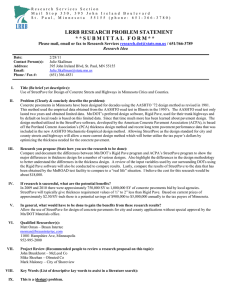

PORTLAND CEMENT ASSOCIATION Thickness Design for C:r;c.-Zt Highway and The author of this engineering bulletin is Robert G. Packard, P. E., principal paving engineer, Paving Transportation Department, Portland Cement Association. - -- - This publication is intended SOLELY for use by PROFESSIONAL PERSONNEL who are competent to evaluate the significance and limitations of the information provided herein, and who will accept total responsibility for the application of this information. The Portland Cement Association DISCLAIMS any and all RESPONSIBILITY and LIABILITY for the accuracy of and the application of the information contained in this publication to the full extent permitted by law. O Portland Cement Association 1984, reprinted 1995 Thickness Design for Concrete Highway and Street Pavements CONTENTS . Chapter 1 Introduction .......................... 3 Applications of Design Procedures ............... 3 Computer Programs Available . . . . . . . . . . . . . . . . . .4 Basis for Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 Metric Version ................................ 4 Chapter 2. Design Factors ........................ 5 Flexural Strength of Concrete ................... 5 Subgrade and Subbase Support ................. 6 Design Period ................................ 6 Traffic ....................................... 8 Projection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8. ADTT ..................................... 8 Truck Directional Distribution . . . . . . . . . . . . . . .10 Axle-Load Distribution ..................... 10 Load Safety Factors .......................... 10 Chapter 3. Design Procedure (Axle-Load Data Available) . . . . . . . . . . . . . . . . . . . . . I 1 Fatigue Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 1 Erosion Analysis ............................. I I Sample Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 Chapter 4. Simplified Design Procedure (Axle-Load Data Not Available) .................. 23 Sample Problems ............................30 Comments on Simplified Procedure . . . . . . . . . . . . . 30 Modulus of Rupture ........................ 30 Design Period ............................. 30 Aggregate Interlock or Doweled Joints ........ 30 User-Developed Design Tables . . . . . . . . . . . . . . . . .30 Appendix A . Development of Design Procedure ..................................... 32 Analysis of Concrete Pavements . . . . . . . . . . . . . . . . 32 Jointed Pavements ......................... 32 Continuously Reinforced Pavements .......... 33 Truck-Load Placement ........................ 33 Variation in Concrete Strength .................34 Concrete Strength Gain with Age . . . . . . . . . . . . . .34 Warping and Curling of Concrete ............... 34 Fatigue ..................................... 34 Erosion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35 Appendix B . Design of Concrete Pavements with Lean Concrete Lower Course ................36 Lean Concrete Subbase .......................36 Monolithic Pavement . . . . . . . . . . . . . . . . . . . . . . . . . 36 Appendix C . Analysis of Tridem Axle Loads ....... 39 Appendix D . Estimating Traffic Volume by Capacity ................................... 42 Appendix E . References . . . . . . . . . . . . . . . . . . . . . . . . .44 Design Worksheet for Reproduction .............. 47 Figures 1. Flexural strength, age, and design relationships. 2. Approximate interrelationships of soil classifications and bearing values. 3. Proportion of trucks in right lane of a multilane divided highway. 4. Design I A. 5. Fatigue analysis-allowable load repetitions based on stress ratio factor (with and without concrete shoulders). 6a. Erosion analysis-allowable load repetitions based on erosion factor (without concrete shoulder). 6b. Erosion analysis-allowable load repetitions based on erosion factor (with concrete shoulder). 7. Design 1 D. 8. Design 2A. Al. Critical axle-load positions. A2. Equivalent edge stress factor depends on percent of trucks at edge. A3. Fatigue relationships. B1. Design chart for composite concrete pavement (lean concrete subbase). B2. Design chart for composite concrete pavement (monolithic with lean concrete lower layer). B3. Modulus of rupture versus compressive strength. C l . Analysis of tridems. Tables 1. Effect of Untreated Subbase on k Values 2. Design k Values for Cement-Treated Subbase 3. Yearly Rates of Traffic Growth and Corresponding Projection Factors 4. Percentages of Four-Tire Single Units and Trucks (ADTT) on Various Highway Systems 5. Axle-Load Data 6a. Equivalent Stress-No Concrete Shoulder 6b. Equivalent Stress-Concrete Shoulder 7a. Erosion Factors-Doweled Joints, No Concrete Shoulder 7b. Erosion Factors-Aggregate-Interlock Joints, No Concrete Shoulder 8a. Erosion Factors-Doweled Joints, Concrete Shoulder 8b. Erosion Factors-Aggregate-Interlock Joints, Concrete Shoulder 9. Axle-Load Categories 10. Subgrade Soil Types and Approximate k Values 11. Allowable ADTT, Axle-Load Category 1-Pavements with Aggregate-Interlock Joints 12a. Allowable ADTT, Axle-Load Category 2-Pavements with Doweled Joints 12b. Allowable ADTT, Axle-Load Category 2-Pavements with Aggregate-Interlock Joints 13a. Allowable ADTT, Axle-Load Category 3-Pavements with Doweled Joints 13b. Allowable ADTT, Axle-Load Category 3-Pavements with Aggregate-Interlock Joints 14a. Allowable ADTT, Axle-Load Category 4-Pavements with Doweled Joints 14b. Allowable ADTT, Axle-Load Category 4-Pavements with Aggregate-Interlock Joints 15. Axle-Load Distribution Used for Preparing Design Tables 1 1 Through 14 C l . Equivalent Stress - Tridems C2. Erosion Factors Tridems - Doweled Joints C3. Erosion Factors - Tridems - Aggregate-Interlock Joints D l . Design Capacities for Multilane Highways D2. Design Capacities for Uninterrupted Flow on Twoan; Highways - customary unit in. ft Metric unit rnrn m Ib Ibf kg N kip kN kPa MPal m Ib/in.2 Ib/in.-' (k value) Conversion coefficient 25.40 0.305 0.454 4.45 4.45 6.89 0.27 1 CHAPTER 1 Introduction This bulletin deals with methods of determining slab thicknesses adequate t o carry traffic loads on concrete streets, roads, and highways. The design purpose is the same as for other engineered structures-to find the minimum thickness that will result in the lowest annual cost as shown by both first cost and maintenance costs. If the thickness is greater than needed, the pavement will give good service with low maintenance costs, but first cost will be high. If the thickness is not adequate, premature and costly maintenance and interruptions in traffic will more than offset the lower first cost. Sound engineering requires thickness designs that properly balance first cost and maintenance costs. While this bulletin is confined to the topic of thickness design, other design aspects are equally important to ensure the performance and long life of concrete pavements. These includeProvision for reasonably uniform support. (See Subgrades and Subbases for Concrete Pavements.*) Prevention of mud-pumping with a relatively thin untreated o r cement-treated subbase on projects where the expected truck traffic will be great enough t o cause pumping. (The need for and requirements of subbase are also given in the booklet cited above.) Use of a joint design that will afford adequate load transfer; enable joint sealants, if required, t o beeffective; and prevent joint distress due to infiltration. (See Joint Design for Concrete Highway and Street Pavements.**) Use of a concrete mix design a n d aggregates that will provide quality concrete with the strength and durability needed for long life under the actual exposure conditions. (See Design and Control of Concrete Mixtures.7) The thickness design criteria suggested are based on general pavement performance experience. If regional o r local specific performance experience becomes available for more favorable o r adverse conditions, the design criteria can be appropriately modified. This could be the case for particular climate, soil, o r drainage conditions and future design innovations. Applications of Design Procedures The design procedures given in this text apply to the following types of concrete pavements: plain, plain doweled, reinforced, and continuously reinforced. Plain pavements are constructed without reinforcing steel or doweled joints. Load transfer at the joints is obtained by aggregate interlock between the cracked faces below the joint saw cut o r groove. For load transfer to be effective, it is necessary that short joint spacings be used. Plain-doweled pavements are built without reinforcing steel; however, smooth steel dowel bars are installed as load transfer devices at each contraction joint and relatively short joint spacings are used to control cracking. Reinforced pavements contain reinforcing steel and dowel bars for load transfer at the contractionjoints. The pavements are constructed with longer joint spacings than used for unreinforced pavements. Between thejoints, one o r more transverse cracks will usually develop; these are held tightly together by the reinforcing steel and good load transfer is provided. Commonly used joint spacings that perform well are 15 ft for plain pavements,tt not more than 20 ft for plaindoweled pavements, and not more than about 40 ft for reinforced pavements. Joint spacings greater than these have been used but sometimes greater spacing causes pavement distress at joints and intermediate cracks between joints. Continuously reinforced pavements are built without contraction joints. Due to the relatively heavy, continuous-steel reinforcement in the longitudinal direction, these pavements develop transverse cracks at close intervals. A high degree of load transfer is developed at these crack faces held tightly together by steel reinforcement. The design procedures given here cover design conditions that have not been directly addressed before by *Portland Cement Associat~onpubl~cationIS029P. **Portland Cement Association publication IS059P. tPortland Cement Association publ~cationEB001T. t t For very thin pavements,a 15-ftjoint spacing may beexcessive -see the aforementioned PCA publication on joint design. other procedures. These include recognition of1. The degree of load transfer a t transverse joints provided by the different pavement types described. 2. The effect of using a concrete shoulder adjacent to the pavement; concrete shoulders reduce the flexural stresses and deflections caused by vehicle loads. 3. The effect of using a lean concrete (econocrete) subbase, which reduces pavement stresses and deflections, provides considerable support when trucks pass over joints, and provides resistance t o subbase erosion caused by repeated pavement deflections. 4. Two design criteria: (a) fatigue, t o keep pavement stresses due t o repeated loads within safe limits and thus prevent fatigue cracking; and (b) erosion, to limit the effects of pavement deflectionsat slabedges, joints, and corners and thus control the erosion of foundation and shoulder materials. The criterion for erosion is needed since some modes of pavement distress such as pumping, faulting, and shoulder distress are unrelated t o fatigue. 5. Triple axles can be considered in design. While the conventional single-axle and tandem-axle configurations are still the predominant loads on highways, use of triple axles (tridems) is increasing. They are seen on some over-the-road trucks and on special roads used for hauling coal o r other minerals. Tridems may be more damaging from a n erosion criterion (deflection) than from a fatigue criterion. Selection of an adequate thickness is dependent upon the choice of other design features-jointing system, type of subbase if needed, and shoulder type. With these additional design conditions, the thickness requirements of design alternatives, which influence cost, can be directly compared. Chapter 2describes how the factors needed for solving a design problem are determined. Chapter 3 details the full design procedure that is used when specific axle-loaddistribution data are known or estimated. If detailed axle-load data are not available, the design can be accomplished a s described in Chapter 4, by the selection of one of several categories of data that represent a range of pavement facilities varying from residential streets up to busy interstate highways. Computer Programs Available Thickness design problems can be worked out by hand with the tables and charts provided here or by computer and microcomputer with programs that are available from Portland Cement Association. I . Theoretical studies of pavement slab behavior by ~ e s t e r ~ a a r d , " - ~Pickett '* and ~ a ~"and , ' recently ~ developed finite-element computer analyses, one of which is used as the basis for this design procedure.'8' 2. Model and full-scale tests such as Arlington ~ e s t s " ' and several research projects conducted b PCA and Y"andconother agencies on s~bbases,'~~~'~'joints"~ Crete shoulder^."^ 20' 3. Experimental pavements subjected to controlled test traffic, such as the Bates Test ~ o a d , " " the Pittsburg Test ~ i ~ h w a the ~ , Mar ' ~ ~ land ' Rbad ~ e s t , " " the AASHO** Road Test, ( 2 4 - 2 4 and studies of inservice highway pavements made by various state departments of transportation. 4. The performance of normally constructed pavements subject to normal mixed traffic. All these sources of knowledge are useful. However, the knowledge gained from performance of normally constructed pavements is the most important. Accordingly, it is essential t o examine the relationship between the roles that performance and theory play in a design procedure. Sophisticated theoretical methods developed in recent years permit the responses of the pavementstresses, deflections, pressures-to be more accurately modeled. This theoretical analysis is a necessary part of a mechanistic design procedure, for it allows consideration of a full range of design-variable combinations. An important second aspect of the design procedure is the criteria applied t o the theoretically computed valuesthe limiting or allowable values of stress, deflection, or pressure. Defining the criteria so that design results are related t o pavement performance experience and research data is critical in developing a design procedure. The theoretical parts of the design procedures given here are based on a comprehensive analysis of concrete stresses and deflections by a finite-element computer program.'8' The program models the conventional design factors of concrete properties, foundation support, and loadings, plus joint load transfer by dowels or aggregate interlock and concrete shoulder, for axle-load placements at slab interior, edge, joint, and corner. The criteria for the design procedures are based on the pavement design, performance, and research experience referenced above including relationships t o performance of avements at the A A S H O Road ~ e s t 'and ~ ~ to ' studies'' ") of the faulting of pavements. More information on development and basis of the design procedure is given in Appendix A and Reference 30. Metric Version A metric version of this publication is also available from Portland Cement Association-publication EB209P. Basis for Design The thickness design methods presented here are based on knowledge of pavement theory, performance, and research experience from the following sources: *Superscript numbers In parentheses denote referencesat the end of this text. **Now the American Association of State Hlghway and Transportation Officials (AASHTO). CHAPTER 2 Design Factors After selection of the type of concrete pavement (plain pavement with o r without dowels, reinforced jointed pavement with dowels, o r continuously reinforced pavement), type of subbase if needed, and type of shoulder (with o r without concrete shoulder, curb and gutter o r integral curb), thickness design is determined based on four design factors: 1. Flexural strength of the concrete (modulus of rupture, M R ) 2. Strength of the subgrade, o r subgrade and subbase combination (k) 3. The weights, frequencies, and types of truck axle loads that the pavement will carry 4. Design period, which in this and other pavement design procedures is usually taken a t 20 years, but may be more o r less These design factors are discussed in more detail in the following sections. Other design considerations incorporated in the procedure are discussed in Appendix A. Flexural Strength of Concrete Consideration of the flexural strength of the concrete is applicable in the design procedure for the fatigue criterion, which controls cracking of the pavement under repetitive truck loadings. Bending of a concrete pavement under axle loads produces both compressive and flexural stresses. However, the ratios of compressive stresses to compressive strength are too small to influence slab thickness design. Ratios of flexural stress to flexural strength are much higher, often exceeding values of 0.5. As a result, flexural stresses and flexural strength of the concrete are used in thickness design. Flexural strength is determined by modulus of rupture tests, usually made on 6 x 6 ~ 3 0 - i n .beams. For specific projects, the concrete mix should be designed to give both adequate durability and flexural strength a t the lowest possible cost. Mix design procedures are described in the Portland Cement Association publication Design and Control of Concrete Mi.utures. The modulus of rupture can be found by cantilever, center-point, o r third-point loading. An important difference in these test methods is that the third-point test shows the minimum strength of the middle third of the test beam, while the other two methods show strength at only one point. The value determined by the more conservative third-point method (American Society for Testing and Materials, ASTM C78) is used for design in this procedure.* Modulus of rupture tests are commonly made at 7, 14, 28, and 90 days. The 7- and 1 4 d a y test results are compared with specification requirements forjob control and for determining when pavements can be opened to traffic. The 28-day test results have been commonly used for thickness design of highways and streets and are recommended for use with this procedure; 9 0 d a y results are used for the design of airfields. These values are used because there are very few stress repetitions during the first 28 o r 90days of pavement lifeas compared to the millions of stress repetitions that occur later. Concrete continues t o gain strength with age as shown in Fig. I . Strength gain is shown by the solid curve, which represents average M R values for several series by laboratory tests, field-cured test beams, and sections of concrete taken from pavements in service. In this design procedure the effects** of variations in concrete strength from point t o point in the pavement and gains in concrete strength with age are incorporated in the design charts and tables. The designer does not directly apply these effects but simply inputs the average 28-day strength value. * F o r a standard 3 0 - ~ n beam. . center-polnt-loading test values will be about 75 psi higher, and cantdever-loading test values about 160 p s ~ higher than thlrd-potnt-loading test values. These higher values are not intended t o be used for design purposes. If these other lest methods are used, a downward adjustment should be made by establishinga correlation t o third-point-load test values. **These effects a r e discussed In Appendix A. Table 1. Effect of Untreated Subbase on k Values, S u b b a s e k value, Subgrade k value. pci 12 in 100 200 300 130 220 320 140 230 330 160 270 370 190 320 430 Table 2. Design k Values for CernentTreated Subbases Age Subgrade k value, pci Fig. 1. Flexural strength, age, and design relationships. 50 100 200 S u b b a s e k value, p c ~ 4 ~ n . 6 tn 8 in 10 In 170 280 470 230 400 640 310 520 830 390 640 - Subgrade and Subbase Support The support given to concrete pavements by the subgrade, and the subbase where used, is the second factor in thickness design. Subgrade and subbase support is defined in terms of the Westergaard modulus of subgrade reaction (k). It is equal to the load in pounds per square inch on a loaded area (a 30-in.diameter plate) divided by the deflection in inches for that load. The k values are expressed a s pounds per square inch per inch (psilin.) or, more commonly, as pounds per cubic inch (pci). Equipment and procedures for determining k values are given in References 3 1 and 32. Since the plate-loading test is time consuming and expensive, the k value is usually estimated by correlation to simpler tests such as the California Bearing Ratio (CBR) or R-value tests. The result is valid because exact determination of the k value is not required; normal variations from a n estimated value will not appreciably affect pavement thickness requirements. The relationships shown in Fig. 2 are satisfactory for design purposes. The A A S H O Road ~ e s t 'gave ~ ~ a' convincing demonstration that the reduced subgrade support during thaw periods has little or no effect on the required thickness of concrete pavements. This is true because the brief periods when k values are low during spring thaws are more than offset by the longer periods when the subgrade is frozen and k values are much higher than assumed for design. T o avoid the tedious methods required to design for seasonal variations in k , normal summer- or .fallwealher k values are used as reasonable mean values. It is not economical to use untreated subbases for the sole purpose of increasing k values. Where a subbase is used,* there will be a n increase in k that should be used in the thickness design. If the subbase is a n untreated granular material, the approximate increase in k can be taken from Table 1. The values shown in Table I are based on the Burmister'j3' analysis of two-layer systems and plate-loading tests made to determine k values on subgrades and subbases for full-scale test s ~ a b s . " ~ ' Cement-treated subbases are widely used for heavyduty concrete pavements. They are constructed from A A S H T O Soil Classes A- I , A-2-4, A-2-5, and A-3granular materials. The cement content of cement-treated subbase is based on standard A S T M laboratory freeze-thaw and wet-dry tests'j4 3 5 ' and PCA weight-loss riter ria.')^' Other procedures that give a n equivalent quality of material can be used. Design k values for cement-treated subbases meeting these criteria are given in Table 2. In recent years, the use of lean concrete subbases has been on the increase. Thickness design of concrete pavements on these very stiff subbases represents a special case that is covered in Appendix B. Design Period The term design period is used in this publication rather than pavement life. The latter is not subject to precise definition. Some engineers and highway agencies consider the life of a concrete pavement ended when the first overlay is placed. The life of concrete pavements may vary from less than 20 years on some projects that have carried more traffic than originally estimated o r have had design, material, o r construction defects t o more than 40 years on other projects where defects are absent. The term design period is sometimes considered to be synonymous with the term traffic-analysis period. Since traffic can probably not be predicted with much accuracy for a longer period, a design period of 20 years is commonly used in pavement design procedures. However, there are often cases where use of a shorter o r longer design period may be economically justified, such as a special haul road that will be used for only a few years, o r a *Use of subbase is recommended for projects where condit~onsthat would cause mud-pump~ngprevail; for discussion of when subbases should be used and how thick they should be, see the PCA publication. Subgrades and Subbases for Concrete Pavements. CALIFORNIA BEARING RATIO- CBR(" (1) For the basic Idea, see 0. J. Porter, "Foundations for Flex~blePavements," H~ghwayResearch Board Proceedfngs of the Twenty-second Annual Meetfng, 1942, Vol 22, pages 100-136. (2) ASTM Oes~gnatlon02487 (3) "Classif~cat~on of H~ghwaySubgrade Mater~als."Htghway Research Board Proceedfngs 01 the Twenty-111th Annual Meetmg. 1945. Vol 25, pages 376-392. (4) Afrport Pavfng. U.S Department of Commerce. Federal A v ~ a t ~ oAgency, n May 1948, pages 11-16 Est~mateduslng values gtven In FAA Desfgn Manual for Afrport Pavements (Formerly used FAA Classif~catton.U n ~ f ~ eClassiflcatlon d now used ) (5) C E Warnes. "Correlation Between R Value and k Value," unpubl~shedreport. Portland Cement Assoc~at~on. Rocky Mounta~n-Northwest Reg~on.October 1971 (best-fit correlat~onwtth correction for saturat~on) (6) See T. A M~ddlebrooksand G. E Bertram. "So11Tests for Design of Runway Pavements." Htghway Research Board Proceedtngs of the Twentysecond Annual Meet~ng,1942, Vol 22, page 152 (7) See Item (6). page 184. Fig. 2. Approximate interrelationships of soil classifications and bearing values. premium facility for which a high level of performance for a long time with little o r no pavement maintenance is desired. Some engineers feel that the design period for rural and urban highways should be in the range of 30 to 35 years. The design period selected affects thickness design since it determines how many years, and thus how many trucks, the pavement must serve. Selection of the design period for a specific project is based on engineering judgment and economic analysis of pavement costs and service provided throughout the entire period. The numbers and weights of heavy axle loads expected during the design life are major factors in the thickness design of concrete pavement. These are derived from estimates of -ADT (average daily traffic in both directions, all vehicles) -ADTT (average daily truck traffic in bothdirections) -axle loads of trucks Information on A D T is obtained from special traffic counts o r from state, county, o r city traffic-volume maps. This A D T is called the present o r current ADT. The design A D T is then estimated by the commonly used methods discussed here. However, any other method that gives a reasonable estimate of expected traffic duringthedesign life can be used. Projection One method for getting the traffic volume data (design ADT) needed is to use yearly rates of traffic growth and traffic projection factors. Table 3 shows relationships between yearly rates of growth and projection factors for both 20- and 40-year design periods. In a design problem, the projection factor is multiplied by the present A D T t o obtain a design ADTrepresenting the average value for the design period. In some procedures, this is called A A D T (average annual daily traffic). The following factors influence yearly growth rates and traffic projections: I. Attracted o r diverted traffic-the increaseoverexisting traffic because of improvement of a n existing roadway. 2. Normal traffic growth-the increasedue to increased numbers and usage of motor vehicles. 3. Generated traffic-the increase due to motor vehicle trips that would not have been made if the new facility had not been constructed. 4. Development traffic-the increase due to changes in land use due to construction of the new facility. The combined effects will cause annual growth rates of about 2% to 6%. These rates correspond to 20-year traffic projection factors of 1.2 to 1.8 as shown in Table 3. The planning survey sections of state highway departments are very useful sources of knowledge about traffic growth and projection factors. Table 3. Yearly Rates of Traffic Growth and Corresponding Projection Factors' I I Yearly rate of traffic O/O I I 1 1 Projection factor. 20 years 1 I ~roiection factor. 40 years 'Factors represent values at the middesign period that are widely used in current practice. Another method of computing these factors is based on the average annual value. Differences (both compound interest) between these two methods w ~ l lrarely affect design. Where there is some question about the rate ofgrowth, it may be wise t o use a fairly high rate. This is true on intercity routes and on urban projects where a high rate of urban growth may cause a higher-than-expected rate of traffic growth. However, the growth of truck volumes may be less than that for passenger cars. High growth rates d o not apply on two-lane-ruralroads and residential streets where the primary function is land use o r abutting property service. Their growth rates may be below 2% per year (projection factors of 1.1 to 1.3). Some engineers suggest that the use of simple interest growth rates may be appropriate, rather than compound interest rates, which when used with a long design period may predict unrealistically heavy future traffic. Capacity The other method of estimating design A D T is based on capacity-the maximum number of vehicles that can use the pavement without unreasonable delay. This method of estimating the volume of traffic is described in Appendix D and should be checked for specific projects where the projected traffic volume is high; more traffic lanes may be needed if reasonable traffic flow is desired. ADTT The average daily truck traffic in both directions (ADTT) is needed in the design procedure. It may be expressed as a percentage of A D T o r as a n actual value. The ADTT value includes only trucks with six tires o r moreand does not include panel and pickup trucks and other four-tire vehicles. The data from state, county, o r city traffic-volume maps may include, in addition to ADT, the percentage of trucks from which ADTT can be computed. For design of major Interstate and primary system projects, the planning survey sections of state departments of transportation usually make specific traffic surveys. These data are then used to determine the percentage relationship between ADTT and ADT. ADTT percentages and other essential traffic data can also be obtained from surveys conducted by the highway department at specific locations on the state highway system. These locations, called loadometer stations, have been carefully selected to give reliable information on traffic composition, truck weights, and axle loads. Survey results are compiled into a set of tables from which the ADTT percentage can be determined for the highway classes within a state. This makes it possible to compute the ADTT percentage for each station. For example, a highway department loadometer table (Table W-3) for a Midwestern state yields the following vehicle count for a loadometer station on their Interstate rural system: All vehicles-ADT . . . . . . . . . . . . . . . . . . . . . . .9492 Trucks: All single units and combinations . . . . . . . . 1645 Panels and pickups.. . . . . . . . . . . . . . . . . . 353 Other four-tire single units . . . . . . . . . . . . 76 Therefore, for this station: ADTT = 1216 x 9492 It is important to keep in mind that the ADTT percentages in Table 4 are average values computed from many projects in all sections of the country. For this reason, these percentages are only suitable for design of specific projects where ADTT percentages are alsoabout average. For design purposes, the total number of trucks in the design period is needed. This is obtained by multiplying design A D T by ADTT percentage divided by 100, times the number of days in the design period (365 X design period in years). For facilities of four lanes or more, the ADTT is adjusted by the use of Fig. 3 100 = 13% This ADTT percentage would be appropriate for design of a project where factors influencing the growth and composition of traffic are similar to those at this loadometer station. Another source of information on ADTT percentages is the National Truck Characteristic ~ e ~ o r t . ' "Table ' 4, which is taken from this study, shows the percentages of four-tire single units and trucks on the major highway systems in the United States. The current publication, which is updated periodically, shows that two-axle, fourtire trucks comprise between 40% to 65% of the total number of trucks, with a national average of 49%. It is likely that the lower values on urban routes are due to larger volumes of passenger cars rather than fewer trucks. Fig. 3. Proportion of trucks in right lane of a multilane divided highway. (Derived from Reference 38.) *Trucks-excludes Table 4. Percentages of Four-Tire Single Units and Trucks (ADTT) on Various Highway Systems I Rural average daily traffic I Hlghway system Interstate Other federala~d prlmary Federal-a~d secondary Urban average daily traffrc panels and pickups and other four-tire vehicles. Truck Directional Distribution In most design problems, it is assumed that the weights and volumes of trucks traveling in each directionare fairly equal-50-50 distribution-the design assumes that pavement in each direction carries half the total ADTT. This may not be true in special cases where many of the trucks may be hauling full loads in one direction and returning empty in the other direction. If such is the case, an appropriate adjustment is made. Table 5. Axle-Load Data (3) Axles per Axles per 1000 1000 trucks (adjusted) Axle load. kips trucks -- p - S ~ n g l eaxles 28-30 0.28 26-28 0.65 24-26 1.33 22-24 2.84 Axle-Load Distribution 20-22 4.72 Data on the axle-load distribution of the truck traffic is needed to compute the numbers of single and tandem axles* of various weights expected during the design period. These data can be determined in one of three ways: (I) special traffic studies t o establish the Ioadometer data for the specific project; (2) data from the state highway department's loadometer weight stations (Table W-4) or weigh-in-motion studies on routes representing truck weights and types that are expected to be similar to the project under design; (3) when axle-load distribution data are not available, methods described in Chapter 4 based on categories of representative data for different types of pavement facilities. The use of axle-load data is illustrated in Table 5 in which Table W-4 data have been grouped by 2-kip and 4-kip increments for single- and tandem-axle loads, respectively. The data under the heading "Axles per 1000 Trucks" are in a convenient form for computing the axleload distribution. However, an adjustment must be made. Column 2 of Table 5 gives values for all trucks, including the unwanted values for panels, pickups, and other fourtire vehicles. T o overcome this difficulty, the tabulated values are adjusted as described in the Table 5 notes. Column 4 of Table 5 gives the repetitions of various single- and tandem-axle loads expected during a 20-yeardesign period for the Design I sample problem given in Chapter 3. 18-20 10.40 16-18 13.56 Load Safety Factors In the design procedure, the axle loads determined in the previous section are multiplied by a load safety factor (LSF). These load safety factors are recommended: For Interstate and other multilane projects where there will be uninterrupted traffic flow and high volumes of truck traffic, L S F = 1.2. For highways and arterial streets where there will be moderate volumes of truck traffic, L S F = 1.1. For roads, residential streets, and other streets that will carry small volumes of truck traffic, L S F = 1.0. Aside from the load safety factors, a degree of conservatism is provided in the design procedure to compensate Axles In design period 14-16 18 64 12-14 25 89 10-12 81 05 Tandem axles Columns 1 and 2der1vedfrom loadometer W-4 Table Thls tablealsoshows 13 215 total trucks counted wlth 6 918 two-axle four-tlre trucks (52%) Column 3 Column 2 values adjusted for two-axle four-t~retrucks, equal to Column 21(1 - 521100) ~ Seesampleproblem Column 4 = C o l u m n 3 (trucks1ndes1gnper1od)l1000 Des~gn1 In which trucks In deslgn pertod (oned~rectton) total 10,880.000 for such things as unpredicted truck overloads and normal construction variations in material properties and layer thicknesses. Above that basic level of conservatism (LSF = 1.0), the load safety factors of 1.1 or 1.2 provide a greater allowance for the possibility of unpredicted heavy truck loads and volumes and a higher level of pavement serviceability appropriate for higher type pavement facilities. In special cases, the use of a load safety factor as high as 1.3 may be justified to maintain a higher-than-normal level of pavement serviceability throughout the design period. An example is a very busy urban freeway with no alternate detour routes for the traffic. Here, it may be better t o provide a premium facility to circumvent for a long time the need for any significant pavement maintenance that would disrupt traffic flow. *See Appendix C i f i t isexpected that trucks with tridem loads will be ~ncludedin the traffic forecast. CHAPTER 3 Design Procedure (Axle-Load Data Available) The methods in this chapter are used when detailed axleloaddistribution data have been determined or estimated as described in Chapter 2.* Fig. 4 is a worksheet** showing the format for completing design prob1ems.t It requires as input data the following design factors discussed in Chapter 2. Type of joint and shoulder Concrete flexural strength (MR) at 28 days k value of the subgrade or subgrade and subbase combinationtt Load safety factor (LSF) Axle-load distribution (Column 1) Expected number of axle-load repetitions during the design period (Column 3) Both a fatigue analysis (to control fatigue cracking) and a n erosion analysis (to control foundation and shoulder erosion, pumping, and faulting) are shown on the design worksheet. The fatigue analysis will usually control the design of light-traffic pavements (residential streets and secondary roads regardless of whether the joints are doweled or not) and medium traffic pavements with doweled joints. The erosion analysis will usually control the design of medium- and heavy-traffic pavements with undoweled (aggregate-interlock) joints and heavy-traffic pavements with doweled joints. For pavements carrying a normal mix of axle weights, single-axle loads are usually more severe in the fatigue analysis, and tandem-axle loads are more severe in the erosion analysis. The step-by-step design procedure is as follows: The design input data shown at the top of Fig. 4 are established and Columns I and 3 are filled out. The axle loads are multiplied by the load safety factor for Column 2. Without concrete shoulder, use Table 6a and Fig. 5 With concrete shoulder, use Table 66 and Fig. 5 Procedure Steps: 1. Enter as items 8 and I I on the worksheet from the appropriate table the equivalent stress factors depending on trial thickness and k value. 2. Divide these by the concrete modulus of rupture and enter as items 9 and 12. 3. Fill in Column 4, "Allowable Repetitions," determined from Fig. 5. 4. Compute Column 5 by dividing Column 3 by Column 4, multiplying by 100; then total the fatigue at the bottom. Erosion Analysis Without concrete shoulder Doweled joints or continuously reinforced pavements$-use Table 7a and Fig. 6a. Aggregate-interlock joints-use Table 76 and Fig. 60. With concrete shoulder Doweled joints o r continuously reinforced pavementsf-use Table 8a and Fig. 66. Aggregate-interlockjoints-use Tablegband Fig. 66. Procedure Steps: I. Enter the erosion factors from the appropriate table as items 10 and 13 in the worksheet. 2. Fill in Column 6, "Allowable Repetitions," from Fig. 60 or Fig. 6b. - Fatigue Analysis Results of fatigue analysis, and thus the charts and figures used, are the same for pavements with doweled and undoweled joints, and also for continuously reinforced pavements.$ *See Chapter 4 when axle-load distribution data are unknown. **A blank worksheet is provided as the last page of this bulletin for purposes of reproduction and use in specific design problems. t Computer programs for solving design problems are available from Port'and t t S e e Appendix B if lean concrete subbase is used. IIn this design procedure, continuously reinforced pavements are treated the same as doweled, jointed pavements-see Appendix A Calculation of Pavement Thickness T r ~ ath~ckness l 9.5 ~n Doweled jo~nts yes no - Subbase-subgrade k /?fl PC1 Concrete shoulder yes no J 650 PSI rupture. MR M O ~ U I U S of Load safety factor, LSF /. 2 Fat~gueanalys~s Axle load, k~ps Mult~pl~ed by LSF Expected repet~t~ons /. 2 1 2 Single Axles Tandem Axles Fig. 4. Design 1A. 12 3 Allowable repetltlons 4 Eros~onanalys~s Fat~gue. percent 5 8. Equwalent stress 2 0& 9. Stress ratlo factor 0. 3 7 11. Equ~valentstress 19 2 12. Stress ratlo factor 4 5 - Allowable repet~t~ons Damage percent 6 7 10. Eros~onfactor 2.59 13. Eros~onfactor 2.74 1 3. Compute Column 7 by dividing Column 3 by Column 6, multiplying by 100; then total the erosion damage at the bottom. In the use of the charts, precise interpolation of allowable repetitions is not required. If the intersection line runs off the top of the chart, the allowable load repetitions are considered to be unlimited. The trial thickness is not an adequate design if either of the totals of fatigue or erosion damage are greater than 100%. A greater trial thickness should be selected for another run.* A lesser trial thickness is selected if the totals are much lower than 100%. Sample Problems Two sample problems are given to illustrate the steps in the design procedure and the effects of alternate designs. Design 1 is for a four-lane rural Interstate project; several variations on the design-use of dowels or aggregateinterlock joints, use of concrete shoulder, granular and cement-treated subbases-are shown as Designs 1A through 1E. Design 2 is for a low-traffic secondary road, and variations are shown as Designs 2A and 2B. Design 1 Project and Traffic Data: Four-lane Interstate Rolling terrain in rural location Design period = 20 years Current ADT = 12,900 Projection factor = 1.5 ADTT = 19% of ADT Traffic Calculations: Design ADT = 12,900 X 1.5 = 19,350 (9675 in one direction) ADTT = 19,350 X 0.19 = 3680 (1840 in one direction) For 9675 one-direction ADT, Fig. 3 shows that the proportion of trucks in the right lane is 0.81. Therefore, for a 20-year-design period, the total number of trucks in one direction is 1840 X 0.8 1 X 365 X 20 = 10,880,000 trucks Axle-load data from Table 5 are used in this design example and have been entered in Fig. 4 under the maximum axle load for each group. Values Used to Calculate Thickness:** Design 1A: doweled joints, untreated subbase, no concrete shoulder Clay subgrade, k = 100 pci 4-in.-untreated subbase Combined k = 130 pci (see Table 1) LSF = 1.2 (see page 10) Concrete MR = 650 psi Design 1B: doweled joints, cement-treated subbase, no concrete shoulder Same as 1A except: 4-in. cement-treated subbaset Combined k = 280 pci (see Table 2) Design 1C: doweled joints, untreated subbase, concrete shoulder Same as 1A except: Concrete shoulder Design ID: aggregate-interlock joints, cement-treated subbase, no concrete shoulder Same as I B except: Aggregate-interlock joints Design 1E: aggregate-interlock joints, cement-treated subbase, concrete shoulder Same as I D except: Concrete shoulder Thickness Calculations: A trial thickness is evaluated by completing the design worksheettt shown in Fig. 4 for Design 1A using the axle-load data from Table 5. For Design lA, Table 6a and Fig. 5 are used for the fatigue analysis and Table 7a and Fig. 6a are used for the erosion analysis. Comments on Design 1 For designs 1A through IE, a subbase of one type or another is used as a recommended practice1 on fine-textured soil subgrades for pavements carrying an appreciable number of heavy trucks. In Design IA: (I) Totals of fatigue use and erosion damage of 63% and 39%, respectively, show that the 9.5in. thickness is adequate for thedesignconditions. (2) This design has 37% reserve capacity available for heavy-axle loads in addition to those estimated for design purposes. (3) Comments 1 and 2 raise the question of whether a 9.0in. thickness would be adequate for Design IA. Separate calculations showed that 9.0 in. is not adequate because of excessive fatigue consumption (245%). (4) Design 1A is controlled by the fatigue analysis. A design worksheet, Fig. 7, is shown for Design I D to illustrate the combined effect of using aggregate-interlock joints and a cement-treated subbase. In Design 1D: (1) Totals of fatigue use and erosion damage of I%$f and 97%, respectively, show that 10 in. is adequate. (2) Separate calculations show that 9.5 in. is not adequate because of excessive erosion damage (142%), and (3) Design 1D is controlled by the erosion analysis. (continued o n page 21) 'Some guidance is helpful in reducing the number of trial runs. The effect of thickness on both the fatigue and erosion damage approximately follows a geometric progression. For example, if 33% and 178% fatigue damage are determined at trial thicknesses of 10 and 8 in., respectively, the approximate fatigue damage for a thickness of 9 in. is equal to J33X178 = 77%. **Concrete M R , LSF, and subgrade k valuesare thesame for Designs I A through I E. tCement-treated subbase meeting requirements stated on page 6. t t A blank worksheet is provided as the last page of this bulletin for the purposes of reproduction and use in specific design problems. :See Subgrades and Subbases for Concrete Pavements. Portland Cement Association publication f f For pavements wlth aggregate-interlock joints subjected to an appreciable number of trucks, the fatigue analysis will usually not affect design. Table 6a. Equivalent Stress - No Concrete Shoulder (Single Axlenandem Axle) Slab thickness, in. 50 100 150 200 300 500 700 4 4.5 825/679 699/586 726/585 616/500 671 /542 571/460 634/516 540/435 584/486 498/406 523/457 448/378 484/443 41 7/363 5 5.5 602/516 526/461 531/436 464/387 493/399 431 /353 467/376 409/331 432/349 379/305 390/321 343/278 363/307 320/264 6 6.5 465/416 417/380 411/348 367/317 382/316 341/286 362/296 324/267 336/271 300/244 304/246 273/220 285/232 256/207 7 7.5 375/349 340/323 331 /290 300/268 307/262 279/241 292/244 265/224 271 /222 246/203 246/199 224/18 1 231 /I86 2 10/169 500 700 k of subgrade-subbase, pci Table 6b. Equivalent Stress - Concrete Shoulder (Single AxleITandem Axle) Slab thickness, ~n. k of subgrade-subbase, p c ~ . 50 100 150 200 300 I 0 0 - " - o N I h) 1 P o u I m I 0 0 c o o - o P I 1 nl I 8 I I o 6, I I I I I 2I I CD o "co 8 nl I I P ALLOWABLE L O A D REPETITIONS P P - 1 I I I I I I I 1 I TANDEM A X L E LOAD, KlPS I - 2 : k g g g 8 g g C D 0 r u 5 ; a , m - SINGLE A X L E LOAD, KlPS m c o 8 '0 s (o 0 nl o 0 - 0 0 P ma30 8 - 0 nl - Pb, 8 -0 80 0, .o - ru 0 Table 7a. Erosion Factors - Doweled Joints, No Concrete Shoulder (Single Axlenandem Axle) Slab th~ckness. k of subgrade-subbase, p c ~ in. 50 100 200 300 500 700 4 4.5 3.74/3.83 3.59/3.70 3.73/3.79 3.57/3.65 3.72/3.75 3.56/3.61 3.71/3.73 3.55/3.58 3 70/3.70 3 54/3.55 3 68/3 67 3 52/3.53 5 55 3.45/3.58 3.33/3.47 3.43/3.52 3.31/3.41 3.42/3.48 3.29/3 36 3 41/3.45 3 28/3.33 3.40/3.42 3.27/3.30 3.38/3.40 3 26/3.28 Table 7b. Erosion Factors - Aggregate-Interlock Joints, No Concrete Shoulder (Single Axle/Tandem Axle) Slab th~ckness, ~n 50 100 200 300 500 700 4 4.5 3.94/4.03 3.79/3.91 3.91/3.95 3.76/3.82 3.88/3.89 3.73/3.75 3.8W3.86 3 71/3.72 382/3.83 3 68/3.68 3.7713.80 3.64/3.65 k of subgrade-subbase, pcl -I m t m I (D a, , 0 N 0 I I I - P m - - aD 0 10 0 IU 0 W II l aiTI A P 0 N 0 1 1 1 o P 0 W 1 0 0 1 1 1 W in P cJ 1 1 1 W N 1 1 o cJ 1 1 I I I I in r in l I N 1 I I' N EROSION FACTOR 0 0, ALL0WABL.E LOAD REPETITIONS OD cEl P 0 TANDEM A X L E LOAD, KlPS W 0 1 1 N P 0 (I, l ~ I ~ I ~ I i I I ~I r , r ~p lw~: , ~ l ~ h) - SINGLE A X L E LOAD, KlPS 1 II 0, 0 iu 1 1 o N ' I ' I1 ' - - 0 (0 o o o g N 1 ~ 0 0 Table 8a. Erosion Factors - Doweled Joints, Concrete Shoulder (Single AxleITandem Axle) Slab th~ckness, in. 50 100 200 300 500 700 4 4.5 3.28/3.30 3.13/3.19 3.24/3.20 3.09/3.08 3.21/3.13 3.06/3.00 3.19/3.10 3. 04/2. 96 315/3.09 3.01/2.93 3.12/3.08 2.98/2.91 k of subgrade-subbase, pci Table 8b. Erosion Factors - Aggregate-Interlock Joints, Concrete Shoulder (Single AxleITandem Axle) Slab th~ckness, ~n. k of subgrade-subbase, pci 50 100 200 300 500 700 Fig. 6b. Erosion analysis-allowable load repetitions based on erosion factor (with concrete shoulder). Calculation of Pavement Thickness T r ~ a th~ckness l - /fl. in A pcl Modulus of rupture, MR - M L PSI Subbase-subgrade k Load safety factor, LSF Doweled j o ~ n t s yes n Concrete shoulder yes Mult~pl~ed by LSF Expected repet~t~ons 1-Z 1 2 3 Allowable repetltfons Eros~onanalys~s Fat~gue. percent 5 4 8. Equivalent stress- Single Axles 9. Stress ratlo factor m 11. Equ~valents t r e s s . / C L = Tandem Axles Fig. 7. Design I D . a Des~gnp e r ~ o d2 0 years /. 2 Fatlgue analys~s Axle load. k~ps o v no 12. Stress ratlo factor Allowable repetltlons Damage percent 6 7 10. Eros~onfactor 2.72 T 13. Eros~onfactor -2.90 Worksheets for the other variations of Design 1 are not shown here but the results are compared as follows: Joints Design Subbase 1A IB 1C 4-in. g r a n u l a r 4-in. cement-treated ID 4-in. cement-treated aggregate interlock 1E 4-in. cement-treated aggregate interlock 4-in. g r a n u l a r Thickness requirement, in. Concrete shoulder doweled doweled doweled Design 2B: doweled joints,** no subbase, no concrete shoulder Same as 2A except: Doweled joints Thickness Calculations: For Design 2A, a trial thickness of 6 in. is evaluated by completing the worksheet shown in Fig. 8, according t o the procedure given on page 1 1. Table 6a and Fig. 5 are used for the fatigue analysis and Table 76 and Fig. 6a are used for the erosion analysis. For Design 2B, a worksheet is not shown here but the design was worked out for comparison with Design 2A. Comments on Design 2 For Design 1 conditions, use of a cement-treated subbase reduces the thickness requirement by 1.0 in. (Design 1 A versus I B); and concrete shoulders reduce the thickness requirement by 1.0 to 1.5 in. (Designs 1A versus 1C and 1 D versus 1E). Use of aggregate-interlock joints instead of dowels increases the thickness requirement by 1.5 in. (Design 1 B versus 1D). These effects will vary in different design problems depending on the specific design conditions. Design 2 Project and Traffic Data: Two-lane-secondary road Design period = 40 years Current ADT = 600 Projection factor = 1.2 ADTT = 2.5% of A D T - Traffic Calculations: Design ADT = 600 X 1.2 = 720 ADTT = 720 X 0.025 = 18 Truck traffic each way For Design 2A: (1) Totals of fatigue use and erosion damage of 89%and 8%, respectively, show that the 6.0-in. thickness is adequate. (2) Separate calculations show that a 5.5-in. pavement would not be adequate because of excessive fatigue consumption. (3) The thickness design is controlled by the fatigue analysis-which is usually the case for light-truck-traffic facilities. The calculations for Design 2B, which is the same as Design 2A except the joints are doweled, show fatigue and erosion values of 89% and 296, respectively. Comments: (1) The thickness requirement of 6.0 in. is the same as for Design 2A. (2) The fatigue-analysis values are exactly the same as in Design 2A. (3) Because of the dowels, the erosion damage is reduced from 8% t o 2%; however, this is immaterial since the fatigue analysis controls the design. For the Design 2 situation, it is shown that doweled joints are not required. This is borne out by pavementperformance experience on light-truck-traffic facilities such as residential streets and secondary roads and also by studies'2829' showing the effects of the number oftrucks on pavements with aggregate-interlock joints. 18 2 = - = 9 For a 40-year design period: 9 X 365 X 40 = 13 1,400 trucks Axle-load data are shown in Table 15, Category I , and the expected number of axle-load repetitions are shown in Fig. 8. Values Used t o Calculate Thickness: Design 2A: aggregrate-interlock joints, no subbase,* no concrete shoulder Clay subgrade, k = 100 pci L S F = 1.0 Concrete M R = 650 psi *Performance experience has shown that subbases are not requ~red when truck traffic 1s very Ilght; see the PCA publicatlon, Subgradesand Subbases for Concrete Pavemenrs. **Design 2B is shown for illustrative purposes only. Doweledjolnts are not needed where truck traffic 1s very I~ght;see the PCA publication Joinr Des~gnfor Concrete Hrghwav und Streer Pavements. t The type of load transfer at thejoints--dowels, or aggregate interlock-does not affect the fatigue calculations since the critical axle-load position for stress and fatigue is where the axle loads are placed at pavement edge and midpanel, away from the joints. See Appendix A. Calculation of Pavement Thickness Trtal th~ckness '4.0 Subbase-subgrade k /DO - Modulus of rupture. MR Load safety factor, LSF ~n Doweled joints yes no r / pc~ Concrete shoulder yes no r/ ps~ Deslgn perlod /. 0 %years no J ~ ~ L Z S P Fat~gueanalys~s Axle load, klps Mult~plied by LSF Expected repet~tions 1.L 7 1 2 3 Allowable repetit~ons Single Axles Fatlgue. percent 5 4 8. Equivalent stress Eros~onanalys~s y// Fig. 8. Design 2A. Damage. percent 6 7 10. Eros~onfactor 3.F D 9. Stress ratlo factor 11. Equlvalent stress-*!?. Tandem Axles Allowable repet~t~ons 12. Stress ratlo factor 0-5 3 5 13. Eroslon factor -=- CHAPTER 4 Simplified Design Procedure (Axle-Load Data Not Available) The design steps described in Chapter 3 include separate calculations of fatigue consumption and erosion damage for each of several increments of single- and tandem-axle loads. This assumes that detailed axle-load data have been obtained from representative truck weigh stations, weigh-in-motion studies, or other sources. This chapter is for use when specific axle-load data are not available. Simple design tables have been generated based on composite axle-load distributions that represent different categories of road and street types. A fairly wide range of pavement facilities is covered by four categories shown in Table 9.* The designer does not directly use the axle-load data** because the designs have been presolved by the methods described in Chapter 3. For convenience in design use, the results are presented in Tables 1 1, 12, 13, and 14, which correspond to the four categories of traffic. Appropriate load safety factors of 1.0, 1.1, 1.2, and 1.2, respectively, have been incorporated into the design tables for axleload Categories 1, 2, 3, and 4. The tables show data for a design period of 20 years. (See the section "Design Period", following.) In these tables, subgrade-subbase strength is characterized by the descriptive words Low,Medium, High, and Very High. Fig. 2 shows relationships between various subgrade-bearing values. In the event that test data are not available, Table 10 lists approximate k values fordifferent soil types. If a subbase is to be used-see Chapter 2 *On page 30, guidelines for preparing design tables f o r axle-load distributions different f r o m those given here are discussed. **Axle-load data f o r the f o u r categories are given i n Table 15. Table 9. Axle-Load Cate~ories Traffic I Axle-load category Description I 2 3 4 ADT Residential streets Rural and secondary roads (low to medium') Collector streets Rural and secondary roads (high') Arterial streets and primary roads (low') Arterial streets and primary roads (medium') Expressways and urban and rural lnterstate (low to medium') Arterial streets, primary roads. expressways (high') Urban and rural lnterstate (medium to high') 3000-12,000 2 lane 3000-50.000+ 4 lane or more 3000-20,000 2 lane 3000-150,000+ 4 lane or more ADTT" 1 7 1 Per day 8-30 8-30 'The descriptors high, m e d ~ u mor , low refer to the relat~vewe~ghtsof axle loads for the type of street or road. that IS. "low" for a rural lnterstate would represent heavier loads than "low" for a secondary road 'Trucks -two-axle, four-tire trucks excluded. Maximum axle loads, kips Single axles Tandem axles Table 10. Subgrade Soil Types and Approximate k Values k values range. Type of soil Support Fine-gramed soils in which silt and clay-size particles predominate Sands and sand-gravel mixtures with moderate amounts of silt and clay Sands and sand-gravel mixtures relatively free of plastic fines Cement-treated subbases (see page 6) I 1 Low 75-1 20 Medium 13C-170 High Very high 1 1 188220 25C-400 under "Subgrade and Subbase Supportw-the estimated k value is increased according to Table I or Table 2. The design steps are as follows: 1. Estimate ADTT* (average daily truck traffic, two directions, excluding two-axle, four-tire trucks) 2. Select axle-load Category I, 2, 3, or 4. 3. Find slab thickness requirement in the appropriate Table I I, 12, 13, or 14. (In the use of these tables, see discussion under "Comments on Simplified Procedure," page 30.) In the correct use of Table 9, the ADT and ADTT values are not used as the primary criteria for selecting the axle-load category-the data are shown only to illustrate typical values. Instead, it is correct to rely more on the word descriptions given or to select a category based on the expected values of maximum-axle loads. The ADTT design value should be obtained by a truck classification count for the facility or for another with a similar composition of traffic. Other methods of estimating ADT and ADTT are discussed on pages 8 and 9. The allowable ADTT values (two directions)listed in the tables include only two-axle, six-tire trucks, and single or combination units with three axles or more. Excluded are panel and pickup trucks and other two-axle, four-tire trucks. Therefore, the number of allowable trucks ofall types will begreaterthanthe tabulated ADTT (continued on page 30) *For facilities of four lanes or more, the ADTT IS adjusted by the use of Fig. 3. Table 11. Allowable ADTT,* Axle-Load Categpry 1 Pavements with Aggregate-Interlock Joints (Dowels not needed) Concrete Shoulder or Curb No Concrete Shoulder or Curb I in. ' 1 Low Medium Slab thickness, ~n. Hiah Subgrade-subbase support Low Medium High Note: Fatigue analysis controls the des~gn Note: A fractional ADTT Indicates that the pavement can carry unlim~tedpassenger cars and two-axle, fourtire trucks, but only a few heavy trucks per week (ADTT of 0.3 x 7 days ind~catestwo heavy trucks per week.) 'ADTT excludes two-axle, f o u r - t ~ r etrucks, so total number of trucks allowed w ~ l be l greater-see text Table 12a. Allowable ADTT,* Axle-Load Category 2 - Pavements with Doweled Joints Concrete Shoulder or Curb No Concrete Shoulder or Curb Slab thickness. in. Subgrade-subbase support Low Medium Hlgh Very high I Slab thickness, ~n. I Subgrade-subbase support Low 5 Note. Fatlgue analysis controls the deslgn. I Medium Very hlgh 9 42 Concrete Shoulder or Curb Subgrade-subbase support Low High - Pavements with Aggregate-Interlock Joints No Concrete Shoulder or Curb ~n. 3 'ADTT excludes two-axle, four-t~retrucks so total number of trucks allowed w ~ l be l greater-see Table 126. Allowable ADTT,* Axle-Load Category 2 thickness, Medlum Hlgh Very high Slab th~ckness. ~n Subgrade-subbase support Low Medium Hlgh Very high 3 42 9 120 42 450 96 650" 380 1000" 700" 1400" 970'' 2100" 1100" 1900" 5 5.5 6 6.5 7 'ADTT excludes two-axle, four-tlre trucks, total number of trucks allowed w ~ l be l greater-see "Eros~on analys~scontrols the des~gn,otherwse fatlgue analys~scontrols 9 text text Table 1%. Allowable ADTT,* Axle-Load Category 3- Pavements with Doweled Joints No Concrete Shoulder or Curb Slab hickness, in. Concrete Shoulder or Curb Subgrade-subbase support Low Medium High Very high Slab thickness, in. Subgrade-subbase support I 7.5 8 8.5 9 9.5 'ADTT excludes two-axle, four-tire trucks; total number of trucks ailowed wtll be greater-see "Erosion analysis controls the design; otherwise fat~gueanalysis controls. text. Low Medium High Very high Table 13b. Allowable ADTT,* Axle-Load Category 3 - Pavements with Aggregate Interlock Joints Concrete Shoulder or Curb No Concrete Shoulder or Curb thickness. slab ~n. I I Subgrade-subbase support Low Medium High Very high I th~ckness, in. 'ADTT excludes two-axle, four-t~retrucks; total number of trucks allowed w ~ l be l greater-see "Fat~gue analysis controls the design, otherw~seeroslon analysis controls. Subgrade-subbase support Low text. Medium High Very high Table 14a. Allowable ADTT,* Axle-Load Category 4 - Pavements with Doweled Joints No Concrete Shoulder or Curb I I1 Slab Ith~c:~ness, Concrete Shoulder or Curb Subgrade-subbase support Low Med~um Hlqh Very hlqh II Slab th~ckness. ~n. 'ADTT excludes two-axle four-t~retrucks total number of trucks allowed wlll be greater-see .Eros~onanalys~scontrols the d e s ~ g notherwise fat~gueanalys~scontrols text Subgrade-subbase support Low Medium H~oh Verv hiah Table 14b. Allowable ADTT,* Axle-Load Category 4 - Pavements with Aggregate-Interlock Joints Concrete Shoulder or Curb No Concrete Shoulder or Curb I I Slab th~ckness. in. Subgrade-subbase support Low Medium Hiah Verv hiah Subgrade-subbase support Slab thickness. tn. Low 7 7.5 8 Medium High Very high 240" 100" 620" 400" 910 8.5 330" 720 770 1,300 1,100 1.900 1,700 3,100 9 9.5 1,100 1.700 2.100 3.400 3.200 5.500 5.7CO 10,200 'ADTT excludes two-axle, four-t~retrucks, total number of trucks allowed w ~ l be l greater-see "Fat~gue analys~scontrols the des~gn,otherw~seeroslon analys~scontrols text values by about double for many highways on up toabout triple or more for streets and secondary roads. Tables 1 1 through 14 include designs for pavements with and without concrete shoulders or curbs. Forparking lots, adjacent lanes provide edge support similar to that of a concrete shoulder or curb so the right-hand side of Tables 1 1 through 14 are used. Sample Problems Two sample problems follow to illustrate use of the simplified design procedure. Design 3 Arterial street, two lanes Design ADT = 6200 Total trucks per day = 1440 ADTT = 630 Clay subgrade 4-in. untreated subbase Subgrade-subbase support = low Concrete M R = 650 psi* Doweled joints, curb and gutter Since it is expected that axle-load magnitudes will be about the average carried by arterial streets, not unusually heavy or light, Category 3 from Table 9 is selected. Accordingly, Table 13a is used for design purposes. (Table 13a is for doweled joints, Table 13h is for aggregate-interlock joints.) For a subgrade-subbase support conservatively classed as low, Table 13a, under the concrete shoulder or curb portion, shows an allowable ADTT of 1600 for an 8-in.slab thickness and 320 for a 7.5-in. thickness. This indicates that, for a concrete strength of 650 psi, the 8-in. thickness is adequate to carry the required design ADTT of 630. Design 4 Residential street, two lanes ADT = 410 Total trucks per day = 21 ADTT = 8 Clay subgrade (no subbase), subgrade support = low Concrete M R = 600 psi* Aggregate-interlock joints (no dowels) Integral curb In this problem, Table 11 representing axle-load Category 1 is selected for design use. In the table under "Concrete Shoulder or Curb," the following allowable ADTT are indicated: Slab Thickness. in. 1 ADTT Therefore, a 5.5-in.-slab thickness is selected to meet the required design ADTT value of 8. Comments on Simplified Procedure Modulus of Rupture Concrete used for paving should be of high quality** and have adequate durability, scale resistance, and flexural strength (modulus of rupture). In reference to Tables I I through 14, the upper portions of the tables represent concretes made with normal aggregates that usually produce good quality concretes with flexural strengths in the area of 600 to 650 psi. Thus, the upper portions of these tables are intended for general design use in this simplified design procedure. The lower portions of the tables, showing a concrete modulus of rupture of 550 psi, are intended for design use only for special cases. In some areas of the country, the aggregates are such that concretes of good quality and durability produce strengths of only about 550 psi. Design Period The tables list the allowable ADTTs for a 20-year design period. For other design periods, multiply the estimated ADTT by the appropriate ratio to obtain an adjusted value for use in the tables. For example, if a 30-year design period is desired instead of 20 years, the estimated ADTTvalue is multiplied by 30120. In general, the effect of the design period on slab thickness will be greater for pavements carrying larger volumes of truck traffic and where aggregate-interlock joints are used. Aggregate-Interlock or Doweled Joints Tables 12 through 14 are divided into two parts, a and b, to show data for doweled and aggregate-interlockjoints,t respectively. In Table 11, thickness requirements are the same for pavements withdoweled and aggregate-interlock joints; doweled joints are not needed for the low truck traffic volumes tabulated for Category 1. Whenever dowels are not used, joint spacings should be short-see discussion on page 3. User-Developed Design Tables The purpose of this section is to describe how the simplified design tables were developed so that the design engineer who wishes to can develop a separate set of design tables based on an axle-load category different from those given in this chapter. Some appropriate situations include *See discussion under "Comments on Simplified Procedure-Modulus of Rupture," above. **See Portland Cement Association publication Design and Control of Concrete Mixtures. When fatigue analys~scontrols the design (see footnotes of Tables 12 through 14). it will be noted that the ADTTvalues for doweled joints and for aggregate-interlock joints are the same (see topic "Jointed Pavements" in Appendix A). If erosion analys~scontrols, concrete modulus of rupture will have no effect on the allowable ADTT. (1) preparation of standard sections from which a pavement thickness is selected based on amount of traffic and other design conditions, (2) unusual axle-load distributions that may be carried on a special haul road or other special pavement facility, and (3) an increase in legal axle loads that would cause axle-load distribution to change. Axle-load distributions for Categories 1 through 4 are shown in Table 15. Each of these is a composite of data averaged from several state loadometer (W-4) tables representing pavement facilities in the appropriate category. Also, at the high axle-load range, loads heavier than those listed on state department of transportation W-4 tables were estimated based on extrapolation. These two steps were desired for obtaining a more representative general distribution and smoothing irregularities that occur in individual W-4 tables. The steps are considered appropriate for the design use of these particular categories described earlier in this chapter. As described in Chapter 2, the data is adjusted to exclude two-axle, four-tire trucks, and then the data are partitioned into 2000- and 4000-lb axle-load increments. To prepare design tables, design problems are solved with the given axle-load distribution by computer with the desired load safety factor at different thicknesses and subbase-subgrade k values. Allowable ADTT values to be listed in design tables are easily calculated when a constant, arbitrary ADTT is input in the design problems as follows: assume input ADTT is 1000 and that 45.6% fatigue consumption is calculated in a particular design problem, then Allowable ADTT = 100 X (input ADTT) % fatigue or erosion damage ' Table 15. Axle-Load Distributions Used for Preparing Design Tables 11 Through 14 load, Axles per 1000 trucks* Category 2 Single axles 1693.31 4 732.28 6 483.10 8 10 204.96 12 124.00 14 56.11 16 38.02 15.81 18 4.23 20 0.96 22 24 26 28 30 32 34 m Tande axles 4 31.90 85.59 8 12 139.30 75.02 16 57.10 20 39.18 24 68.48 28 69.59 32 4.19 36 40 44 48 52 56 60 L 'Exclud~ngall two-axle, four-t~retrucks Category 3 Category 4 APPENDIX A Development of Design Procedure The thickness design procedure presented here was prepared to recognize current practices in concrete pavement construction and performance experience with concrete pavements that previous design procedures have not addressed. These include: Pavements with different types of load transfer at transverse joints o r cracks Lean concrete subbases under concrete pavements Concrete shoulders Modes of distress, primarily due to erosion of pavement foundations, that are unrelated to the traditional criteria used in previous design procedures A new aspect of the procedure is the erosion criterion that is applied in addition to the stress-fatigue criterion. The erosion criterion recognizes that pavements can fail from excessive pumping, erosion of foundation, and joint faulting. The stress criterion recognizes that pavements can crack in fatigue from excessive load repetitions. This appendix explains the basis for these criteria and the development of the design procedure. References 30 and 57 give a more detailed account of the topic. the critical placements shown in Fig. A l wereestablished with the following conclusions: I . The most critical pavement stresses occur when the truck wheels are placed a t o r near the pavement edge and midway between the joints, Fig. A I(a). Since the joints are at some distance from this location, transverse joint spacing and type of load transfer have very little effect on the magnitude of stress. In the design procedure. therefore, the analysis based on flexural stresses and fatigue yield the same values for different joint spacings and different types of load transfer mechanisms (dowels o r aggregate interlock) at transverse joints. When a concrete shoulder is tied Analysis of Concrete Pavements The design procedure is based on a comprehensive analysis of concrete stresses and deflections at pavement joints. corners, and edges by a finite-element computer program.'x' It allows considerations of slabs with finite dimensions, variable axle-load placement, and the modeling of load transfer at transverse joints Or cracks and load transfer at the joint between pavement and concrete shoulder. For doweled joints, dowel properties such as diameter and modulus of elasticity are used directly. For aggregate interlock, keyway joints, and cracks in continuously reinforced pavements, a spring stiffness value is used to represent the load-deflection characteristics of such joints based o n field and laboratory tests. (01 Axle - lood p o s ~ f ~ ofor n c r ~ t i c o lflexural stresses -Transverse 1 Troff~c lo"e Free edge or shoulder lolnf I I I 2Concrete shoulder I ( ~ used) f Jointed Pavements After analysis of different axle-load positions on the slab, ~omt Fig. A l . Critical axle-load positions. I I I on to the mainline pavement, the magnitude of the critical stresses is considerably reduced. 2. The most critical pavement deflections occur at the slab corner when a n axle load is placed a t the joint with the wheels a t or near the corner, Fig. Al(b).* In this situation, transverse joint spacing has no effect on the magnitude of corner deflections but the type of load transfer mechanism has a substantial effect. This means that design results based on the erosion criteria (deflections) may be substantially affected by the type of load transfer selected, especially when large numbers of trucks are being designed for. A concrete shoulder reduces corner deflections considerably. Continuously Reinforced Pavements A continuously reinforced concrete pavement (CRCP) is one with no transverse joints and, due to the heavy, continuous steel reinforcement in the longitudinal direction, the pavement develops cracks at close intervals. These crack spacings on a given project are variable, running generally from 3 to 10 ft with averages of 4 to 5 ft. In the finiteelement computer analysis, a high degree of load transfer was assigned at the cracks of C R C P and the crack spacing was varied. The critical load positions established were the same as those forjointed pavements. For the longer crack spacings, edge stresses for loads placed midway between cracks are of about the same magnitude as those for jointed pavements. For the average and shorter crack spacings, the edge stresses are less than those for jointed pavements, because there is not enough length of uncracked pavement to developas much bending moment. For the longer crack spacings, corner deflections are somewhat less than those for jointed pavements with doweled transverse joints. For average to long crack spacings, corner deflections are about the same as those for jointed, doweled pavements. For short crack spacings of 3 o r 4 ft, corner deflections are somewhat greater than those for jointed, doweled pavements, especially for tandem-axle loads. Considering natural variations in crack spacing that occur in one stretch of pavement, the following comparison of continuously reinforced pavements with jointed, doweled pavements is made. Edge stresses will sometimes be the same and sometimes less. while corner deflections will sometimes be less, the same, and greater at different areas of the pavement depending on crack spacing. The average of these pavement responses is neither substantially better nor worse than those for jointed, doweled pavements. As a result, in thisdesign procedure, the same pavement responses and criteria are applied to continuously reinforced pavements as those used with jointed, doweled pavements. This recommendation is consistent with pavement performance experience. Most design agencies suggest that the thickness of continuously reinforced pavements should be about the same as the thickness of doweled-jointed pavements. *The greatest deflect~onsfor t r ~ d e m occur s when two axles are placed at one s ~ d eof the jolnt and one axle at the other s ~ d e Truck Load Placement Truck wheel loads placed at the outside pavement edge create more severe conditions than any other load position. As the truck placement moves inward a few inches from the edge, the effects decrease s u b ~ t a n t i a l l ~ . " ~ ' Only a small fraction of all the trucks run with their outside wheels placed at the edge. Most of the trucks traveling the pavement are driven with their outside wheel placed about 2 ft from the edge. ~ a r a g i n ' s ' ~studies " reported in 1958, showed very little truck encroachment at pavement edge for 12-ft lanes for pavements with unpaved shoulders. More recent studies by ~ m e r ~ ' " " s h o w e d more trucks at edge. Other recent s t ~ d i e s ' ~showed " fewer trucks at edge than Emery. For this design procedure, the most severe condition, 6% of trucks at edge,* is assumed so as to be on the safe side and to take account of recent changes in United States law permitting wider trucks. At increasing distances inward from the pavement edge, the frequency of load applications increases while the magnitudes of stress and deflection decrease. Data on truck placement distribution and distribution of stress and deflection due to loads placed at and near the pavement edge are difficult to use directly in a design procedure. As a result, the distributions were analyzed and more easily applied techniques were prepared for design purposes. For stress-fatigue analysis, fatigue was computed incrementally at fractions of inches inward from the slab edge for different truck-placement distributions: this gave the equivalent edge-stress factors shown in Fig. A2. (This factor, when multiplied by edge-load stress, gives the same degree of fatigue consumption that would result from a given truck placement distribution.) The most severe condition, 6% truck encroachment, has been incorporated in the design tables. Percent trucks of or off edge Taragm 2 lone 04 6 Emery (paved shoulder) 600 - - - -- - - PERCENT TRUCKS AT EDGE Fig. A2. Equivalent edge stress factor depends on percent of trucks at edge. *As used here, the term "percent trucks at edge" is defined as the percent of total trucks that are traveling with the outside of the contact area of the outside tire at or beyond the pavement edge. For erosion analysis, which involves deflection at the slab corner, the most severe case (6% of trucks at edge) is again assumed. Where there is no concrete shoulder, corner loadings (6% of trucks) are critical; and where there is a concrete shoulder, the greater number of loadings inward from the pavement corner (94% of trucks) are critical. These factors are incorporated into the design charts as follows: Percent erosion damage = 100 Cn, (C/ Ni) where: n, = expected number of axle-load repetitions for axle-group i Ni = allowable number of repetitions for axle-group i C = 0.06 for pavements without shoulder, and 0.94 for pavements with shoulder T o save a design calculation step, the effects of (C/Ni] are incorporated in Figs. 6a and 6b of Chapter 3 and Tables 11 through 14 of Chapter 4. Variation in Concrete Strength Recognition of the variations in concrete strength is considered a realistic addition to the design procedure. Expected ranges of variations in the concrete's modulus of rupture have far greater effect than the usual variations in the properties of other materials, such a s subgrade and subbase strength, and layer thicknesses. Variation in concrete strength is introduced by reducing the modulus of rupture by one coefficient of variation. For design purposes, a coefficient of variation of 15% is assumed and is incorporated into the design charts and tables. The user does not directly apply this effect. The value of 15% represents fair-to-good quality control, and, combined with other effects discussed elsewhere in this appendix, was selected as being realistic and giving reasonable design results. effect is influenced greatly by creep. Curling refers to slab behavior due to variations of temperature. During the day, when the top surface is warmer than the bottom, tensile-restraint stressesdevelop a t the slab bottom. During the night, the temperature distribution is reversed and tensile restraint stresses develop a t the slab surface. Temperature distribution is usually nonlinear and constantly changing. Also, maximum daytime and nighttime temperature differentials exist for short durations. Usually the combined effect of curling and warping stresses are subtractive from load stresses because the moisture content and temperature a t the bottom of the slab exceed that a t the top more than the reverse. The complex situation of differential conditions at a slab's top and bottom plus the uncertainty of the zerostress position make it difficult to compute o r measure the restraint stresses with any degree of confidence or verification. At present, the information available on actual magnitudes of restraint stresses does not warrant incorporation of the items in this design procedure. As for the loss of support, this is considered indirectly in the erodibility criterion, which is derived from actual field performance and therefore incorporates normal loss of support conditions. Calculated stress increase due to loss of support varies from about 5% to 15%. This theoretical stress increase is counteracted in the real case because a portion of the load is dissipated in bringing the slab edges back in contact with the support. Thus, the incremental load stressdue to a warping-type loss of support is not incorporated in this design procedure. Fatigue The flexural fatigue criterion used in the procedure presented here is shown in Fig. A3. It is similar to that used in the previous PCA method'j4' based conservatively on Concrete Strength Gain With Age The 2 8 d a y flexural strength (modulus of rupture) is used a s the design strength. This design procedure, however, incorporates the effect of concrete strength gain after 28 days. This modification is based on a n analysis that incremented strength gain and load repetitions month by month for 20-year and 40-year design periods. The effect is included in the design charts and tables so the user simply inputs the 28-day value a s the design strength. Warping and Curling of Concrete In addition to traffic loading, concrete slabs are also subjected to warping and curling. Warping is the upward concavedeformation of the slab due to variationsin moisture content with slab depth. The effect of warping is twofold: It results in loss of support along the slab edges and also in compressive restraint stresses in the slab bottom. Since warping is a long-term phenomenon, its resultant 04 lo2 lo3 I o4 I o5 LOAD REPETITIONS Fig. A3. Fatigue relationships. I o6 10' (45-49) except that it is applied to studies of fatigue research edge-load stresses that are of higher magnitude. A modification in the high-load-repetition range has been made t o eliminate the discontinuity in the previous curve that sometimes causes unrealistic effects. The allowable number of load repetitions for a given axle load is determined based on the stress ratio (flexural stress divided by the 28-day modulus of rupture). The fatigue curve is incorporated into the design charts for use by the designer. Use of the fatigue criterion is made on the Miner hypothesis'48' that fatigue resistance not consumed by repetitions of one load is available for repetitions of other loads. In a design problem, the total fatigue consumed should not exceed 100%. Combined with the effect of reducing the design modulus of rupture by one coefficient of variation, the fatigue criterion is considered to be conservative for thickness design purposes. Erosion Previous mechanistic design procedures for concrete pavements are based on the principle of limiting the flexural stresses in a slab to safe values. This is done to avoid flexural fatigue cracks due to load repetitions. It has been apparent that there is a n important mode of distress in addition t o fatigue cracking that needs t o be addressed in the design process. This is the erosion of material beneath and beside the slab. Many repetitions of heavy axle loads at slab corners and edges cause pumping; erosion of subgrade, subbase, and shoulder materials; voids under and adjacent to the slab; and faulting of pavement joints, especially in pavements with undoweled joints. These particular pavement distresses are considered to be more closely related to pavement deflections than to flexural stresses. Correlations of deflections computed from the finiteelement analysis'x' with A A S H O Road ~ e s t 'perform~~' ance data were not completely satisfactory for design purposes. (The principal mode of failure of concrete pavements at the A A S H O Road Test was pumping o r erosion of the granular subbase from under the slabs.) It was found that to be able to predict the A A S H O Road Test performance, different values of deflection criteria would have to be applied to different slab thicknesses, and to a small extent, different foundation moduli (k values). More useful correlation was obtained by multiplying the computed corner deflection values (w) by computed pressure values (p)at the slab-foundation interface. Power, o r rate of work, with which a n axle load deflects the slab is the parameter used for the erosion criterion-for a unit area, the product of pressure and deflection divided by a measure of the length of the deflection basin (f--radius of relative stiffness, in inches). The concept is that a thin pavement with its shorter deflection basin receives a faster load punch than a thicker slab. That is, at equal pw's and equal truck speed, the thinner slab is subjected to a faster rate of work or power (inch-pound per second). A successful correlation with road test performance was obtained with this parameter. The development of the erosion criterion was also gen29' These erally related t o studies on joint f a ~ l t i n g . " ~ studies included pavements in Wisconsin, Minnesota, North Dakota, Georgia, and California, and included a range of variables not found a t the A A S H O Road Test, such as a greater number of trucks, undoweled pavements, a wide range of years of pavement service, and stabilized subbases. Brokaw's ~ t u d i e s ' ~ 'of ' undoweled pavements suggest that climate o r drainage is a significant factor in pavement performance. S o far, this aspect of design has not been i'ncluded in the design procedure, but it deserves further studv. Investigations of the effects of climate on design and performance of concrete pavements have also been reported by ~ a r t e r . ' ~ ~ ' The erosion criterion is suggested for use as a guideline. It can be modified according t o local experience since climate, drainage, local factors, and design innovations may have a n influence. Accordingly, the 100% erosiondamage criterion, a n index number correlated with general performance experience, can be increased or decreased based o n specific performance data gathered in the future for more favorable o r more adverse conditions. APPENDIX B Design of Concrete Pavements with Lean Concrete Lower Course Following is the thickness design procedure for composite concrete pavements incorporating a lower layer of lean concrete, either as a subbase constructed separately or as a lower layer in monolithic construction. Design considerations and construction practices for such pavements are discussed in References 50 through 52. Lean concrete is stronger than conventional subbase materials and is considered to be nonerodable. Recognition of its superior structural properties can be taken by a reduction in thickness design requirements. Analysis of composite concrete pavements is a special case where the conventional two-layer theory (single slab on a foundation) is not strictly applicable. The design procedure indicates a thickness for a twolayer concrete pavement equivalent to a given thickness of normal concrete. The latter is determined by the procedures described in Chapters 3 and 4. The equivalence is based on providing thickness for a two-layer concrete pavement that will have the same margin of safety* for fatigue and erosion as a single-layer normal concrete pavement. In the design charts, Fig. B1 and Fig. B2, the required layer thicknesses depend on the flexural strengths of the two concrete materials as determined by ASTM C78. Since the quality of lean concrete is often specified on the basis of compressive strength, Fig. B3 can be used to convert this t o a n estimated flexural strength (modulus of rupture) for use in preliminary design calculations. Lean Concrete Subbase The largest paving use of lean concrete has been as a subbase under a conventional concrete pavement. This is nonmonolithic construction where the surface course of normal concrete is placed on a hardened lean concrete subbase. Usually, the lean concrete subbase is built at least 2 ft wider than the pavement on each side to support the tracks of the slipform paver. Thisextra width is structurally beneficial for wheel loads applied a t pavement edge. The normal practice has been to select a surface thick- ness about twice the subbase thickness; for example, 9 in. of concrete on a 4- o r 5-in. subbase. Fig. Bl shows the surface and subbase thickness requirements set t o be equivalent to a given thickness of normal concrete without a lean concrete subbase. A sample problem is given t o illustrate the design procedure. From laboratory tests, concrete mix designs have been selected that give moduli of rupture of 650 and 200 psi,**respectively, for the surface concrete and the lean concrete subbase. Assume that a 10-in.-thickness requirement has been determined for a pavement without lean concrete subbase a s set forth in Chapter 3 or 4. As shown by the dashed example line in Fig. B1, designs equivalent t o the 10-in. pavement are (1) 7.7-in. concrete on a 5-in. lean concrete subbase, and (2) 8.1-in. concrete o n a 4-in. lean concrete subbase. Monolithic Pavement In some areas, a relatively thin concrete surface course is constructed monolithically with a lean concrete lower layer. Local o r recycled aggregates can be used for the lean concrete, resulting in cost savings and conservation of high-quality aggregates. *The criterla are that (I) stress ratios in either of the two concrete layers not exceed that of the reference pavement; and (2)erosionvalues at the subbase-subgrade interface not exceed those ofthereferencepavernent. Rationale for the criteria is given in Reference 50 plus two additional considerations: (I) erosion criteria is included in addition to the fatigue approach given in the reference; and (2) for nonmonolithicconstruction, some structural benefit (I4) is added because the subbase is constructed wider than the pavement. Flexural strength of lean concrete to be used as a subbase is usually selected to be between 150 to 250 p s ~ (compressive strength, 750 to 1200 PSI);these relatively low strengths are used to rn~nlmizereflectlvecrackIng from the unjolnted subbase (usual practice is to leave the subbase unjolnted) through the concrete surface. If, contrary tocurrent practice. jolnts are placed in the subbase, the strength of the lean concrete would not have to be restricted to the lower range. ** Modulus of Rupture of L e a n Concrete, p s i 350 450 I 250 ../ 150 250 350 450 / 14 - 13 -- 12 - - II 10 5" Sub base 4" Subbase Dimensions shown on curves are thicknesses of concrete surface course Fig. B1. Design chart for composite concrete pavement (lean concrete subbase). 9 Modulus of Rupture of Lean Concrete, psi 450 150 250 3 5 0 4 5 0 I 3" Surface 4" Surface Fig. 82. Design chart for composite concrete pavement (monolithic with lean concrete lower layer). Unlike the lean concrete subbases discussed in the previous section, the lower layer of lean concrete is placed at the same width as the surface course, and joints are sawed deep enough to induce full-depth cracking through both layers at the joint locations. Fig. B2 is the design chart for monolithic pavements. T o illustrate its use, assume that the design strengths of the two concretes are 650 and 350 psi, and that the design procedures of Chapter 3 or 4 indicate a thickness requirement of 10 in. for fulldepth normal concrete. As shown by the dashed example line in Fig. B2, monolithic designs equivalent to the 10-in. pavement are (1) 4in. concrete surface on 8.3-in. lean concrete, or (2) 3-in. surface on 9.3-in. lean concrete. COMPRESSIVE STRENGTH. PSI Fig. 83. Modulus of rupture versus compressive strength (from Reference 50). APPENDIX C Analysis of Tridem Axle Loads Tridem loads* can be included along with single- and tandem-axle loads in the design analysis by use of data given in this appendix. The same design steps and format outlined in Chapter 3 are followed except that Tables C I through C 3 are used. From these tables for tridems, equivalent stress and erosion factors are entered in an extra design worksheet. Then Fig. 5 and Fig. 6a o r 66 are used to determine allowable numbers of load repetitions. Fatigue and erosion damage totals for tridems are added t o those for singleand tandem-axle loads. An extension of the sample problem, Design I A given in Chapter 3, is used here to illustrate the procedure for tridem loads. Assume that, in addition to the single- and tandem-axle loads, a section of the highway is to carry a fleet of special coal-hauling trucks equipped with tridems at the rate of about 100 per working day for a n estimated period of 10 years; so: 100 trucks X 250 days X 10 years = 250,000 total trucks The trucks in one direction are normally all loaded t o their capacity of 54,000-lb tridem load plus 7000-lb steering-axle (single-axle) load. (When it is examined, the steering axles are not heavy enough to affect the design results.) Fig. C I represents a portion of the extra design worksheet needed to evaluate the effects of these tridems. Since Design I A (9:5-in. pavement, combined k of 130 pci) is a pavement with doweled joints and no concrete shoulder, Tables C1 and C2 are used t o determine the equivalent stress and erosion factors, Items I I and 13 on the worksheet. For this example, Fig. 5 is used to determine allowable load repetitions for the fatigue analysis and Fig. 6a is used for the erosion analysis. The tridem loads of 54,000 Ib are multiplied by the load safety factor for Design 1A of 1.2, giving a design axle load of 64,800 Ib. Before using the charts for allowable load repetitions, the tridem load (3 axles) is divided by three (64,800/3 = 2 1,600 Ib) so that the load scale for single axles can be used. ** As shown in Fig. C I , the tridem causes only 9.3% erosion damage and 0% fatigue damage. These results, added t o the effects of the singleand tandem axles shown in Fig. 4 are not sufficient to require a design thickness increase. *A tridem or triple axle is a set of three axles each spaced at 48 to 54in. apart. These are used on special heavy-duty haul trucks. **This is not to say that atridem hasthesameeffectasthreesingleaxles. The damaging effects of tridem, tandem, and single axles are incorporated into their respective equivalent stress and erosion factor tables, which in the sequence of the design steps is taken into account before the charts for allowable-load repetitions are entered. This division by three for tridems is made just to avoid the complexity of adding a third scale on the charts for allowable-load repetitions. Calculation of Pavement Thickness -- project /~/AT Ax / e ~ T r ~ ath~ckness l 1-70 Modulus of rupture, MR Load safety factor LSF : load. yes/^ n o Doweled j o ~ n t s Subbase-subgrade k Mult~pl~ed by Concrete shoulder ps~ Des~gnp e r ~ o dA years /. 7 Expected repetltlons Allowable repetlt~ons LSF L2 3 2 yes Fat~gue, percent -Axles x /12 Damage. percent 6 11. Equwalent stress- 5-9 Allowable repet~t~ons 5 4 - no r / pc~ 7 13. E r o s ~ o nfactor 7, , 12. stress ratlo factor A!GLZ~ 3 Total Total 0 ii A= adJd rb &A& skdruh Fig. C1. Analysis of tridems. Table C1. Equivalent Stress-Tridems (Without Concrete ShoulderIWith Concrete Shoulder) Slab thickness, 5'. 3 k of subgrade-subbase, pcl ~ n . 50 100 150 200 300 500 700 4 4.5 51W431 439/365 456/392 380/328 437/377 359/313 428/369 349/305 419/362 339/297 414/360 331/292 41 2/359 328/291 /> fi++ Table C2. Erosion Factors-Trldems-Doweled Joints (Without Concrete ShoulderIWith Concrete Shoulder) Slab thickness, ~n. k of subgrade-subbase, p c ~ 50 100 200 300 500 700 Joints Table C3. Erosion Factors-Tridems-Aggregate-Interlock (Without Concrete ShoulderIWith Concrete Shoulder) Slab thickness, ~n. 4 4.5 k of subgrade-subbase, pci 50 100 200 300 500 700 4.06/3.50 3.95/3.40 3.97/3.38 3.85/3.28 3.88/3.30 3.76/3.18 3.82/3.25 3.70E.13 3.7413.21 3.6313.08 3.67/3.16 3.5613.04 APPENDIX D Estimating Traffic Volume by Capacity (Note: At the time of preparing this bulletin. information on highway capacity is under extensive revision and computational methods and results may be substantially changed. New publications of AASHTO and theFH WA "Highway Capacity Manual," expected to be published in 1984 and 1985, should be used when available and they will replace the methods and references presented in this appendix.) In Chapter 2, the traffic volume (ADT) is estimated by a method based on the projected rates of traffic growth. When the projected traffic volume is relatively high for a specific project, this method should be checked by the capacitymethod described here. The practical capacity of a pavement facility is defined as the maximum number of vehicles per lane per hour that can pass a given point under prevailing road and traffic conditions without unreasonable delay or restricted freedom to maneuver. Prevailing conditions include composition of traffic, vehicle speeds, weather, alignment, profile, number and width of lanes, and area. The term practical capacity is commonly used in reference to existing highways, and the term design capacity is used for design purposes. Where traffic flow is uninterrupted-or nearly so-practical capacity and design capacity are numerically equal and have essentially the same meaning. In accordance with AASHTO usage'" 5 4 ' the term design capacity is used in this text. Design capacities for various kinds of multilane highways are summarized in Table Dl. A D T Capacity of Multilane High ways For thickness design it is necessary to convert the passenger cars per hour in Table D l to average daily traffic in both directions, ADT. For multilane highways with uninterrupted flow the following formula is used: ADT = Table D l . Design Capacities for Multilane Highways Design capacity. passenger cars' per 12-ft lane per hour Type of hlghway Urban freeways wlth full access control (30 to 35 mph) Suburban freeways with full access control (35 to 40 mph) Rural freeways wlth full or partlal access control - - - -- Rural major hlghways w ~ t hmoderate cross trafflc and roadslde interference Rural major h~ghwaysw ~ t hconsiderable cross traffic and roadslde Interference 'Also Includes panels p ~ c k u p sand other four-tlre commerc~alvehlcles that functlon as passenger cars In terms of trafflc capacity Values are taken from References 53 and 54 j = number of passenger cars equivalent to one truck K = 4 in rolling terrain = 2 in level terrain = design hour volume, DHV, expressed as a percentage of ADT = 15% for rural freeways in this text = 12% for urban freeways in this text** D = traffic, percent, in direction of heaviest travel during peak hours-about 50% to 75% = 67% for rural freeways in this text = 60% for urban freeways in this text IOOP x - 5000N 100 + T,hO- 1) KD where P = passenger cars* per lane per hour (from Table D l ) N = number of lanes-total both directions Tph = trucks, percent, during peak hours = 213 ADTT in this booklet *See footnote a t b o t t o m o f Table D l . **See Reference 54, pages 96 t o 98, and Reference 56 Detailed discussions of this formula will be found in References 53, 54, and 55. As presented here, the symbol for one term, T, of the formula, Tph,differs from the symbol for this term in the references. In this text: T = trucks-includes only single units with more than four tires and all combinations. (Does not include panels, pickups, and other single units with only four tires.) ADTT = average daily truck traffic in both directions-may be expressed as a percentage of ADT or as an actual value. Capacity of Two-Lane Highways Important factors in the design capacity of two-lane highways are ( I ) the percent of total project length where sight distance is less than 1500 ft, and (2) lane widths of less than 12 ft.* The design capacity in vehicles per hour (vph) for uninterrupted flow on two-lane highways is shown in Table D2. It is good practice t o use both traffic projection factors and design capacity for thickness design of specific projects. For example, if a n existing two-lane route is carrying 4000 A D T and the projection factor is 2.7, the projected A D T would be 10,800. This is more than 4000 vehicles per day (vpd) greater than the design capacity of virtually all two-lane highways.** On the other hand, 10,800 A D T is below the design capacity of most fourlane highways.7 Hence, the design should be made for 10,800 A D T on a four-lane roadway. Design capacity should not be used where it shows a greater A D T than shown by traffic projection. *Lane widths of less than 12 ft are rarely used in current practice, except for very lightly traveled two-lane roads where Land service is a primary function. **See Table D2. tSee Reference 53, Table 11-14, Table D2. Design Capacities for Uninterrupted Flow on Two-Lane Highways* Terrain Level Design capac~ty,both directions. In vph" where: L = lane w ~ d t hin feet Tph =trucks, %. ~npeak h o u r t Al~gnment, percent of total project length with s ~ g h td~stance of less than 1500 ft 0 10 20 0 10 20 0 10 20 0 20 40 900 860 800 780 750 700 690 660 620 770 740 690 670 640 600 600 570 530 690 660 620 600 580 540 530 510 480 L = 11 L = 12 Tph ' L Tph ' = 10 Tph 'Source Reference 53. Table 1 1 10 page 88 "Tabular values apply where lateral clearance 1s not restr~cted Where clearance apply factors In Reference 53 Table 11-11 page 89 t Trucks does not ~ n c l u d ef c u r - t ~ r eveh~cles IS less than 6 ft ' APPENDIX E References I. Westergaard, H. M., "Computation of Stresses in Concrete Roads," Highway Research Board Proceedings, Fifth Annual Meeting. 1925, Part I, pages 90 to 112. 2. Westergaard, H. M., "Stresses in Concrete Pavements Computed by Theoretical Analysis," Public Roads, Vol. 7, No. 2, April 1926, pages 25 to 35. 3. Westergaard, H. M., "Analysis of Stresses in Concrete Roads Caused by Variations in Temperature," Public Roads, Vol. 8, No. 3, May 1927, pages 201 to 215. 4. Westergaard, H. M., "Theory of Concrete Pavement Design," Highway Research Board Proceedings, Seventh Annual Meeting, 1927, Part I, pages 175 to 181. 5. Westergaard, H. M., "Analytical Tools for Judging Results of Structural Tests of Concrete Pavements," Public Roads, Vol. 14, No. 10, December 1933, pages 185 to 188. 6. Pickett, Gerald; Raville, Milion E.; Jones, WilliamC.; and McCormick, Frank J., "Deflections, Moments and Reactive Pressures for Concrete Pavements," Kansas State College Bulletin No. 65, October 1951. 7. Pickett, Gerald, and Ray, Gordon K., "Influence Charts for Concrete Pavements," American Society of Civil Engineers Transactions, Paper No. 2425, Vol. 116, 1951, pages 49 to 73. 8. Tayabji, S. D., and Colley, B. E., "Analysis of Jointed Concrete Pavements," report prepared by the Construction Technology Laboratories of the Portland Cement Association for the Federal Highway Administration, October 1981. 9. Teller, L. W., and Sutherland, E. C., "The Structural Design of Concrete Pavements," Public Roads, Vol. 16, Nos. 8, 9, and 10 (1935); Vol. 17, Nos. 7 and 8 (1936); Vol. 23, No. 8 (1943). 10. Childs, L. D., Colley, B. E., and Kapernick, J. W., "Tests to Evaluate Concrete Pavement Subbases," Proceedings of American Society of Civil Engineers, Paper No. 1297, Vol. 83 (HW-3), July 1957, pages I to 41;. also PCA Development Department Bulletin DXOI I. 11. Childs, L. D., and Kapernick, J . W., "Tests of Concrete Pavement Slabs on Gravel Subbases," Proceedings of American Society of Civil Engineers, Vol. 84 (HW-3), October 1958; also PCA Development Department Bulletin DX021. 12. Childs, L. D., and Kapernick, J. W., "Tests of Concrete Pavements on Crushed Stone Subbases," Proceedings of American Society of Civil Engineers, Proc. Paper No. 3497, Vol. 89 (HW-I), April 1963, pages 57 to 80; also PCA Development Department Bulletin DX065. 13. Childs, L. D., "Tests of Concrete Pavement Slabs on Cement-Treated Subbases," Highway Research Record 60, Highway Research Board, 1963, pages 39 to 58; also PCA Development Department Bulletin DX086. 14. Childs, L. D., "Cement-Treated Subbases for Concrete Pavements," Highway Research Record 189, Highway Research Board, 1967, pages 19 to 43; also PCA Development Department Bulletin DX 125. 15. Childs, L. D., and Nussbaum, P. J., "Repetitive Load Tests of Concrete Slabs on Cement-Treated Subbases," RD025P, Portland Cement Association, 1975. 16. Tayabji, S. D., and Colley, B. E., "Improved Rigid Pavement Joints," paper presented at Annual Meeting of Transportation Research Board, January 1983 (to be published in 1984). 17. Childs, L. D., and Ball, C. G., "Tests of Joints for Concrete Pavements," RD026P, Portland Cement Association, 1975. 18. Colley, B. E., and Humphrey, H. A., "Aggregate Interlock at Joints in Concrete Pavements," Highway Research Board Record No. 189, Transportation Research Board, 1967, pages 1 to 18. 19. Colley, B. E., Ball, C. G., and Arriyavat, P., "Evaluation of Concrete Pavements with Tied Shoulders or Widened Lanes," Transportalion Research Record 666, Transportation Research Board, 1978; also Port- land Cement Association, Research and Development Bulletin RD065P, 1980. 20. Sawan, J. S., Darter, M. I., and Dempsey, B. J., "Structural Analysis and Design of PCC Shoulders," Report No. FHWA-RD-81-122, Federal Highway Administration, April 1982. 21. Older, Clifford, "Highway Research in Illinois," Proceedings of American Society of Civil Engineers, February 1924, pages 175 to 217. 22. Aldrich, Lloyd, and Leonard, Ino B., "Report of Highway Research at Pittsburg, California, 19211922," California State Printing Office. 23. Road Test One-MD, Highway Research Board Special Report No. 4, 1952. 24. The AASHO Road Test, Highway Research Board Special Report No. 6 1 E, 1962. 25. The AASHO Road Test, Highway Research Board Special Report No. 73, 1962. 26. AASHTO Interim Guide for Design of Pavement Structures, 1972, Chapter 111 Revised, 1981, American Association of State Highway and Transportation Officials, 1981. 27. Fordyce, Phil, and Teske, W. E., "Some Relationships of the AASHO Road Test to Concrete Pavement Design," Highway Research Board Record No. 44, 1963, pages 35 to 70. 28. Brokaw, M. P., "Effect of Serviceability and Roughness at Transverse Joints on Performance and Design of Plain Concrete Pavement," Highway Research Board Record 471, Transportation Research Board, 1973. 29. Packard, R. G., "Design Considerations For Control of Joint Faulting of Undoweled Pavements," Proceedings of International Conference on Concrete Pavement Design, Purdue University, February 1977. 30. Packard, R. G . , and Tayabji, S. D., "Mechanistic Design of Concrete Pavements to Control Joint Faulting and Subbase Erosion," International Seminar on Drainage and Erodability at the Concrete Slab-Subbase-Shoulder Interfaces, Paris, France, March 1983. 3 1. Standard Method for Nonrepetitive Static Plate Load Tests of Soils and Flexible Pavement Components, for Use in Evaluation and Design of Airport and Highway Pavements, American Society for Testing and Materials, Designation D 1 196. 32. "Rigid Airfield Pavements," Corps of Engineers, U.S. Army Manual, EM 1 1 10-45-303, Feb. 3, 1958. 33. Burmister, D. M., "The Theory of Stresses and Displacements in Layered Systems and Applications to Design of Airport Runways," Highway Research Board Proceedings, Vol. 23, 1943, pages 126 to 148. 34. Standard Methods for Freezing-and-Thawing Tests of Compacted Soil-Cement Mixtures, American Society for Testing and Materials, Designation D560. 35. Standard Methods for Wetting-and-Drying Tests of Compacted Soil-Cement Mixtures, American Society for Testing and Materials, Designation D559. 36. Soil-Cement Laboratory Handbook, Portland Cement Association publication EB052S, 1971. 37. "National Truck Characteristic Report, 1975-1979," U.S. Department of Transportation, Federal Highway Administration, Washington, D.C., June 1981. 38. Becker, J. M., Darter, M. I., Snyder, M. B., and Smith, R. E., "COPES Data Collection ProceduresAppendix A," June 1983, Appendix to final report of National Cooperative Highway Research Program, Project 1-19, Concrete Pavement Evaluation System, draft submitted to Transportation Research Board. 39. Load Stress at Pavement Edge, Portland Cement Association publication IS030P, 1969. 40. Taragin, Asriel, "Lateral Placement of Trucks on Two-Lane and Four-Lane Divided Highways," Public Roads, Vol. 30, No. 3, August 1958, pages 7 1 to 75. 41. Emery, D. K., Jr., "Paved Shoulder Encroachment and Transverse Lane Displacement for Design Trucks on Rural Freeways," a report presented to the Committee on Shoulder Design, Transportation Research Board, January 13, 1975. 42. "Vehicle Shoulder Encroachment and Lateral Placement Study," Federal Highway Administration Report No. FH WA/ MN-8016, Minnesota Department of Transportation, Research and Development Office, July 1980. 43. Darter, M. I., "Structural Design for Heavily Trafficked Plain-Jointed Concrete Pavement Based on Serviceability Performance," T R R 671, Analysis of Pavement Systems, Transportation Research Board, 1978, pages 1 to 8. 44. Thickness Design for Concrete Pavements, Portland Cement Association publication ISOIOP, 1974. 45. Kesler, Clyde E., "Fatigue and Fracture of Concrete," Stanton Walker Lecture Series of the Materials Sciences, National Sand and Gravel Association and National Ready Mixed Concrete Association, 1970. 46. Fordyce, Phil, and Yrjanson, W. A,, "Modern Design of Concrete Pavements," American Society of Civil Engineers, Transportation Engineering Journal, Vol. 95, No. TE3, Proceedings Paper 6726, August 1969, pages 407 to 438. 47. Ballinger, Craig A., "The Cumulative Fatigue Damage Characteristics of Plain Concrete," Highway Research Record 370, Highway Research Board, 197 1, pages 48 to 60. 48. Miner, M. A,, "Cumulative Damage in Fatigue," American Society of Mechanical Engineers Transactions, Vol. 67, 1945, page A 159. 49. Klaiber, F. W., Thomas, T. L., and Lee, D. Y., "Fatigue Behavior of Air-Entrained Concrete: Phase 11," Engineering Research Institute, Iowa State University, February 1979. 50. Packard, R. G., "Structural Design of Concrete Pavements with Lean Concrete Lower Course," Proceedings of Second International Conference on Concrete Pavement Design, Purdue University, April 198 1. 51. Yrjanson, W. A., and Packard, R. G., "Econocrete Pavements-Current Practices," Transportation Research Record 741, Performance of Pavements Designed with Low-Cost Materials, Transportation Research Board, 1980, pages 6 to 13. 52. Ruth, B. E., and Larsen, T. J., "Save Money with Econocrete Pavement Systems," Concrete International, American Concrete Institute, May 1983. 53. A Policy on Geometric Design of Rural Highways, American Association of State Highway Officials, Washington, D.C., 1954. 54. A Policy on Arterial Highways in Urban Areas, American Association of State Highway Officials, Washington, D.C., 1957. 55. Highway Capacity Manual, Bureau of Public Roads, U.S. Department of Commerce, Washington, D.C., 1966. 56. Schuster, J. J., and Michael, H. L., "Vehicular Trip Estimation in Urban Areas," Engineering Bulletin of Purdue University, Vol. XLVIII, No. 4, July 1964, pages 67 to 92. 57. Packard, R. G., and Tayabji, S. D., "New PCA Thickness Design Procedure for Concrete Highway and Street Pavements," Proceedings of Third International Conference on Concrete Pavement Design and Rehabilitation, Purdue University, April 1985. Calculation of Pavement Thickness Project T r ~ ath~ckness l ~n. Doweled jo~nts: yes no Subbase-subgrade k PC1 Concrete shoulder. yes no Modulus of rupture. MR PSI Design penod years Load safety factor. LSF Fat~gueanalys~s Axle load, klps Mult~pl~ed by LSF 1 2 Expected repetitlons Allowable repetitions 4 3 Eros~onanalys~s Fat~gue. percent 5 8. Equ~valentstress Allowable repetlt~ons Damage. percent 6 7 10. Eros~onfactor 9. Stress ratlo factor Single Axles 11. Equwalent stress 13. Eros~onfactor 12. Stress ratlo factor Tandem Axles I Total I Total I \ I Microcomputer Program for Thickness Design of Concrete Highways, Streets, and Parking Lots PCAPAV-the low-cost software for concrete pavement design PCAPAVs easy-to-use, menu-driven routine offers High-speed solutions to pavement thickness design problems Pavement fatigue and subbase erosion calculations Comprehensive theory Realistic design criteria The computer program design procedures, based on this manual and verified by performance, consider !oad transfer at transverse and longitudinal joints (doweled or undoweled), concrete shoulders, curbs and gutters, and adjacent parking-lot lanes. Traffic load considerations are simplified. Any designer can choose a stored traffic load category to fit the situation. Or available traffic load data can be input. The software runs on IBM personal computers and compatibles (128K, DOS 2.0 or later), and the package includes a floppy diskette, the user's manual, and this design manual, Thickness Design for Concrete Highway and Street Pavements. To order PCAPAV (MCOO3),contact the Portland Cement Association, Order Processing Department, 5420 Old Orchard Road, Skokie, IL 60077-1083, (800)868-6733 PORTLAND CEMENT ASSOCIATION An organmation of cement manufadurento improve and extend the user of portland cement and concrete through market development, eng~neerlng,research. education, and public aifdlrs work. / 5420 Old Orchard Road, Skok~e,lll~no~s 60077-1083 Printed in U.S.A. EB109.01P