sous-vide salmon's shelf life was determined to be 18 days. -The dorsal cut of pirarucu performed best for producing the SV product when compared to other raw pirarucu cuts.- On the hedonic scale, the SV product obtained sensory scores of 7 for acceptance on day 0 while the qualities obtained an average score of 5 on day 49. Anaerobes remained within permissible levels throughout storage. -Raw lobster that had been cooked or compressed at 350 MPa had During storage, microbial numbers are (Florkiewicz et al., 2019) (Gonnella et al., 2018) (Da Silva et al., 2017) Yang et al. (Díaz et al., 2009) (Rondanelli et al., 2017) (Humaid et al., 2020) (continued on next page) 549 P. Singh, Z. Sultan, V.K. Pandey et al. Food and Humanity 1 (2023) 543–552 Table 1 (continued) Food Treatment Analysis Sacha inchi kernels Sous-vide at 100 °C for 135 min Cowpea and maple pea HPP (700 MPa/20 °C/10 min) and sous vide treatment (80 °C/15 min) chicken breast Two steps sous-vide treatment markedly reduced.-No pre-treatment with HPP increased the shelf life of SV-cooked goods. SV can encourage the availability of cooled lobster tails for sale commercially in order to produce a variety of products made from lobster that are superior quality and more readily available than refrigerated lobsters. A 5% increase in total phenolic content in Sacha inchi kernels High-pressure processing has no impact on how wellliked pulse products are in general when compared to raw samples and SV pulse spreads. Compared to chicken breast treated at a single temperature, those treated at two temperatures (50 and 60 °C) possessed improved texture traits, reduced cooking losses, manageable redness values, and reduced lipid degradation levels. Furthermore, compared to the one-step sous vide technique, The chicken breast's total protein soluble content was substantially higher using the two-step sous vide technique. Reference (Štˇerbová et al., 2017) (Ķirse et al., 2017) (Hasani et al., 2022). Table 2 Sous-vide processing and effect on microorganisms. Microorganism Remarks References Non-proteolytic bacteria spores Unless storage conditions are below 2.5 °C, in which case storage should not go beyond 90 days without affecting the food's nutrient value or organoleptic qualities only a 10-day storage life is suggested. Bacterial spores that are damaged by the high temperatures created by SV may or may not restore and develop.Vacuumed packs contain some residual oxygen but not enough to prevent Bacillus and Clostridium from reproducing and growing. Inhibiting microbial spores and inhibiting spore germination/outgrowth T. gondii tissue cysts in meat are generally inhibited at a minimal cooking temperature of 67 °C Even low heat treatments using swine meat, such as 49 °C (5.6 min), 55 °C (44 sec), and 61 °C (6 sec), have been found to deactivate this parasite. MNV-1 and Tulane virus (TV) were inhibited substantially faster when treated with SV at temperatures over 58 °C. After 1 m of thermal processing at 67 °C for MNV-1 and 63 °C for TV, the infection rate was below the detection limit. the preservation of an improved cold chain to guard against C. perfringens in tomato sauce-marinated SV-processed pork meat. The combination of pediocin and nisin stopped Bacillus subtilis and Bacillus licheniformis from growing at a temperature of 15 °C. (Onyeaka et al., 2022). Bacillus and Clostridium C. perfringens spore T. gondii tissue T. gondii tissue MNV-1 and Tulane virus (TV) C. perfringens spore mushrooms and Bacillus licheniformis in shellfish salad at 15 °C. It is well known that the biopeptides nisin and pediocin kill Gram-positive microbes as well as spore-forming bacteria and clostridium (Scott & Taylor, 1981; Onyeaka et al., 2022). (Hart et al., 2022) (Cosansu & Juneja, 2018) (Hill & Dubey, 2016) (Mirza Alizadeh et al., 2018) (Shao et al., 2018) (Miguel-Garcia et al., 2009) 44 sonds, and 61 °C for 6 sonds using swine meat (Mirza Alizadeh et al., 2018). Greening et al. (2001), discovered that viruses are reasonably constant at 37 °C and can keep the infection rate for weeks or days at 4 °C, as well as being infectious after freezing. Feline calicivirus and murine norovirus injected into spinach were shown to be inactivated at 56 °C, with D-values ranging from 0.16 (72 °C) to 14.57 (50 °C) and 0.15 (72 °C) to 17.39 (50 °C), respectively (Bozkurt et al., 2014). In another investigation using oysters, both MNV-1 and Tulane virus (TV) were inhibited substantially faster when treated with SV at temperatures over 58 °C. The infection rate was below the detection limit after 1 m of thermal processing at 67 °C for MNV-1 and 63 °C for TV (Shao et al., 2018). Similar results were observed for non-vacuum-packed dried mussels at 60 °C, where HAV decreased by 16 logs. 4.2. Effect on parasites and viruses Noroviruses and the hepatitis A virus are the two most prevalent human pathogens that cause foodborne infections. An emerging foodborne virus is the Hepatitis E virus (HEV). There are unconfirmed reports that canned foods may contain live virus particles because there are no culture techniques to identify them, limiting the ability to examine how norovirus and hepatitis E virus are affected by heat (Horn et al., 2016). Because of this, viruses do not grow on food. However, at low infectious dosages of 10–100 particles, there is a tendency for low-level infections to progress to full-blown infections as a result of exposure. In the food industry, temperature control, such as high or low-temperature treatments, is frequently used to inactivate parasites (Kotula et al., 1991). One of the most common parasitic diseases brought on by food is toxoplasmosis, which is brought on by Toxoplasma gondii. At a minimum cooking temperature of 67 °C, T. gondii tissue cysts in meat are typically inhibited (Hill & Dubey, 2016). This parasite, however, has been found to be deactivated by even low heat treatments of 49 °C for 5.6 min, 55 °C for 5. Advantages When compared to conventional cooking techniques, SV can increase the nutritional value of food products while also lengthening their shelf life. SV may also offer consistency and repeatability of cooking results that traditional cooking methods cannot match because it allows for better control of cooking time and temperature (Onyeaka et al., 2022; Da Silva et al., 2017). In addition, the SV technology is easy to use and does not require workers to be professionally trained, saving 550 P. Singh, Z. Sultan, V.K. Pandey et al. Food and Humanity 1 (2023) 543–552 labor costs and improving the industrial application of SV to food products. Contrary to conventional cooking, sous vide uses plastic bags to minimize mineral loss and increase bioavailability. The researcher examined the availability of copper, calcium, potassium, iron, and magnesium in the bovine liver, and supported these conclusions. Even though the evaluation's primary concern is food safety, it will be helpful to emphasize the advantages of SV cooking (Da Silva et al., 2017). The approach has been shown to preserve mineral content, and increase the digestibility of nutrients and solubility (Rondanelli et al., 2017). Other advantages of SV technology include preventing aerobic bacterial growth, minimizing volatile flavor, aroma, and moisture loss, preserving nutritional value, lowering chemical species known to be harmful to human health, such as heterocyclic amines and aromatic hydrocarbons, improving the juiciness and tenderness of the meat, and preventing plant pigment oxidation (Kilibarda et al., 2018a). Although SV technology has many benefits, one significant drawback is the lack of microbiological safety of products that have undergone SV processing when treatment is carried out alone. According to reports, SV technology effectively inactivates aerobic and reproductive bacteria like Bacillus and Clostridium species. Additionally, using SV cooking requires the use of specialized tools and training. Overall, mild thermal treatment and anoxic, as well as a decline in the method's acceptance by food producers and regulators, are the biggest problems with SV. Witte, B., Trabalón, L., Fernandes, J. O., Cunha, S. C., & Marques, A. (2018). Effects of steaming on contaminants of emerging concern levels in seafood. Food and Chemical Toxicology, 118, 490–504. https://doi.org/10.1016/j.fct.2018.05.047 Bozkurt, H., D’Souza, D. H., & Davidson, P. M. (2014). Thermal inactivation of human norovirus surrogates in spinach and measurement of its uncertainty. Journal of Food Protection, 77(2), 276–283. https://doi.org/10.4315/0362-028X.JFP-13-289 Cabo, M. L., Torres, B., Herrera, J. J., Bernárdez, M., & Pastoriza, L. (2009). Application of nisin and pediocin against resistance and germination of bacillus spores in sous vide products. Journal of Food Protection, 72(3), 515–523. https://doi.org/10.4315/0362028x-72.3.515 Carlin, F. (2014). Microbiology of sous-vide products. In R. Robinson, C. Batt, & C. A. Batt (Vol. Eds.), In Encyclopediafoodmicrobiology: Vol. 2, (pp. 621–626). Academic Press. Chiavaro, E., Mazzeo, T., Visconti, A., Manzi, C., Fogliano, V., & Pellegrini, N. (2012). Nutritional quality of sous vide cooked carrots and brussels sprouts. Journal of Agricultural and Food Chemistry, 60(23), 6019–6025. https://doi.org/10.1021/ jf300692a Choi, M. J., Abduzukhurov, T., Park, D. H., Kim, E. J., & Hong, G. P. (2018). Effects of deep freezing temperature for long-term storage on quality characteristics and freshness of lamb meat. Korean Food Science of Animal Resources, 38(5), 959–969. https://doi.org/10.5851/kosfa.2018.e28 Cosansu, S., & Juneja, V. K. (2018). Growth of clostridiumperfringensin sous vide cooked ground beef with added grape seed extract. Meat Science, 143, 252–256. https://doi. org/10.1016/j.meatsci.2018.05.013 Cropotova, J., Mozuraityte, R., Standal, I. B., & Rustad, T. (2019). The influence of cooking parameters and chilled storage time on quality of sous-vide atlantic mackerel (Scomber scombrus). Journal of Aquatic Food Product Technology, 28(5), 505–518. https://doi.org/10.1080/10498850.2019.1604595 Da Silva, F. L. F., de Lima, J. P. S., Melo, L. S., da Silva, Y. S. M., Gouveia, S. T., Lopes, G. S., & Matos, W. O. (2017). Comparison between boiling and vacuum cooking (sous vide) in the bioaccessibility of minerals in bovine liver samples. Food Research International, 100(1), 566–571. https://doi.org/10.1016/j.foodres.2017.07.054 Díaz, P., Nieto, G., Bañón, S., & Garrido, M. D. (2009). Determination of shelf life of sous vide salmon (salmosalard) based on sensory attributes. Journal of Food Science, 74(8), S371–S376. https://doi.org/10.1111/j.1750-3841.2009.01317.x Dominguez-Hernandez, E., Salaseviciene, A., & Ertbjerg, P. (2018). Low-temperature long-time cooking of meat: Eating quality and underlying mechanisms. Meat Science, 143, 104–113. https://doi.org/10.1016/j.meatsci.2018.04.032 dos Reis, L. C. R., de Oliveira, V. R., Hagen, M. E. K., Jablonski, A., Flôres, S. H., & de Oliveira Rios, A. (2015). Effect of cooking on the concentration of bioactive compounds in broccoli (Brassica Oleracea Var. Avenger) and cauliflower (Brassica Oleracea Var. Alphina F1) grown in an organic system. Food Chemistry, 172, 770–777. https://doi.org/10.1016/j.foodchem.2014.09.124 Fabbri, A. D. T., & Crosby, G. A. (2016). A review of the impact of preparation and cooking on the nutritional quality of vegetables and legumes. International Journal of Gastronomy and Food Science, 3, 2–11. https://doi.org/10.1016/j.ijgfs.2015.11.001 Florkiewicz, A., Socha, R., Filipiak-Florkiewicz, A., & Topolska, K. (2019). Sous-vide technique as an alternative to traditional cooking methods in the context of antioxidant properties of brassica vegetables. Journal of the Science of Food and Agriculture, 99(1), 173–182. https://doi.org/10.1002/jsfa.9158 Garrett, E. H. (1999). Fresh-cut produce. In B. A. Blakistone (Ed.). In Principles and Applications of Modifiedatmospherepackaging of Foods (pp. 125–134). Aspen Publishers. Gazzala, S. (2004). Developments in cook-chill and sous-vide processing. In P. Richardson (Ed.). In Improving the Thermalprocessing of Foods (pp. 152–173). Woodhead Publishing. Gil, M., Rudy, M., Stanisławczyk, R., & Duma-Kocan, P. (2022). Effect of traditionalcooking and sousvideheattreatment, coldstoragetime and muscle on physicochemical and sensoryproperties of beefmeat. Molecules, 27(21), 7307. https://doi. org/10.3390/molecules27217307 Głuchowski, A., Czarniecka-Skubina, E., Wasiak-Zys, G., & Nowak, A. D. (2019). Effect of various cooking methods on technological and sensory quality of atlantic salmon (Salmo salar). Foods, 8(8), 323. https://doi.org/10.3390/foods8080323 Gonnella, M., Durante, M., Caretto, S., D’Imperio, M., & Renna, M. (2018). Quality assessment of ready-to-eat asparagus spears as affected by conventional and sous-vide cooking methods. L. W. T. 92, 161–168. https://doi.org/10.1016/j.lwt.2018.02.017 Greening, G. E., Dawson, J., & Lewis, G. (2001). Survival of poliovirus in New Zealand green-lipped mussels, perna canaliculus, on refrigerated and frozen storage. Journal of Food Protection, 64(6), 881–884. https://doi.org/10.4315/0362-028x-64.6.881 Guillén, S., Mir-Bel, J., Oria, R., & Salvador, M. L. (2017). Influence of cooking conditions on organoleptic and health-related properties of artichokes, green beans, broccoli, and carrots. Food Chemistry, 217, 209–216. https://doi.org/10.1016/j.foodchem. 2016.08.067 Hart, A., Anumudu, C., Onyeaka, H., & Miri, T. (2022). Application of supercritical fluid carbon dioxide in improving food shelf-life and safety by inactivating spores: A review. Journal of Food Science and Technology, 59(2), 417–428. https://doi.org/10. 1007/s13197-021-05022-7 Hasani, E., Csehi, B., Darnay, L., Ladányi, M., Dalmadi, I., & Kenesei, G. (2022). Effect of combination of time and temperature on qualitycharacteristics of sousvidechickenbreast. Foods, 11(4), 521. https://doi.org/10.3390/foods11040521 Hill, D. E., & Dubey, J. P. (2016). Toxoplasma gondii as a parasite in food: Analysis and control. Microbiology Spectrum Journal, 4(4), 227–247. https://doi.org/10.1128/ microbiolspec.PFS-0011-2015 Horn, B.; Hewitt, J.; Withers, H.; Olsen, L.; Lymburn, J. Review of Microbial Pathogen Inactivation Relevant to Sous Vide Cooking at Temperatures Below 55 °C. https:// www.mpi.govt.nz/dmsdocument/17881-Review-of-microbial-pathogen-inactivationrelevant-to-sous-vide-cooking-at-temperatures-below-55C; Ministry of Primary Industries, New Zealand Government, 2016. 6. Conclusion In order to assess the nutritional value, microbiological security, and storage stability of food products, SV has primarily been studied in vacuum and low-temperature cooking. The use of SV cooking techniques satisfies modern consumer preferences for fresh produce that hasn't been heated to a high temperature. The technique's effectiveness has been demonstrated by the effective results obtained in the processing of meat, vegetable, and plant-based foods, and seafood treatment. Even though this technology enhances the nutritional and organoleptic qualities of food, concerns remain regarding the microbiological quality of processed foods. Combining SV cooking with other barriers can help remove microbial pathogens from food more effectively. With these methods, commercially sterile food can be produced at temperatures lower than those required for traditional cooking, which may alter the idea of SV cooking. Future uses of SV technology should consider the creation of standardized, precisely controllable tools that produce uniform cooking. Treatment variables like heat and cooking time should be modified for different food varieties and classes. Future research must focus on synergistic benefits in conjunction with non-thermal food production technologies in the case of food quality and spore deactivation. In the upcoming years, SV-food products are likely to garner more interest and market share as convenient, wholesome, and healthful goods. Declaration of Competing Interest The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper. References Aguilera, J. M. (2018). Relating food engineering to cooking and gastronomy. Comprehensive Reviews in Food Science and Food Safety, 17(4), 1021–1039. https://doi. org/10.1111/1541-4337.12361 Amoroso, L., Rizzo, V., & Muratore, G. (2019). Nutritional values of potato slices added with rosemary essential oil cooked in sous vide bags. International Journal of Gastronomy and Food Science, 15, 1–5. https://doi.org/10.1016/j.ijgfs.2018.11.007 Banerjee, R., & Verma, A. K. (2015). Minimally processedmeat and fishproducts. In M. W. Siddiqui, & M. S. Rahman (Eds.). In Minimally processedfoods: Technologies for Safety, Quality, and Convenience (pp. 193–250). Springer. https://doi.org/10.1007/978-3319-10677-9_10 Barbosa, V., Maulvault, A. L., Alves, R. N., Kwadijk, C., Kotterman, M., Tediosi, A., Fernández-Tejedor, M., Sloth, J. J., Granby, K., Rasmussen, R. R., Robbens, J., De 551 P. Singh, Z. Sultan, V.K. Pandey et al. Food and Humanity 1 (2023) 543–552 Hosomi, R., Yoshida, M., & Fukunaga, K. (2012). Seafood consumption and components for health. Global Journal of Health Science, 4(3), 72–86. https://doi.org/10.5539/ gjhs.v4n3p72 Humaid, S., Nayyar, D., Bolton, J., Perkins, B., & Skonberg, D. I. (2020). Refrigerated shelflife evaluation of high pressure processed, raw and sous vide cooked lobster. High Pressure Research, 40(3), 444–463. https://doi.org/10.1080/08957959.2020.1774753 Iborra-Bernad, C., Tárrega, A., García-Segovia, P., & Martínez-Monzó, J. (2014). Advantages of sous-vide cooked red cabbage: structural, nutritional and sensory aspects. Lebensmittel-Wissenschaft & Technologie, 56(2), 451–460. https://doi.org/10. 1016/j.lwt.2013.12.027 Karki, R., Bremer, P., Silcock, P., & Oey, I. (2022). Effect of sous vide processing on quality parameters of beef short ribs and optimisation of sous vide time and temperature using third-order multiple regression. Food and Bioprocess Technology, 15(7), 1629–1646. https://doi.org/10.1007/s11947-022-02849-6 Kilibarda, N., Brdar, I., Baltic, B., Markovic, V., Mahmutovic, H., Karabasil, N., & Stanisic, S. (2018b). The safety and quality of sous vide food. Scientific journal Meat Technology, 59(1), 38–45. https://doi.org/10.18485/meattech.2018.59.1.5 Kilibarda, N., Brdar, I., Baltić, B., Marković, V., Mahmutović, H., Karabasil, N., & Stanisic, S. (2018a). The safety and quality of sous vide food. Meat Technology, 59(1), 38–45. https://doi.org/10.18485/meattech.2018.59.1.5 Kirse, A., Karklina, D., & Muizniece-Brasava, S. (2016). Consumer acceptance of new pulse spreads before and after sous vide treatment. International Journal of Agriculture and Food Science, 4, 104–114. Ķirse, A.; Kārkliņa, D.; Muižniece-Brasava, S.; Galoburda, R.. Influence of Sous Vide Treatment and High-Pressure Processing on Nutritional Value and Overall Acceptance of Pulse Spreads. In Proceedings of the LatvianAcademy of Sciences (Vol. 71, No. 6, p. 474); De Gruyter, 2017, November. Kosewski, G., Górna, I., Bolesławska, I., Kowalówka, M., Wi˛eckowska, et al. (2018). Comparison of antioxidative properties of raw vegetables and thermally processed ones using the conventional and sous-vide methods. Food Chemistry, 240, 1092–1096. https://doi.org/10.1016/j.foodchem.2017.08.048 Kotula, A. W., Dubey, J. P., Sharar, A. K., Andrews, C. D., Shen, S. K., & Lindsay, D. S. (1991). Effect of freezing on infectivity of toxoplasma gondii tissue cysts in pork. Journal of Food Protection, 54(9), 687–690. https://doi.org/10.4315/0362-028X-54.9.687 Kristinova, V., Mozuraityte, R., Aaneby, J., Storrø, I., & Rustad, T. (2014). Iron-mediated peroxidation in marine emulsions and liposomes studied by dissolved oxygen consumption. European Journal of Lipid Science and Technology, 116(2), 207–225. https:// doi.org/10.1002/ejlt.201300301 Martínez-Hernández, G. B., Artés-Hernández, F., Gómez, P. A., & Artés, F. (2013). Quality changes after vacuum-based and conventional industrial cooking of kailan-hybrid broccoli throughout retail cold storage. Lebensmittel-Wissenschaft & Technologie, 50(2), 707–714. https://doi.org/10.1016/j.lwt.2012.07.014 Miguel-Garcia, D. Y., Juneja, V. K., Valenzuela-Melendrez, M., Díaz-Cinco, M. E., Thippareddi, H., & Aida Peña-Ramos, E. (2009). Clostridium perfringens Growth from spore inocula in sous-vide processed pork-based mexican entrée. Journal of Food Science, 74(4), M172–M176. https://doi.org/10.1111/j.1750-3841.2009.01131.x Mirza Alizadeh, A., Jazaeri, S., Shemshadi, B., Hashempour-Baltork, F., Sarlak, Z., Pilevar, Z., & Hosseini, H. (2018). A review on inactivation methods of toxoplasma gondii in foods. Pathogens and Global Health, 112(6), 306–319. https://doi.org/10.1080/ 20477724.2018.1514137 Mo, H., Nikitchina, T., Manoli, T., & Cui, Z. (2020). Trends of processed products of squid. Journal of Food Science and Technology, 14. Onyeaka, H., Nwabor, O., Jang, S., Obileke, K., Hart, A., Anumudu, C., & Miri, T. (2022). Sous vide processing: A viable approach for the assurance of microbial food safety. Journal of the Science of Food and Agriculture, 102(9), 3503–3512. https://doi.org/10.1002/jsfa.11836 Pilavtepe-Celik, M., Ozer, N. P., Ozkoc, S. O., Seyhun, N., & Dede, N. (2014). Infrared assisted microwave cooking of atlantic salmon (Salmo salar). Turkish Journal of Fisheries and Aquatic Sciences, 14(3), https://doi.org/10.4194/1303-2712-v14_3_08 Przybylski, W., Jaworska, D., Kajak-Siemaszko, K., Sałek, P., & Pakuła, K. (2021). Effect of heat treatment by the sous-vide method on the quality of poultry meat. Foods, 10(7), 1610. https://doi.org/10.3390/foods10071610 Puertollano, M. A., Puertollano, E., de Cienfuegos, G.Á., & de Pablo, M. A. (2011). Dietary antioxidants: Immunity and host defense. Current Topics in Medicinal Chemistry, 11(14), 1752–1766. https://doi.org/10.2174/156802611796235107 Rondanelli, M., Daglia, M., Meneghini, S., Di Lorenzo, A., Peroni, G., Faliva, M. A., & Perna, S. (2017). Nutritional advantages of sous vide cooking compared to boiling on cereals and legumes: Determination of ashes and metals content in ready-to-eat products. Food Science & Nutrition, 5(3), 827–833. https://doi.org/10.1002/fsn3.469 Scott, V. N., & Taylor, S. L. (1981). Effect of nisin on the outgrowth of clostridium botulinum spores. Journal of Food Science, 46(1), 117–126. https://doi.org/10.1111/j. 1365-2621.1981.tb14543.x Shao, L., Chen, H., Hicks, D., & Wu, C. (2018). Thermal inactivation of human norovirus surrogates in oyster homogenate. International Journal of Food Microbiology, 281, 47–53. https://doi.org/10.1016/j.ijfoodmicro.2018.05.013 Sila, D. N., Smout, C., Elliot, F., Loey, A. V., & Hendrickx, M. (2006). Non-enzymatic depolymerization of carrot pectin: Toward a better understanding of carrot texture during thermal processing. Journal of Food Science, 71(1), E1–E9. https://doi.org/10. 1111/j.1365-2621.2006.tb12391.x Singh, C. B., Kumari, N., Senapati, S. R., Lekshmi, M., Nagalakshmi, K., Balange, A. K., Chouksey, M. K., Venkateshwarlu, G., & Xavier, K. A. M. (2016). Sous vide processed ready-to-cook seerfish steaks: process optimization by response surface methodology and its quality evaluation. L. W. T. 74, 62–69. https://doi.org/10.1016/j.lwt.2016. 07.017 Smith, C.J. Selection and Application of Naturalantimicrobials to controlClostridium perfringens in Sous-Videchickenbreasts, 2020 (Doctoral Dissertation; University of Georgia). Štěrbová, L., HlásnáCepkov, á, P., Viehmannová, I., & Huansi, D. C. (2017). Effect of thermal processing on phenolic content, tocopherols and antioxidant activity of Sachainchi kernels. J. Food Process Preserv, 41, 1–8. Tehri, N.; Kumar, N.; Raghu, H.; Shukla, R.; Vashishth, A. Microbial Spores: Concepts and Industrial Applications. In Microbial Bioprospecting for Sustainabledevelopment; Springer, 2018, pp 279–289. Wan, J., Cao, A., & Cai, L. (2019). Effects of vacuum or sous-vide cooking methods on the quality of largemouth bass (Micropterus salmoides). International Journal of Gastronomy and Food Science, 18. https://doi.org/10.1016/j.ijgfs.2019. 100181 Zavadlav, S., Blažić, M., Van de Velde, F., Vignatti, C., Fenoglio, C., Piagentini, A. M., Pirovani, M. E., Perotti, C. M., Bursać Kovačević, D., & Putnik, P. (2020). Sous-vide as a technique for preparing healthy and high-quality vegetable and seafood products. Foods, 9(11), 1537. https://doi.org/10.3390/foods9111537 552