Ni-Fe-P Coating Roughness: Taguchi, GA, Fuzzy Logic Modeling

advertisement

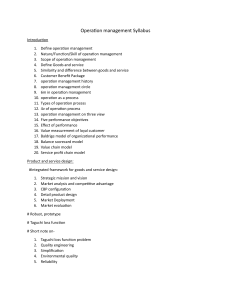

Modelling and prediction of Surface roughness of Electroless Ni-Fe-P coatings using Taguchi,GA and Fuzzy Logic Abstract Keywords: 1. Introduction. The electroless coating is a process used to deposit a coating onto a surface without using an external electrical power source. In this process, the electrons required for the deposition of the coating are supplied by a reducing agent present in the solution. In this era, with constant technological improvements, coatings with better tribological, mechanical, and chemical properties are always preferred over the others. Majumdar, et al. (2002) [1] studied the microhardness of metal alloy electroless binary, ternary and duplex coating, comprising of Nickel-Phosphorous and Nickel-TungstenPhosphorous over the copper substrate, and the results indicated increase in porosity upon the inclusion of tungsten between the Ni-P layers. Studies by Wei, et al. (2015) [2] too revealed that with the addition of an extra element/complex (the third one) in the binary alloy coating, better tribological properties can be observed. Surface roughness refers to the irregularities and deviations present on the surface of a specimen at the micro level. These irregularities are measured in terms of the height and distance of the peaks and valleys present on the surface. Surface roughness can be quantified by measuring the average height difference between the peaks and valleys, which is known as the roughness average (Ra). The measurement of surface roughness is typically done using specialized instruments such as stylus profilometers, atomic force microscopes (AFM), or scanning electron microscopes (SEM). Surface roughness can impact the physical properties of a material, such as friction, wear, corrosion resistance, and adhesion, making it an important parameter in various industries, including manufacturing, engineering, and materials science. Taheri et al. [1] studied the tribological features, especially the surface roughness of electroless Ni-P coatings, and concluded that the coating followed the substrate surface profile rather than just filling the spaces between the surface asperities. Also, a transition substrate roughness existed for EN coating. However, at a given substrate Ra value, the Ra of EN coatings is independent of coating thickness. Norkus et al. [2] obtained high-surface roughness copper deposits by an electroless plating process. Sahoo [3] presented an experimental study of the roughness of electroless Ni-P coatings and optimized the coating process parameters using the Grey-based Taguchi method. Results showed that the concentration of the reducing agent and its interaction with the concentration of the nickel source solution had a significant influence in controlling the roughness characteristics of electroless Ni-P coating. Bonin et al. [5] worked on the optimization of electroless Ni-B coating with surface roughness as one of the many parameters considered. The plating bath parameters were optimized using an experimental design approach. Taguchi modelling is a statistical method used for quality control and optimization in manufacturing processes. The method has found wide application in various industries, including automotive, electronics, and chemical manufacturing. Farzaneh et al. (2010) investigated using the Taguchi method, the key parameters that could affect the coating properties of electroless nickel. Using the Taguchi Method, Sahoo et al. [12,13] evaluated and thereby optimized several parameters that affected the tribological characteristics and friction performance of electroless Ni-B and Ni-P coatings respectively. Genetic Algorithm (GA) is a search and optimization algorithm that mimics the process of natural selection and evolution. GA has several advantages over other optimization methods, such as its ability to handle non-linear, non-differentiable, and discontinuous functions. It is also highly scalable, parallelizable, and able to search large solution spaces efficiently. GA is widely used in various fields, including machine learning, artificial intelligence, engineering design, and optimization problems. Some applications of GA include image processing, data mining, scheduling, robotics, and financial forecasting. Vijayanand et al. (2021) had previously performed mathematical modelling studying the influence of surfactant concentration on electroless Ni-B coating and optimized the data using a genetic algorithm. Srivastwa et al. (2022) studied maximizing the deposition rate on electroless Ni-P-CNT coating with the help of a firstorder regression-based equation, thereby developing a response order response surface model after parametric optimization using a genetic algorithm. Genetic algorithm also found its usage previously in the optimization of wear properties as studied by Mukhopadhyay et al. (2016) in the study of electroless NiP-W coating. Fuzzy logic is a mathematical framework for dealing with uncertainty and vagueness in decision-making problems. Fuzzy logic had been vastly applied and researched by Mukhopadhyay et al. [6,7] towards parametric optimization of several tribological features like wear analysis of electroless Ni-B coating, friction properties of Ni-P coatings, and electroless Ni-P-W coating under lubricated conditions. Greybased fuzzy logic has also been applied by Mukhopadhyay et al. [8-10] in the study and optimization of tribological features of electroless Ni-P coatings and Ni-B coatings. 2. Details of the Experiment. 2.1 Preparation of substrate and coating deposition 2.2 Surface roughness Measurement 2.3 Taguchi modelling. The Taguchi method uses orthogonal arrays to design experiments that enable engineers to study and optimize the effect of multiple input parameters on the output response. The goal of Taguchi modelling is to achieve robustness in product and process design by minimizing the variation in output due to changes in input parameters. By selecting the optimal combination of input parameters, Taguchi modelling helps to improve product performance, reduce costs, and increase efficiency. The orthogonal array comprises of various factors also known as experimental variables that can take a discrete number of values called levels. In this work, the primary purpose of Taguchi method is to determine an optimum combination of various factors where a minimum surface roughness is obtained, followed by the variation of each set of factor levels and thereby studying the response variations. In each set of variables, The robust parameter design also comprises of some uncontrollable variables which act as noise factors. These are reduced significantly by adjusting the controllable variables. 2.4 Genetic algorithm. Genetic algorithm is a heuristic algorithm that is widely used for solving complex optimization problems. The algorithm starts with a randomly generated population of potential solutions or individuals, which are represented as strings of binary digits or chromosomes. Each individual is evaluated based on its fitness, which is a measure of its suitability for solving the problem. The fitness function is defined by the problem, and it may be simple or complex depending on the application. The GA operates on the principles of natural selection, crossover, and mutation to generate new generations of individuals that are increasingly fit. Selection favors the fittest individuals, and crossover combines the genetic material of two individuals to create offspring with new traits. Mutation introduces random variations in the offspring to maintain diversity in the population. The process of selection, crossover, and mutation is repeated iteratively to generate new generations of individuals until a termination criterion is met. 2.5 Fuzzy Logic Unlike classical logic, which assumes that propositions can only be true or false, fuzzy logic allows propositions to have degrees of truth that lie in a continuous range between 0 and 1. Fuzzy logic is based on the concept of fuzzy sets, which are sets with elements that have degrees of membership rather than crisp, binary membership. Fuzzy logic is particularly useful in situations where there are imprecise or ambiguous criteria for making decisions. It is often used in control systems, where it can help to control systems that are inherently imprecise, such as temperature or humidity control in a building. In such systems, fuzzy logic can help to handle the nonlinear and complex relationships between inputs and outputs, and can provide robust and stable control. 3. Results and Discussions 3.1 Optimization of process parameters using Taguchi mathematical modelling 3.2 Optimization of process parameters using GA 3.3 Fuzzy Modelling 3.4 Response Surface Plot Analysis From Taguchi 3.5 Analysis of Variance (ANOVA) 3.6 Surface analysis from fuzzy model 4. Comparision and Validation test 5. Characterization of the electroless coated Ni-Fe-P substrate deposited in optimized condition 5.1 Surface Morphology using Optical and Scanning Electron Microscopy 5.2 EDX study of the as-deposited optimized sample 6. Conclusion References