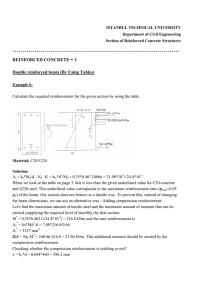

BHEL - 1500 MW CCPP PRAGATI-III PE-DC-314-653-C001-PART-3 CW PUMP HOUSE - 3D ANALYSIS AND DESIGN E.1 Part – 3 – Design of Columns, Isolated Footings, Tie Beams at EL (-) 4.500, Grade Beams , Corbel and RC Wall. DESIGN OF CORBEL ( For crane girder support on CWPH Columns along Grid- A & C ) (i) Material Data Strength of Concrete fck = 25 N/mm2 Strength of Steel fy = 500 N/mm2 0.45 x 25 = 11.25 N/mm2 tcmax = 3.1 N/mm2 b = 500 mm 520.08 x 10^3 /(11.25 * 500 ) = 92.46 mm Let = 500 mm Bearing Strength of Concrete ( sbr ) 0.45 * Fck = Maximum Shear Stress ( Table 20 of IS 456 ) (ii) Structure information / Dimension : Width of Bearing Plate Length of Bearing Plate (l), Adopting = = Fv / ( sbr * b ) l 500 x 500mm Bearing Plate Width of Column = B = 600 mm Clear Cover = Cc = 50 mm Dia of Rebar = f = 25 mm (iii) Loading information : The following loads are obtained as support reactions (with impact factor) from the Analysis and Design of Crane girder. Refer Doc. no. PE-DC-314-653-C002. Vertical Load on the Corbel = Fv = 346.72 kN Horizontal Load on the Corbel = Fh = 22.46 kN Longitudinal Load on the Corbel = Fl = 15.46 kN Factored Vertical Load on the Corbel = Fv,u = = 346.72 x 1.5 520.08 kN Factored Horizontal Load on the Corbel = Fh,u = = 22.46 x 1.5 33.69 kN Factored Longitudinal Load on the Corbel = Fl,u = = 15.46 x 1.5 23.19 kN Factored Loads for Design: file:///conversion/tmp/scratch/378948448.xls BHEL - 1500 MW CCPP PRAGATI-III PE-DC-314-653-C001-PART-3 CW PUMP HOUSE - 3D ANALYSIS AND DESIGN E.2 Part – 3 – Design of Columns, Isolated Footings, Tie Beams at EL (-) 4.500, Grade Beams , Corbel and RC Wall. CALCULATIONS : Assume Shear Stress = tc = Depth of Corbel d = = 520.08 x 10e3 / ( 2.5 x 600 ) Overall Depth of Corbel D d + Cc + f = = 346.72+50+25 = Adopting overall Depth of Corbel d Fv / ( tc * B ) 346.72 mm 421.72 mm = 700 mm = 637.50 mm = 300 mm = 0.471 < 0.6 = = 0.062 0.471 (z/d) 1 - 0.47/(0.47+0.062) 0.062/(0.47+0.062)*0.47^2 = = -0.884 0.026 (z/d) = 0.854 0.854 x 638 = = D 2.5 N/mm2 700 - 50 - 25/2 Check for Strut Action: For Struct action in the Corbel, (av / d) ratio should be less than 0.6. Distance of load from the face of the Column av / d = av 300 / 637.50 Hence the member acts as a Corbel with Strut action Determination of Lever Arm: To determine the Lever arm, the following quadratic equation is solved. (z/d)2 - [r / (r+k)].(z/d) + [k / (r+k)].r2 = 0 k r = = (520.08x 1000) /(0.88*600*638*25) av / d The co-efficients of quadratic equation are, Ax2 + Bx + C = 0 x A B C = = = = x = [ -B ± √(B2 - 4AC) ] / 2A x = Lever Arm, z = 544.30 mm Determination of Neutral Axis (Xu): Location of Compressive force from top compressive edge of the cross-section '0.45Xu' shall be written as, (d - z) = 0.45Xu Depth of Neutral Axis (Xu) file:///conversion/tmp/scratch/378948448.xls = = (d - z) / 0.45 ( 637.5 - 544.3 ) / 0.45 = 207.11 mm BHEL - 1500 MW CCPP PRAGATI-III PE-DC-314-653-C001-PART-3 CW PUMP HOUSE - 3D ANALYSIS AND DESIGN E.3 Part – 3 – Design of Columns, Isolated Footings, Tie Beams at EL (-) 4.500, Grade Beams , Corbel and RC Wall. Xu,max / d = = 0.0035/(0.0055+0.87Fy/Es) = 0.456 Xu,max = 0.456 x 638 = 290.72 mm Xu < Xu,max Hence ok. Tensile force along Horizontal Direction, Ft Fv / 2 = = Fv ( av / z ) 520.08 x ( 300 / 544.30 ) = 286.65 kN = 520.08 / 2 = 260.04 kN = 286.65 kN Ft should be atleast Fv/2 Here, \ Ft > (Fv /2) Ft Determination of Area of Tension Steel: Strain in tension Steel, es = 0.0035 ( d - Xu ) / Xu = 0.0073 > 0.87fy / Es = Hence Steel reaches yield. Stress in Steel = fs Area of Steel required, Ast = ( Fv,u +Fh,u ) / fs Ast = ( 286.65 + 33.69 ) x 1000 / 435 = = 0.87 x 500 435 N/mm2 = 710.60 mm2 = 0.40% Check for Minimum & Maximum Area of Steel: Minimum Percentage of Steel in Corbels Astmin = 0.40% x 600 x 637.50 = 1530 mm2 Ast < Astmin, Hence Provide Minimum reinforcement Maximum Percentage of Steel in Corbels = 1.30% = 4972.5 mm2 Hence Area of Steel required = 1530 mm2 Diameter of Rebar provided = 25 mm Provided Number of 25mm dia. Bars = 5 nos. Hence reinforcement provided, Astprov. = 2454.37 mm2 Astmax = 1.30% x 600 x 637.50 As < Ast,max, Hence ok Astprov. > Astmin HENCE SAFE Hence provide 5 nos. of 25mm dia. Bars for Main Reinforcement file:///conversion/tmp/scratch/378948448.xls 0.0022 BHEL - 1500 MW CCPP PRAGATI-III PE-DC-314-653-C001-PART-3 CW PUMP HOUSE - 3D ANALYSIS AND DESIGN E.4 Part – 3 – Design of Columns, Isolated Footings, Tie Beams at EL (-) 4.500, Grade Beams , Corbel and RC Wall. Area of Horizontal(Longitudinal) Shear Steel: Asu Fl,u / fs = = 23.19 / 435 x 1000 = 53.31 mm2 = 355.30009 mm2 Hence Area of Steel required = 355.30009 mm2 Diameter of Rebar provided = 12 mm Provided Number of 12mm dia. Bars = 4 nos. Hence reinforcement provided, Astprov. = 452.39 mm2 2454.37x100/(600 x 638) = 0.64% tc = 0.54 N/mm2 Minimum Area of Shear steel Astprov. / 2 = Astprov. > Astmin HENCE SAFE Hence provide 4 nos. of 12mm dia. Bars ( in the upper two-third depth) Shear capacity of Section Shear capacity of Concrete Percentage of Main Steel = Nominal Shear Stress Enhancement factor for Shear Stress, f t c1 = 2 x d / av = 2 x 637.50 / 300.0 = 4.25 = = f x tc 4.25 x 0.54 = 2.29 N/mm2 tc1 < tc,max HENCE OK tc1 * b * d Shear Capacity of concrete = = ( 2.29 x 600 x 638 ) / 1000 = 877.29 kN Shear capacity of Steel: Diameter of stirrups provided Number of legs Spacing of Stirrups provided, sv = = = = 12 mm 2 nos. (700-50-50)/5 120 mm Area of Shear reinforcement provided, Asv = 226.19 mm2 Shear Capacity of Steel Total Shear Capacity (Vu) Vu file:///conversion/tmp/scratch/378948448.xls = (0.87 fy.Asv.d) / sv = (0.87x500x226.19x637.5)/120 = = 877.29 + 522.71 > Fvu = 520.08kN 522.71 kN = 1400.01 kN BHEL - 1500 MW CCPP PRAGATI-III PE-DC-314-653-C001-PART-3 CW PUMP HOUSE - 3D ANALYSIS AND DESIGN E.5 Part – 3 – Design of Columns, Isolated Footings, Tie Beams at EL (-) 4.500, Grade Beams , Corbel and RC Wall. HENCE SAFE file:///conversion/tmp/scratch/378948448.xls BHEL - 1500 MW CCPP PRAGATI-III PE-DC-314-653-C001-PART-3 CW PUMP HOUSE - 3D ANALYSIS AND DESIGN E.6 Part – 3 – Design of Columns, Isolated Footings, Tie Beams at EL (-) 4.500, Grade Beams , Corbel and RC Wall. OUTPUT RESULTS : (i) Materials Concrete Steel = = Width of Corbel Depth of Corbel = = M25 Fe 500 (ii) Dimensions : (iii) Steel Details : Tension Reinforcement Provide 5 - 25 mm Horizontal Shear Reinforcement Provide file:///conversion/tmp/scratch/378948448.xls 4 - 12 mm f Bars as Tension Reinforcement 600 mm 700 mm