ASME Boiler & Pressure Vessel Code Part A: Ferrous Materials

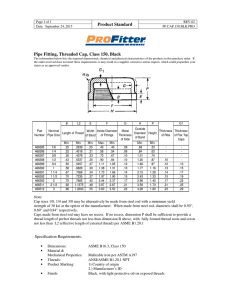

advertisement