JSA-23--REV-0 CONCRETE WORKS, RE-INFORCED MASS CONCRETE POURING ACTIVITIES

advertisement

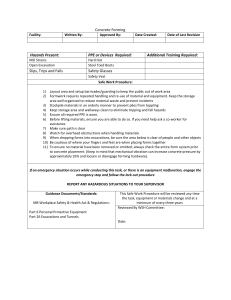

References (GI): 1. Work Permit System – GI.2.100 JOB SAFETY ANALYSIS RECORD SHEET Plant/Equipment Department/Location: B1-10-10056 DLPS-SSSP-05 All Areas Division/Unit: Date: Feb 06, 2022 Document No. DLPS-SSSP-HSEJSA NO. DLPS-SSSP-51-HSE-JSA-0015 Description of Activity Rev:00 CONCRETE WORKS, RE-INFORCED MASS CONCRETE POURING ACTIVITIES Craft/Personnel involved: Site Engineers, Helpers, Supervisors, Foreman, Safety Supervisor, Safety Officer, Work Permit Receiver, Drivers, Equipment Fire watcher, Flagman and all supporting workers. Tools/ Equipment required: Hand Tools, Power Tools, Torque Wrench, Boom Truck Lifting Tools & Tackles Cable Detector, Hand Tools, , , , , Wheel Loader ,Transit Mixer, Concrete Pump, Concrete Vibrator and Compactor, Mechanical Floats, Scaffold Tubes, carpentry tools PREPARED BY: (Name & REVIEWED BY: APPROVED BY: Signature) Name: Name: 1. SIRAT GUL KHAN Safety Manager: _____________________ Name: Name: Name: __________________ ____________________ ____________________ _________________ _________________ __________________ Signature _________________ Signature: Signature: Signature: Signature: ________________ ____________________ ____________________ Date _____________ Date ________________ Date ________________ (Project Manager) SAMPT Field Compliance Coordinator) (Area Supervisor) Date _____________ (Project Engineer) Date ______________ (Const Manager) Saudi Aramco: Company General Use 1 2. GI 6.012 Isolation, Lockout and Use of Hold Tags 3. GI 8.01 (Safety requirements for Scaffolds) 4. Fire & Safety Watch – GI.002.711 5. Construction Safety Manual Confined Space 1-6 rev. 2016 6. Mobile Heavy Equipment Operator Testing and Certification – GI. 7.025 7. Lift, Critical Crane Lifts – G1. 7.028 8. Inspection, Use and Maintenance of below-the hook Lifting Equipment For Cranes – GI. 7.029 9. Inspection and Testing Requirements of Elevating/Lifting Equipment – GI. 7.030 10. GI 7.709 – Gas Testing with Portable Gas Monitor 11. Safety Handbook 12. CSM I-12 Materials Handling 13. CSM I-8 Traffic Vehicle Safety 14. SAES-A-114, Excavation and Backfill 15. GI 1021.000, Street & Road Closure 16. SAES-H-003 Protective Coatings for Industrial Concrete Structure 17. SAES-Q-001 Criteria for design and construction of concrete structures 18. SAES-Q-005 Concrete Foundations 19. SAES-Q-007 Foundations and Supporting Structures for Heavy Machinery 20. SAES-Q-009 Concrete Retaining Walls Safety Equipment’s Personal Protective Equipment (hard hat, safety glasses, Safety Shoes with steel tole caps, Ear Plugs, heavy-duty Safety Gloves, Dust Mask) Full body harness, lanyards& lifeline must be implemented if the work is above 6 feet/1.8 meter from ground level. Gun boots shall be provided Castle gas detector to be used in place Rattler T-40 Personal H2 S monitor Fire Resistant Clothing Warning signs, Barricades (Hard or Soft) Rattler T-40 Personal H2S Monitor Fire Extinguishers (Inspected & tagged) Appropriate respiratory equipment (as necessary to prevent inhalation of dust and/or particulates) Saudi Aramco: Company General Use 2 # 1 SEQUENCE OF BASIC JOB STEPS Visual Inspection of Site for detection of underground utilities POTENTIAL HAZARDS REQUIRED HAZARD CONTROLS 1. Miscommunication 1. 2. 2. Emergency Evacuation 3. Action By Obtain the work permit to use cable detector Machine. All Personnel conducting visual inspection must have safety orientation card in possession with them. All personnel conducting visual inspection should know the Emergency Assembly Area and Evacuation Routes Worksite supervisor , Site Engineer, Safety Officer, Permit Receiver Secure hot work permit for this activity Wear required PPE (Working Gloves, safety glasses, hard hat, Safety Shoes, etc.) 3. Ensure that all personnel deployed on site had undergone safety orientation. 4. Tool box talk regarding heavy equipment safety must be done to site personnel prior to start work. 5. Heavy equipment operators must be SA certified. 6. Movement of equipment especially when reversing must be assisted with a flagman and reverse alarm must be working. PWAS must be provided to all moving heavy equipment. 7. Ensure that all heavy equipment to be mobilized on site are in good working condition. It must have valid Safety inspection sticker. 8. Maintain safe distance of heavy equipment to existing facilities in the area such as pipe rack, fire hydrants, etc. Minimum of 3 meters distance. 9. Close supervision is required. 10. Ground surface must be clear all the time 11. Access and egress must be clear 12. Toolbox about Hand tools and power tools shall be communicated to the employees Worksite supervisor , Site Engineer, Safety Officer, Permit Receiver 1. 2. 1. Crushing 2. Damage to existing facilities 2 Mobilization of tools and equipment’s on site. 3. Collision 4. Slips, trips & falls 5. Electrical hazards Saudi Aramco: Company General Use 3 3 Concrete Foundations, Slabs Columns, Walls, and Beams Installations 1. Exposure to concrete dust 2. Falling of concrete foundations 3. 4. Sandwich in between the slabs Hand and Foot Injuries 5. Skin irritations 6. Slip, Trip and Fall 1. 2. 3. 4. 5. 6. 7. 8. Obtain Work Permit for concrete works Ensure that proper PPE is provided to the employees before they are set on work It shall be ensured that proper trainings shall be provided to the workers set on concrete works Ensure that MSDS ,chemical bulletins are available on the site and communicated to the workers The area should be barricaded with warning signage’s posted and with adequate space for entry/exit of personnel and equipment’s Proper close supervision shall be provided to the working area Ensure that the slabs and columns installation shall be only through Aramco approved inspected equipment Crane and Boom truck operators shall be SA certified Saudi Aramco: Company General Use 4 Worksite supervisor , Site Engineer, Safety Officer, Permit Receiver 1. 2. 1. 2. Damage to underground utilities Damaged Hand Tools 3. Hand and Foot Injuries 4 Placement of Form Works In excavation, Dunk Banks, and Manholes 3. 4. Access & Egress Fall from heights 5. Slip, Trip and Fall 6. 7. Fall of excavated material Exposed Protruding Rebar 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. Use certified carpenters for adjusting carpentry works Ensure that required approved method statements, preexcavation and daily excavation checklists, technical drawings and MS for Form are available and complied with Use proper PPEs Allow only authorized person on the site. Ensure that proper carpentry tools are used and maintained… Use enough water to avoid spark and dust during the work…… Make temporary bridge using Steel plates for vehicles and pedestrians movement. Use proper traffic sings or Flagman at least 5m away from the excavation to divert the driver attention to the temporary road. Remove the spoils to a dump location, and maintain good housekeeping. No materials to be kept at the edge of the excavations Use Standby man on the site. Ensure that proper inspected hammers are used Ensure that proper PPE is provided to the employees Ensure that proper denailing has been done for used ply woods Ensure that used plywood have been removed from the site Ensure that the plywood materials are not stored on the corners of excavations, trenches and manholes Protruding rebar shall be properly capped (covering by caps) Proper chemical PPE shall be available on the site ( Chemical gloves, chemical glasses ,chemical shoes ,disposable cover all) Saudi Aramco: Company General Use 5 Worksite supervisor , Site Engineer, Safety Officer, Permit Receiver 1. 2. 1.Risk of uncertified machines 3. 2.Risk of Improper handling 4. 3.Human body at risk 5 Concrete Pouring (Placement of Concrete Pouring machines) 4.Equipment failure 5. 5.Risk of wrong erection of concrete carrier steel structure 6. 7. 8. 6.Risk of Concrete splashing into eyes from the end hose 9. 10. 11. 12. 13. 14. 7.Concrete burns to hands and feet 8.Fire hazard 9.Oil spillage 15. 16. 17. 18. Concrete Gang should wear a safety helmet, safety footwear, impervious gloves / gauntlets, high impact goggles and high visibility clothing. Until concrete is flowing smoothly out of the end of the delivery hose, or when a blockage occurs in the boom pipeline, all personnel should remain clear of the delivery hose and placing boom. Under no circumstances should any unauthorized personnel attempt to open the pipeline. All unnecessary personnel including the general public should be kept well away from the concreting area in lower floors and staircases Use of ropes and good manual handling practices to be adopted Plywood sheets must be provided on mesh in the laying area Make it sure that the operators are approved and certified Make it sure that the cement concrete pump is approved and inspected Provide spot boy to manage the traffic flow on the area Provide sign boards and barricades. Arrange the concrete area and avoid spillage of concrete Make it sure that the hand carriages do not damage. Do not overload the hand carriages with concrete. Spillage shall not be ignored. Oil spillage with effected soils to be collected at plastic bags Spillage trays shall be provided to the equipements Do not kink placing hoses in the ground line. Do not attempt to pump very old concrete or concrete other than a pump mix. . The danger zone is the area around the end hose in which it can strike out. The diameter of the zone is twice the length of the end hose Move away from end hose during boom movement. Concrete Gang to be alert Saudi Aramco: Company General Use 6 Worksite supervisor , Site Engineer, Safety Supervisor 6 Operations (Concrete pouring activity) 1.Risk of hand injuries 2.damage to underground utilities 3. falls, trips 4. equipment failure 5.Risk of spillage of concrete debris 6.environmental damage 7.loose hold the concrete large hose 8.particles going into eyes, 9.Head injury 10.Broken limbs, severe injury caused by whiplash of placing hoses 11.Injury splash of concrete 12.Crushing in between 1. 2. 3. 4. Provide hard barricading to the concrete pouring area Provide scope of the job (drawings and safe work methods) Provide fire extinguisher to the concrete pouring pump Make it sure that the concrete mixer should be in a safe distance with the concrete pump machines 5. The concrete Pump operator should have always a watch on the concrete operations 6. Make it sure that in case of any emergency, it should have emergency stop button to close the activity soon 7. Make it sure that chemical PPE is provided to all the workers (coveralls and long rubber boots) 8. Make it sure that there should be provided access points from the excavations to the workers 9. MSDS for cement should be available on the working area 10. High visibility clothing must be worn and do not back truck on out of view of mixer driver who will be reversing using mirrors. Keep site personnel out of reversing area 11. Keep hopper full and inform mixer driver of risk Saudi Aramco: Company General Use 7 Worksite supervisor , Site Engineer, Safety Supervisor 1. 2. 3. 4. 5. 1. 2. 3. 7 Backfilling & Compacting activities 4. 5. Crushing injuries Slips, trips and fall Damage to existing facilities Heat/Burn Injuries Fire 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 1. 2. 8 Demobilization of tools, debris & equipment’s 1. Injuries 2. Damage to existing facilities 3. 4. 5. Secure hot work permit for this activity. Wear required PPE (working gloves, hard hat, safety glasses, etc.) Heavy equipment operators must be SA certified. Movement of heavy equipment especially when reversing must be assisted with flagman and reverse alarm must be working. PWAS must be provided to all moving heavy equipment. Warning signs and barricades must be in place around open excavations. Restrict entry of unnecessary personnel on the work areas. Maintain good housekeeping on the work area. Safe access and egress must be provided on excavations. Maintain safe distance of heavy equipment to existing facilities in the area such as pipe rack, fire hydrants, etc. Minimum of 3 meters distance. The asphalt machines/equipment’s should be in good working condition and free from damage/defects Ensure fire-watcher is available and fire extinguisher is inspected and tagged while the asphalt is in progress. All the crew working with asphalt should wear appropriate PPE to avoid heat/burn injuries Upon completion of Asphalt works the asphalt waste/debris should be immediately removed from site to maintain good housekeeping The worker spreading the asphalt should use a bull float from a safer distance to avoid heat/burn injuries Close supervision is required. Secure hot work permit for this activity. Wear required PPE (working gloves, hard hat, safety glasses, etc). Maintain good housekeeping on the work area and dispose contaminated soil on proper disposal area. Movement of equipment must be assisted with spotter/Flagman. Close supervision is required Saudi Aramco: Company General Use 8 Worksite supervisor , Site Engineer, Safety Supervisor Worksite supervisor, Safety Officer, Permit Receiver Procedure upon discovering damage to any nearby structure/utility/equipment Upon discovering damage to any nearby structure/utility/equipment the following procedures should be followed 1. 2. 3. Hold the job temporarily and inform the permit issuer, PMT Safety and PMT Project Engineer Wait for further instructions from Permit Issuer and confirmation from PMT Safety and SA Project Engineer Upon Approval and confirmation to resume the job inform the Permit Issuer and PMT Safety and Project Engineer NOTE: 1. Supervisor, Foremen must discuss the JSA to their crew prior to the execution of work to ensure safety of everyone. 2. In case of an accident the standby man must call the Security, Emergency number or dial (911) 3. In case of fire, the qualified fire watchman shall extinguish the fire immediately and must inform the immediate supervisor. 4. Safety Advisor/Engineer/Officer shall oversee the whole duration of activity and submit Accident/Incident report if there’s any. Saudi Aramco: Company General Use 9