APRIL 2009

HPIMPACT

SPECIALREPORT

FORECAST

Economy, capacity

pressure polyolefins

PETROCHEMICAL

DEVELOPMENTS

ACHEMA 2009

No short-term recovery

for Asian demand

Innovation sustains

profits and safety

Trade associations

report on chemicals

markets and outlook

www.HydrocarbonProcessing.com

sky's the limit

OneWireless solutions give you the freedom

to extend beyond your limits.

From helping you manage your rotating equipment to making

your employees mobile and more efficient, Honeywell has

helped our customers solve process and business challenges

with innovative wireless-enabled solutions. Our OneWireless

TM

universal mesh network supports multiple industrial protocols and applications

simultaneously, giving you flexibility without sacrificing reliability or bandwidth. Why stay

chained to multiple networks, when there is one that will let you soar. OneWireless.

To learn more about OneWireless solutions, please call

1-877-466-3993 or visit www.honeywell.com/ps/wireless

© 2008 Honeywell International, Inc. All rights reserved.

Select 52

51 at www.HydrocarbonProcessing.com/RS

APRIL 2009 • VOL. 88 NO. 4

www.HydrocarbonProcessing.com

SPECIAL REPORT: ACHEMA 2009/

PETROCHEMICAL DEVELOPMENTS

ACHEMA 2009: A Special Report

29

57

29 Middle East; 39 Asia-Pacific; 51 South America; 55 North America

Lead or get out of the way

We do have choices in shaping our future energy market

J. D. Morris

61

Improve product ethylene separation

71

Reevaluate your process safety systems

for hazardous material storage

New high-capacity trays enable retrofitting existing splitter superfractionator

to expand unit capacity and conserve energy

A. Bernard, W. de Villiers and D. R. Summers

How safe is ‘safe enough’ when it comes to managing

potentially risky processes in chemical plants?

M. P. Sukumaran Nair

81

Update catalyst technology for syngas production

Changes in bed support maintain lower pressure drop across

shift reactor in ammonia processes

W. Khalid

RELIABILITY/MAINTENANCE

Extreme failure analysis: never again a repeat failure

87

Apply root-cause failure analysis to recurring reliability problems

K. Bloch

COMPUTER TECHNOLOGY/PIPING

Computational fluid dynamics simulation

of solid–liquid slurry flow

Cover The Ludwigshafen site is BASF’s

largest production facility. With

approximately 32,600 workers, the

company at Ludwigshafen is the largest

employer of the metropolitan Rhine

Neckar region. This site was established

143 years ago. Over 200 production

enterprises are linked together via a

2,000-km aboveground pipeline network.

Photo courtesy and copyright by BASF, The

Chemical Co.

HPIMPACT

17 Economy, capacity

additions pressure

polyolefins markets

19 Asia’s thirst for oil

likely to swell again,

but when?

19 EPA chemicals oversight

questioned in new GAO

report

99

The resulting model’s predictions showed reasonably good agreement

with the experimental data

S. K. Lahiri and K. C. Ghanta

SAFETY

Apply new trends for safety-instrumented systems

107

Take a closer look at advancements for emergency shutdown designs

P. Gruhn

111

Maximize up-time for sulfur testing

117

Rethink your overpressure systems

New analyzer determines trace level amounts quickly

R. Van Der Windt and A. Van Strien

Consider multiple relief valve designs

S. Rahimi Mofrad

ASSET MANAGEMENT

Transforming refining best practices with 3D virtual models

121

The technology, from laser scanning to management of change,

is mature, functional, cost-effective and proven

K. M. Renner and C. Lanza

ENGINEERING CASE STUDIES

Case 49: Isolating foundations

from machinery vibrating forces

COLUMNS

9 HPIN RELIABILITY

Pump suction strainer

issues

11 HPIN EUROPE

CO2 constraints

‘may be the best news

for Shell’—CEO

13 HPINTEGRATION

STRATEGIES

Reducing cost

through an integrated

approach to power and

automation

134 HPIN AUTOMATION

SAFETY

Are you the designated

jailee?

129

Vibration can be detrimental to nearby equipment

T. Sofronas

DEPARTMENTS

7 HPIN BRIEF • 15 HPIN ASSOCIATIONS • 17 HPIMPACT •

21 HPINNOVATIONS • 25 HPIN CONSTRUCTION •

130 HPI MARKETPLACE • 133 ADVERTISER INDEX

View this month’s

LETTERS TO THE EDITOR

online at: www.

HydrocarbonProcessing.com

www.HydrocarbonProcessing.com

Houston Office: 2 Greenway Plaza, Suite 1020, Houston, Texas, 77046 USA

Mailing Address: P. O. Box 2608, Houston, Texas 77252-2608, USA

Phone: +1 (713) 529-4301, Fax: +1 (713) 520-4433

E-mail: editorial@HydrocarbonProcessing.com

www.HydrocarbonProcessing.com

London Office: Nestor House, Playhouse Yard London, EC4V 5EX, UK,

Phone: +44 (0) 20 7779 8800, Fax: +44 (0) 20 7779 8996/8899

Publisher Mark Peters mark.peters@gulfpub.com

EDITORIAL

Editor Les A. Kane

Senior Process Editor Stephany Romanow

Managing Editor Wendy Weirauch

Process Editor Tricia Crossey

Reliability/Equipment Editor Heinz P. Bloch

News Editor Billy Thinnes

European Editor Tim Lloyd Wright

Contributing Editor Loraine A. Huchler

Contributing Editor William M. Goble

Contributing Editor Y. Zak Friedman

Contributing Editor ARC Advisory Group (various)

MAGAZINE PRODUCTION

Director—Editorial Production Sheryl Stone

Manager—Editorial Production Chris Valdez

Artist/Illustrator David Weeks

Manager—Advertising Production Cheryl Willis

ADVERTISING SALES

See Sales Offices page 132.

CIRCULATION +1 (713) 520-4440

Director—Circulation Linda K. Johnson

E-mail: circulation@gulfpub.com

SUBSCRIPTIONS

Subscription price (includes both print and digital versions): United

States and Canada, one year $140, two years $230, three years $315.

Outside USA and Canada, one year $195, two years $340, three

years $460, digital format one year $140. Airmail rate outside North

America $175 additional a year. Single copies $25, prepaid.

Because Hydrocarbon Processing is edited specifically to be of greatest

value to people working in this specialized business, subscriptions are

restricted to those engaged in the hydrocarbon processing industry, or

service and supply company personnel connected thereto.

Hydrocarbon Processing is indexed by Applied Science & Technology

Index, by Chemical Abstracts and by Engineering Index Inc. Microfilm

copies available through University Microfilms, International, Ann

Arbor, Mich. The full text of Hydrocarbon Processing is also available

in electronic versions of the Business Periodicals Index.

ARTICLE REPRINTS

If you would like to have a recent article reprinted for an upcoming

conference or for use as a marketing tool, contact us for a price quote.

Articles are reprinted on quality stock with advertisements removed;

options are available for covers and turnaround times. Our minimum

order is a quantity of 100.

For more information about article reprints, call Cheryl Willis at

+1 (713) 525-4633 or e-mail EditorialReprints@gulfpub.com

HYDROCARBON PROCESSING (ISSN 0018-8190) is published monthly by Gulf Publishing Co., 2 Greenway Plaza,

Suite 1020, Houston, Texas 77046. Periodicals postage paid at Houston, Texas, and at additional mailing office.

POSTMASTER: Send address changes to Hydrocarbon Processing, P.O. Box 2608, Houston, Texas 77252.

Copyright © 2009 by Gulf Publishing Co. All rights reserved.

Permission is granted by the copyright owner to libraries and others registered with the Copyright Clearance Center

(CCC) to photocopy any articles herein for the base fee of $3 per copy per page. Payment should be sent directly to

the CCC, 21 Congress St., Salem, Mass. 01970. Copying for other than personal or internal reference use without

express permission is prohibited. Requests for special permission or bulk orders should be addressed to the Editor.

ISSN 0018-8190/01.

www.HydrocarbonProcessing.com

GULF PUBLISHING COMPANY

John D. Meador, President/CEO

Mark Peters, Vice President

Ron Higgins, Vice President

Maggie Seeliger, Vice President

Pamela Harvey, Business Finance Manager

Part of Euromoney Institutional Investor PLC.

Other energy group titles include:

World Oil®

Petroleum Economist

Publication Agreement Number 40034765

Printed in U.S.A

䉳 Select 151 at www.HydrocarbonProcessing.com/RS

INT ENS E HE AT. A GGR E S S IVE CHE MICALS . E XT R E ME COLD.

WE’RE PUSHING THE

LIMITS OF ENDURANCE.

NOT YOUR PATIENCE.

MATERIAL TECHNOLOGY

ENGINEERED FOR

REFINERIES

THERMICULITE®

835 Spiral Wound Filler

UÊÊ>`iÃÊÌ iÊÌÕ} iÃÌÊ>««V>ÌÃ

UÊÊ"ÕÌ«iÀvÀÃÊ}À>« ÌiÊ>`ÊwLiÀ

UÊÊ*ÀÛ`iÃÊÌÌ>ÊvÀii`ÊvÀÊÝ`>Ì

UÊÊ"vviÀÃÊÌÀÕiÊÕÌ>}iÌÕÌ>}iÊ>ÃÃÕÀ>Vi

UÊÊ,i`ÕViÃÊÛiÌÀÞÊÀiµÕÀiiÌÃ

*

G

AS

ALSO AVAILABLE IN:

U 815 Tanged Sheet

U 815 Cut Gaskets

UÊ845 Flexpro™ (kammprofile) Facing

Select 93 at www.HydrocarbonProcessing.com/RS

IÊÓäänÊÀÃÌÊEÊ-ÕÛ>Ê ÀÌ ÊiÀV>Ê*À`ÕVÌÊ6>ÕiÊi>`iÀÃ «ÊvÊÌ iÊ9i>ÀÊÜ>À`Ê,iV«iÌ°

R

UR GLOBAL

YO

K ET

P R O VI

DE

log onto:

www.flexitallic.com

or call:

US +1 281.604.2400

UK +44 (0) 1274 851273

As an internationally renowned engineering

partner and plant construction company,

Uhde offers complete service packages from

the initial concept to the turnkey plant.

Uhde provides these services to refineries

around the world. Two of our main specialities

are naphtha and middle distillate processing.

In line with the trend towards improving the

quality of gasoline and diesel, our Edeleanu

Refining Technologies Division has executed

numerous hydrodesulphurisation projects

during the last few years. Several plants, not

only based on world-class technologies

supplied by well-known licensors such as

·

·

·

·

Axens

Haldor Topsoe

Kellogg Brown & Root

UOP

but also proprietary Edeleanu technologies

designed in co-operation with catalyst

suppliers such as Albemarle or BASF, are

currently under construction.

Middle Distillate Desulphurisation Unit for

Shell Deutschland Oil GmbH in Wesseling, Germany

The total capacity of all our naphtha and

diesel hydrotreating projects since 2001 now

exceeds 15 million tonnes per year. The

treated products meet the European Clean

Fuels Directive.

Isomerisation of light gasoline or gas condensate yields another valuable blending component for gasoline. Our Edeleanu Refining

Technologies Division executes projects for

grassroots plants or revamps of catalytic

reformers for that purpose.

Solutions in Refining

Technologies

C5/C6 Isomerisation, PCK Schwedt, Germany

In keeping with our slogan Engineering with

ideas, we provide a comprehensive range of

supplies and services which extends from the

initial feasibility study and financing right

through to operation of the turnkey plant.

Uhde GmbH

Edeleanu Refining Technologies Division

Friedrich-Uhde-Str. 2

65812 Bad Soden

Germany

Phone +49 (61 96) 205 1711

Fax +49 (61 96) 205 1717

www.uhde.eu

Uhde

A company of ThyssenKrupp Technologies

Select 81 at www.HydrocarbonProcessing.com/RS

Visit us at

Frankfurt a.M., May 11 - 15, 2009,

Hall 9.1, Stand O33 - R40

ThyssenKrupp

HPIN BRIEF

WENDY WEIRAUCH, MANAGING EDITOR

WW@HydrocarbonProcessing.com

Now’s the time to ‘position yourself for the next curve,’ says Donald

L. Paul, founder and president of Energy and Technology Strategies, LLC and retired chief

technology officer of Chevron. In examining enterprise-wide solutions to industry threats, he

posited in a keynote presentation that cyber-security is a game that cannot be won, but is an

ongoing challenge. “Get better” at fighting the battle, he advised. Devote more intellectual

resources to IT now that those departments are not as busy in this economic downturn.

However, it is not necessary to throw more capital investment at the problem. Regarding the

industry’s carbon-reduction controversy, he favors a carbon tax as more efficient than the cap

and trade alternative, but doesn’t think this will be “the way political winds will go.”

Integrated look at product quality for EU refiners in terms of demand

changes, investment requirements, energy consumption and CO2 emissions is the subject

of a new study from CONCAWE. Meeting the EU policy goal of reducing the absolute

level of CO2 emissions from refineries is a tough challenge because mitigating measures

available to refiners are limited. Energy efficiency improvement still presents opportunities. This analysis, however, questions whether feedstock substitution would indeed result

in global emissions reductions. “Increased reliance on lighter crude oils might reduce EU

refinery emissions, but would simply cause the opposite switch somewhere else in the

world,” according to the association’s research (www.concawe.org).

An owner/operator’s perspective on the EPC project handover. With

over 100,000 documents on each project, ChevronTexaco’s expectation of an engineering,

procurement and construction contractor (EPC) is to see most of the project information

generated. So says Steven Fowlkes, manager of information management support for major

capital projects with that corporation. In handling information migration, the contract

stipulates how the information is transferred. What system an EPC uses to manage project

information is not a deal-breaker in his organization on whether that EPC receives the

contract, he says. However, he wonders if that policy might change in the next 10 years. Mr.

Fowlkes noted that, with owners now focusing more on using project data for operations

and maintenance purposes, it becomes a waste of the EPC’s high-level design information

if that intelligence is not transferred to the owner.

Criticality of cost and schedule engineers. J. Phil Wilbourne, a retired general

manager of Texaco and presently an associate professor at Tennessee Tech University, examined the role of the cost engineer at an international conference on project management

best practices held recently in Houston (www.bmc-online.com). Cost engineering requires

a specific expertise. “The problem with most projects is the substitution of another discipline for a cost engineer,” according to Mr. Wilbourne. Cost engineering in the 1970s was

generally a corrosion engineer’s role; in the 1980s, it was a safety engineer; in the 1990s, it

was an environmental engineer’s responsibility. Presently, he says that the expertise of cost

engineering is being incorporated into everyone’s job description and that the “jury’s still

out” on whether the position will continue being a separate function.

The US Air Force has purchased ultra-clean synthetic jet fuel from

Rentech, which produces the product at its fully integrated synthetic fuels and chemicals

facility in Commerce City, Colorado. According to the company, the Air Force will use

the purchased synthetic fuel for performance and emissions testing in a turbine engine.

Previously, the Air Force conducted laboratory testing of the company’s synthetic jet fuel,

which confirmed that the quality and characteristics of the fuel met the Air Force’s specifications for synthetic fuels. The company’s proprietary technology is claimed to convert

synthesis gas from biomass and fossil resources into hydrocarbons that can be processed and

upgraded into ultra-clean synthetic fuels, specialty waxes and chemicals. The lower density

of the fuel has the potential to enable aircraft to reduce take-off weight, thus conserving fuel

and decreasing operating costs. HP

■ Harnessing

social networking

Shell faces similar business challenges as

its peers in the oil and gas industry, says

Mike Hinkle, lead IT architect with Royal

Dutch Shell. Key issues include: managing costs, reducing travel, leveraging the

disappearing expertise and knowledge

of experienced staff, and getting new

and younger hires “up to speed” and

engaged in high-value activities quickly.

Shell views social networking (SN) as a

set of viable methods to address many

of these problems. SN can “amplify

informal flows” and is a “richer method

to connect to other people in an organization,” he says. He estimates that

over 50,000 Shell employees are using

wikis and discussion forums. Thus, SN

becomes a different way to digitize

informal but important information

flows within the business.

Ideas and solutions can be shared broadly, and SN makes it possible for others

to find these ideas at the right time.

For example: external websites such

as LinkedIn, Facebook and MySpace

may be useful for corporate employees,

according to Mr. Hinkle. Companies

should anticipate their employees’ use

of public messaging services like blogs,

instant messaging and Twitter.

The challenge, however, is to manage

the confidential information, as the

information might not stay within the

enterprise intranet. Mr. Hinkle recommends “controlled but not restrictive”

security so that good communications

still happens.

Confidential information must be

managed appropriately, however. The

most effective management method

is to follow the corporate Information,

Confidentiality, Privacy and Usage policies, according to Mr. Hinkle. These

policies should be updated to account

for the new SN realities, and reviewed

by all staff at least annually. HP

HYDROCARBON PROCESSING APRIL 2009

I7

You Get More Than Just a Process Gas Compressor

Lubricated up to 1’000 bar, non-lubricated up to 300 bar

For longest running time: We recommend our own designed,

in-house engineered compressor valves and key components

Designed for easy maintenance

We are the competent partner with the full range

of services – worldwide

Your Benefit:

Lowest Life Cycle Costs

More benefits: www.recip.com/api618

Select 55 at www.HydrocarbonProcessing.com/RS

HPIN RELIABILITY

HEINZ P. BLOCH, RELIABILITY/EQUIPMENT EDITOR

HB@HydrocarbonProcessing.com

Pump suction strainer issues

Does your process piping have strainers located just upstream

of the pump suction nozzles? Perhaps you are using them to protect pumps from unintended ingestion of tower packing, nuts,

bolts and other debris. While it would be smart to investigate why

this stuff shakes loose, we will confine our comment to common

misunderstandings about strainers.

Whenever strainers are used because the upstream equipment

is flawed, be sure to understand the important requirements

imposed on strainers by reliability-focused engineers. These engineers recognize, first and foremost, that a distinction is to be made

between temporary and permanent strainers.

Temporary strainers are generally installed with the tip pointed

in the upstream direction, which places the material in compression instead of tension. These temporary strainers must be

removed about one week after commissioning the piping loop.

They are often fabricated on site using the general configuration

shown in Fig. 1.

In contrast, permanent strainers are designed to be left in place

and must be cleanable without shutting down the pump. They

are typically available from a variety of commercial sources, must

be made of high-grade corrosion-resistant materials and can be

expensive.

Here are the strainer guidelines found in Maximizing Machinery Uptime:

Identification tab at

top for raised-face

flanges. Mount on

flange bolts.

Preferred flow

direction

Strainer screen

Spool piece

Screen seam

Install gasket on each

side of strainer flange.

Strainer assembly

12 gauge x 1-in. wide

identification tab.

½-in.

Mount 20-gauge wire mesh

inside a three-mesh guard

screen and stagger the

longitudinal seams.

½-in.

12 gauge

ASTM “A”

167 type

316

90°

Screen section

See detail “A”

FIG. 1

Temporary strainer.

1-in.

1. Strainers (both temporary and permanent designs) may be

cone- or basket-shaped and shall be installed between the suction

flange and the suction block valve. The preferred orientation is

shown in Fig. 1.

2. The strainer mesh size (typically per Fig. 1) shall be

selected to stop all objects too large to pass through the pump

main flow passage.

3. Temporary strainers shall be used during flushing and

initial (one week) operating periods, unless permanent strainers

are specified.

4. Piping layout shall permit removal of strainers without

disturbing pump alignment; spool pieces are typically used.

5. If permanent strainers are selected, the design and location

of these strainers shall permit cleaning without removing the

strainer body.

6. Strainer arrangement shall permit cleaning without interrupting the pumping service.

7. For installations with permanent strainers and equipped

with a spare pump, a permanent strainer shall be installed in the

suction line of each pump.

8. Twin or self-cleaning strainers may be used for pumps

without spares.

9. Y-type strainers shall be restricted to 2-in. maximum size.

10. Suction lines for proportioning pumps shall be chemically

or mechanically cleaned to permit operation without strainers.

There are three very important points we wish to emphasize:

• Best-practices companies (BPCs) distinguish between

startup strainers and permanent strainers. They insist on removing startup strainers long before they will have become a serious

disintegration risk. Also, BPCs have established that strainers are

not needed upstream of most conventional process pumps after

the initial startup period.

• On the other hand, once BPCs determine strainers should

be left in place for some reason, they allocate the resources needed

to upgrade entire systems in order to reduce failure risk and maximize equipment uptime.

• Because BPCs are serious about maximizing pump uptime,

they insist on best practices being implemented at all times. At

those facilities deviations from best practice have to be justified

in writing and a manager is asked to accept responsibility in

those instances. HP

Detail “A”

Both sides of strainer

flange must be free of

gouges, weld spatter,

or other imperfections

that might impair proper

gasket seating.

The author is HP’s Equipment/Reliability Editor. A practicing engineer and ASME

Life Fellow with close to 50 years of industrial experience, he advises process plants on

maintenance cost reduction and reliability upgrade issues. His 16th and 17th textbooks

on reliability improvement subjects were published in 2006. The excerpt on strainers is

taken from Bloch-Geitner, Maximizing Machinery Uptime, pp. 629–630 (Gulf Publishing, ISBN 10:0-7506-7725-2).

HYDROCARBON PROCESSING APRIL 2009

I9

Select 75 at www.HydrocarbonProcessing.com/RS

HPIN EUROPE

TIM LLOYD WRIGHT, EUROPEAN EDITOR

tim.wright@gulfpub.com

CO2 constraints ‘may be the best news for Shell’—CEO

As the voluminous correspondence on climate change sparked

by Editor Les Kane’s editorial (HP, July 2008) continues, it’s good

to hear that the reader debate it started is powering ahead on the

worldwide web.

HP has run extra correspondence on climate on its online

pages, and one reader has even been in touch to say he’s setting

up a dedicated website. Refining engineer, and passionate HP

reader, Jeffrey Temple, has created www.CCD4E.org—or Climate

Change Debate for Engineers.

Online topic. Mr. Temple says that he wanted to set up a site

where all parties, “climate sceptics” included, could discuss the

science of climate change. He’s been approaching those who have

written in to the magazine to ask them to join the dialogue there.

“Les Kane really got a debate going, but it’s not very easy to

follow a discussion across a period of a year,” he told me when I

called him up in Kazakhstan, where he’s been technical manager

of the Chinese-owned Shymkent refinery. “The debate can now

be read side-by-side, instead of from month-to-month.”

Mr. Temple makes clear he’s not interested in debate for its

own sake: “Action on climate change needs to be taken with

urgency – not delayed until after some notional ticker-tape parade

when the debate is won,” he says. He mentions the newsletter he’s

just had from McKinsey, the consultants, which is about climate

change (search the web using “What Matters” and “McKinsey”).

“Nowhere, repeat nowhere, among all the voices they’ve brought

to the debate—from Bjorn Lomborg to Jeffrey Sachs—is there

any doubt expressed that anthropogenic emissions are indeed

causing serious climate change,” he says.

Conference topic. And that’s certainly how it felt when I

attended the plenary sessions and some of the seminars (and a lot

of parties) at International Petroleum Week in London in February.

Climate change was referred to in almost every plenary paper, and

at length by keynoters such as Nobuo Tanaka of the International

Energy Agency (IEA) and Jeroen van der Veer, chief executive of

Shell. But the problem description wasn’t in question—the discussion was about how best to respond.

For better and sometimes for worse, that response is taking

shape, and it’s already affecting your operations in ways you may

not yet have noticed. It’s partly due to the response that, if you

live in the world’s rich nations, “peak oil demand” lies several years

behind us in 2005. It’s partly due to policies enacted to date that

a staggering 84% of non-OPEC oil supply growth in 2009, or

335,000 bpd, is set to come from plants growing and capturing

carbon today, or recently harvested ones, rather than fossil fuels.

The IEA estimates that at least two thousand significant pieces

of new law are under development at national level worldwide.

Most noteworthy, as I write, is the new transatlantic consensus

on climate policy. It means that for the first time there is agree-

ment between Europe and the US administration that greenhouse

gas emissions must be cut by at least 80% by 2050. In fact, the

Obama budget proposal calls for cuts of 83% and anticipates that,

between 2012 and 2019, billions of dollars will be raised through

a cap and trade system.

We have one of those systems over here, already making itself

felt on refining and power generation through the local permit-tooperate process. It’s taken some stick from its critics recently because

the price of CO2 emission permits has plummeted to less than $10/

metric ton. The money supply crisis and the global recession it

spawned have cut fossil fuel demand and CO2 emissions since last

fall. But it’s a rather useful feature of a cap and trade system that the

burden on industry is light when economic times get tough.

Of course, the low carbon price means that you would need

nerves of steel to invest in a carbon-capturing coal project right

now, and it’s hard to invest in other projects that make undeniable

long-term sense. Shell recently dropped out of a sea-based wind

park and the Shell CEO has a point when he says, “We could

open a zero-emission refinery, but it would be out of business in a

week.” However, that doesn’t mean that there aren’t tremendous

opportunities for companies like his in the policy response to

climate change if the policy framework is far-reaching and stable.

As Jeroen van der Veer says, “Constraints on the emission of CO2

may be the best news for companies like Shell.”

The World Business Council for Sustainable Development’s

Electricity Utilities Sector Project estimates that capital investment

and infrastructure development to deploy existing climate mitigating technology through 2030 will be approximately $11.6 trillion.

This includes carbon capture and storage, electrification and grid

upgrades; Europe is estimated to need 60,000 wind turbines,

accounting for €450 billion in construction costs right there.

Shell sees a lot of value added in the company’s engineering skills,

its patents in gasification, its offshore experience, its trading skills—

even one day that pie-in-the-sky hydrogen economy stuff. We’re not

there yet, but the sooner the industry engages and embraces the challenge, the better the solutions will be. Perhaps then we can avoid some

of the false dawns we’ve seen in the biofuels and fuel cell sagas.

According to the IEA, you can have your cake and eat it. The

world’s going to need fossil fuels and more of them even as it

aims to reduce the impact of their use. “Don’t be afraid of this

development,” says Mr. Tanaka. “The world will need a lot of your

products—12 million bpd more from OPEC by 2030.” We’d best

use them efficiently. By the same period, he says, emitting CO2

will cost at least $180/metric ton. HP

The author is HP’s European Editor and has been active as a reporter and

conference chair in the European downstream industry since 1997, before which

he was a feature writer and reporter for the UK broadsheet press and BBC radio.

Mr. Wright lives in Sweden and is founder of a local climate and sustainability

initiative.

HYDROCARBON PROCESSING APRIL 2009

I 11

Select 80 at www.HydrocarbonProcessing.com/RS

HPINTEGRATION STRATEGIES

LARRY O’BRIEN, CONTRIBUTING EDITOR

lobrien@arcweb.com

Reducing cost through an integrated approach

to power and automation

Industry is the number one power consumer, yet, as a whole, it

has a remarkably poor sense of how much power is being used at

different times across manufacturing processes. In the HPI, many

potential cost-saving opportunities related to power and energy consumption are ignored simply because people in refineries and petrochemical plants don’t have the appropriate visibility or control.

Using automation to cut energy costs. Energy ranks

as one of the top cost pressures affecting manufacturers today.

However, the benefits of a sound energy management strategy

go beyond simple cost reductions. Effective energy management

is essential for a “triple bottom line” business strategy addressing

social, economic and environmental concerns.

According to the US Department of Energy, industry accounts

for about a third of all energy used in the US. The most energyintensive industries also just happen to be the process industries,

including refining and chemicals. Most of this energy goes to fired

heaters, steam generation and machine drives.

Automation and electrification, however, remain largely separate islands of functionality in today’s plants, as are drives and

motor control centers. Process operators, and even maintenance

personnel, have limited visibility into what is really happening

in their electrical systems, or control over how much energy

their manufacturing and automation assets are consuming. ARC

believes that taking a more proactive stance toward integrating

the automation and power/energy domains of the manufacturing

process can yield significant energy cost savings.

HPI owner-operators can benefit in several areas from integrating their power and automation assets. Typically, this would

involve integrating electrical distribution systems with automation

systems and plant asset management (PAM) systems; integrating

intelligent motor control centers and drives; deploying intelligent

field devices to more efficiently monitor and control energy usage;

using optimization, simulation and process modeling technologies; and adopting common hardware platforms that can handle

control tasks spanning process control and power applications.

IEC 61850 brings digital network technology. IEC

61850, a global communication standard for substation automation,

defines the communication between intelligent electrical devices

(IEDs) in switchgear and associated systems. IEC 61850 is the key

enabler for integrating automation and electrical systems. By providing a greater level of interoperability between electrical devices from

different suppliers, the IEC 61850 standard also does for electrical

products what process fieldbus does for instrumentation and control

valves. IEC 61850 also promises the same level of enhanced diagnostics and PAM capabilities offered in process fieldbus devices.

Intelligent motor control. Motors are a major source of energy

consumption. HPI plants can significantly reduce their energy costs

just by addressing inefficiencies that reside in their motor loads. A

good rule-of-thumb is that, in a single year, a motor can consume

enough energy to account for 10 times its initial cost.

Deploying variable-speed drives and intelligent motor control

centers integrated with the automation system can significantly

reduce energy costs. For example, it is common practice to control

the output of variable-torque loads (such as in pumps, fans and

blowers) by inefficiently throttling their input or output. In contrast, applying AC drives to large fans and pumps to control flow by

modulating their speed can produce significant energy savings.

Using intelligent field instrumentation. HPI plants can

also use intelligent field instrumentation to help reduce energy

cost. Intelligent Coriolis flowmeters, for example, can be used to

improve fuel gas measurement. Electrical and motor control centers can also be integrated into PAM systems, enabling early detection of impending device failures. Intelligent relays, for example,

can provide valuable diagnostic data to PAM systems, such as

circuit-breaker wear indication, transformer temperature and

life expectancy, motor thermal capacity and statistical data, and

time-stamped sequence-of-events reports. Some suppliers are also

integrating machinery health management into PAM systems.

Optimization, simulation and modeling approaches.

Optimization and simulation software can also be used to significantly reduce energy costs. In most energy-intensive operations,

such as in a refinery or chemical plant, energy consumption can

vary considerably due to changing operating conditions, equipment degradation and inefficient control strategies. The result is

that plants typically use more energy than necessary, yet are unable

to improve efficiency because they lack the means to collect and

analyze real-time performance information.

End users not only need real-time solutions that inform when

energy consumption in a plant is higher than it needs to be, they also

are looking for intelligent solutions that provide plant personnel with

specific advice for bringing the plant back to optimal energy usage.

ARC believes that energy savings on the order of 10% can be

achieved in many process plants by integrating power and automation. However, successful implementation will require some

changes in the work processes and also depends on implementing

a coherent energy management strategy. HP

Larry

O’Brienis ispart

partofofthe

theautomation

automationconsulting

consultingteam

teamatat ARC

ARC covering

covering the

the

The author

process

editor.

HeHe

is responsible

for for

tracking

the

processindustries,

industries,and

andananHPHPcontributing

contributing

editor.

is responsible

tracking

market

for process

automation

systems (PASs)

and(PASs)

has authored

PAS market

the market

for process

automation

systems

and hasthe

authored

the studPAS

ies

for ARC

sincefor

1998.

O’Brien

hasMr.

alsoO’Brien

authored

market

research,

market

studies

ARCMr.

since

1998.

hasmany

also other

authored

many

other

strategy

custom

research

reports

on topics

including

fieldbus,

collaborative

market and

research,

strategy

and

custom

research

reportsprocess

on topics

including

process

partnerships,

total automation

market trends

and others. He

has been

with

ARC

since

fieldbus, collaborative

partnerships,

total automation

market

trends

and

others.

January

his career

with 1993,

marketand

research

in the

instrumentation

He has1993,

been and

withstarted

ARC since

January

started

his field

career

with market

markets.

research in the field instrumentation markets.

HYDROCARBON PROCESSING APRIL 2009

I 13

HEURTEY & PETRO-CHEM GROUP

PROUD TO BE THE REFLECTION OF A MOVING WO

ORLD

World largest independent group Expert in design & fabrication of Process Fired Heaters

Paris - New York - Houston - Tulsa - Mumbai - Saint Petersburg - Seoul - Singapore - Johannesburg - Bucharest - Hamburg - Istanbul

www.heurtey.com

Select 58 at www.HydrocarbonProcessing.com/RS

HPIN ASSOCIATIONS

BILLY THINNES, NEWS EDITOR

bt@HydrocarbonProcessing.com

Association news in brief

Aker Solutions manager wins

award in India

Pothen Paul, Aker Solutions’ India country manager, has been named the “business

leader of the year for engineering services” by

the Chemtech Foundation, India’s process

industry body. This award is in recognition

of Paul’s contribution to the engineering

and construction (E&C) sector in India.

Mr. Paul has over 40 years of experience

in organization management, operations

management, construction management

and plant design. During his time with

Aker Powergas Pvt. Ltd., he oversaw the

development of a project management culture and an organizational mind set and

focused on high standards of quality within

project execution. Currently, he is also the

executive chairman of Aker Powergas Pvt.

Ltd., and the president of Aker Solutions’

global process business. Mr. Paul has also

served as chairman of the Process Plant

and Machinery Association of India and is

a member of the National Council of the

Confederation of Indian Industry (CII).

The Chemtech Foundation recognizes exceptional contributions to Indian

industry, the environment and research

and development through the ChemtechCEW Awards. This award and others were

announced in February at the Chemtech

World Expo 2009 in Mumbai, India.

Syngas professionals

converge on Tulsa

The SynGas Association is hosting SynGas 2009 in Tulsa, Oklahoma,

from April 20–22. This association,

which describes itself as an organization

of “ammonia, hydrogen, ammonium

nitrate/nitric acid, urea and methanol

producers—along with the material and

service suppliers that support these industries,” is featuring economist and author

Jeff Thredgold as its keynote speaker. Mr.

Thredgold wrote econAmerica: Why the

American Economy is Alive and Well... And

What that Means to Your Wallet and currently works as an economic consultant

to Zions Bancorporation. His remarks

will no doubt reflect the mission statement of the SynGas Association, which

seeks to “provide a forum where there is an

open exchange of ideas and information

to promote better safety, technical, environmental, operational and maintenance

techniques for the mutual benefit of the

organization and its participants.”

“SynGas holds the leading conference

for producers of ammonia, hydrogen,

methanol and coal/coke gasification syngas where common topics, issues and solutions are discussed,” said Darrell Allman of

PCS Nitrogen and the chairman of SynGas

2009. “Key information updates that will

impact all of our industries and facilities are

presented. Breakout sessions are smaller to

allow more information to be exchanged in

a casual roundtable format and to promote

excellent networking opportunities. Suppliers of various products and services to

the synthetic gas industries are showcased

in the exhibit area where key producer personnel, who are the potential customers,

have the opportunity to view the most current technology and services.”

Another much anticipated presentation will feature Charles Farnam and Roger

Sharp of FM Global. They will discuss fire

protection for steam turbine-driven syngas

compressors and share their belief that these

compressors, housed at chemical manufacturing sites, are essential to plant production, even though they are costly and difficult to replace and under constant exposure

to serious oil and syngas fire hazards. Mr.

Farnam and Mr. Sharp will point out that

while the likelihood of a fire involving one

of these pieces of equipment is relatively

low, the consequences can be severe, with up

to millions of dollars in damage and many

months of interrupted production.

In addition to general sessions on the

economy, employee diversity and plant

safety topics, there will also be specific

breakout sessions, including topics

related to safety, environment, maintenance, reliability, operations and new

technologies. For more information, visit

www.syngasassociation.com.

Rajiv Gandhi Institute

of Petroleum Technology

appoints professor

Jeet Bindra, president of Chevron

Global Manufacturing, was recently

named a distinguished honorary professor at the Rajiv Gandhi Institute of Petroleum Technology (RGIPT) in Jais, India.

RGIPT was established in 2007 by India’s

Ministry of Petroleum and Natural Gas

to produce high-quality professionals and

provide practical solutions to a variety of

energy-related challenges.

ExxonMobil wins safety

awards from Gas Processors

Association

ExxonMobil’s US operations have

earned the Gas Processors Association

(GPA) 2009 Company Safety Award and

the President’s Award for Safety Improvement. Some 500 employees at the company’s gas processing facilities received

the honors for outstanding safety performance during more than a million

work hours.

Gas Processors Association President

Bob Dunn presented the awards at the

88th annual GPA Convention in San

Antonio, Texas.

“These safety awards are among the

most important recognition we provide at

this convention each year, because safety is

a primary focus within all of our member

companies,” said Mr. Dunn, announcing

the recipients. “The gas processing industry is one of the safest in the world.”

The President’s Award for Safety Improvement recognizes continuous improvement in

safety performance measured by a reduction

of 25% or more in recordable incident rates

over the past three years.

“The company has always set very high

standards for safety performance,” said

Randy Cleveland, ExxonMobil US production manager. “The achievement by

our employees at gas processing facilities

demonstrates their commitment to excellence in pursuing our vision that nobody

gets hurt.” HP

HYDROCARBON PROCESSING APRIL 2009

I 15

Lurgi – your clean conversion partner.

Lurgi is the worldwide leading partner when clean conversion is postulated. We command

sustainable processes which allow us to make better use of oil resources or biomass than

ever before.

With our technologies we can produce synthesis gases, hydrogen or carbon monoxide: for

downstream conversion to petrochemicals. Based on resources like natural gas, coal and tar

sand we produce synthesis gas which we convert into low-pollutant fuels.

Enhanced sustainability: from biomass which does not compete with the food chain, we

can recover ultra-pure fuels burning at a low pollutant emission rate which are excellently

suited for reducing the carbon footprint. You see, we are in our element when it comes to

sustainable technologies.

Build on our technologies.

Call us, we inform you: +49 (0) 69 58 08-0

www.lurgi.com

1127_e

A member of the Air Liquide Group

Select 92 at www.HydrocarbonProcessing.com/RS

Visit us in Hall 9.1

Stand K32–N40

HPIMPACT

WENDY WEIRAUCH, MANAGING EDITOR

WW@HydrocarbonProcessing.com

Economy, capacity

additions pressure

polyolefins markets

PP

HDPE

LLDPE

LDPE

Actual

stocking of the value chain. North America and Western Europe were particularly

affected, while the Asian market, a strong

performer in recent years, saw minimal

growth. ChemSystems’ outlook projects

a relatively high growth rate, which can be

attributed to the penetration into end-use

applications served by traditional materials, and also with polypropylene benefiting from inter-polymer competition with

polystyrene, ABS and HDPE.

Supply. Total polyolefins capacity

increased by 51 MMton from 1998 to

2008. In 2008, however, the industry experienced a somewhat quiet year for capacity additions as skills shortages delayed the

startup of many units.

In 2008, LDPE net additions were relatively low. In contrast to modest growth

in LDPE capacity, combined LLDPE and

HDPE capacity has been growing at an

average of over 2 MMton/yr. Polypropylene is also forecast to see unprecedented

new capacity of over 5 MMton/yr coming

onstream during 2009–2011.

The near-term investment wave is

focused in regions with advantaged feedstock such as the Middle East, or regions

of high market growth such as Asia. “Looking further ahead, a period of low investment is expected for all polyolefins during

2014 and 2015, followed by a new wave of

capacity additions in the second

half of the decade,” according to

Nexant ChemSystems.

Scenario

Global trade. Mature mar-

Million tons/yr

The first half of 2008 saw polyolefins

prices rising to record highs as industry

supply and demand balances enabled producers to pass through extraordinary feedstock prices. In contrast, second-half 2008

witnessed an unprecedented demand crash

as a result of problems in credit markets

and its effects on economic activity.

“The decline in demand was exacerbated by falling feedstock prices, with crude

prices dropping 70% from July 2008 values

by the end of the year,” according to a new

outlook from Nexant ChemSystems (www.

chemsystems.com). With falling polymer

prices, purchasers withdrew from the market, and inventories along the value chain

were significantly reduced.

The degree of inventory contraction

is reflected in a demand drop-off that far

exceeded what industry analysts anticipated

from the economic downturn. The 2008

consumption is estimated to have shrunk

by 1.6%, compared to an estimated 3%

growth in global economic output.

Demand is expected to improve slightly

over 2008 figures, but is not projected to

return to 2007 levels in mature economies.

This small increase in demand will be dwarfed

by new capacity additions coming onstream

in the Middle East and Asia.

Over the next few years,

12

global trade patterns are forecast

to evolve noticeably as the US

10

and Western Europe become

major net importers of LLDPE,

8

HDPE and polypropylene. The

6

Middle East takes its position as

supplier to the world.

4

The following are other key

highlights from Nexant Chem2

Systems’ outlook.

combined LLDPE/LDPE market has continued to climb every year. In 2008, it reached

over 51%. Demand for LDPE is projected

to remain flat due to this continued pressure

from competitively priced conventional and

second-generation LLDPE.

Consumption of LLDPE fell an estimated 1.2% in 2008, after growing 5.6%

in 2007. “In spite of this, LLDPE is still

the polyolefin with the brightest demand

outlook, and is projected to grow at almost

6%/yr for the next seven years,” says this

analysis. Single-site/metallocene LLDPE

was one area that continued to grow in

2008, albeit at low rates.

Global HDPE demand shrank by 2.1%

in 2008 compared to 2007. “HDPE will

recover growth in the next few years as the

industry restocks the inventory chain and

as the economic outlook improves,” according to this research (Fig. 1).

Approximately half of this projected

growth in demand will be in Asia. Bimodal

HDPE continues to be a focus for much

of the uptick based on an expanding product performance envelope. The supply side

will also be boosted by the potential for

single-gas-phase reactor production, giving

a lower capital and production cost.

After a 6% growth in 2007, polypropylene global demand is estimated to have

declined by almost 1% in 2008 due to

the economic climate and significant de-

0

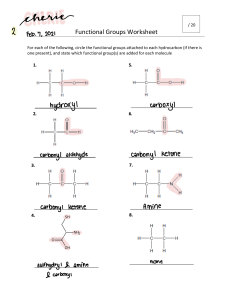

Demand. Global polyolefins

demand is estimated at 113 million

tons (MMton) in 2008, a decline

of 1.6% compared to 2007.

The demand growth for LDPE

continues to be impacted by competition from LLDPE. The degree

of penetration of LLDPE into the

-2

-4

2001

2004

2007

2010

2013

2016

2019

Source: Nexant ChemSystems

FIG. 1

A look at demand growth along the polyolefins chain.

kets such as Western Europe

and North America will experience limited polyolefins capacity

additions, and even closures of

less competitive units.

While demand is expected

to be heavily focused in China,

Western Europe and North

America are projected to see

growth. Although low in terms

of rate, this growth will have

an impact in terms of absolute

demand increment. These regions

are therefore expected to become

far more dependent on imports

over the coming decade.

HYDROCARBON PROCESSING APRIL 2009

I 17

How

H

ow m

much

uch nitrogen

nitrogen

do you

do

you waste

waste during

during your

your

ethylene cracker

ethylene

cracker shutdown?

shutdown?

The one company you can rely on to deliver efficient world-class

nitrogen performance during your shutdown is BJ Services.

Nitrogen is critical to a safe and successful ethylene cracker turnaround. Why risk using your operational

resources or a gas supply company when BJ Services provides a dedicated, engineered nitrogen capability

that can save you time and money while reducing your risk?

The BJ Services difference is our expertise and focus on achieving an efficient turnaround by minimizing

nitrogen consumption and time. BJ has built a resource capability that optimizes product freeing,

accelerated cooling, hot stripping and safe inerting operations to get your cracker unit ready for access

quickly. And when you are ready to start up, BJ will help ensure that you achieve a clean, dry, leak-free

and inert unit ready to receive product.

For a no-cost assessment of your ethylene cracker needs, contact your BJ Services process and

pipeline representative.

Real world. World class. Worldwide.

www.bjservices.com

Select 72 at www.HydrocarbonProcessing.com/RS

HPIMPACT

Asia’s thirst for oil

likely to swell again,

but when?

1,000

800

600

“Missing” demand

and the bursting of the technology bubble.

In fact, the surprise 2-MMbpd

surge in Asian demand in the

second halves of 2003 and 2004

set the stage for the 2004–2008

price run-up. “We would not

be surprised—and in fact we

expect—the cycle to repeat itself

starting in late 2010 or 2011,”

according to FACTS.

In short, the combination of

Asia’s huge population and continued economic progress ensure

that its thirst for oil products

will grow, albeit with stops and

starts. Over the mid- to longterm, oil supply will struggle to

keep pace.

Thousand bpd

Over the past decade, Asian

400

demand growth has been a critical

driver of the global oil market—

200

typically accounting for about

0

40% to 50% of global incremen-200

tal demand. In 2003–2004, a

surge in Asian demand stretched

-400

global oil supply, setting the stage

-600

for a four-year price run-up.

During 2006–2008, the

-800

Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4

market focus was on supply con2008

2009

2010

2005 2006

2007

straints, but attention quickly

Source:

FACTS

Global

Energy

switched back to the demand

side when OECD oil consumpFIG. 2 Dramatic sweeps in Asian oil product demand, year-onyear changes.

tion collapsed as the impact of

the credit crisis spread. “For

a time, some thought Asia’s develop- particularly dramatic. Japan, Korea, and EPA chemicals

ing economies (and oil demand) would Taiwan all experienced y-o-y declines in

emerge relatively unscathed, but it is now naphtha consumption as the petrochemi- oversight questioned

obvious that the region is suffering as the cal sector is highly exposed to the impact in new GAO report

scope of the crisis has broadened,” reports of an economic downturn. Additionally,

The Environmental Protection Agena new analysis from FACTS Global Energy Asia’s energy-intensive industrial sector is cy’s (EPA) assessment and control of toxic

(www.fgenergy.com).

particularly hard hit. Chinese manufactur- chemicals has been added to a “high-risk”

ing, which accounts for over 40% of GDP, category on a newly updated government

Financial contraction. Initially, Asia contracted for the fifth consecutive month report. Biennially, the US Government

appeared well positioned to weather the cri- in December. India’s industrial output fell Accountability Office (GAO) updates its

sis. Most monetary authorities had accumu- for the first time in 14 years in October.

list of federal programs, policies and operlated substantial foreign reserves and regional

FACTS anticipates that, overall, there ations that are in danger of waste, fraud,

banks were typically well capitalized. Regula- will be some recovery in Q3-Q409 com- abuse and mismanagement or in need of

tory oversight had also improved following pared to a weak 2008 baseline, but regional broad-based transformation.

the 1997–98 Asian economic crises.

demand is only expected to fully recover in

“EPA’s ability to protect public health

In the past few months, it has become 2010. This, of course, is contingent on a and the environment depends on credible

clear that talk of an Asian “de-linkage” from recovery in the regional economy.

and timely assessments of the risks posed by

the global economy was misguided. After

toxic chemicals. Its Integrated Risk Inforaveraging a 14% annual growth since 2002, Implications for HPI. Asia’s demand mation System, which contains assessments

Chinese power demand was down by 3% weakness comes at about the worst possible of more than 500 toxic chemicals, is at seriyear-on-year (y-o-y) in October and 8% time for regional and global refiners. Approx- ous risk of becoming obsolete because EPA

in November. Auto sales have also slowed imately 1.5 million barrels/day (MMbpd) of has been unable to keep its existing assesssharply in both China and India. The impact new crude distillation unit capacity is com- ments current or to complete assessments of

of lethargic global/regional trade on highly ing online in Asia alone in the first half of important chemicals of concern,” according

export-dependent economies, such as Singa- 2009. Additionally, 950 Mbpd of conver- to the GAO’s report.

pore, Taiwan, and Hong Kong, has become sion capacity will come online.

Other programs added to the listing this

readily apparent. This will impact demand

Viewed y-o-y, Asia’s crude distillation year are the regulatory system governing US

for transport fuels as well as industrial use.

unit capacity will increase by 1.7 MMbpd in financial institutions and markets, and the

first-half 2009 versus first-half 2008. Conver- Food and Drug Administration’s oversight

Oil demand. Asian oil demand is expected sion capacity will increase by 1.1 MMbpd. of medical products.

to decline by 575 thousand barrels/day Over the same period, regional demand will

Overall, EPA has finished only nine assess(Mbpd) in 1Q09 versus 1Q08. This follows decline by approximately 270 Mbpd.

ments in the past three years. At the end of

on a 520-Mbpd y-o-y decline in 4Q08. On

2007, most of the 70 ongoing assessments

an annual basis, Asian demand will expand Path forward. Once Asian economies had been underway for more than five years.

by only 82 Mbpd in 2009. Viewed against a do recover, we expect to see a substantial The analysis concludes that EPA “urgently”

baseline regional growth expectation of 600 rebound in demand driven by a surge in needs to streamline and increase the transparMbpd to 800 Mbpd in “normal” times, the consumer spending and investment. The ency of its assessment process and also “shift

contrast is striking (Fig. 2).

same phenomenon was observed in 1999 more of the burden” to chemical companies

There is weakness across all products, following the Asian economic crisis and in to demonstrate the safety of their products.

but the decline in naphtha demand is 2003–2004 following the SARS epidemic To view the report, go to www.gao.gov. HP

HYDROCARBON PROCESSING APRIL 2009

I 19

Thousands of CCC customers worldwide don’t think so.

In the industrial environment, no one can afford to sacrifice the high quality

of a control system and a responsive customer service, which is often a

key to a long-lasting protection of your plant, process, and equipment (your

own peace of mind should not be overlooked either!).

CCC offers real value in turbomachinery control. We call it the CCC Value

Triangle: Profit Enhancement Opportunity. Quality. Service.

CCC high-quality, precision-designed control systems and field-proven

proprietary control algorithms along with the unsurpassed lifetime

engineering support provide real profit enhancement opportunities

resulting from:

Preventing unnecessary process trips and downtime

Minimizing process disturbances

Preventing surge, overspeed and associated damage

Automating startup and shutdown

Operating close to limits, safely

Operating at lowest possible energy levels

Minimizing antisurge recycle or blow-off

Optimizing load sharing of multiple units

We are on your side, at your site and at your service,

24/7, offering lifetime support, guaranteed by our large

body of technical resources, experience on thousands of

installations worldwide, and institutional memory.

The Right Solution —

The First Time, Every Time

P o w e r B e h i n d B e t t e r Tu r b o m a c h i n e r y C o n t r o l ™

International Headquarters:

4725 121st Street • Des Moines, Iowa 50323-2316, U.S.A. • Tel: (1) 515 - 270 - 0857 • Fax: (1) 515 -270 -1331

E-mail: solutions@cccglobal.com • Web site: http://www.cccglobal.com

Select

at www.HydrocarbonProcessing.com/RS

www.HydrocarbonProcessing.com/RS

Select 74

77 at

HPINNOVATIONS

SELECTED BY HYDROCARBON PROCESSING EDITORS

editorial@gulfpub.com

New process produces

methanol from waste

Isis Innovation, the technology transfer

company for the University of Oxford, has

announced that researchers in the school’s

chemistry department have discovered a

new way to produce methanol (MeOH)—

a valuable biofuel—from glycerol. About

90% of MeOH is produced from natural

gas; this new process offers an alternative

that does not rely on fossil fuels.

The new catalytic process converts

glycerol, an unwanted byproduct from

biodiesel production, to MeOH, which is

a high-value petrochemical and alternative

transportation fuel (Fig. 1). Glycerol is the

major byproduct in biodiesel production

with applications in foods and personal

care industries. However, glycerol has no

large-scale industrial demand.

Catalytic hydrogenolysis of glycerol

has been studied, but the main products

from glycerol and hydrogen reaction are

propanediols and ethylene glycols, which

require a degree of carbon-oxygen bonds

cleavage accompanied by hydrogen addition under harsh conditions. Conversely,

choosing the right catalyst under appropriate mild conditions may allow only the

total breakage of C-C bonds with hydrogen addition without cleaving the C-O

bonds, thus avoiding the production of

hydrocarbon gases such as methane and

carbon dioxide.

In this case, catalytic hydrogenolysis of

glycerol to MeOH can be formed selectively. MeOH is one of the key chemicals

with a huge potential as a renewable energy

source and also a building block for other

chemicals. The new MeOH technology is

a carbon-neutral process using a supported

precious metal catalyst. The reaction proceeds under mild conditions of 100°C and

20 bar hydrogen to produce methanol as

the exclusive product.

Select 1 at www.HydrocarbonProcessing.com/RS

Breakthrough separator

removes oil from water

Aqueous Recovery Resources, Inc. has

developed what is claimed to be an innovative oil/water separation system called

the Suparator. This technology incorporates a three-step separation mechanism

that requires no moving parts or media.

This unit takes advantage of the Bernoulli

effect—the phenomenon whereby increased

stream velocity in a fluid results in internal

pressure reduction.

These forces facilitate removing oil

from process water and wastewater in a

three-step process:

Step 1. Collection. Water and oil enter the

first compartment, where, ultimately, only

water is sucked out through an opening at the

bottom. This design ensures that any amount

of oil, even small traces, is collected.

Step 2. Concentration. The oil, still

containing some water and chemicals, is

concentrated into a floating layer of considerable thickness, while water and chemicals

migrate toward the interface and re-enter

the water flow. The oil is then further concentrated to force water and chemicals out

to yield an oil-only layer.

Step 3. Separation. The upper fraction of the accumulated floating layer

is “skimmed off,” thus isolating the oil.

Finally, this “dry” (typically less than 1%

free water) oil is separated and ready for

downstream refining or storage.

The Suparator’s special construction is

claimed to collect any amount of oil, even

Hydrogen

Glycerol

(byproduct)

Methanol

Exclusive

product

Low T

Low P

Biodiesel

and veg. oil

manufacture

FIG. 1

Fuel and

industrial

use

Process takes byproduct glycerol

and converts it directly to

methanol.

As HP editors, we hear about new products,

patents, software, processes, services, etc.,

that are true industry innovations—a cut

above the typical product offerings. This section enables us to highlight these significant

developments. For more information from

these companies, please go to our Website

at www.HydrocarbonProcessing.com/rs and

select the reader service number.

the smallest traces. The oil is concentrated

to force water and chemicals out of the

Suparator; thus no consumables such as

absorbents, coalescing media, absorbing

filter bags, etc., are used. This processing

method eliminates costs for the consumables and expenses for disposal of spent

consumables. Finally, the dry oil is separated and removed.

Select 2 at www.HydrocarbonProcessing.com/RS

Gas-to-liquid process

lowers capital costs

Energix Research, Inc. has successfully

produced liquid fuels from natural gas

with a process that is claimed to be more

efficient— ultimately reducing capital

costs and enabling mobility. The company’s tests indicate that its technology

enables the entire gas-to-liquids (GTL)

process to consume a lower percentage

of the energy in the gas source. Due to

the lower capital costs, production can be

competitive with conventional, large-scale

refineries that produce these fuels from

crude oil.

Energix expects to develop affordable,

micro-GTL plants to monetize under-utilized resources, such as abandoned natural

gas fields, coal-bed methane fields, flared

gases, etc.

“We believe our process can affordably

produce 50 to 200 tons/day of methanol, gasoline, diesel or DME with truckmounted units using methane derived

from biogas sources, such as landfills.

Another source would be abandoned gas

wells with very small reserves, which currently are not viable due to the inability to

economically transport the fuel from the

site,” according to Juzer Jangbarwala, the

company’s CEO.

The company aims to first focus on

producing methanol and DME. Its vision

is to eliminate the carbon footprint associated with transporting fuel or other hydrocarbon chemical products such as solvents

and alcohols.

Energix Research executed the GTL

process via the syngas and Fischer-Tropsch

synthesis route at a high conversion rate

(87%) and selectivity rate (99%) using

its patent-pending, electrically activated

nanocatalyst process. The proprietary proHYDROCARBON PROCESSING APRIL 2009

I 21

HPINNOVATIONS

EVERY PROCESS

RECIPROCATING

COMPRESSOR

COMES WITH

A PROMISE.

Visit us at OTC .09, Booth 10839

cess uses local electronic excitation to the

catalyst, using conductive nanofibers and

nanocatalysts and applies a low-level DC

current to them.

This technique is claimed to reduce

the required bulk feed gas temperatures to

less than 50% of conventional processes,

as the energy of reaction and activation

of catalyst is provided directly where it is

needed to create very narrowly targeted

reactions with high selectivity and yields.

The lower bulk gas temperature reduces

the capital costs typically associated with

exotic metals and energy recovery equipment in GTL refineries while increasing

energy efficiency.

Select 3 at www.HydrocarbonProcessing.com/RS

Industrial mass flow controller

with ANSI or DIN flanges

Sierra Instruments is offering Max-Trak

Model 180 industrial mass flowmeters and

controllers with 316 stainless steel (ANSI

or DIN) flange mounting for gas flowrates

up to 1,000 slpm (pipe sizes up to 1 in.).

The significant design enhancement expands the processes and applications where the flanges can be installed.

The company’s Dial-A-Gas technology is

claimed to make Max-Trak the industry’s

only multigas-capable industrial mass flow

controller. The model has excellent accuracy (±1% of FS) and repeatability (±0.2%

of FS) as well as unsurpassed instrument

stability. These characteristics result from

a patented, inherently-linear design,

advanced platinum sensor technology and

a strong, flexible and forgiving valve. The

controller can communicate to a user workstation via RS-232, RS-485 or one of four

analog signals.

The product line is an industry

NEMA 6/IP67-rated mass flow controller conforming to rigorous water-resistant

requirements.

Select 4 at www.HydrocarbonProcessing.com/RS

Virtual reality tool

‘revolutionizes’ training

www.dresser-rand.com

Select 152 at www.HydrocarbonProcessing.com/RS

Invensys Process Systems (IPS) has

unveiled its Immersive Virtual Reality Process technology, a next-generation human

machine interface solution that the company claims will “revolutionize” the way

engineers and operator trainees see and

interact with the plant and the processes

they control.

The innovative process can create a

3D computer-generated representation of

either a real or proposed process plant. Via

a stereoscopic headset, users enter a totally

immersive environment in which they can

move through the plant in any direction.

Such freedom is made possible because

the virtual environment is rendered at 60

frames/second, significantly faster than

what can be achieved by traditional, nonreal-time rendering.

“The ability to simulate complex processes in connection with virtual actions

allows the user to directly experience an

environment that changes over time, making it more effective at transferring skills

learned in training to the work environment,” according to Maurizio Rovaglio,

director, IPS global consulting. “And

because rarely performed volatile tasks

such as plant shutdowns can be rehearsed

in a stable, realistic environment, users and

operator trainees have the opportunity to

learn and make mistakes without putting

themselves, the community or the environment at risk.”

IPS is making Immersive Virtual Reality

Process truly realistic by applying its proprietary DYNSIM software to emulate the

plant environment, linking process simulation models with physical-spatial models

to create virtually any scenario that a user

could encounter in real life.

Select 5 at www.HydrocarbonProcessing.com/RS

Unmatched early detection

of equipment problems

SmartSignal’s EPI*Center software,

based on its patented Similarity Based

Modeling (SBM) technology, is claimed to

provide better insight into potential equipment reliability problems than was previously possible. Backed by over 40 patents,

the technology is successfully being used by

progressive super majors in oil and gas.

These companies are using the software

to detect, diagnose and prioritize developing reliability problems caused by faulty

process operation and mechanical issues to

prevent equipment outages. When avoiding an outage is not possible, the early

warning allows for proper maintenance

planning and minimizes equipment damage. This is claimed to provide tremendous

cost benefits.

The software is successfully being used

to monitor reciprocating and centrifugal

compressors, many varieties of pumps,

steam and gas-fired turbines, turboexpanders, blowers, heat exchangers, reactors, distillation columns and fired heaters. Some

of the reliability problems that have been

detected weeks and sometimes months

The new RecipCOM

delivers diagnostics,

protection and

therapy for your

reciprocating

compressors.

Spread the word!

For more information please contact compressor-mechatronics@hoerbiger.com

Select 61 at www.HydrocarbonProcessing.com/RS

www.hoerbiger.com

at the

Visit us

nkfurt

09, Fra

0

2

a

m

Ache

y

German 4–P37

3

Booth P

,

0

.

8

l

Hal

HPINNOVATIONS

before normal engineering monitoring are

turbine blade fouling, precursors to seal

damage like pump cavitation and liquid

in compressors, bearing damage prevention from poor lubrication, weak valves in

reciprocating compressors, malfunctioning instrumentation, efficiency loss, reactor

channeling, tower and exchanger fouling,

and heater coking.

SmartSignal works by sifting through

all the mounds of data that most companies have from their data infrastructures.

The solution uses prognostic models for

online process monitoring and diagnosis.

The models produce estimates for each

sensor as a function of current signal data

and historical data collected during normal process operation. The differences

between current signal data and model

estimates, termed residuals, are used to

generate “alerts” when the deviations in

the residuals are statistically significant.

These alerts and residuals are analyzed

to determine if the process is operating abnormally. If an abnormal condition is detected, diagnostic algorithms

are used to identify the cause as being a

process upset, degraded sensor response

or mechanical fault specific to the monitored equipment.

One significant advantage of using SBM

is that process and mechanical sensors can

be modeled together when they are linked

in behavior. No regression or other parametric analysis is needed. The parameters

move together, and identifiable patterns of

behavior will be present.

The prognostic model SBM is a

proprietary multivariate-state estimation technique using a nonparametric

regression approach. This nonparametric method is claimed to simplify model

development and to be very tolerant of

real-world problems, such as bad sensors

and poor data quality.

Select 6 at www.HydrocarbonProcessing.com/RS

Adaptive system automatically

learns process dynamics

Emerson Process Management offers

a newly developed adaptive capability for

DeltaV InSight that is claimed to enable

the control system to automatically learn

process dynamics, diagnose control problems and re-tune control loops for optimal performance.

Further extending the predictive intelligence of PlantWeb architecture, this

new capability is embedded in the digital

control system with automatic configuration to provide increased performance and

availability for all DeltaV and Foundation

fieldbus-based control loops. The technology is uniquely automatic—it provides

system-wide performance monitoring and

diagnostics with no additional configuration or maintenance effort.

Performance monitoring is automatically updated for any changes made to

the system. The technology also accounts

for process changes by automatically

learning process dynamics from normal day-to-day operations. This process

knowledge may be applied to improve

plant performance and availability with

adaptive loop tuning, non-linear control,

loop diagnostics, process simulation and

model-based control.