ECAP Aluminum Workability Study: Mechanical Properties & Fractography

advertisement

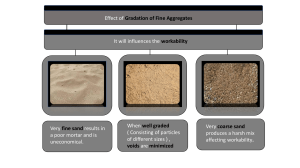

Materials and Manufacturing Processes, 29: 691–696, 2014 Copyright # Taylor & Francis Group, LLC ISSN: 1042-6914 print=1532-2475 online DOI: 10.1080/10426914.2014.892978 Workability Study on 99.04% Pure Aluminum Processed by ECAP S. Surendarnath1, K. Sankaranarayanasamy1, and B. Ravisankar2 1 Downloaded by [Lancaster University Library] at 14:25 05 February 2015 2 Department of Mechanical Engineering, National Institute of Technology, Tiruchirappalli, India Department of Metallurgical and Materials Engineering, National Institute of Technology, Tiruchirappalli, India This paper presents the workability of pure aluminum processed by equal channel angular pressing (ECAP) with different routes and the increasing number of passes. The experiments have been carried out to ECAP die using channel angle (2/) of 90 and corner angle (w) of 20 . The ECAP samples were carried out up to three successive passes using Route A and C. The annealed and ECAPed samples were used to find out the mechanical property. Workability of the material is an important process parameter for the material to withstand up to initial cracking. The workability studies were looked into the normal compression tests on cylindrical sample machined from ECAP samples with a constant diameter of 20 mm with different aspect ratios 0.75, 1.0, and 1.5. Mechanical property and fractography studies were carried out before and after ECAP process. The observed results have been validated through Cockcroft ductile fracture criterion. An increased mechanical property with a little step down in formability of the consequent ECAP at the second and third passes of both the Routes was observed. Keywords CP aluminum; ECAP; Fractography; Mechanical properties; Workability study. and inhomogeneity of aluminum, magnesium, and lead alloy using the higher channel angle (90 ) and increased the flow property of the material. A complete study of microstructural characterization using commercially pure aluminum processed by ECAP was done by El-Danaf; Hoseinia et al.; and Kawasakia et al. [7–10]. Iwahasi et al. [11] proposed the modified equivalent plastic strain equation, INTRODUCTION Equal channel angular pressing (ECAP) is playing a significant role in severe plastic deformation techniques for producing nanostructure materials. Vladimir Segal (1995) initially developed ECAP. The grain size acts the main role to develop high strength and ductility of the materials. Valiev and Langdon, and Shanmugasundaram et al. [1, 2] improved the mechanical properties with high specific strength and ductility through Hall–Petch relation, K ry ¼ r0 þ pffiffiffi d 1 / w / w ep ¼ pffiffiffi 2 cot þ þ w cosec þ 2 2 2 2 3 ð1Þ ð2Þ where / is the channel angle and w is the corner angle. Sivaraman and Uday Chakkingal [12] investigated the workability of CP aluminum resulted in improved mechanical properties with a slight decrement in workability compared with the annealed samples. Soliman et al. [13] investigated the properties of CP aluminum processed by ECAP using two processing routes up to four successive passes. The average grain size, misorientation angle, and high angle grain boundaries (HAGB) were investigated from both X and Y planes. In Route Bc, the average grain size was decreased rapidly than the Route A condition of both the plane conditions. At the same time, misorientation angle and HAGB percentage were increased reasonable amount than the Route A of both the planes. The compressive strength is higher than the tensile strength for all the passes and routes. Makhlouf et al. [14] investigated the microstructure and mechanical property improvement of CP aluminum processed by equal channel angular extrusion (ECAE) up to four passes using route C and Bc. After the ECAE process, the X-ray diffraction (XRD) peak shows the grain refinement and lattice orientations clearly, as well as the yield strength and hardness value enhanced the where K is a material constant, d is the average grain size, ry is the allowable stress, and r0 is the frictional stress. Many severe plastic deformation techniques such as ECAP, HPT (Zhilyaev et al. [3]), multidirectional forging, twist extrusion, cyclic-extrusion compression, and ARB have been formulated by Saito et al. [4]. The main advantages of ECAP are obtaining a large strained material without change in the workpiece dimension and repeating the same workpiece many times. Kiyotaka Nakashima et al. [5] carried out the experiments on the pure aluminum die consisting of two intersecting channel angle (u) with an angle from 90 to 157.5 . The maximum strain was imposed in the 90 channel die. Cetlin et al. [6] investigated the reduction of crack Received November 13, 2013; Accepted January 17, 2014 Address correspondence to S. Surendarnath, Department of Mechanical Engineering, National Institute of Technology, Tiruchirappalli – 620015, India; E-mail: surendarmech@gmail.com Color versions of one or more of the figures in the article can be found online at www.tandfonline.com/lmmp. 691 Downloaded by [Lancaster University Library] at 14:25 05 February 2015 692 S. SURENDARNATH ET AL. consecutive passes. Dieter [15] reported the workability of various materials under various conditions. Workability is an important process limit for materials to withstand up to initial cracking of the material on the outer surface. It mainly depends on the ductile fracture and its mode of failures in various materials. Cockcroft and Latham have proposed the equation for a ductile fracture criterion of metals. The workability plays main role in materials and the mode of operation. Therefore, workability ¼ fl (material) f2 (operation) [16]. Abdel Rahman [16] investigated the workability of the material using normal compression and tension test. From the experimentally validated result, the values were plotted and fitted in the straight line which related the fracture strain of the material and the strain increment ratio (b). Equation of the workability line method determined the magnitude of the stress needed, which was used in material and the operation. Gouveia et al. [17] investigated the experimental and theoretical research work of both Cockcroft and Latham and Oyane regarding the ductile fracture criterion for the various geometrical profiles under different loading conditions. Cockcroft and Latham [18] proposed the most generally applicable ductile fracture criterion. The Cockcroft and Latham ductile fracture criterion equation is based on the combination of the effective stress and effective strain of the material. Zef rh d e ¼ C ð3Þ 0 where rh is the ultimate tensile stress, e and ef are the effective strain and effective strain at failure, C is the material constant. Agena et al. [19] investigated the workability of 6082 Al alloy of Freudenthal fracture criterion using both cylindrical and flanged specimens. After deformation, the circular cross section of the workpiece became elliptical in shape due to material anisotropy, which was reflected in the flow stress. Narayanamurthy et al. [20] investigated the six general fracture criteria to calculate the failure in metal forming operation using the spheroidized steel experimental result. All the six ductile fracture criteria of material constant were determined in terms of integral stress function through the axial strain and the hoop strain of the test data of spheroidized steel. The newly proposed criterion can be determined using effective stress, mean stress, and maximum stress of the deformed sample. In this study, we have investigated the workability of commercially pure aluminum before and after ECAP process under various processing conditions up to three passes. EXPERIMENTAL DETAILS The commercially pure aluminum (99.04%) was machined to 25 mm diameter and 80 mm length. The specimens were annealed at 350 C for 1 h and cooled in the furnace itself before ECAP processing. The schematic diagram of the die with a channel diameter of 25 mm, channel angle (2u) of 90 , and corner angle (w) of 20 is shown in Fig. 1(a), and die setup is shown in Fig. 1(b). The workpiece was extruded with a constant speed of 1 mm=s using a 100 ton hydraulic press. Molybdenum disulfide (MoS2) was applied as a lubricant substance in the specimen to reduce the friction. For the mechanical property study, the tensile test specimen was machined from the ECAP sample with 5:1 proportion as per ASTM E8 M11 standard. The testing sample dimensions are shown in Fig. 2. Tensile test was accomplished using a 30 KN Instron machine at the constant speed of 0.5 mm=min. For each condition, three trials were made in finding out the errors. The material flow properties such as strength coefficient (K) and strain-hardening exponent (n) were estimated using power law Eq. (4) from the normal compression test data of the annealed and ECAP samples with the 10 mm in diameter and 15 mm in height as given in Table 1. r ¼ Ken FIGURE 1.—(a) Schematic diagram of conventional die; (b) Conventional die setup. ð4Þ WORKABILITY STUDY ON 99.04% PURE ALUMINUM PROCESSED BY ECAP FIGURE 2.—Dimensions of tensile test specimen. TABLE 1.—Material flow property obtained from the normal compression test ECAP specimens. Downloaded by [Lancaster University Library] at 14:25 05 February 2015 Conditions Annealed First pass Second pass Route A Second pass Route C Third pass Route A Third pass Route C K (MPa) N 226 238 250 274 289 319 0.22 0.26 0.31 0.45 0.451 0.423 RESULTS AND DISCUSSION After completing the ECAP, the specimens were cut into the longitudinal direction to measure the hardness values. The hardness values were measured on the top surface of the ECAPed specimen with a gap of 2.5 mm distance from the center position. The hardness values were uniform in all the regions. The hardness measurement mainly depended on the strain imposed on the material. The hardness measurement was carried out in all the routes up to the third pass as shown in Fig. 3. After FIGURE 3.—Vickers microhardness along the surface of the annealed and various processing routes of ECAP specimen. 693 annealing, the sample showed an average value of 37 HV. After the first pass, the hardness value reached 53 HV and in the corresponding second pass, the maximum hardness value obtained were 61.6 and 63 HV in RA and RC, respectively. In the third pass, the hardness was 66.5 and 68 HV in RA and RC, respectively. The tensile test results were plotted in Fig. 4(a). A gradual increment in the tensile strength of the ECAP specimen can be seen in the consecutive passes. After annealing condition, the tensile strength was 144 MPa. After a first pass, the tensile strength reaches 191 MPa. After the successive second and third passes of Route A, the tensile strength was 199 and 201 MPa, respectively. Similarly, in Route C, the UTS were 207 and 218 MPa. Figure 4(b). shows the percentage of elongation to the failure with subsequent passes. The percentage of failure elongation of the before ECAP sample was 26% and it reduced to 17% in RA and 15.7% in RC at the end of third pass. The fractography study was carried out from the tensile test samples using a scanning electron microscope. It was seen that the ECAP samples from the first pass to the third pass showed a ductile fracture in all the specimens. The specimens initially formed the necking and then they developed failures. This is clearly visible in the SEM images shown in Fig. 5. For the workability study of the ECAP samples, a simple compression test was followed using cylindrical specimens with the aspect ratio (h=d) of 0.75, 1.0, and 1.5. The diameter was constant for all the aspect ratio 20 mm. For reducing the errors, two specimens were machined for each condition. The compression test data were used to find out the strain increment ratio (a) and the fracture strain of the material. The strain increment ratio of different processing routes is given in Table 2. The specimens were compressed under incremental load conditions, and when a specimen was in uniform deformation the middle portion of the specimen bulged. The upsetting was carried out still the occurrence of visible cracks on the outer barrel of the specimen. After upsetting, the axial and circumferential strain were estimated from the specimen initial and final dimension. From the initial and final gage height of the compressed sample, the compressive strain (eZ) was estimated. The circumferential strain or hoop strain (eh) was estimated from the specimen initial and the final diameter. The axial versus circumferential strain was plotted to find the slope of the line. All the compression-tested materials were nearer to the linear fit of the line. It indicated that the ECAP specimens in all the processing routes showed the homogeneous condition of the material. The Cockcroft and Latham constant C1 was calculated from the tensile test result and the effective fracture strain of the material. The various processing routes of ECAP results are given in Table 3. The workability diagram of various ECAP samples is shown in Fig. 6. Figure 6 shows the compressive and circumferential strain of the samples. The axial vs. hoop strain of the annealed sample was experimentally validated through the empirical formula, and also the different passes of ECAP samples were 694 S. SURENDARNATH ET AL. Downloaded by [Lancaster University Library] at 14:25 05 February 2015 FIGURE 4.—(a) Tensile strength vs. no. of passes; (b) Percentage of elongation vs. no. of passes. FIGURE 5.—Fracture surface of the ECAPed tensile test samples (a) First pass; (b) Second pass RA; (c) Second pass RC; (d) Third pass RA; (d) Third pass RC. TABLE 2.—Strain increment ratio (a) of various ECAP samples. (Aspect ratio) 0.75 1.0 1.5 Annealed First pass Second pass RA Second pass RC Third pass RA Third pass RC 0.538 0.531 0.522 0.536 0.527 0.520 0.527 0.510 0.507 0.512 0.513 0.510 0.516 0.507 0.504 0.503 0.50 0.498 WORKABILITY STUDY ON 99.04% PURE ALUMINUM PROCESSED BY ECAP TABLE 3.—Cockcroft and Latham ductile fracture criteria (C1) for various processing routes. C1 (MPa) Annealed First pass Second pass Route A Second pass Route C Third pass Route A Third pass Route C 27.52 30.6 33.05 40.26 35.92 39.17 695 succeeding passes. From the observed result, it clearly shows the ECAP results in reduction of workability compared to the annealed sample. The second pass, Route C, has slightly higher workability than Route A. Finally, the third pass, both the routes of ECAP samples have a lesser workability than the second pass. Route C is better than Route A for better formability and better strength than Route A of ECAP. Downloaded by [Lancaster University Library] at 14:25 05 February 2015 REFERENCES FIGURE 6.—Workability diagram for annealed and various ECAPed samples. validated and compared with the annealed samples. The annealed samples have superior formability than the ECAP samples. At the end of the first pass, the workability is little bit reduced than the annealed samples. At the end of the second pass, the workability of RA has slightly decreased than that of Route C. However, the workability limits are very close and more or less the same. At the end of third pass, the workability decreased a little bit compared to the second pass in both the routes. As the successive passes, the workability of the material decreases because of increase in strength and the hardness of material, this is clearly observed in this work. The workability plays a significant role in the metal forming processes such as to withstand the material without losing their property. CONCLUSIONS Workability on CP aluminum processed by ECAP has been investigated successfully. The ECAP of commercial aluminum results in improving the mechanical properties like strength and hardness. The Cockcroft and Latham constant C clearly shows the ductility of the material for various processing routes and the 1. Valiev, Ruslan Z.; Langdon, Terence G. Principles of equal channel angular pressing as a processing tool for grain refinement. Progress in Materials Science 2006, 51, 881–981. 2. Shanmugasundaram, T.; Heilmaier, M.; Murty, B.S.; Subramanya Sarma, V. At the Hall–Petch relationship in a nanostructured Al–Cu alloy. Materials Science and Engineering A 2010, 527, 7821–7825. 3. Zhilyaev, A.P.; Nurislamova, G.V.; Kim, B.K.; Baro, M.D.; Szpunar, J.A.; Langdon, T.G. Experimental parameters influencing grain refinement and microstructural evolution during high pressure torsion. Acta Materialia 2003, 51, 753–765. 4. Saito, Y.; Utsunomiya, H.; Tsuji, N.; Sakai, T. Novel ultra-high straining process for bulk materials development of the accumulative roll-bonding (ARB) process. Acta Materialia 1999, 47 (2), 579–583. 5. Nakashima, Kiyotaka; Horita, Zenji; Nemoto, Minoru; Langdon, Terence G. Influence of channel angle on the development of ultrafine grains in equal-channel angular pressing. Acta Materialia 1998, 46 (5), 1589–1599. 6. Cetlin, P.R.; Aguilar, M.T.P.; Figueiredo, R.B.; Langdon, T.G. Avoiding cracks and inhomogeneities in billets processed by ECAP. Journal of Materials Science 2010, 45, 4561–4570. 7. El-Danaf, E.A. Mechanical properties and microstructure evolution of 1050 aluminum severely deformed by ECAP to 16 passes. Materials Science and Engineering A 2008, 487, 189–200. 8. El-Danaf, E.A. Texture evolution and fraction of favorably oriented fibers in commercially pure aluminum processed to 16 ECAP passes. Materials Science and Engineering A 2008, 492, 141–152. 9. Hoseinia, M.; Meratian, M.; Toroghinejad, M.R.; Szpunar, J.A. The role of grain orientation in microstructure evolution of pure aluminum processed by equal channel angular pressing. Materials Characterization 2010, 61, 1371–1378. 10. Kawasakia, M.; Horita, Z.; Langdon, T.G. Microstructural evolution in high purity aluminum processed by ECAP. Materials Science and Engineering A 2009, 524, 143–150. 11. Iwahashi, Yoshinori; Wang, Jingtao; Horita, Zenji; Nemoto, Minoru; Langdon, Terence G. Principle of equal-channel angular pressing for the processing of ultra-fine grained materials. Scripta Materialia 1996, 35 (2), 143–146. 12. Sivaraman, A.; Chakkingal, Uday. Investigations on workability of commercial purity aluminum processed by equal channel angular pressing. Journal of Materials Processing Technology 2008, 202, 543–548. 13. Soliman, Mahmoud S.; El-Danaf, Ehab A.; Almajid Abdulhakim, A. Effect of equal-channel angular pressing process on properties of 1050 Al alloy. Materials and Manufacturing Processes 2012, 27, 746–750. 696 Downloaded by [Lancaster University Library] at 14:25 05 February 2015 14. Makhlouf, T.; Rebhi, A.; Njah, N. Microstructure and mechanical property evolution of 99.1% recycled aluminum during equal channel angular extrusion. IOP Conference Series: Materials Science and Engineering 2010, 13, 1–10. 15. Dieter, G.E.; Kuhn, H.A.; Semiatin, S.L. Handbook of Workability and Process Design; ASM International, 2003 pp. 57–60. 16. Abdel Rahman, M. Determination of workability curves using two mechanical tests. Journal of Materials Processing Technology 1995, 51, 50–63. 17. Gouveia, B.P.P.A.; Rodrigues, J.M.C.; Martins, P.A.F. Ductile fracture in metalworking: experimental and theoretical S. SURENDARNATH ET AL. research. Journal of Materials Processing Technology 2000, 101, 52–63. 18. Cockcroft, M.G.; Latham, D.J. Ductility and workability of metals. Journal of the Institute of Metals 1968, 96, 33–39. 19. Agena, A.S.M.; Krallics, G. Investigation of workability of Al-6082 nanostructured materials. Emirates Journal for Engineering Research 2007, 12 (3), 9–13. 20. Narayana Murty, S.V.S.; Nageswara Rao, B.; Kashyap, B.P. Improved ductile fracture criterion for cold forming of spheroidised steel. Journal of Materials Processing Technology 2004, 147, 94–101.