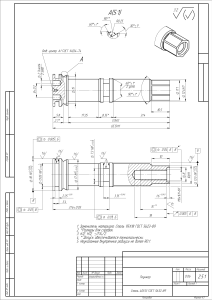

Òåðìîêëååâàÿ ìàøèíà Y ROL G CONT ERUN URE GULI N ERAT URRE LATIO URE G TEMP ERAT REGU ERAT E URIN TEMP COLL URST GLUE TEMP LEIM RATU EMPE LIJMT GENC EMER STOP TOP T E NOTS ARRE GENC P D'UR DSTO NOO ÐOPERATOR ó ê î âîä ñ ò âî Ïîëüçîâàòåëÿ MANUAL Èçäàíî: 12/00 Initial issue: 12/00 Ïîñëåäíÿÿ ðåäàêöèÿ: 11/01 Latest revision :11/01 9.133.459 Ïåðåâåäåíî: Ñ. Ëàçóòêèí. ÇÀÎ “Êîìëàéí Òðåéä” Ìîñêâà, 2003 ã. Ñîäåðæèìîå äàííîé äîêóìåíòàöèè ÿâëÿåòñÿ èñêëþ÷èòåëüíîé ñîáñòâåííîñòüþ êîìïàíèè P. documentation Bourg SA è ïðåäîñòàâëåíî êîíå÷íîìó ïîëüçîâàòåëþ â öåëÿõ Content ofC. this remains the exclusive property of C.P. Bourg SA åãîthe êîððåêòíîé ðàáîòû è ïðàâèëüíîãî îáñëóæèâàíèÿ andîáåñïå÷åíèÿ it is only put at user (including without limitation: Renter or Purchaser îáîðóäîâàíèÿ, ïîñòàâëÿåìîãî Êîìïàíèåé. Âñå ïðàâà çàùèùåíû. or their employees) disposal within the exclusive scope of using and servicing Êîïèðîâàíèå, ïåðåïå÷àòêà ëèáî èçìåíåíèå íàñòîÿùåãî òåêñòà áåç the product. Without C.P. Bourg SA prior agreement in writing, reproductions ðàçðåøåíèÿ as êîìïàíèè - ïðàâîîáëàäàòåëÿ ÇÀÏÐÅÙÅÍÛ. well as changes are prohibited. Ðóêîâîäñòâî ïîëüçîâàòåëÿ Ñòðàíèöà 2 Ïåðåâåäåíî: Ñ. Ëàçóòêèí. ÇÀÎ “Êîìëàéí Òðåéä” Ìîñêâà, 2003 ã. Ñîäåðæàíèå TABLE OF CONTENTS 1. Ââåäåíèå ........................................................................................................................... 1.1.1Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 Ïðåäèñëîâèå ......................................................................................................... 1.1 Forewordòåõíèêè . . . . . .áåçîïàñíîñòè . . . . . . . . . . ....................................................................... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 1.2 Òðåáîâàíèÿ 1.2 Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 1.3 Ïðåäóïðåæäàþùèå çíàêè ..................................................................................... 1.3 Safety labels . . . . . . . . . èñïîëüçîâàíèÿ . . . . . . . . . . . . ....................................................... . . . . . . . . . . . . . . . . . . . . . . . .6 1.4 Èíñòðóêöèÿ äëÿ áåçîïàñíîãî 1.4 Instructions for safe use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 1.5 Äàííûå ïî ÒÁ ........................................................................................................ 1.5 Safety data sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11 5 5 5 6 9 11 2. Îïèñàíèå óñòðîéñòâà ...................................................................................................... 2. System description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12 2.1 Ñïåöèôèêàöèÿ ....................................................................................................... 2.1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12 2.2 Îáùåå .................................................................................................................... 2.2 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13 2.3 Êîíòðîëüíàÿ ïàíåëü ............................................................................................. 2.3 Control Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14 2.4 Êîíòðîëüíàÿ ïàíåëü - ìåíþ è ñèñòåìíûå ñîîáùåíèÿ ...................................... 2.4 Control panel menus and messages . . . . . . . . . . . . . . . . . . . . . . . . . . . .15 2.5 Èçìåíåíèå ïàðàìåòðîâ ñêëåéêè ......................................................................... 2.5 Change of binding parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16 2.6 Èñïîëüçîâàíèå ðåëå âðåìåíè (äîïîëíèòåëüíàÿ îïöèÿ) ................................... 2.6 Instructions for timer use (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18 2.7 Ñòîë ïîäà÷è îáëîæåê ........................................................................................... 2.7 Cover station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21 2.8 Ðåãóëèðîâêà ãëóáèíû ôðåçåðîâàíèÿ .................................................................. 2.8 Milling depth adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27 2.9 Ñêëåèâàíèå ........................................................................................................... 2.9 Glue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29 2.10 Óñòàíîâêà ïàðàìåòðîâ òåðìîêëååâîé ìàøèíû ............................................... 2.10 To set up the Binder module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31 2.11 Âûâîäíîé ìîäóëü (äîïîëíèòåëüíàÿ îïöèÿ) ..................................................... 2.11 Output unit (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32 2.12 Íà÷àëî ðàáîòû ................................................................................................... 2.12 Binding condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33 2.13 Îïèñàíèå êëååâîãî öèêëà .................................................................................. 2.13 Cycle description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34 12 12 13 14 15 16 18 21 27 29 31 32 33 34 3. Îáñëóæèâàíèå .................................................................................................................. 3. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35 3.1 Ïåðèîäè÷åñêîå îáñëóæèâàíèå. ............................................................................. 3.1 Preventive maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35 3.2 Çàìåíà ìåøêà äëÿ ñáîðà ïûëè .......................................................................... 3.2 Paper dust bag replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36 35 35 36 4. Mechanical troubleè shooting . . .................................................................. . . . . . . . . . . . . . . . . . . . . . . . .37 4. Ìåõàíè÷åñêèå íåïîëàäêè èõ óñòðàíåíèå 37 5. Someðàñïðîñòðàíåííûå common glueingäåôåêòû defects ñêëåéêè . . . . . ...................................................... . . . . . . . . . . . . . . . . . . .38 5. Íåêîòîðûå 38 Ðóêîâîäñòâî ïîëüçîâàòåëÿ Ñòðàíèöà 3 Ïåðåâåäåíî: Ñ. Ëàçóòêèí. ÇÀÎ “Êîìëàéí Òðåéä” Ìîñêâà, 2003 ã. Cette page est intentionnellement vide. This page is intentionallyîñòàâëåíà left blank. Äàííàÿ ñòðàíèöà Deze blad is opzettelijk in het wit gebleven. Diese ïóñòîé Seite wurdeñïåöèàëüíî absichtlich leer gelassen. Ðóêîâîäñòâî ïîëüçîâàòåëÿ Ñòðàíèöà 4 Ïåðåâåäåíî: Ñ. Ëàçóòêèí. ÇÀÎ “Êîìëàéí Òðåéä” Ìîñêâà, 2003 ã. Ââåäåíèå 1. 1. INTRODUCTION 1.1 1.1 Ïðåäèñëîâèå Foreword Thank youçàfor choosing a BOURG product.Ñ. P. Bourg. Ñïàñèáî âûáîð ïðîäóêöèè êîìïàíèè Òåðìîêëååâàÿ ìàøèíà BOURG BINDER 3001 îòëè÷íàÿ ìàøèíà äëÿ ñêëåèâàíèÿ áóêëåòîâ. The BOURG BINDER 3001 is a perfect binder destined for the off line production of bound booklets. Äàííîå èçäàíèå ÿâëÿåòñÿ èíñòðóêöèåé ïî èñïîëüçîâàíèþ òåðìîêëååâîé ìàøèíû BOURG BINDER 3001. This manual is a guide to operate the BOURG BINDER 3001. Àêêóðàòíî ñëåäóéòå óêàçàíèÿì äàííîé èíñòðóêöèè è Âàøà òåðìîêëååâàÿ ìàøèíà áóäåò ñëóæèòü Âàì äîëãèå ãîäû. Follow the instructions carefully and you should obtain years of excellent service from your Finishing on Demand system. Åñëè Âû èñïûòûâàåòå êàêèå-ëèáî òðóäíîñòè ïðè èñïîëüçîâàíèè ìàøèíû, ïîæàëóéñòà, ïîçâîíèòå â ñëóæáó òåõíè÷åñêîé ïîääåðæêè C. P. Bourg (òåëåôîííûå íîìåðà óêàçàíû íà ïîñëåäíåé ñòðàíèöå äàííîãî ðóêîâîäñòâà). Ìû ïîñòàðàåìñÿ ïîìî÷ü Âàì. If you have any difficulty using your equipment, please call us and ask for technical assistance (phone numbers are listed on the last page). We will be delighted to help you. 1.2 Òðåáîâàíèÿ òåõíèêè áåçîïàñíîñòè. 1.2 Safety information Ìû ñ "Èíñòðóêöèåé èñïîëüçîâàíèÿ" ïðåæäå, ÷åì You ðåêîìåíäóåì are advised to îçíàêîìèòüñÿ read the "Instructions for a safeäëÿ use"áåçîïàñíîãî before you start to actually use the Âû íà÷íåòå ïîëüçîâàòüñÿ òåðìîêëååâîé ìàøèíîé. device. Òåõíè÷åñêàÿ èíôîðìàöèÿ òåõíèêå áåçîïàñíîñòè â ïóíêòå, îáîçíà÷åííîì, êàê Technical safety informationïî such as safety data sheet ñîäåðæèòñÿ can also be found. "Äàííûå ïî ÒÁ". Where applicable, cautions and warnings are used to draw your attention to safety precautions  ìåñòàõ íà ìàøèíå ïðèêëååíû ïðåäóïðåæäàþùèå òàáëè÷êè, åñëè Âû âèäèòå to íåîáõîäèìûõ be taken. òàêóþ òàáëè÷êó, ýòî çíà÷èò, ÷òî ïðè ðàáîòå â ýòèõ ìåñòàõ îò îïåðàòîðà òðåáóåòñÿ ïîâûøåííîå âíèìàíèå. All information in this publication is based on the latest information available at the time of approval for printing. Âñÿ èíôîðìàöèÿ, ñîäåðæàùàÿñÿ â äàííîì Ðóêîâîäñòâå, ÿâëÿåòñÿ ñàìîé ñâåæåé èíôîðìàöèåé, íà this äàííûé ìîìåíò. We reserve the äîñòóïíîé right to revise publication and to make changes in the content without obligation to notify any person of such revisions or changes. Ìû îñòàâëÿåì çà ñîáîé ïðàâî âíåñòè èçìåíåíèÿ â äàííóþ äîêóìåíòàöèþ áåç ïðåäâàðèòåëüíîãî óâåäîìëåíèÿ êîíå÷íûõ ïîëüçîâàòåëåé. Ðóêîâîäñòâî ïîëüçîâàòåëÿ Ñòðàíèöà 5 Ïåðåâåäåíî: Ñ. Ëàçóòêèí. ÇÀÎ “Êîìëàéí Òðåéä” Ìîñêâà, 2003 ã. 1.3 òàáëè÷êè. 1.3Ïðåäóïðåæäàþùèå Safety labels Please pay particular attention to the description of the following pictograms: Ïîæàëóéñòà, îáðàòèòå âíèìàíèå íà îïèñàíèå ñëåäóþùèõ ïðåäóïðåæäàþùèõ òàáëè÷åê: Âíèìàíèå: òàáëè÷êè íà æåëòîì ôîíå ãîâîðÿò î âîçìîæíîì âîçíèêíîâåíèè îïàñíîé Caution:Ïðåäóïðåæäàþùèå on a yellow background, ñèòóàöèè, êîòîðàÿ ìîæåò ïðèâåñòè ê íåáîëüøîìó èëè ñåðüåçíîìó âðåäó äëÿ çäîðîâüÿ îïåðàòîðà. indicates a hazardous situation that can cause small or severe injury. Ïðåäóïðåæäåíèå: òàáëè÷êè îðàíæåâîì ôîíå ãîâîðÿò î âîçìîæíîì âîçíèêíîâåíèè Warning: on aÏðåäóïðåæäàþùèå orange background isíà used to indicate a hazardous situation which îïàñíîé ñèòóàöèè, êîòîðàÿ ìîæåò ïðèâåñòè ê ñìåðòè îïåðàòîðà èëè íàíåñåíèþ ñåðüåçíîãî óùåðáà äëÿ has some probability of death or severe injury. Warning should not be åãî çäîðîâüÿ. Ïðè ñîáëþäåíèè îïåðàòîðîì âñåõ òðåáîâàíèé ïî òåõíèêå áåçîïàñíîñòè, îïàñíàÿ ñèòóàöèÿ for property damaged accidents unless personal injury risk is âîçíèêíóòü íåconsidered ìîæåò. present. Îïàñíîñòü: òàáëè÷êè íà êðàñíîì ôîíåañèãíàëèçèðóþò âåðîÿòíîñòè Danger:Ïðåäóïðåæäàþùèå on a red background:indicates hazardousî âûñîêîé situation with aâîçíèêíîâåíèÿ high risk of îïàñíîé ñèòóàöèè, êîòîðàÿ ìîæåò ïðèâåñòè ê ñìåðòè îïåðàòîðà èëè íàíåñåíèþ ñåðüåçíîãî óùåðáà äëÿ åãî çäîðîâüÿ. death or severe injury. The ‘danger’ sign does apply to accidents Ïðè ñîáëþäåíèè îïåðàòîðîì âñåõ òðåáîâàíèé ïî òåõíèêå áåçîïàñíîñòè, îïàñíàÿnot ñèòóàöèÿ âîçíèêíóòü íå ìîæåò.cau- sing material damage, unless they can cause personal injury. Äëÿ àâàðèéíîãî íåìåäëåííîãî âûêëþ÷åíèÿ òåðìîêëååâîé ìàøèíû ñëóæèò àâàðèéíûé An Emergency(áîëüøàÿ stop on the control panel can be pressed to disableíà the binder. âûêëþ÷àòåëü êíîïêà êðàñíîãî öâåòà) ðàñïîëîæåííàÿ êîíòðîëüíîé ïàíåëè ìàøèíû. Îïàñíàÿ çîíà. Áóäüòå âíèìàòåëüíû ñ ðóêàìè. Dangerous area. Keep hands clear ! WARNING KEEP HANDS CLEAR CAN CAUSE SEVERE INJURY Ãîðÿ÷èé êëåé. Îïàñíîñòü îæîãà. Hot glue. Burn hazard Ðóêîâîäñòâî ïîëüçîâàòåëÿ Ñòðàíèöà 6 Ïåðåâåäåíî: Ñ. Ëàçóòêèí. ÇÀÎ “Êîìëàéí Òðåéä” Ìîñêâà, 2003 ã. Íà Onâåðõíåé the Top êðûøêå: Cover ® MODEL : BB3001 SER. N° : 3P+PE 60 Hz 208 / 220 / 230 / 240 V 20 A LISTED I.T.E. E125337 3P+PE 50 Hz 220 / 230 / 240 V 20 A 3P+N+PE 50 Hz 380 / 400 / 415 V 20 A geprüfte Sicherheit Refer to specifications in Installation Manual. GLUE TEMPERATURE CONTROL c p bourg S.A. LEIMTEMPERATURREGULIERUNG MADE IN BELGIUM BY . . B-1340 Ottignies - rue des Technologies, 22 Tel : +32 / 10 / 62 22 11 Fax : +32 / 10 / 61 36 38 REGULATION TEMPERATURE COLLE 9139560 LIJMTEMPERATUURSTURING Âíóòðè òåðìîêëååâîé ìàøèíû: Inside the Binder WARNING KEEP HANDS CLEAR CAN CAUSE SEVERE INJURY TAG Factory wired for / Verdrahtet für Cablé pour: 380 / 400 / 415 V 220 / 230 / 240 V 208 / 220 / 230 / 240 V Υ ∆ ∆ 50 Hz 50 Hz 60 Hz GB To connect to different networks, rewiring according to service manual is compulsary. Caution: wiring errors can result in heavy damage and void the guarantee. D Für Anschluss an andere Netzspannung, Verdrahtung wie in Installationsanweisung ändern. Wichtig: Falscher Anschluss kann schwere Schäden verursachen und die Garantie ausschliessen. F Pour des réseaux différents, il y a lieu de modifier le raccordement comme indiqué dans le manuel d'installation. Attention: un raccordement erroné peut entraîner des dommages graves que la garantie ne couvre pas 9.139.158 Ðóêîâîäñòâî ïîëüçîâàòåëÿ Ñòðàíèöà 7 Ïåðåâåäåíî: Ñ. Ëàçóòêèí. ÇÀÎ “Êîìëàéí Òðåéä” Ìîñêâà, 2003 ã. High leakage current earth connection essential before connecting supply 9.139.163 Íà áëîêå ïèòàíèÿ: In the Power Rack Courant de fuite élevé Raccordement à la terre indispensable avant le raccordement au réseau Ðàçúåì ïîäêëþ÷åíèÿ çàçåìëåíèÿ: Main Ground Pictogram E P L3 L2 1 L N Ðàçúåì ïîäêëþ÷åíèÿ Power supply ýëåêòðîïèòàíèÿ connection Íà çàäíåé ïàíåëè (âíóòðè): On the back (inside) GB WARNING D WARNUNG F ATTENTION S E E I N S T A L L A T I O N I N S T RS UI ECHT EI OI N S T A L L A T I O N S A N VL OE I R T UI N N SG T R U C T I O N S D E M O N T A G E B E F O R E C O N N E C T I N G T O V TOHRE AS NU SP CP HL LY U S S A N S S TARV OA M N N T ER TAZC C O ER SDEEAMU E N T A U R LORS DU RACCORDEMENT A UN BEIM ANSCHLUSS DER MASCHINE ANS WHEN WIRING THE BINDER TO A RESEAU 380v ou 415v Y LES 5 380v oder 415v Y NETZ MÜSSEN 380v or 415v Y NETWORK ALL CONDUCTEURS DOIVENT ETRE UNBEDINGT ALLE 5 ADERN OF THE 5 WIRES MUST BE RACCORDES. ANGESCHLOSSEN WERDEN. CONNECTED. WENN DIE NEUTRALE ADER NICHT UN RACCORDEMENT ERRONE THE OMISSION OF THE NEUTRAL ANGESCHLOSSEN WIRD, ENTSTEHEN ENTRAINERAIT DES DOMMAGES " WILL RESULT IN HEAVY DAMMAGE SCHWERWIEGENDE SCHADEN UND IMPORTANTS QUE LA GARANTIE " AND BREACH OF WARANTY DIE GARANTIE FALLT. NE COUVRE PAS. " (BEWARE OF EXTENSION CORDS) (ACHTUNG BEI VERLANGERUNGSSCHNUR) (MEFIEZ- VOUS DES CORDONS PROLONGATEURS) Ðóêîâîäñòâî ïîëüçîâàòåëÿ Ñòðàíèöà 8 Ïåðåâåäåíî: Ñ. Ëàçóòêèí. ÇÀÎ “Êîìëàéí Òðåéä” Ìîñêâà, 2003 ã. 1.4 Èíñòðóêöèÿ äëÿ áåçîïàñíîãî èñïîëüçîâàíèÿ Ïðîäóêöèÿ êîìïàíèè C. P. safe Bourguse ïðîòåñòèðîâàíà â ñîîòâåòñòâèè ñ èíòåðíàöèîíàëüíûìè 1.4 Instructions for òðåáîâàíèÿìè ïî òåõíèêå áåçîïàñíîñòè. Äëÿ áåçîïàñíîãî èñïîëüçîâàíèÿ òåðìîêëååâîé ìàøèíû Bourg products haveïðàâèëàì: been tested in accordance with the strictest international safety stanñëåäóéòå ñëåäóþùèì dards. To help assure safety it is important that you observe the following rules: Ïîäêëþ÷åíèå: Connection: = Íå ïåðåìåùàéòå ñàìîñòîÿòåëüíî, äëÿ ýòîãî ñâÿæèòåñü ñî ñëóæáîé ñåðâèñíîé • Do not move theìàøèíó machine yourself, but contact our Customer Service. ïîääåðæêè. • For equipment connected via a fixed connection to the network. The cable connection to the = Âñåinterface ñîåäèíèòåëüíûå äîëæíû áûòü ëåãêî äîñòóïíû äëÿ òåõíè÷åñêîãî ïåðñîíàëà. box shouldêàáåëè be easily accessible. = Íå óñòàíàâëèâàéòå òåðìîêëååâóþ ìàøèíó â î÷åíü ìàëåíüêèå ïîìåùåíèÿ, ëèáî â See ïîìåùåíèÿ • Do not place the machine in rooms which are too small and insufficiently ventilated. íå îáîðóäîâàíûå ñèñòåìîé âåíòèëÿöèè. Ñâåðüòåñü about ñ Äàííûìè ÒÁventilation äëÿ óòî÷íåíèÿ safety data sheet in this appendix for information space ïî and requirements. õàðàêòåðèñòèê òðåáóåìîãî ïîìåùåíèÿ è âåíòèëÿöèè. Surroundings: Îêðóæàþùàÿ ñðåäà: • Do not block the ventilation openings of the machine. • Ensure that the machine is placed on a level, horizontal surface of sufficient strenght. See = Íåmachine çàêðûâàéòå âåíòèëÿöèîííûå îòâåðñòèÿ â the êîðïóñå ìàøèíû. specifications for information about weight of the equipment. = Óáåäèòåñü, ÷òî òåðìîêëååâàÿ ìàøèíà ðàñïîëîæåíà íà ãîðèçîíòàëüíîé ïîâåðõíîñòè, äîñòàòî÷íîãî ðàçìåðà. Ñìîòðèòå ñïåöèôèêàöèþ íà òåðìîêëååâóþ ìàøèíó, äëÿ óòî÷íåíèÿ âåñà Maintenance: îáîðóäîâàíèÿ. • Do not remove any screws from fixed panels. • Do not carry out maintenance activities except for the parts and maintenance materials menÎáñëóæèâàíèå: tioned in this manual. • not place any liquids on ñthe machine. = ÍåDo óäàëÿéòå íèêàêèõ âèíòîâ çàôèêñèðîâàíûõ ïàíåëåé • To avoid the risk of introducing hazards, all modifications to òåðìîêëååâîé Bourg equipment are = Íå ïðîèçâîäèòå îáñëóæèâàíèÿ íèêàêèõ ÷àñòåé è óñòðîéñòâ ìàøèíû çà strictly reserved to properly qualified and trained service technicians. èñêëþ÷åíèåì ñïåöèàëüíî óêàçàííûõ â äàííîé èíñòðóêöèè. = Íå íàíîñèòå íèêàêèõ ñìàçî÷íûõ ìàòåðèàëîâ íà óçëû ìàøèíû. = Äëÿ óìåíüøåíèÿ ðèñêà íàíåñåíèÿ âðåäà çäîðîâüþ, âñå îïåðàöèè ïî ðåìîíòó ìàøèíû äîëæíû ïðîèçâîäèòñÿ êâàëèôèöèðîâàííûì, ñïåöèàëüíî ïîäãîòîâëåííûì ñåðâèñíûì ïåðñîíàëîì. Ðóêîâîäñòâî ïîëüçîâàòåëÿ Ñòðàíèöà 9 Ïåðåâåäåíî: Ñ. Ëàçóòêèí. ÇÀÎ “Êîìëàéí Òðåéä” Ìîñêâà, 2003 ã. Ãëàâíîå: General: = Âñåãäà èñïîëüçóéòå ìàòåðèàëû, ðåêîìåíäîâàííûå êîìïàíèåé C. P. Bourg è ñïåöèàëüíî ðàçðàáîòàííûå èñïîëüçîâàíèÿ ñ òåðìîêëååâîé íå ðåêîìåíäîâàííûå • Always use äëÿ materials recommended by Bourg andìàøèíîé. developedÌàòåðèàëû, for the Binder. êîìïàíèåé C. P. Bourg ìîãóò âûçâàòü ïîâðåæäåíèå óñòðîéñòâà. Materials not approved by Bourg may result in machine failures. = Íå èñïîëüçóéòå çâóêè, íåõàðàêòåðíûå äëÿ íåå. Îáåñòî÷üòå • Do not use theìàøèíó, machineåñëè whenîíà it isèçäàåò emitting unusual sounds. Remove the plug from the power òåðìîêëååâóþ ìàøèíó è ñâÿæèòåñü ñî ñëóæáîé ñåðâèñíîé ïîääåðæêè. socket or switch off the fixed connection to the network, and contact your Service provider. Îïàñíàÿ çîíà. Áóäüòå Dangerous area âíèìàòåëüíû ñ ðóêàìè. keep hands clear Ãîðÿ÷èé Hot glueêëåé. Îïàñíîñòü îæîãà. burn hazard Çàìå÷àíèå: Äàííûå ñèìâîëû ïðåäíàçíà÷åíû äëÿfor Âàøåé áåçîïàñíîñòè: íå Note: These safety alert symbols are yourïåðñîíàëüíîé personal safety. NeverÍèêîãäà operate ðàáîòàéòå ñ òåðìîêëååâîé ìàøèíîé ñî ñíÿòûìè çàùèòíûìè êðûøêàìè. all safety covers in place. without Ïðåäóïðåæäåíèå: Äàííîå îáîðóäîâàíèå áûëî has ïðîòåñòèðîâàíî è ïðèçíàíî òðåáîâàíèÿì ê WARNING: This equipment been tested and found to ñîîòâåòñòâóþùèì comply with the limits for a Class A öèôðîâûì óñòðîéñòâàì êëàññà À, â ÷àñòè 15 ïðàâèë FCC. digital device, pursuant to part 15 of the FCC* Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own expense. *F.C.C. = Federal Communications Commission. Canadian Department of Communications Compliance Statement: This equipment does not exceed Class A limits per radio noise emissions for digital apparatus set out in the Radio Interference Regulation of the Canadian Departement Communications. Ðóêîâîäñòâî ïîëüçîâàòåëÿ Ñòðàíèöà 10 Ïåðåâåäåíî: Ñ. Ëàçóòêèí. ÇÀÎ “Êîìëàéí Òðåéä” Ìîñêâà, 2003 ã. 1.5 Äàííûå ïî ÒÁ Ìîäåëü: BB 3001 1.5 Safety data sheet Îïèñàíèå: Òåðìîêëååâàÿ ìàøèíà Ìàêñèìàëüíàÿ ñêîðîñòü ðàáîòû: Ìàêñèìóì 500 öèêëîâ â ÷àñ Model BB 3001 Ðàçìåðû (Äëèíà õ Øèðèíà õ Âûñîòà): 1,88ì õ 1,16ì õ 1,06ì Description Glue binder Âåñ: Max. process speed 400 êèëîãðàìì Maximum 500 cycles/hour Èñòî÷íèê ïèòàíèÿ: 208V/220V/230V/240V/3 220V/230V/240V/3 380V/400V/415V/3 N Dimensions & Weight Lenght: 1,88 m 6.17 ft ×àñòîòà: 60 Hz 50 Hz 50 Hz Width: 1,16 m (3.8 ft) (with the possibility to split machine to have 695 mm Ïîòðåáëÿåìûé òîê: 20 A 20 A 20 A (2.28 ft) width for narrow way) Ïîòðåáëÿåìàÿ ìîùíîñòü (â ïîêîå): 1500 Âò Height: 1,06 m 3.48 ft Ïîòðåáëÿåìàÿ ìîùíîñòü (âî âðåìÿ ðàáîòû): 3000 Âò Weight: 400kg 882 lbs Ïîòðåáëÿåìàÿ ìîùíîñòü (ìàêñèìàëüíàÿ): 5500 Âò Voltage 208V/220V/230V/240V/3 220V/230V/240V/3 Òèï ñèëîâîãî ïîäêëþ÷åíèÿ: Êàáåëü ñ ôèêñèðîâàííûì380V/400V/415V/3 ñîåäèíåíèåì Nè Frequency 60 Hz 50 Hz 50 ðàçäåëüíûì îòêëþ÷åíèåì Hz Current, rated 20 A 20 A 20 A Êëàññ áåçîïàñíîñòè: 1 (IEC 536) ñ çàùèòíûì çàçåìëåíèåì Power consumption, stand by 1500 W Êëàññ çàùèòû: IP 20 (IEC 529) Powerøóìà: consumption, operation 3000 W Óðîâåíü  ïîêîå Âî âðåìÿ ðàáîòû Power consumption, maximum 5500 W Ñ ìåñòà îïåðàòîðà: 55 äÁ 76 äÁ Mains Cable with fixed connection and separation switch 89/336/ÅÅÑ Çàùèòà îòconnection ýëåêòðîìàãíèòíîãî èçëó÷åíèÿ: Ñîîòâåòñòâóåò äèðåêòèâå Safety class èçëó÷åíèå: I (IEC Îòñóòñòâóåò 536) Protective earth connection Ðàäèàêòèâíîå Protection class IP 20 (IEC 3ÊÂò 529) â ÷àñ Òåïëîâîå èçëó÷åíèå: Îçîí:Sound pressure level Îòñóòñòâóåò Standby In operation Ðàçìåðû ïîìåùåíèÿ: Ðåêîìåíäîâàíî: 95 êóá. ì. (7 õ 4,5 õ 3 ì.) Operator position 55 db(A) 76 db(A) Âåíòèëÿöèÿ ïîìåùåíèÿ: Ðåêîìåíäîâàíî: ìèíèìóì 47,5 êóá. ì. â ÷àñ Radio interference Complies with Directive 89/336/EEC (åñòåññòâåííàÿ âåíòèëÿöèÿ) Radiation Not applicable Äëÿ óñòðàíåíèÿ ïàðîâ ðàçîãðåòîãî êëåÿ Radiant heat 10224 Btu/hour äîïóñòèìà óñòàíîâêà äîïîëíèòåëüíûõ Ozone emission Not applicable âåíòèëÿöèîííûõ ñèñòåì. Room volume Recommendation: 95 m3 (7 x 4,5 x 3 m) 3336 ft3 (23x14.8x9.8 ft) Êîíöåíòðàöèÿ ïûëè: 0,04 ìã. â êóáè÷åñêîì ìåòðå ïðè Room ventilation Recommendation: min. 47,5 m3/h (natural ventilation) ïðîäîëæèòåëüíîé ðàáîòå. For heat evacuation at continuous binding extra ventilation may be necessary Äîïîëíèòåëüíàÿ èíôîðìàöèÿ: 0,04 mg/m3 at continous Äëÿ operation óìåíüøåíèÿ ïðîèçâîäèìîãî øóìà, ìàøèíà Dust concentration ìîæåò áûòü3 óñòàíîâëåíà â ïîìåùåíèè (TLV for nuisance dust = 10 mg/m ) áÎëüøåì, íåæåëè ðåêîìåíäîâàííîå âûøå, â Additionnal safety information To avoid higher sound pressure levels than given above, the machine ïîìåùåíèè ìîãóò áûòü óñòàíîâëåíû ñèñòåìû should be installed in a room with at least minimum room volume (see çâóêîèçîëÿöèè. above) and favourable acoustical properties. 3P+PE 50 Hz 220 / 230 / 240 V 20 A 3P+N+PE 50 Hz 380 / 400 / 415 V 20 A ® MODEL : BB3001 SER. N° : 3P+PE 60 Hz 208 / 220 / 230 / 240 V 20 A LISTED I.T.E. E125337 geprüfte Sicherheit Refer to specifications in Installation Manual. c p bourg S.A. MADE IN BELGIUM BY . . B-1340 Ottignies - rue des Technologies, 22 Tel : +32 / 10 / 62 22 11 Fax : +32 / 10 / 61 36 38 9139560 Ðóêîâîäñòâî ïîëüçîâàòåëÿ Ñòðàíèöà 11 Ïåðåâåäåíî: Ñ. Ëàçóòêèí. ÇÀÎ “Êîìëàéí Òðåéä” Ìîñêâà, 2003 ã. 2. Îïèñàíèå óñòðîéñòâà 2. SYSTEM DESCRIPTION 2.1 2.1 Ñïåöèôèêàöèÿ Specifications Ìàêñèìàëüíûå ðàçìåðû áóêëåòà MAX. BOOK DIMENSIONS 320mm (12.6in.) 385mm (15.2in.) Max.thickness 45mm (1.8in.) Ìèíèìàëüíûå ðàçìåðû MIN. BOOK DIMENSIONS áóêëåòà • With manual reception • With automatic reception • Padding mode (without BBR - with manual reception and only by the low exit) 100mm (3.9in.) 140mm (5.5in.) 90mm (3.5in.) 100mm (3.9in.) 210mm (8.3in.) Min. thickness: 2 sheets (theorecal, with very thin cover) 75mm (2.95in.) Áóêëåò Ðàçìåðû (ìàêñ. - ìèí.): Ñìîòðè èëëþñòðàöèþ âûøå Book Òèï îáëîæêè: Ãëÿíöåâàÿ áóìàãà, ïðåäâàðèòåëüíî áèãîâàííàÿ, ñ Dimensions (max - min) See the illustration above ïðîçðà÷íîé ïåðåäíåé ÷àñòüþ è ò. ä. Cover types Glossy paper, with cutouts, with transparent front, “kromekote”, etc. Âåñ îáëîæêè: îò 80 äî 250 ãðàìì íà êâ. ìåòð (äëÿ ïëîòíîé áóìàãè Cover weight 80-250 gsm (may require creasing) 30-90 lb cover ìîæåò ïîòðåáîâàòüñÿ ïðåäâàðèòåëüíàÿ áèãîâêà). Paper weight 60-160 gsm 15-40 lb bond Âåñ áóìàãè: îò 60 äî 160 ãðàìì íà êâ. ìåòð Features Îñîáåííîñòè: Cover pile height 60 mm 2.4 in. Âûñîòà ñòîïû îáëîæåê: 60 ìì Miss detector Yes Äåòåêòîð ïðîïóùåííîé îáëîæêè: Èìååòñÿ Speed max. up to 500 cycles/hour. Ìàêñèìàëüíàÿ ñêîðîñòü ðàáîòû: äî 500 C öèêëîâ ÷àñ Glue temperature From 140° C to 165° (284°Fâ to 392°F) Òåìïåðàòóðà êëåÿ: îò 140 ãð. Ñ äî 165 ãð. Ñ Milling + notching Yes Ôðåçåðîâàíèå + òîðøîíèðîâàíèå: Èìååòñÿ Paper waste collection Yes Ñáîðêà áóìàæíîé ïûëè: Yes Èìååòñÿ Book counter Ñ÷åò÷èê áóêëåòîâ: Èìååòñÿ Start up timer optional Òàéìåð âêëþ÷åíèÿ: Ïîñòàâëÿåòñÿ îïöèîíàëüíî. Fume extractor Ñáîð èñï. êëåÿ ñ óãîëüíûì ôèëüòðîì: Ïîñòàâëÿåòñÿ îïöèîíàëüíî. with active charcoal filter optional Âûâîä èñïàðåíèé êëåÿ çà ïðåäåëû ïîìåùåíèÿ: Ïîñòàâëÿåòñÿ îïöèîíàëüíî. Outdoor fume exhaust optional Machine Ìàøèíà: Dimensions: (l x w x h) (äëèíà 1,88 õmøèðèíà x 1,16 mõ xâûñîòà): 1,06 m 1,88ì (6.17 ftõ x1,16ì 3.8 ft õx 1,06ì 3.48ft) Ðàçìåðû óñòðàîéñòâà Weight Âåñ: Binder 400 kg (882 lbs) Òåðìîêëååâàÿ ìàøèíà: 55 kg 400 êã. Output Unit (optional) (121 lbs) Âûâîäíîå óñòðîéñòâî (ïîñòàâëÿåòñÿ îïöèîíàëüíî): 55 êã. ∆ -20A ∆ -20A Y -20A Electrical supply Ýëåêòðîïèòàíèå: 208V/220V/230V/240V (60Hz) 208V/220V/230V/240V (60Hz) 220V/230V/240V (50Hz) 220V/230V/240V (50Hz) 380V/400V/415V (50Hz) 380V/400V/415V (50Hz) Òåïëîâîå èçëó÷åíèå: Radiant heat Óðîâåíü øóìà: Noise level (Lpa) 3 ÊÂò â ÷àñ 10224 Btu/hour 76 äÁ (íà ðàáî÷åì ìåñòå îïåðàòîðà) 76 dB (A) (at operator position) Ðóêîâîäñòâî ïîëüçîâàòåëÿ Ñòðàíèöà 12 Ïåðåâåäåíî: Ñ. Ëàçóòêèí. ÇÀÎ “Êîìëàéí Òðåéä” Ìîñêâà, 2003 ã. 2.2 Îáùåå. Îïèñàíèå òåðìîêëååâîé ìàøèíû 2.2 General description ïèòàíèÿ 1. Binder Âûêëþ÷àòåëü 2. Òàéìåð âêëþ÷åíèÿ (ïîñòàâëÿåòñÿ îïöèîíàëüíî) 1. Main Switch 3. Îáëàñòü çàãðóçêè ñòîïû 2. Start up timer (optional) 4. Êîíòðîëüíàÿ ïàíåëü (to skip the 35 minutes warm up) 5. Òåðìîñòàò Handling loading area 6. 3. Ðåãóëèðîâêà ãëóáèíû òîðøîíèðîâàíèÿ 4. Control panel 7. Èíäèêàòîð ãëóáèíû òîðøîíèðîâàíèÿ Thermostat 8. 5. Ñòîë ïîäà÷è îáëîæåê 6. Depth milling äëÿ adjustment 9. Êðûøêà îòñåêà çàãðóçêè êëåÿ 7. Depth milling indicator 10. Âûâîäíîå óñòðîéñòâî (ïîñòàâëÿåòñÿ îïöèîíàëüíî) 8. Cover station 9. Glue tank access 10. Output unit (optional) 5 9 3 8 2 L TRO NG CON IERU RE GUL ATU TION RE PER ATURRE ULA ATU REG PER LE TURING E TEM PER TEM COL URS GLU TEM ATU LEIM PER TEM LIJM EME NCY RGE P P STO STO ET CE NOT ARR GEN OP D'UR DST NOO 4 7 10 1 6 Ðóêîâîäñòâî ïîëüçîâàòåëÿ Ñòðàíèöà 13 Ïåðåâåäåíî: Ñ. Ëàçóòêèí. ÇÀÎ “Êîìëàéí Òðåéä” Ìîñêâà, 2003 ã. 2.3 Êîíòðîëüíàÿ ïàíåëü 2.3 Control Panel 12 13 14 15 c.p. bourg MENU 5 7 8 9 2 1 1. 1. 2. 3. 2. 4. 3. 5. 4. 6. 5. 7. 6. 8. 7. 8. 9. 9. 10.10. 11.11. 12.12. 13.13. 14.14. 15. 15. ENTER 6 4 3 1 S.A. N.V. PROGR. 10 2 3 4 6 5 7 8 10 11 1 9 Íàæàòèå êíîïîê ïðèâîäèò ê çàêðûòèþ êàðåòêè è íà÷àëó ïðîöåññà ñêëåéêè (íàæìèòå îáå êíîïêè îäíîâðåìåííî). Closes the carriage and starts the Binding Process Ðåãóëèðîâêà âðåìåíè ïðèæèìà îáëîæêè. (press the two start buttons simultaneously) Ðåãóëèðîâêà óñèëèÿ ïðèæèìà îáëîæêè ê êîðåøêó áëîêà. Adjusts the clamping duration Ðåãóëèðîâêà âàêóóìà ïðèñîñîê. Adjusts the óðîâíÿ lateral clamping pressure Ïîçâîëÿåò âûáèðàòü ìåíþ, ïóíêòû ìåíþ è ïðîèçâîäèòü îïåðàöèè ñ ýòèìè ïóíêòàìè. Adjusts the suction level Âêëþ÷åíèå âðàùåíèÿ ôðåçû. Allows you/ âûêëþ÷åíèå to select menus and perform operation from these menus * Toggles the blade rotation ON/OFF Âûáîð ïðîãðàìì Selects the programs* âðàùåíèÿ êëååâîãî áàðàáàíà (áàðàáàí íà÷èíàåò âðàùàòüñÿ Âêëþ÷åíèå / âûêëþ÷åíèå Toggles tank heating (theäîñòèãíåò drum rotation starts whenóðîâíÿ). the glue is warm enough) ïîñëå òîãî,the êàêglue òåìïåðàòóðà êëåÿ íåîáõîäèìîãî Confirms the selection Ïîäòâåðæäåíèå ñäåëàííîãî âûáîðà. Stop all operations in an emergency Àâàðèéíûé âûêëþ÷àòåëü. Ïðåêðàùåíèå âûïîëíåíèÿ âñåõ îïåðàöèé â ñëó÷àå îïàñíîñòè. Opens the êàðåòêè. carriage Îòêðûâàíèå Toggles jogger ON/OFF ñòàëêèâàòåëÿ êàðåòêè. Âêëþ÷åíèå / âûêëþ÷åíèå Carriage normal or large pre-opening Íîðìàëüíîå èëè øèðîêîå ðàñêðûòèå êàðåòêè. Fixed speed ON/OFF Ïåðåêëþ÷àòåëü ðåæèìà âðàùåíèÿ ôðåçû - ôèêñèðîâàííàÿ ñêîðîñòü âðàùåíèÿ, èëè Liquid Crystal Display for menus and messages ïåðåìåííàÿ, â çàâèñèìîñòè îò òîëùèíû áëîêà. Æèäêîêðèñòàëè÷åñêèé äèñïëåé, äëÿ îòîáðàæåíèÿ ìåíþ è ñëóæåáíûõ ñîîáùåíèé * Ïðîãðàììà ñêëåéêè ñ îáëîæêîé * With cover èëè áåç îáëîæêè, èçâëå÷åíèå áëîêà ââåðõ or ñêëåéêè Without cover evacuation:top (for padding) èëè áåç îáëîæêè, èçâëå÷åíèå áëîêà âíèç or ñêëåéêà Without cover evacuation:bottom (for padding) Îñòàíîâèòå êëååâîãî áàðàáàíà äëÿ âûáîðà ïðîãðàììû. Stop theâðàùåíèå drum rotation to select the program. Ïîäòâåðäèòå âûáîð, ñíîâà çàïóñòèâ âðàùåíèå áàðàáàíà Confirm the choice by starting the drum rotation. è åñëè âûáðàíà îïöèÿ ïîäà÷è îáëîæêè (pre-feed: yes): -isåñëè íà N 1 ðåæèìà, mode with pre-feed : yes.ïðåäâàðèòåëüíîé If the message “Cover sheet misfeed” èíäèêàòîðå îòîáðàæàåòñÿ ñîîáùåíèå “Cover sheet misfeed”, èçìåíåíèå ïðîãðàììû áóäåò íåâîçìîæíî.  ýòîì displayed, it is not possible to change the program. ñëó÷àå, îïåðàòîð äîëæåí íàæàòü íà êíîïêó àâàðèéíîé îñòàíîâêè, è òîëüêî ïîñëå ýòîãî èçìåíèòü ïðîãðàììó. You have to press on the emergency button and then change the program. Çàìå÷àíèå: Note:äëÿ In Ðóêîâîäñòâî ïîëüçîâàòåëÿ Ñòðàíèöà 14 Ïåðåâåäåíî: Ñ. Ëàçóòêèí. ÇÀÎ “Êîìëàéí Òðåéä” Ìîñêâà, 2003 ã. 2.42.4 Êîíòðîëüíàÿ ïàíåëü è ñèñòåìíûå ñîîáùåíèÿ Control panel menus- ìåíþ and messages c.p. bourg MENU 5 S.A. N.V. ENTER 6 7 4 8 3 9 2 1 PROGR. 10 Íîìåð îøèáêè íà òåðìîêëååâûõ ìàøèíàõ ðàííèõ âûïóñêîâ: messages # on (earlier) eprom Ïðè âêëþ÷åíèè: At switch on: . NR . OF B I ND I NGS : X X X N – > 1 L : X X X CORR : X MENU Display of the values previously selected in next two menu steps. MOD E : N – > 1 PR E - F E E D : BOOK S I Z E : S I Z E COR RE C T I ON : MENU E X T RA CORREC T I ON COV ER POS I T I ON OV ER L AP ( mm ) : XXX MENU GL UE F I LM L ENGT H ± 7 ±16 MENU CHANGE TOT A L NUMBER O F B I ND I NGS N R . OF B I ND I NGS : COUN T ER RE S E T MENU L ANGU : F ( GB ) D NL I E P Ñïèñîê èíñòðóêöèé: List of ñîîáùåíèé messagesè and instructions: = Emergency pressed or hood not closed: •íàæàòà Emergency hood not cloêíîïêà pressed àâàðèéíîéor îñòàíîâêè èëè íå çàêðûòû sed çàùèòíûå êðûøêè. = Reset: Ïåðåçàãðóçêà. Drum is heating but is still too cold: Êëååâîé •= Reset áàðàáàí íàãðåâàåòñÿ, íî âñå åùå î÷åíü •õîëîäíûé. Drum is heating but is still too cold. Problem with book in delivery area: Ïðîáëåìà •= Problem with book in delivery area ñ áóêëåòîì â çîíå âûäà÷è Lift perpex remove cover cover if any: if any •= Lift perpexguard guard remove Ïîäíèìèòå çàùèòíóþ êðûøêó äëÿ óäàëåíèÿ •îáëîæêè Press key drum to start heating Press key drum to start •= Remove paper fromheating: binder if any Íàæìèòå êíîïêó âêëþ÷åíèÿ âðàùåíèÿ êëååâîãî äëÿ íà÷àëà •áàðàáàíà Cover feeder did íàãðåâàíèÿ not move êëåÿ = Remove paper from binder if any: •Óäàëèòå Binder áóìàãó is in test mode èç òåðìîêëååâîé ìàøèíû. Cover feeder did not move: •= Spine is drying Íå ïåðåìåñòèëñÿ ïîäàò÷èê îáëîæêè Binder is inboth test mode: •= Depress green push buttons Òåðìîêëååâàÿ ìàøèíà íàõîäèòñÿ â ðåæèìå •äèàãíîñòèêè Cover sheet misfeed Spine ismotor drying: is overheated •= Milling Êîðåøîê áëîêà ñóøèòñÿ •= Switch open Depress off bothand green pushhood buttons Îòïóñòèòå îáå íàæàòûå çåëåíûå êíîïêè. •= Binding in progress Cover sheet misfeed: îáëîæêà •Ïðîïóùåíà Problems/ ïîòåðÿíà with carriage position = Milling motor is overheated: •Ïåðåãðåëñÿ Remove cover ìîòîð sheet ïðèâîäà ôðåçû = Switch off and open hood: •Âûêëþ÷èòå Heating isìàøèíó disabled. è îòêðîéòå êðûøêó êëååâîãî îòñåêà Push key to restore = Binding in progress: •Ïðîèñõîäèò Delivery conveyer ïðîöåññ ñêëåéêè áëîêà = Not Problem with/ carriage position: ready connected Êàðåòêà íå óñòàíîâëåíà â ïðàâèëüíîå •ïîëîæåíèå Replace MCU battery = Remove cover sheet: •Óäàëèòå Glue temperature too high îáëîæêó Heating is disabled. •= Replace dust bagPush key to restore: Íàãðåâàíèå êëåÿ îòêëþ÷åíî. Íàæìèòå êíîïêó •âêëþ÷åíèÿ Binder isâðàùåíèÿ ready êëååâîãî áàðàáàíà äëÿ íàãðåâàíèÿ êëåÿ •gðîäîëæåíèÿ Open carriage and remove book = Delivery conveyer Not ready / Connected: Ïðèåìíûé êîíâåéåð íå ãîòîâ äëÿ ðàáîòû èëè îòêëþ÷åí = Replace MCU battery: Çàìåíèòå áàòàðåþ ýíåðãîíåçàâèñèìîé ïàìÿòè. = Glue temperature too high: Òåìïåðàòóðà êëåÿ î÷åíü âûñîêàÿ = Replace dust bag: Çàìåíèòå ìåøîê äëÿ ñáîðà ïûëè = Binder is ready: Òåðìîêëååâàÿ ìàøèíà ãîòîâà ê ðàáîòå = Open carriage and remove book: Îòêðîéòå êàðåòêó è èçâëåêèòå áëîê MENU O t M l Ðóêîâîäñòâî ïîëüçîâàòåëÿ Ñòðàíèöà 15 Ïåðåâåäåíî: Ñ. Ëàçóòêèí. ÇÀÎ “Êîìëàéí Òðåéä” Ìîñêâà, 2003 ã. N# 1 Ðàñøèôðîâêà ñîîáùåíèÿ: ERROR MESSAGES Ïðîáëåìà ñ äâèãàòåëåì ïðèâîäà Carriage open/close îòêðûâàíèÿ/ çàêðûòèÿ êàðåòêè Ì7 F35 Motor problem M7 F35 2 Ïðîáëåìà ñ äâèãàòåëåì ïðèæèìà Shutter motor Ì14 - F5 Problem M15 F5 4 Ïðîáëåìà ñ äâèãàòåëåì ïðèâîäà Cover nipping motor ïðèæèìà îáëîæêè M14 (F12) Problem - M14 (F12) 8 Ïðîáëåìà ñ äâèãàòåëåì ïðèâîäà Suction bar problem ïðèñîñîê. Up/down motor M13 (F4) Up/down motor M13 (F4) 9 10 17 18 Ïåðåãðóçêà K12 (F2) Clutch or brake problem K12 (F2) Ïðåâûøåíîð âðåìÿ îæèäàíèÿ, T21 Time out/process ïðîöåññ äëèòñÿ äîëüøå,longer ÷åì îäíà than one min ìèíóòà. Ïðîáëåìàtools ïîçèöèîíèðîâàíèÿ ôðåçû Notching index probl. Îøèáêà. Ïðîâåðüòå ðàçúåìû S49, Error check S45 S 45 è äàò÷èê äâèæåíèÿ S49 and Tacho 19 Î÷åíü òîëñòûé áëîê, èëè ïðîáëåìà ñ Book too thick or äàò÷èêîì íàëè÷èÿ áëîêà â êàðåòêå carr switch probl Ïåðåâåäåíî: Ñ. Ëàçóòêèí. ÇÀÎ “Êîìëàéí Òðåéä” Ìîñêâà, 2003 ã. ENTER + MENU ENTER ( mm ) : XXX : Äà yes Êðàé îáëîæêè ðàñïîëîæåí Isâðîâåíü coverñ îáðåçîì leadingêîðåøêà edge áëîêà?book ? flush with OV ER L A P E X T RA CORREC T I ON COV ER POS I T I ON Confirms the ñäåëàííîãî èçìåíåíèÿ selected parameters Ïîäòâåðæäåíèå Èçìåíåíèå çíà÷åíèÿ Changes the âûáðàííîãî parameters ïàðàìåòðà Âûáîð ïóíêòà Selects the ìåíþ desired line screen Èçìåíåíèå ïîçèöèè Changes the ìåíþ MENU MOD E : N – > 1 PRE - F E ED BOOK S I Z E : S I Z E CORRECT I ON MENU NR . OF B I ND I NGS : XX N – > 1 W : X XX CORR : X XX B I NDER READY Íàæìèòå êíîïêó Press oníàbutton START MENU Íåò no : Íåò no + MOD E : N – > 1 PR E - F E E D : BOOK S I Z E : S I Z E CORRECT I ON Äà yes Ïðåäâàðèòåëüíàÿ Pre-feed ïîäà÷à îáëîæêè isêîððåêòíà correct Äà yes Realign Êàæäîå Ðåãóëèðîâêà. (each push ==0.2 íàæàòèå 0,2mm) ìì MOD E : N – > 1 PR E - F E E D : BOOK S I Z E : S I Z E CORRECT I ON Äà yes correct Ðåæèì ðàáîòû Mode is êîððåêòåí Íåò no Ðåæèì è ïàðàìåòðû Mode and parameters ðàáîòû êîððåêòíû are correct : Äà yes Ðàçìåð áëîêà Book size óñòàíîâëåí isïðàâèëüíî correct + MOD E : N – > 1 PR E - F E E D : BOOK S I Z E : S I Z E CORRECT I ON Íåò no + : Íåò no CYCLE RUN Âûïîëíåíèå ðàáî÷åãî öèêëà Äà yes Äëèíà áëîêà Book length óñòàíîâëåíà isïðàâèëüíî correct + Íåò no + Press on both green buttons ENTER ENTER ENTER ENTER ENTER Íàæìèòå äâå çåëåíûå êíîïêè îäíîâðåìåííî MENU MENU MENU MENU 2.5 Èçìåíåíèå ïàðàìåòðîâ ñêëåéêè 2.5 Change of binding parameters Ðóêîâîäñòâî ïîëüçîâàòåëÿ Ñòðàíèöà 16 Ðóêîâîäñòâî ïîëüçîâàòåëÿ Ñòðàíèöà 17 Ïåðåâåäåíî: Ñ. Ëàçóòêèí. ÇÀÎ “Êîìëàéí Òðåéä” Ìîñêâà, 2003 ã. MENU ±16 : X XX L ANGU : F ( GB ) D NL I E P MENU CHANGE TOT A L NUMBER O F B I ND I NGS x x x N R . OF B I ND I NGS : x x x COUN T ER RE S E T ± 7 GL UE F I LM L ENGT H . MENU ±16 : XXX Äà yes ßçûê äèàëîãîâ The language ìåíþ âûáðàí isïðàâèëüíî correct Íåò no CHANGE TOT A L NUMBER O F B I ND I NGS x x x N R . OF B I ND I NGS : COUN T ER RE S E T Äà yes Êîëè÷åñòâî âûïîëíåíûõ Number of bindings öèêëîâ ñêëåéêè óêàçàíî isêîððåêòíî correct ± 7 GL UE F I LM L ENGT H . Äà yes glue film is correct Äà yes Íåò no Íåò no the counter Îáíóëåíèå Reset of ñ÷åò÷èêà + ± INHIBITION CYL.1: Äà yes glue film is correct Ïðàâûé êðàé êëååâîãî ñëîÿ The right end of ðàñïîëîæåí ïðàâèëüíî Äà + Äà yes Äà Íåò no Ðåæèì äëÿ öèëèíäðà ïðåäâ. ïðîêëåéêè âûáðàí ïðàâèëüíî Íåò Ðåæèì äëÿ öèëèíäðà Inhibition cylinder ïðåäâ. ïðîêëåéêè âûáðàí ïðàâèëüíî state is correct Íåò no Ïðàâûé êðàé êëååâîãî ñëîÿ ðàñïîëîæåí ïðàâèëüíî GL UE F I LM L ENGT H Íåò no + Äà Ëåâûé êðàé êëååâîãî ñëîÿ The left ïðàâèëüíî end of ðàñïîëîæåí Íåò Ëåâûé êðàé êëååâîãî ñëîÿ ðàñïîëîæåí ïðàâèëüíî + Íåò ENTER ENTER ENTER ENTER ENTER ENTER MENU MENU MENU MENU MENU MENU MENU MENU 2.6 Èíñòðóêöèÿ ïî èñïîëüçîâàíèþ ðåëå âðåìåíè 2.6 Instructions for timer use (optional) (ïîñòàâëÿåòñÿ ïî äîïîëíèòåëüíîìó çàïðîñó) Ñåëåêòîð / Èíäèêàòîð òåêóùåãî ðåæèìà ðàáîòû Operation selector óñòðîéñòâà Èíäèêàòîð Power âêëþ÷åíèÿ indicator with indicator POWER ON Ïåðåìû÷êè äëÿ óñòàíîâêè âðåìåíè Time setting âêëþ÷åíèÿ brackets óñòðîéñòâà OFF 2 1 24 23 2 2 3 21 4 40 30 8 7 6 10 ×àñîâîé 19 18 17 16 60 5 20 50 ìåõàíèçì Dial 20 9 15 14 Ðó÷êà Knob 13 12 11 10 ON AUTO OFF Ðó÷íîé ïåðåêëþ÷àòåëü Manual switch ðåæèìîâ ðàáîòû Ìåñòî äëÿ õðàíåíèÿ Time setting çàïàñíûõ ïåðåìû÷åê bracket storage compartment Íàèìåíîâàíèå Name Operation selector Ñåëåêòîð / Èíäèêàòîð òåêóùåãî ðåæèìà ðàáîòû with indicator óñòðîéñòâà Ïåðåìû÷êè Time settingäëÿ óñòàíîâêè âðåìåíè âêëþ÷åíèÿ brackets óñòðîéñòâà Knob Ðó÷êà Dial ×àñîâîé ìåõàíèçì Ìåñòî äëÿ õðàíåíèÿ Time setting çàïàñíûõ ïåðåìû÷åê bracket storage compartment Ôóíêöèÿ Function Îòîáðàæàåò ÂÊË/ÂÛÊËstatus ñòàòóñ ðàáîòû Indicates the ON/OFF of the òåðìîêëååâîé ìàøèíû; ïîâîðîò control output; rotating the ñåëåêòîðà ïî ÷àñîâîé ñòðåëêå ïðèâåäåò ê èçìåíåíèþ òåêóùåãî knob clockwise the control ñòàòóñà íàturns ïðîòèâîïîëîæíûé. ouput ON/OFF. Ïðåäîñòàâëåíû äâà òèïà ïåðåìû÷åê: ïåðåìû÷êè äëÿ Two time setting brackets are provided: óñòàíîâêè âðåìåíè âêëþ÷åíèÿ óñòðîéñòâà è ïåðåìû÷êè ONäëÿtime setting bracket óñòàíîâêè âðåìåíè âûêëþ÷åíèÿ óñòðîéñòâà. Ñ ïîìîùüþ äàííûõ ïåðåìû÷åê óñòàíàâëèâàåòñÿ âðåìÿ, â and OFF time setting bracket. They êîòîðîå òåðìîêëååâàÿ ìàøèíà áóäåò àâòîìàòè÷åñêè âêëþ÷àòüñÿ è âûêëþ÷àòüñÿ. turn the control output ON or OFF at the specified time. Âðó÷íóþ rotates ïîâîðà÷èâàåò ÷àñîâîé è Manually the dial andìåõàíèçì indicates îòîáðàæàåò òåêóùåå âðåìÿ â ìèíóòàõ. the present time in 1-minute units. Ïàíåëü ïðåäíàçíà÷åíà óñòàíîâêèand ïåðåìû÷åê è Holds time setting äëÿ brackets îòîáðàæåíèÿ 15-ìèíóòíûõ èíòåðâàëîâ âðåìåíè indicates the time in every 15 minutes. Stores the time setting bracket not in â Çäåñü õðàíÿòñÿ ïåðåìû÷êè, íå èñïîëüçóåìûå äàííîå âðåìÿ use. Ðó÷íîé ïåðåêëþ÷àòåëü Manual switch Ðó÷íîå ïåðåêëþ÷åíèå ðåæèìàoutput ðàáîòûas AUTO: Produces the control òåðìîêëååâîé specified by theìàøèíû: time setting AUTO: Âêëþ÷àåò è âûêëþ÷àåò bracket positionìàøèíó on theâ çàðàíåå dial. òåðìîêëååâóþ óñòàíîâëåííîå ïåðåìû÷êàìè ON: Normally turns ON the output âðåìÿ. irrespective of the time setting ON: Òåðìîêëååâàÿ ìàøèíà âêëþ÷åíà bracket position on the dial. íåçàâèñèìî îò óñòàíîâëåííûõ OFF: Normally turns OFF the output ïåðåìû÷åê OFF: Òåðìîêëååâàÿ ìàøèíà irrespective of the timeâûêëþ÷åíà setting íåçàâèñèìî îò óñòàíîâëåííûõ bracket position on the dial. ïåðåìû÷åê Èíäèêàòîð âêëþ÷åíèÿ Power indicator Ñâåòèòñÿ,when êîãäà íà power ðåëå âðåìåíè ïîäàíî ýëåêòðîïèòàíèå è Lights is applied and ñèãíàëèçèðóåò, ÷òî òàéìåð ðàáîòàåò. indicates that the timer is in operation. ðåæèìîâ ðàáîòû Ðóêîâîäñòâî ïîëüçîâàòåëÿ Ñòðàíèöà 18 Ïåðåâåäåíî: Ñ. Ëàçóòêèí. ÇÀÎ “Êîìëàéí Òðåéä” Ìîñêâà, 2003 ã. Óñòàíîâêà Settings 1. Îòêðîéòå çàùèòíóþ ïåðåäíþþ êðûøêó. 1. Remove the transparent cover from the front panel. ER POW ON " ! $ " # " ! # ! ' $ ! % & % $ # ' " ÷àñà 3 3o'clock OFF 50 50 ìèíóò minutes & ON O AUT FF O 2. öåíòðàëüíóþ ðó÷êó ïî ÷àñîâîé ñòðåëêå äëÿ âûáîðà âðåìåíè. ìîæåò áûòü 2.Ïîâåðíèòå Rotate the center knob in the arrow direction (i.e., clockwise) to Òåêóùåå set the âðåìÿ time. The present óñòàíîâëåíî ñ òî÷íîñòüþ äî îäíîé ìèíóòû. Íà ðèñóíêå èçîáðàæåíî, êàê óñòàíîâèòü âðåìÿ 3 ÷àñà 50 ìèíóò. ÍÅ time can be set in 1-minute units. For example 3:50 as shown in the figure. Do not rotate ÏÎÂÎÐÀ×ÈÂÀÉÒÅ ðó÷êó ÏÐÎÒÈ ×ÀÑÎÂÎÉ ÑÒÐÅËÊÈ! the knob counterclockwise. 3. Äâà òèïà ïåðåìû÷åê ïðåäîñòàâëåíû äëÿ óñòàíîâêè âðåìåíè: ïåðåìû÷êè äëÿ óñòàíîâêè âðåìåíè âêëþ÷åíèÿ 3. Two time setting brackets are provided: ON (gold) and OFF (silver). Be sure÷òî to use the cor(çîëîòûå) è ïåðåìû÷êè äëÿ óñòàíîâêè âðåìåíè âûêëþ÷åíèÿ (ñåðåáðÿííûå). Óáåäèòåñü, äëÿ óñòàíîâêè òðåáóåìîãî Âàì âðåìåíè Âû ïðàâèëüíî ïåðåìû÷êó è ïëîòíî rect bracket and securely insert itâûáðàëè in the groove of the dial. âñòàâüòå åå â ñîîòâåòñòâóþùåå ãíåçäî ÷àñîâîãî ìåõàíèçìà. 4.Óñòàíîâèòå Alternatelyâðåìÿ set the ON andè âûêëþ÷åíèÿ OFF time setting brackets. 4. âêëþ÷åíèÿ òåðìîêëååâîé ìàøèíû, ïîëüçóÿñü ñîîòâåòñòâóþùèìè ïåðåìû÷êàìè 5.Ïîñëå After óñòàíîâêè setting the time, reattach theçàêðîéòå transparent coverçàùèòíóþ to the front panel. 5. òðåáóåìîãî âðåìåíè, ïåðåäíþþ êðûøêó òàéìåðà. Ðàáîòà Operation 6. Àêêóðàòíî âñòàâüòå ïåðåìû÷êè âêëþ÷àþùèå/âûêëþ÷àþùèå óñòàíîâêó â ïàçû, ñîîòâåòñòâóþùèå òðåáóåìîìó 6. FirmlyÍåinsert the ON/OFF time setting bracket to the desired setting groove. âðåìåíè. óñòàíàâëèâàéòå ïåðåìû÷êè â ïàçû, îïðåäåëÿþùèå âðåìÿ âtime ïðåäåëàõ +/- 15 ìèíóò However, îò òåêóùåãî do not insert it in a groove within ± 15 minutes distance from the dial groove that indicates âðåìåíè. the present time. 7. Ïîñëå òîãî, êàê âðåìÿ óñòàíîâëåíî, ïîâåðíèòå ðó÷êó íà îäèí îáîðîò ïî ÷àñîâîé ñòðåëêå, äëÿ òîãî, ÷òî áû óáåäèòñÿ, ÷òî time òàéìåð ñðàáàòûâàåò ìîìåíòû âðåìåíè, ñîîòâåòñòâóþùèå óñòàíîâëåííûì. 7. After the setting bracketâ is fixed and with the power and load connected to the timer, rotate the knob the arrow direction. Turníàthe dial one complete to check 8. Ïîâåðíóâ ðó÷êó ïî in ÷àñîâîé ñòðåëêå, óñòàíîâèòå òàéìåðå òåêóùåå âðåìÿ rotation òàê, êàê ýòî îïèñàíîif âthe ïóíêòå 2. control output is turned ON/OFF in accordance wit the setting of the time setting bracket on the dial. 8. Rotate the knob in the arrow direction and set the desired time according to step 2. Ðóêîâîäñòâî ïîëüçîâàòåëÿ Ñòðàíèöà 19 Ïåðåâåäåíî: Ñ. Ëàçóòêèí. ÇÀÎ “Êîìëàéí Òðåéä” Ìîñêâà, 2003 ã. 9. Òåïåðü òàéìåð ãîòîâ ê ðàáîòå. 9. Now start the operation of the timer. Ïðèìåð: Example: " $ ! ! # " $ $ # " % ! # OFF ' ! " & ON OFF OFF ON ON ' & % ON OFF Ñ ïåðåìû÷êàìè, óñòàíîâëåííûìè òàê, êàê ïîêàçàíî íà ðèñóíêå ââåðõó, òåðìîêëååâàÿ ìàøèíà áóäåò With theïîabove settingãðàôèêó: the timing chart will be as follows: ðàáîòàòü ñëåäóþùåìó " ! " # $ % & ' ! " # $ % & ' ! Ðóêîâîäñòâî ïîëüçîâàòåëÿ Ñòðàíèöà 20 Ïåðåâåäåíî: Ñ. Ëàçóòêèí. ÇÀÎ “Êîìëàéí Òðåéä” Ìîñêâà, 2003 ã. 2.7 2.7 Óñòðîéñòâî Cover stationäëÿ ïîäà÷è îáëîæåê Çàãðóçêà óñòðîéñòâà äëÿ ïîäà÷è îáëîæåê Loading of the cover station 4 1 3 2 = = = = Ïîäíèìèòå ââåðõ ðàçäåëèòåëü ëèñòîâ (1) • Ïåðåìåñòèòå Release theìàãíèòíûå cover separators support bar (1). îãðàíè÷èòåëè (2) • Ïåðåìåñòèòå Move the magnetic side (3) guides çàäíèå óïîðû åñëè (2). èçìåíÿåòñÿ ôîðìàò ïîäàâàåìûõ îáëîæåê (çàäíèå óïîðû • ôèêñèðóþòñÿ Move the rear guide (3) if the äîñòóï formatê changes (the rear guides areñòîëà locked knurled ñ ïîìîùüþ âèíòîâ, êîòîðûì îñóùåñòâëÿåòñÿ ñíèçó äëÿwith ïîäà÷è îáëîæåê) Çàãðóçèòå îáëîæêè, âûðîâíÿâ èõ ïî ïåðåäíèì è ïî ïðàâûì (4) óïîðàì. knob located under the cover station). • Load covers against the front guides and the right guide (4). Çàìå÷àíèå: Îáëîæêà íà ñòîëå ðàáî÷åé ïîâåðõíîñòüþ (“ëèöîì”) âíèç Note:- Visible=part faceðàñïîëàãàåòñÿ down. = Ïåðåäíÿÿ ÷àñòüfront îáëîæêè ðàñïîëîæåíà ó ïåðåäíèõ (â ðåæèìå N -> 1, ïî óìîë÷àíèþ) - Front page towards guides (in Mode N➞ 1,óïîðîâ by default). = Óñòàíîâèòå çàäíèå íàïðàâëÿþùèå (3) è áîêîâûå îãðàíè÷èòåëè (2) ïî êðàÿì îáëîæêè. • Adjust rear guides (3) and side guides (2), against the pile of covers. Òðè âîçìîæíûõ ïîëîæåíèÿ îáëîæêè ìîæíî Three possibilities are selectable in menu # 2 óñòàíîâèòü â ìåíþ #2: Ðåæèì ïî by óìîë÷àíèþ: Mode default: N 1 ar Re 1 N Ðåæèì äëÿ Mode for special ñïåöèàëüíûõ ðàáîò: applications: 1 Îáëîæêà âñåãäà ðàñïîëàãàåòñÿ Theîäíîì cover èare always loaded íà òîì æå ìåñòå, âíå at the same place, whatever çàâèñèìîñòè îò òîëùèíû áëîêà. the thickness ýòîò book ðåæèì is. Èñïîëüçóéòå äëÿ Use this mode for an optimal äîñòèæåíèÿ îïòèìàëüíîé production. ïðîèçâîäèòåëüíîñòè ïðè ðàáîòå. N nt o Fr N äëÿ ModeÐåæèì for symmetrical ñèììåòðè÷íîãî cover: ðàñïîëîæåíèÿ îáëîæêè íà áëîêå: 1 Sym. Ðóêîâîäñòâî ïîëüçîâàòåëÿ Ñòðàíèöà 21 Ïåðåâåäåíî: Ñ. Ëàçóòêèí. ÇÀÎ “Êîìëàéí Òðåéä” Ìîñêâà, 2003 ã. Èñïîëüçóéòå ýòîò ðåæèì, â ñëó÷àå, åñëè íà êîðåøêå Âàøåé îáëîæêè ðàñïîëîæåí êàêîé-ëèáî Use this mode for booklet òåêñò. with notes on the spine of the cover. Ðàçìåðû îáëîæêè: Cover dimensions : Îáðåçêà è âûðàâíèâàíèå áëîêîâ îáÿçàòåëüíû ïðè èñïîëüçîâàíèè áëîêîâ áîëüøèõ ðàçìåðîâ. Trimming of the book is mandatory for larger dimensions. Êðàÿ îáëîæêè äîëæíû ðàñïîëàãàòüñÿ ïàðàëëåëüíî ñîîòâåòñòâóþùèì êðàÿì áëîêà â ðàéîíå The grain of the covers should be parallel with the arrow for sharp folds around the spine. êîðåøêà. Creasing of the cover may îáëîæêè be necessary if the covers are cross-grained if stiff is Ïðåäâàðèòåëüíàÿ áèãîâêà ìîæåò áûòü íåîáõîäèìà, â ñëó÷àå,oråñëè âûmaterial èñïîëüçóåòå äëÿ used forî÷åíü the cover. îáëîæêè ïëîòíóþ áóìàãó, èëè áóìàãó ñ ïîïåðå÷íûì ðàñïîëîæåíèåì âîëîêîí. It is not possible to press heavy covers on very thin books. Thin covers should notîáëîæêà be pressed Íåâîçìîæíî õîðîøî ïðèæàòü ïëîòíóþ îáëîæêó ê î÷åíü òîíêîìó áëîêó. Òîíêàÿ íå on thick books either. ìîæåò áûòü õîðîøî ïðèæàòà ñ äâóõ ñòîðîí ê î÷åíü òîëñòîìó áëîêó. e l m h L=l +e+ h m +1 l+1 mm  ñëó÷àå, åñëè èñïîëüçóåòñÿ îáëîæêà ñ ïðîçðà÷íîé ïëàñòèêîâîé ïåðåäíåé ÷àñòüþ è áóìàæíûì The paper side of covers with transparent fronts and paper backs, must be wrapped around çàäíèêîì, ÷àñòü äîëæíà áûòü ñìåùåíà îòíîñèòåëüíî êîðåøêà îáëîæêè íå the spine áóìàæíàÿ at least 4 mm (.16îáëîæêè in.). ìåíåå ÷åì íà 4 ìèëëèìåòðà (ñì. ðèñóíîê íèæå). Operator Manual Ðóêîâîäñòâî ïîëüçîâàòåëÿ Ñòðàíèöà 22 Ïåðåâåäåíî: Ñ. Ëàçóòêèí. ÇÀÎ “Êîìëàéí Òðåéä” Ìîñêâà, 2003 ã. Óñòàíîâêè Settings Ïîçèöèîíèðîâàíèå îáëîæêè îòíîñèòåëüíî áëîêà: Positioning the cover on the book: Íà çàâîäå ìàøèíà îòðåãóëèðîâàíà äëÿ ïîäà÷è The machine has been factory set to place a perfectly ïðàâèëüíî îáðåçàííîé, ïðÿìîóãîëüíîé îáëîæêè âðîâåíü squared cover, in line with the right edge of the booklet. ñ ïðàâûì êðàåì áóêëåòà. Ðåãóëÿòîð óãëîâîãî ñìåùåíèÿ The guide angular adjustment is “0”. And its RH LH îáëîæêè óñòàíîâëåí â “0”. Ðåãóëÿòîð áîêîâîãî ñìåùåíèÿ adjustment is made to get the cover aligned with the (RH <--> LH) ïîìîãàåò óñòàíîâèòü îáëîæêó ìàêñèìàëüíî right edge of the booklet. Do not change this except : òî÷íî ïî îòíîøåíèþ ê ïðàâîìó êðàþ áëîêà áóìàãè. Íå • if you use an unsquared cover. ìåíÿéòå ðåãóëèðîâêè â ñëó÷àå, åñëè: • if you do not want to align the cover with the right edge = Âû èñïîëüçóåòå îáëîæêó íåïðÿìîóãîëüíîé ôîðìû. of the booklet. = Âû íå æåëàåòå âûðàâíèâàòü îáëîæêó ïî ïðàâîìó êðàþ áóêëåòà. 1 2 3 Áîêîâàÿ ðåãóëèðîâêà: Lateral adjustment: 1 2 3 = Îòðåãóëèðóéòå ïîëîæåíèå ïðàâîé íàïðàâëÿþùåé (1) èñïîëüçóÿ ðó÷êó (2) äëÿ êîððåêòèðîâêè • Adjust the position of the right side guide (1) using the knob (2) to correctly align the cover to ïîëîæåíèÿ îáëîæêè îòíîñèòåëüíî áóêëåòà. the book. = Ðàçìåñòèòå ìàãíèòíûå íàïðàâëÿþùèå (3) ñ ëåâîãî êðàÿ îáëîæêè. • Lock the magnetic side guides (3) on the left against the pile of covers. Ðóêîâîäñòâî ïîëüçîâàòåëÿ Ñòðàíèöà 23 Ïåðåâåäåíî: Ñ. Ëàçóòêèí. ÇÀÎ “Êîìëàéí Òðåéä” Ìîñêâà, 2003 ã. Ïðÿìîóãîëüíîñòü îáëîæêè: Squaring of the covers: 1 2 Compensation for covers not cut exactly is provided for by Êîìïåíñàöèÿ íåïðÿìîóãîëüíîñòè îáëîæêèsquare ïðîèçâîäèòñÿ moving right side guideóïîðà (1) askew by means of knob ïåðåìåùåíèåì ïðàâîãî ñ ïîìîùüþ ðó÷êè (2). (2). Before adjusting (2),óáåäèòåñü, verify that the is unlocked to prevent Ïåðåä ðåãóëèðîâêîé ÷òî guide óïîð ðàçáëîêèðîâàí, äëÿ bows or warps. èçãèáàíèÿ èëè ïîâðåæäåíèÿ íàïðàâëÿþùåé. ïðåäîòâðàùåíèÿ After ðåãóëèðîâêè the adjustment, lock the knob (2). (2). Ïîñëå çàáëîêèðóéòå ðó÷êó 2 0 Çàõâàò è îòäåëåíèå âåðõíåé îáëîæêè îò ñòîïû: Coverîáëîæêè picking and front cover separators: 3 4 5 6 7 4 8 3 9 2 1 10 1 # 2 = Åñëè ëåâûé áëîêà çà ïðåäåëû ñòîïû îáëîæêàìè, • If the êðàé suction cupsïðèñîñîê on the leftâûõîäèò extend beyond the width of ñthe cover, you çàãëóøèòå must place ëèøíèå the ïðèñîñêèplastic ñïåöèàëüíûìè ïëàñòèêîâûìè â êîìïëåêò ïîñòàâêè studs (1) from the tool kit çàãëóøêàìè, in the suction âõîäÿùèìè cups. òåðìîêëååâîé ìàøèíû. • According to cover material, one more plastic stud (1) may be required in the suction =  çàâèñèìîñòè îò êîòîðîãî èçãîòîâëåíû îáëîæêè, ìîæåò ïîòðåáîâàòüñÿ cup situed inòèïà the ìàòåðèàëà, middle of theèç front edge as well. çàãëóøèòü ïëàñòèêîâîé çàãëóøêîé ïðèñîñêó öåíòðå • Vacuum is continuously adjustable byâpot (5). áëîêà ïðèñîñîê. = Óðîâåíü âàêóóìà ìîæåò áûòü îòðåãóëèðîâàí â ëþáîå ïîâîðîòîì (5) • Adjust the position and number of the front cover âðåìÿ separators (4) onlyðó÷êè if necessary for = Îòðåãóëèðóéòå è ïîëîæåíèå ðàçäåëèòåëåé îáëîæêè (4) . optimum êîëè÷åñòâî cover separation. = Èñïîëüçóéòå âèíòû ïåðåìåùåíèÿ ñåïàðàòîðîâ (4) • Use knobs (2)(2) to äëÿ move the separators (4). = Èñïîëüçóéòå âèíò (3)(3) äëÿ • Use the knob to ðåãóëèðîâêè adjust the air óðîâíÿ flow. ðàçäóâà îáëîæåê. Ðóêîâîäñòâî ïîëüçîâàòåëÿ Ñòðàíèöà 24 Ïåðåâåäåíî: Ñ. Ëàçóòêèí. ÇÀÎ “Êîìëàéí Òðåéä” Ìîñêâà, 2003 ã. =  íåêîòîðûõ ñëó÷àÿõ, ïîëîæåíèå êðàÿ ñòîëà äëÿ îáëîæåê (1) ìîæåò • In some case, the leading áûòü îòðåãóëèðîâàíî ñ ïîìîùüþ edge (1) of the cover store âèíòà (2) can be lifted by adjusting knob (2). = Óáåäèòåñü, ÷òî îäíîâðåìåííî Âû îòðåãóëèðîâàëè ïîëîæåíèå áëîêà • Make sure to adjust the sucïðèñîñîê, îòâîðà÷èâàíèåì âèíòà tion cup support bar accor(3). Ýòà ðåãóëèðîâêà ïîçâîëèò dingly by loosening the ñîõðàíèòü ïàðàëåëüíîñòü screw (3). ïîëîæåíèÿ îáëîæêè îòíîñèòåëüíî This keeps the cover parallel áëîêà ïðèñîñîê. with the tilted suction cups. 2 1 Operator Manual Ðóêîâîäñòâî ïîëüçîâàòåëÿ Ñòðàíèöà 25 Ïåðåâåäåíî: Ñ. Ëàçóòêèí. ÇÀÎ “Êîìëàéí Òðåéä” Ìîñêâà, 2003 ã. 3 Îáæèì îáëîæêè: Cover clamping : Íà Onêîíòðîëüíîé control panelïàíåëè: : = •Ðåãóëÿòîð (1)provides îïðåäåëÿåò ïðîäîëæèòåëüíîñòü Selector (1) choices for its duration. ïðèæèìà îáëîæêè ê áëîêó. • Potentiometer (2) adjusts lateral clamping pressure. = Ðåãóëÿòîð (2) îïðåäåëÿåò óñèëèå áîêîâîãî ïðèæèìà îáëîæêè ê áëîêó. c.p. bourg S.A. N.V. MENU 5 6 1 10 ENTER 7 4 8 3 9 2 1 PROGR. 2 Íà ñòîëå ïîäà÷è îáëîæåê: Under cover stockplate: =•Ðó÷êà (3) ðåãóëèðóåò ïðèæèì îáëîæêè ê êîðåøêó ñíèçó.adjusts pressure on book The notched handle (3), located under the cover station, = Ðó÷êà spine.èìååò øåñòü ïîëîæåíèé, äëÿ óñòàíîâêè îïòèìàëüíîãî ïðèæèìà îáëîæêè ê áëîêó, çàâèñèìîñòè îò òîëùèíû îáëîæêè. • The âsix positions correspond to the various thicknesses of the covers. 3 3 Ðóêîâîäñòâî ïîëüçîâàòåëÿ Ñòðàíèöà 26 Ïåðåâåäåíî: Ñ. Ëàçóòêèí. ÇÀÎ “Êîìëàéí Òðåéä” Ìîñêâà, 2003 ã. Ðåãóëèðîâêà ãëóáèíû ôðåçåðîâàíèÿ 2.8 Milling depth adjustment Ïîâåðíèòå ðåãóëèðîâî÷íîå êîëåñî (1) äëÿ ðåãóëèðîâêè âûñîòû ñòàëêèâàòåëÿ è, Turn knurling wheel (1) toôðåçåðîâàíèÿ adjust the jogger height.áëîêà. ñîîòâåòñòâåííî, ãëóáèíû êîðåøêà 2 Y ROL G CONT ERUN URE GULI N ERAT URRE LATIO URE G TEMP ERAT REGU ERAT E URIN TEMP COLL URST GLUE TEMP LEIM RATU EMPE LIJMT GENC EMER STOP TOP T E NOTS ARRE GENC P D'UR DSTO NOO 1 Òîðøîíèðóþùèå ðåçöû Notching knives Óêàçàòåëü cursor 0 2 2,5 mm (0.1 in.) 2.5 2 1.5 1 0.5 0 Òîðøîíèðóþùèå ðåçöû Notching knives Ôðåçà Blade Ñòàëêèâàòåëü Jogger Óêàçàòåëü (2) óêàçûâàåò íà òåêóùåå ïîëîæåíèå óðîâíÿ ïëîùàäêè ñòàëêèâàòåëÿ îòíîñèòåëüíî ôðåçû. The cursor (2) indicates the jogger level according to the milling blade. Âûñîòà ïëîùàäêè ñòàëêèâàòåëÿ ìîæåò áûòü èçìåíåíà íà âåëè÷èíó äî 2,5 ìì äëÿ îáåñïå÷åíèÿ ôðåçåðîâàíèÿ The jogger can be adjusted to remove until 2.5 mm (0.1 in.) of material from the spine êîðåøêà áëîêàheight íà ñîîòâåòñòâóþùóþ ãëóáèíó. of the book. Ïîëîæåíèå óêàçàòåëÿ (2) ðàâíîå “0” ñîîòâåòñòâóåò îòêëþ÷åíèþ ôðåçåðîâàíèÿ êîðåøêà áëîêà. O means “no milling”. Ïîëîæåíèå óêàçàòåëÿ (2) ðàâíîå “2,5 ìì” îçíà÷àåò ìàêñèìàëüíóþ ãëóáèíó ôðåçåðîâàíèÿ (2,5 ìì) 2,5 ìì ìàòåðèàëà áóäåò óäàëåíî ñ êîðåøêà áëîêà. 2.5 mm (0.1 in.) means maximum milling 2.5 mm (0.1 in.) of material are removed from the spine of the book. Ðóêîâîäñòâî ïîëüçîâàòåëÿ Ñòðàíèöà 27 Ïåðåâåäåíî: Ñ. Ëàçóòêèí. ÇÀÎ “Êîìëàéí Òðåéä” Ìîñêâà, 2003 ã. = Äâèãàòåëü ôðåçû áóäåò âêëþ÷åí àâòîìàòè÷åñêè, åñëè ïëîùàäêà ñòàëêèâàòåëÿ íå óñòàíîâëåíà Milling motor will automatically if jogger is not in upper position. There is a time out on â •âåðõíåå (íóëåâîå) ïîëîæåíèå. start ×åðåç íåêîòîðå âðåìÿ, åñëè íå áóäåò çàïóùåí ïðîöåññ the milling motor rotation. ñêëåéêè, äâèãàòåëü ôðåçû îñòàíîâèòñÿ àâòîìàòè÷åñêè, äî íà÷àëà ñëåäóþùåãî öèêëà. • When jogger is in upper position, the operator will have to make ïîëîæåíèå, a choice: îïåðàòîð =  ñëó÷àå, åñëè ñòàëêèâàòåëü óñòàíîâëåí â âåðõíåå (íóëåâîå) • If operator ask èìååò for the âîçìîæíîñòü motor to run ( âûáðàòü notching íåñêîëüêî without milling) the motor will immediateòåðìîêëååâîé ìàøèíû âàðèàíòîâ äàëüíåéøåé ðàáîòû: ly start and there will be no time out on the motor rotation ( unless the operator ask for = Åñëè îïåðàòîð âðó÷íóþ âêëþ÷èò äâèãàòåëü ïðèâîäà ôðåçû, (ðåæèì òîðøîíèðîâàíèÿ the áåç motor to stop , activate the emergency knob or open any cover). áëîêà ôðåçåðîâàíèÿ) äâèãàòåëü áóäåò íåìåäëåííî âêëþ÷åí è âûêëþ÷àòüñÿ óæå íå • If the operator ask to not use motor, the machineíàæàòèåì will check ñîîòâåòñòâóþùåé if the paper path is êíîïêè, áóäåò, åñëè òîëüêî îïåðàòîð íåthe îòêëþ÷èò äâèãàòåëü, clear from scoring tools. îñòàíîâêè, ëèáî, îòêðûâ ëþáóþ èç çàùèòíûõ êðûøåê. íàæàòèåì êíîïêè àâàðèéíîé • If paper path is clear fromðàáîòû tools, the will indicateôðåçû, “binderòåðìîêëååâàÿ ready”. = Åñëè îïåðàòîð âûáåðåò ðåæèì áåçUIâêëþ÷åíèÿ ìàøèíà • If the notching tools are in ïðîâåðèò, the paper path, the binderëèwill readyòîðøîíèðîâàíèÿ after the ïåðåä íà÷àëîì îïåðàöèè ñêëåéêè íå íàõîäÿòñÿ ðåçöû íà indexation tools (a few seconds). ïóòè ñëåäîâàíèÿ áëîêà áóìàãè. = Åñëè ïóòü ïðîõîæäåíèÿ áëîêà ñâîáîäåí, ìàøèíà îòîáðàçèò íà êîíòðîëüíîé ïàíåëè ñîîáùåíèå “binder ready” (“òåðìîêëååâàÿ ìàøèíà ãîòîâà ê ðàáîòå”) = Åñëè íà ïóòè ïðîõîæäåíèÿ áîëîêà íàõîäÿòñÿ ðåçöû òîðøîíèðîâàíèÿ, òåðìîêëååâàÿ ìàøèíà áóäåò ãîòîâà ê ðàáîòå ïîñëå óñòàíîâêè ðåçöîâ â ïîëîæåíèå, ïðè êîòîðîì îíè íå áóäóò ìåøàòü ïðîõîæäåíèÿ áëîêà (ýòî ìîæåò çàíÿòü íåêîòîðîå âðåìÿ). Ðóêîâîäñòâî ïîëüçîâàòåëÿ Ñòðàíèöà 28 Ïåðåâåäåíî: Ñ. Ëàçóòêèí. ÇÀÎ “Êîìëàéí Òðåéä” Ìîñêâà, 2003 ã. 2.4 Êëåé 2.9 Glue Òåìïåðàòóðà íà ïîâåðõíîñòè êëååâîãî áàðàáàíà: Glue drum êëåÿ temperature: Äëÿ òåìïåðàòóðû êëåÿ íà ïîâåðõíîñòè êëååâîãî áàðàáàíà â äèàïàçîíå ìåæäó 1400 To âûáîðà select between 140° and 165°C using the knob (1) 0 è For 165 the Ñ èñïîëüçóéòå ðó÷êó (1).select Äëÿ êëåÿ, ïîñòàâëÿåìîãî êîìïàíèåé C. P. supplied glueðåãóëèðîâî÷íóþ (National coolbind 1300) 140°C. 0 Bourg (National coolbind 1300) âûáåðèòå òåìïåðàòóðó 140 Ñ Óðîâåíü êëåÿinâ the ðåçåðâóàðå ñ êëååì: Glue level tank: Óðîâåíü êëåÿofâthe ðåçåðâóàðå ïðîâåðÿòü ïðè âðàùàþùåìñÿ êëååâîì áàðàáàíå. The check glue level íåîáõîäèìî takes place when the drums are rotating. When the level gets Êîãäà óðîâåíü êëåÿmark ñíèçèòñÿ ìèíèìàëüíî äîïóñòèìîãî, èç-ïîä ñëîÿ êëåÿ ñòàíåò âèäíà low, the minimum in theäî bottom of the tank in the glue compartment becomes ìåòêà “mini”* visible.* Äëÿ çàñûïàéòå íåãî to êëåé òåõ ïîð, êàê To ïðåäóïðåæäåíèÿ avoid an overflow,ïåðåïîëíåíèÿ fill the tank withðåçåðâóàðà, glue granules until they âreach the äî bottom of the ãðàíóëû äîñòèãíóò íèæíåãî êðàÿ çàãðóçî÷íîãî ëîòêà (3) funnel (3). Ïîñëå äîëæåí áûòü âðîâåíü ñ ìåòêîé “maxi” Whenïîëíîãî melted, ïëàâëåíèÿ, they should êëååâîé just coverñëîé the maximum mark. ÂÍÈÌÀÍÈÅ:The Êëååâîé íèêîãäà íå äîëæåí ìàêñèìàëüíûé óðîâåíü, è below CAUTION: glueñëîé amount should neverïðåâûøàòü be over the maximum level either îïóñêàòüñÿ íèæå óðîâíÿ ìèíèìàëüíîãî. Ïåðèîäè÷åñêè äîáàâëÿéòå êëåé â ðåçåðâóàð. the minimum level. Prefer a regular filling. * * Íåïðîâåäåííîå ìîæåò ïðèâåñòè to ê âûõîäó èç ñòðîÿ Neglectingâîâðåìÿ to refilläîçàïîëíåíèå in time mayêëååì result in damage the glue tank.íàãðåâàòåëÿ êëååâîãî ðåçåðâóàðà. Ðàáî÷àÿ òåìïåðàòóðà Òåêóùàÿ êëåÿ Glue T° òåìïåðàòóðà êëåÿ Working T° (red needle) ÌèíèìàëüíàÿMinimum òåìïåðàòóðà, (black needle) T° for drum rotation ïðè êîòîðîé êëååâîé áàðàáàí (green needle) íà÷èíàåò âðàùàòüñÿ. 2 150 10 0 50 200 25 0 3 1 Íàíåñåíèå êëåÿ: Glue distribution : = Òîëùèíà êëååâîãî ñëîÿ ïîâåðõíîñòè áàðàáàíîâ ðåãóëèðóåòñÿ àâòîìàòè÷åñêè. • The film of glue on theíà drum is controlled automatically. = ×èñòÿùåå ëåçâèå óäàëÿåò èçëèøêè êëåÿ ñ êîðåøêà áëîêà, êëååâîãî ñëîÿ • A glue spreader removes the excess of glue from the spineòîëùèíà of the book, íà êîðåøêå ðåãóëèðóåòñÿ êîëåñà (2): its height is adjustableïîâîðîòîì by means of a thumbwheel (2): =  •ïîëîæåíèè “0” âåñü êëåé óäàëÿåòñÿ ñ êîðåøêà. At zero, almost all the glue is removed from the spine. =  •ïîëîæåíèè íà êîðåøêå At 9, about “9” 1 mm of glue is îñòàåòñÿ left on theêëååâîé spine. ñëîé ïðèáëèçèòåëüíî 1 ìì òîëùèíû. ÂÀÆÍÎ: íå èçìåíÿéòå ïîëîæåíèå êîëåñà áîëåå ÷åìtwo íà äâà äåëåíèÿ Important: Íèêîãäà Never change the adjustment (2) by (2) more than graduations áåç ïðîâåðêè ðåçóëüòàòîâ ðåãóëèðîâêè. without checking the result. Íèêîãäà íå èçìåíÿéòå ïîëîæåíèå ðåãóëèðîâî÷íîãî êîëåñà (2), ïîêà êëåé íå ïðîãðåëñÿ Never change the adjustment when glue is not at fusion temperature äî ðàáî÷åé òåìïåðàòóðû. (glue drums rotating) Operator Manual Ðóêîâîäñòâî ïîëüçîâàòåëÿ Ñòðàíèöà 29 Ïåðåâåäåíî: Ñ. Ëàçóòêèí. ÇÀÎ “Êîìëàéí Òðåéä” Ìîñêâà, 2003 ã. Çàùèòà îò ïåðåãðåâà: Over temperatureñsafety detection: íîðìàìè Òåõíèêè Áåçîïàñíîñòè, êëååâîé áàðàáàí è =  ñîîòâåòñòâèè ìåæäóíàðîäíûìè êëååâîé óñòðîéñòâîì çàùèòû the îò ïåðåãðåâà. Äàííàÿ ñèñòåìà • To ðåçåðâóàð comply withñíàáæåíû international safety regulations, glue tank and the drum are equipped îñòàíàâëèâàåò ðàáîòó òåðìîêëååâîé ìàøèíû â ñëó÷àå, òåìïåðàòóðà êëåÿtemperatuïðåâûñèò of temperature regulation circuitry. The system stopsåñëè the machine if the glue 1700Ñ. re exceeds 170°C either on one or on other sensors. 0 = Òåðìîêëååâàÿ íà ðàáîòó ñbelow ìàêñèìàëüíîé òåìïåðàòóðîé This systemìàøèíà requiresðàññ÷èòàíà a working temperature 165°C andðàáî÷åé a glue flash point higher165 Ñ 0 è êëåÿìè, âîñïëàìåíåíèÿ êîòîðûõ âûøå, ÷åì 200 Ñ. thanòåìïåðàòóðà 200°C. = Ïîñëå òîãî, çàùèòíàÿ ñèñòåìà ñðàáîòàëà, âêëþ÷åíèå • After theêàê system activated, the machine shutïîñëåäóþùåå down and the binder restartòåðìîêëååâîé could only be ìàøèíû âîçìîæíî òîëüêî ñ ïîìîùüþ ñåðòèôèöèðîâàíîãî êîìïàíèåé C. P. Bourg òåõíè÷åñêîãî done by a technician. ñïåöèàëèñòà. Ðóêîâîäñòâî ïîëüçîâàòåëÿ Ñòðàíèöà 30 Ïåðåâåäåíî: Ñ. Ëàçóòêèí. ÇÀÎ “Êîìëàéí Òðåéä” Ìîñêâà, 2003 ã. 2.10 Ïîäãîòîâêà òåðìîêëååâîé ìàøèíû ê ðàáîòå 2.10 To set up the Binder module = Âûáåðèòå è óñòàíîâèòå â êàðåòêó íàïðàâëÿþùèå (1) â ñîîòâåòñòâèè ñ âûñîòîé • Select and clip the proper pair of carriage jaws extensions (1) and install them in the ñêëåèâàåìîãî áëîêà corresponding holesíà in ïîäàþùèé carriage jaws. = Çàãðóçèòå îáëîæêè ñòîë (2) = Óñòàíîâèòå ïðàâèëüíûé ðàçìåð ñêëåèâàåìîãî áëîêà âî âòîðîì øàãå ìåíþ • Load the cover station (2) òåðìîêëååâîé ìàøèíû. = Âûáåðèòå íåîáõîäèìîå óñèëèå áîêîâîãî ïðèæàòèÿ îáëîæêè ê áëîêó (3) Select the proper size bookóðîâåíü in the second step ofâîçäóõà the menu =•Óñòàíîâèòå íåîáõîäèìûé âñàñûâàíèÿ äëÿ óñòðîéñòâà ïîäà÷è îáëîæåê (4) Select sideóñèëèå cover clamping =•Âûáåðèòå ïðèæèìàpressure îáëîæêè(3). ê êîðåøêó áëîêà (5) = Óñòàíîâèòå ïðîäîëæèòåëüíîñòü ïðèïðåññîâêè îáëîæêè ê áëîêó (6) Select suction level (4) ïîâåðõíîñòè ñòàëêèâàòåëÿ (7) =•Îòðåãóëèðóéòå âûñîòó • Select spine pressure (5) • Select the duration of the cover clamping (6) • Adjust the jogger height (7) 1 2 L TRO NG CON IERU RE GUL ATU TION RE PER ATURRE ULA ATU REG PER LE TURING E TEM PER TEM COL URS GLU TEM ATU LEIM PER TEM LIJM EME NCY RGE P P STO STO ET CE NOT ARR GEN OP D'UR DST NOO 5 c.p. bourg 7 MENU 5 6 7 4 8 3 9 2 1 6 PROGR. 10 3 4 Ðóêîâîäñòâî ïîëüçîâàòåëÿ Ñòðàíèöà 31 Ïåðåâåäåíî: Ñ. Ëàçóòêèí. ÇÀÎ “Êîìëàéí Òðåéä” Ìîñêâà, 2003 ã. ENTER S.A. N.V. 2.11 Âûâîäíîå óñòðîéñòâî (ïîñòàâëÿåòñÿ äîïîëíèòåëüíî) 2.11 Output unit (optional) = Êîãäà ñêëååíûé áëîê ïîïàäàåò â âûâîäíîå óñòðîéñòâî, êëåé íà êîðåøêå áëîêà • When the booklets are delivered on the output unit, the glue is still soft and âñå åùå ïðîäîëæàåò îñòàâàòüñÿ ãîðÿ÷èé è ðàçìÿã÷åííûé. Íå âûíèìàéòå áëîê èç warm. Do no take them immediately. âûâîäíîãî óñòðîéñòâà íåìåäëåííî ïîñëå ïîïàäàíèÿ åãî òóäà. = Îòðåãóëèðóéòå ðàññòîÿíèå ìåæäó ïðèåìíûìè øëèöàìè ñ ïîìîùüþ ðó÷êè (4) â • Adjust the receiver spline with the thickness book by using the knob (4) ñîîòâåòñòâèè ñ òîëùèíîé ñêëåèâàåìîãî áëîêà, îñòàâèâ äëÿ íåãî â ïðèåìíîì ëîêå according to the size of the books, allow sufficient space. äîñòàòî÷íî ñâîáîäíîãî ìåñòà. = Äëÿ áåçîïàñíîñòè îïåðàòîðà, âûâîäíîå óñòðîéñòâî ñíàáæåíî êíîïêîé • For your convenience there is an emergency stop (1) which you can press with àâàðèéíîãî îñòàíîâà (1), êîòîðóþ îïåðàòîð ìîæåò íàæàòü íîãîé. Ïîñëå îòæàòèÿ your feet. êíîïêè â ïåðâîíà÷àëüíîå ïîëîæåíèå, äëÿ îñóùåñòâëåíèÿ âîçìîæíîñòè Further to the unlocking of the switch, a push on button (2) is required to reset äàëüíåéøåé ðàáîòû, îïåðàòîðó íåîáõîäèìî äîïîëíèòåëüíî íàæàòü êíîïêó the process. ïåðåçàãðóçêè óñòðîéñòâà (2). = Ïðåäîõðàíèòåëè (3) ÿâëÿþòñÿ àâòîìàòè÷åñêèìè, ïîñëå ñðàáàòûâàíèÿ, îíè ìîãóò • The fuses (3) are resettable after tripping. áûòü ïðèâåäåíû â ðàáî÷åå ñîñòîÿíèå íàæàòèåì íà ñîîòâåòñòâóþùèå êíîïêè. = Êîãäà ïðèåìíûé ëîòîê âûâîäíîãî óñòðîéñòâà îêîí÷àòåëüíî çàïîëíèòñÿ, íà • When the unit is full, the message “empty output unit” appears in the display. äèñïëåå òåðìîêëååâîé ìàøèíû îòîáðàçèòñÿ íàäïèñü “empty output unit” Empty the BBR and press on the button (2). (“îñâîáîäèòå ïðèåìíîå óñòðîéñòâî)”. Îñâîáîäèòå ëîòîê îò áëîêîâ è íàæìèòå íà êíîïêó (2). 1 êíîïêà àâàðèéíîé îñòàíîâêè 21Êíîïêà ñáðîñà îøèáîê Emergency stop Reset buttonïðåäîõðàíèòåëè 32Àâòîìàòè÷åñêèå 3 Resettable fuses 4 Spline adjustment 4 Ðåãóëèðîâêà ïðèåìíîãî ëîòêà ïî òîëùèíå áëîêà 4 1 2 3 Ðóêîâîäñòâî ïîëüçîâàòåëÿ Ñòðàíèöà 32 Ïåðåâåäåíî: Ñ. Ëàçóòêèí. ÇÀÎ “Êîìëàéí Òðåéä” Ìîñêâà, 2003 ã. 2.12 Íà÷àëî ðàáîòû. 2.12 Binding condition Ñîîáùåíèÿ íà èíäèêàòîðå ìàøèíû * Äåéñòâèå Display * Action 1. Âêëþ÷èòå ìàøèíó âûêëþ÷àòåëåì 1. ãëàâíûì • Turn on the master switch REMOV E PAP ER F ROM B I NDER I F ANY NB OF B I ND I NGS : 0 2. ☞ Ïåðèîä íàãðåâàíèÿ êëåÿ Warm up period (îêîëî 35 ìèíóò**) (± 35 minutes **) PRE S S KE Y DRUM TO S T AR T HEA T I NG DRUM I S HEA T I NG BU T I S S T I L L TOO COL D Âêëþ÷èòå • Turn oníàãðåâ drum êëååâîãî áàðàáàíà heating Ïðîäîëæèòåëüíîñòü îêîëî Duration ìèíóòû. Åñëè êàðåòêà íå ± 1/2ïîçèöèè, minute íàõîäèòñÿ â ñòàðòîâîé If carriage is not in íàæìèòå îäíîâðåìåííî äâå home position press çåëåíûå êíîïêè íà ïàíåëè ìàøèíû. both green buttons Èíèöèàëèçàöèÿ òåðìîêëååâîé Reset by pressing both ìàøèíû îäíîâðåìåííûì íàæàòèåì green buttons äâóõ çåëåíûõ êíîïîê RE S E T NB OF B I ND I NGS : 0 B I NDER READY NB OF B I ND I NGS : 0 NB OF B I ND I NGS : 0 íà÷àëà 3. Äëÿ • Press startðàáîòû buttonsîäíîâðåìåííî íàæìèòå äâå çåëåíûå êíîïêè, ðàñïîëîæåííûå íà ïàíåëè ìàøèíû. * Íà èíäèêàòîðå íå îòîáðàæàþòñÿ ñîîáùåíèÿ: Îïöèîíàëüíûé òàéìåð âêëþ÷åí, òåêóùåå âðåìÿ * no message: the start up timer is not satisfied. (if running) âûáðàíî íà íåì, êàê íåðàáî÷åå. ** 10 minutes only if tank is already warmed up by start up timer. ** Âðåìÿ îæèäàíèÿ ñîêðàùàåòñÿ äî 10 ìèíóò, åñëè òåðìîêëååâàÿ ìàøèíà áûëà ïðåäâàðèòåëüíî âêëþ÷åíà ïîñðåäñòâîì îïöèîíàëüíîãî òàéìåðà. Ðóêîâîäñòâî ïîëüçîâàòåëÿ Ñòðàíèöà 33 Ïåðåâåäåíî: Ñ. Ëàçóòêèí. ÇÀÎ “Êîìëàéí Òðåéä” Ìîñêâà, 2003 ã. 2.13 Îïèñàíèå ðàáî÷åãî öèêëà ìàøèíû 2.13 Cycle description =•Âñòàâüòå áëîê, ñêëåéêè â êàðåòêó ìàøèíû Insert the setïðåäíàçíà÷åííûé of sheets in theäëÿ carriage. =•Ñòàëêèâàòåëü ìîæåò áûòü âûêëþ÷åí, ïîñðåäñòâîì íîæíîé êíîïêè (see íà ïàíåëè óñòðîéñòâà. The jogging can be interrupted by the footswitch or ïåäàëè switch èëè ON/OFF “control panel”). = Çàêðîéòå êàðåòêó, ïóòåì îäíîâðåìåííîãî íàæàòèÿ íà äâå çåëåíûå êíîïêè íà ïàíåëè ìàøèíû. • Close the carriage by pressing both green buttons simultaneously. Ñêëåèâàíèå áëîêà ñ îáëîæêîé Automatic process with cover Ïðèêëåèâàíèå Cover îáëîæêè clamping Çàìå÷àíèå: Note: Ïðè ðàáîòå ïîäà÷åé Inâ ðåæèìå modeN --> N 1 c ïðåäâàðèòåëüíîé 1 with pre-feed: no, îáëîæêè, ïîäà÷à ïîñëåäíåé êîíòðîëèðóåòñÿ the cover feeding is controlled by îäíîâðåìåííûì íàæàòèåì äâóõ çåëåíûõ êíîïîê íà ïàíåëè òåðìîêëååâîé ìàøèíû pressing both green buttons Ñêëåèâàíèå Glueing Òîðøîíèðîâàíèå / Milling ôðåçåðîâàíèå Notching Ñòàëêèâàíèå Jogging Ñêëåèâàíèå Glueing Ñêëåèâàíèå áëîêà áåç îáëîæêè. Âûáðîñ Automatic process áëîêàwithout âíèç. cover evacuation: bottom Òîðøîíèðîâàíèå / (Milling ôðåçåðîâàíèå Notching) Ñòàëêèâàíèå Jogging Ñêëåèâàíèå Ñêëåèâàíèå áëîêà áåç îáëîæêè. Èçâëå÷åíèå Automatic process áëîêà ñâåðõó. without cover evacuation: top Glueing Òîðøîíèðîâàíèå / (Milling ôðåçåðîâàíèå Notching) Ñòàëêèâàíèå Jogging Êàðåòêà âîçâðàùàåòñÿ â ïåðâîíà÷àëüíîå ïîëîæåíèå (çîíà çàãðóçêè áëîêîâ), ìàøèíà îæèäàåò äàëüíåéøèõ • Carriage goes back to loading area and stand-by.* äåéñòâèé îïåðàòîðà.* * *Øèðèíà ðàñêðûòèÿ êàðåòêèisïðåäâàðèòåëüíî ðåãóëèðóåòñÿ ñîîòâåòñòâèè ñ òîëùèíîé ñêëåèâàåìîãî áëîêà. The carriage opening pre-adjusted to match theâthickness of the previous book. Ðóêîâîäñòâî ïîëüçîâàòåëÿ Ñòðàíèöà 34 Ïåðåâåäåíî: Ñ. Ëàçóòêèí. ÇÀÎ “Êîìëàéí Òðåéä” Ìîñêâà, 2003 ã. 3. Îáñëóæèâàíèå. 3. MAINTENANCE 3.1 îáñëóæèâàíèå. 3.1 Ïåðèîäè÷åñêîå Preventive maintenance  ñèëó êîíñòðóêöèè îáñëóæèâàíèå ñâîäèòñÿ ê is Due toîñîáåííîñòåé the advanced nature ofòåðìîêëååâîé the materialsìàøèíû, used inïåðèîäè÷åñêîå the binder, the preventive åå maintenance âíåøíåìó îñìîòðó, î÷èñòêå îò ïûëè è ðåãóëèðîâîê â ñëó÷àå êðàéíåé íåîáõîäèìîñòè. reduced to the level of inspection, cleaning and occasional adjustments. ÂÍÈÌÀÍÈÅ! Ïåðåä íà÷àëîì Warning: Disconnect ïðîôèëàêòè÷åñêîãî îáñëóæèâàíèÿ, the main power before îòêëþ÷èòå òåðìîêëååâóþ ìàøèíó you perform the mainîò ýëåêòðè÷åñòâà! tenance 1 3 Ïðîâåðüòå òðàêò âûäà÷è áëîêîâ è ñòîë äëÿCheck ïðèæèìà îáëîæåê íà path íàëè÷èå the ejection and îñòàòêîâ êëåÿ. Ïðè íåîáõîäèìîñòè cover clamp for particles of glue. óäàëèòå çàñòûâøèé êëåé., â ïðîòèâíîì Clean as required, otherwise ñëó÷àå, íåóäàëåííûå îñòàòêè ìîãóò the clamps may freeze up and may âûçâàòü çàêëèíèâàíèå ïðèæèìíîãî ñòîëà, è, êàê ñëåäñòâèå, blow a fuse. ïåðåãîðàíèå ïðåäîõðàíèòåëåé. Èñïîëüçóéòå äëÿ Use a cloth with spirit (SOLî÷èñòêè ñàëôåòêó, ñìî÷åííóþ ñïèðòîì. 2 4 9 8 6 8 VOID.RAP N° 9900 107). Çàìå÷àíèå: Ñèëèêîíîâûé ñïðåé ìîæåò Note: Silicone spray èñïîëüçîâàòüñÿ äëÿ ïðåäîòâðàùåíèÿ can be used to íàëèïàíèÿ êëåÿ íà ðàáî÷èå ïîâåðõíîñòè stop the glue from sticòåðìîêëååâîé ìàøèíû. Áóäòå îñòîðîæíû -king íå äîïóñêàéòå ïîïàäàíèÿ to the mechanism, 5 but ñïðåÿ â êëååâîé ðåçåðâóàð èëènot íà to if used, be very careful ïîâåðõíîñòü êëååâîãî áàðàáàíà. Ýòî ìîæåò spray in the glue tank or onto the ïðèâåñòè ê ïîð÷å êëåÿ. 7 drum.This would ruin the glue. Âíèìàíèå: ðåçåðâóàð âîhot. âðåìÿ ðàáîòû ñèëüíî íàãðåâàåòñÿ. Caution : êëååâîé The glue tank is Use protection gloves toÈñïîëüçóéòå çàùèòíûå ìàòåðèàëû ïðè ðàáîòå â íåïîñðåäñòâåííîé áëèçîñòè îò ðåçåðâóàðà. work around it Íîìåð Ref 1 Îïèñàíèå Description ×àñòîòà Frequence Åæåäíåâíî Daily Åæåíåäåëüíî Weekly Ñòàëêèâàòåëü Vibrating X table ×èñòêà Cleaning Êîììåíòàðèè Comment Çàìåíà Replacement X Êàæäûé ðàç, çàìåíÿÿ ìåøîê äëÿ ñáîðà ïûëè, ïðîâåðÿéòå åãî 2 3 4 5 6 Ìåøîê äëÿ ñáîðà ïûëè Dust bag X Ôðåçà Milling housing X Each time you change the dust áóìàãè. bag check for stuffing ñîäåðæèìîå íà íàëè÷èå â íåì ïîëîñîê Åñëè êîëè÷åñòâî òàêèõin ïîëîñîê áóäåòhousing î÷åíü áîëüøèì, âûçîâèòå äëÿIf the milling and for paperñåðâèñíîãî strips in èíæåíåðà the bag. ïðîâåðêè ñîñòîÿíèÿ ðåçöîâ òîðøîíèðîâàíèÿ è ôðåçû. the number of paper strips is excessive, call for service Ôðåçà è ïðîñòðàíñòâî ðÿäîì ñ íåé äîëæíî áûòü î÷èùåíî îò ïûëè è There should be no stuffing in the milling housing ãðÿçè. X Çàãðÿçíåííûé êëåé Ðåçåðâóàð äëÿ êëåÿ Glue tank X X Ïðèñîñêè Suction cup Ñòîë ïðèæèìà Cover nipping îáëîæåê plate X X X X Âûâîäíîé òðàêò 7 Evacuation guide X X 8 Áîêîâîé ïðèæèì Nippers X X 9 Çàäíèé óïîð Rear clamp ïðèæèìíîãî guardñòîëà. nipping X X Purge glue Ïðîâåðÿéòå êëåé íà ïðåäìåò åãî çàãðÿçíåííîñòè. Ïîïîëíåíèå ðåçåðâóàðà ñ êëååì òåðìîêëååâîé Check the glueïðîèçâîäèòñÿ for qualityñèëàìè and îïåðàòîðà for oxidation. Refill ìàøèíû. Çàìåíà êëåÿ ïðîèçâîäèòñÿ ñèëàìè ñåðâèñ - èíæåíåðà. by operator. Call ingeneer for replacement of glue Çàìåíèòå â ñëó÷àå íåîáõîäèìîñòè Replace as necessary Ïðîâåðòå ñîñòîÿíèå òåôëîíîâîãî ïîêðûòèÿ ñòîëà. Check state Teflon covering Ïðîâåðÿéòå îñìîòðîì ñâåðõó, êîãäà áîêîâûå ïðèæèìû ïîëíîñòüþ ðàñêðûòû. Check from the top with clamping station fully open Óäàëèòå çàñòûâøèé êëåé station Ðóêîâîäñòâî ïîëüçîâàòåëÿ Ñòðàíèöà 35 Ïåðåâåäåíî: Ñ. Ëàçóòêèí. ÇÀÎ “Êîìëàéí Òðåéä” Ìîñêâà, 2003 ã. Remove glue strings 3.2 Çàìåíà ìåøêà äëÿ ñáîðà áóìàæíîé ïûëè 3.2 Paper dust bag replacement Ìåøîêbag äëÿ ñáîðà áóìàæíîé ïûëè Dust = •Çàìåíÿéòå ìåøîêabout ÷åðåç every êàæäûå20 20hours ÷àñîâ of ðàáîòû òåðìîêëååâîé ìàøèíû.  ïðîòèâíîì ÷àñòèöû Replacement binding is important, otherwise paper ñëó÷àå, dust could áóìàæíîé ïûëè ìîãóò ïîïàäàòü â êëååâîé ðåçåðâóàð, óõóäøàÿ òåì ñàìûì êà÷åñòâî êëåÿ. ruin the glue. = Óäàëèòå ñòàðûé ìåøîê Removeèëëþñòðàöèþ, and throw away the bag. = •Ñìîòðèòå ÷òî áû ïðàâèëüíî óñòàíîâèòü íîâûé ìåøîê. • See the illustration above to hook a new ÷òî one. = Ñïåöèàëüíûé ìèêðîïåðåêëþ÷àòåëü îïðåäåëèò, ìåøîê äëÿ ñáîðà ïûëè áûë çàìåíåí. • A pressure switch detects the “Replace dust bag” situation. Çàìå÷àíèå: Note : The message “Replace dust bag” is displayed on the control panel. ñîîáùåíèå “Çàìåíèòå ìåøîê äëÿ ñáîðà ïûëè” (“Replace dust bag”) ìîæåò âûñâå÷èâàòüñÿ íà êîíòðîëüíîé ïàíåëè ìàøèíû. machine will not ðàáîòà start íà when this message appears. Ïðè ýòîì, áåçThe çàìåíû ìåøêà, äàëüíåéøàÿ ìàøèíå íåâîçìîæíà. Ïîñëå çàìåíû ìåøêà, íàæìèòå îäíîâðåìåííî äâå çåëåíûå êíîïêè, äëÿ îòêëþ÷åíèÿ è ïðîäîëæåíèÿ íîðìàëüíîé ðàáîòû. Message and stopñîîáùåíèÿ condition can be erased by depressing the 2 green knobs. Îáñëóæèâàíèå óñòðîéñòâà äëÿ èñïàðåíèé êëåÿ (ïîñòàâëÿåòñÿ ïî äîïîëíèòåëüíîìó Glue smell suppression isóñòðàíåíèÿ provided (optional). çàïðîñó): neutralization is time to replace the óñèëèëñÿ, filters. íåîáõîäèìî Åñëè ïðè When ðàáîòå smell òåðìîêëååâîé ìàøèíû,decreases, çàïàõ êëåÿ âit ïîìåùåíèè çíà÷èòåëüíî technician. çàìåíèòü Call ñïåöèàëüíûå ôèëüòðû. Âûçîâèòå ñåðâèñ - èíæåíåðà äëÿ âûïîëíåíèÿ ýòîé ðàáîòû. Ðóêîâîäñòâî ïîëüçîâàòåëÿ Ñòðàíèöà 36 Ïåðåâåäåíî: Ñ. Ëàçóòêèí. ÇÀÎ “Êîìëàéí Òðåéä” Ìîñêâà, 2003 ã. 4. Óñòðàíåíèå ïðîáëåì. 4. MECHANICAL TROUBLE SHOOTING Ïðîÿâëåíèå Symptom Îáëîæêà, The cover ïðèêëååíàÿ is not squareêon áëîêó, íå èìååò ôîðìó the paper offset (skewed). êâàäðàòà (èñêðèâëåíà) Âîçìîæíûå ïðè÷èíû Probable cause Îáëîæêà The coveríåïðàâèëüíî is not cut square. îáðåçàíà The cover station and Áëîê paperíåïðàâèëüíî pile are not square to îáðåçàí the machine. Îáëîæêà The coverñëèøêîì is too far ñèëüíî on ñìåùåíà âïðàâî the right. Îáëîæêà The coverñëèøêîì is too far ñèëüíî on ñìåùåíà the left. âëåâî Óñòðàíåíèå Remedy Ïðîâåðüòå ôîðìó îáëîæêè Check the covers. Ïðîâåðüòå ôîðìó áëîêà Check the squareness Ïðîâåðüòå âçàèìíîå with respect to the nippers. ðàñïîëîæåíèå áëîêà è îáëîæêè Ñìåñòèòå óïîðûstop ñòîëà Adjust theáîêîâûå cover station ïîäà÷è îáëîæåê âëåâî to the left. Adjust theáîêîâûå cover station Ñìåñòèòå óïîðûstop ñòîëà to the right. ïîäà÷è îáëîæåê âïðàâî Íà êîðåøîê áëîêà There is not enough glue íàíîñèòñÿ íåäîñòàòî÷íîå on the back of the book. êîëè÷åñòâî êëåÿ Ëåçâèå óäàëåíèÿ The glue spreaderèçëèøêîâ is too êëåÿ ïîäíÿòî ñëèøêîì high. âûñîêî Ñòðàíèöû áëîêà The pages areïðè warped êîâåðêàþòñÿ where the glue is applied íàíåñåíèè íà íèõ (spread out). êëååâîãî ñëîÿ Áóìàãà ñëèøêîì òîíêàÿ äëÿ Ïðîâåðüòå ñîñòîÿíèå ôðåçû è ðåçöîâ The paper is too weak for Checkòîðøîíèðîâàíèÿ. the cutter. ôðåçåðîâàíèÿ milling. Check the paper quality. Êîðåøîê îáëîæêè èìååò The covers suffer from ôîðìó øëÿïêè ãâîçäÿ nail head. Ïðîâåðòå Check the ïîëîæåíèå glue spreader. ëåçâèÿ äëÿ ñíÿòèÿ èçëèøêîâ êëåÿ. Ïðîâåðüòå êà÷åñòâî áóìàãè Î÷åíü ñèëüíûé ïðèæèì îáëîæêè Ïðîâåðüòå óñèëèå ïðèæèìà Check the pressure. îáëîæêè Ïðîâåðüòå ìàòåðèàë, Check the cover ïðåäíàçíà÷åíûé äëÿmaterial. èçãîòîâëåíèÿ îáëîæêè Îáëîæêà ïëîõî ïðèêëåèâàåòñÿ ê áëîêó, There áëîê is poor ñêëååíûé ïëîõîejection èçâëåêàåòñÿ èç òåðìîêëååâîé ìàøèíû and nipping. Çàñòûâøèé êëåé íà áîêîâûõ There is glue on the exit ïðèæèìàõ èëè âûâîäíîì òðàêòå slide and nippers. ìàøèíû Óäàëèòå èçëèøêè êëåÿ Remove the glue. Áëîê èñêðèâëÿåòñÿ ïîñëå The book buckles ïðèêëåèâàíèÿ îáëîæêè Áóìàãà áëîêà The book isñëèøêîì too thin òîíêàÿ for the äëÿ îáëîæêè äàííîé ïëîòíîñòè Âûáåðèòå áîëåå òîíêóþ Select a lighter cover îáëîæêó Êîðåøîê îáëîæêè èìååò The cover doesíånot show ÷åòêî âûðàæåíîé ãðàíèöû, a sharp crease on îáëîæêà íå ïðèëåãàåò ê áëîêó Ìàòåðèàë ñëèøêîì The cardîáëîæêè is heavy and the òîíêèé Ïðîáèãóéòå Crease theîáëîæêó covers. when cover is applied. the spine. The cover nipping is too Ìàòåðèàë ñëèøêîì ëåãêèé, ÷òî hard. áû èñïîëüçîâàòü åãîweak â êà÷åñòâå The cover is too for îáëîæêè the paper in the nippers. cover weight. covers varnished. Cover cross grained.áûë Ìàòåðèàë äëÿ îáëîæêè íàðåçàí ïîïåðåê âîëîêîí Ðóêîâîäñòâî ïîëüçîâàòåëÿ Ñòðàíèöà 37 Ïåðåâåäåíî: Ñ. Ëàçóòêèí. ÇÀÎ “Êîìëàéí Òðåéä” Ìîñêâà, 2003 ã. 5. Íåêîòîðûå íàèáîëåå ðàñïðîñòðàíåííûå äåôåêòû ñêëåéêè. 5. SOME COMMON GLUEING DEFECTS Ïðîáåëû íà êëååâîì ñëîå Gaps in glue film Íåðàâíîìåðíàÿ ïîâåðõíîñòü êëååâîãî Feather onñëîÿ book spine Ïðîâåðüòå: Check: = Òåìïåðàòóðó êëååâîãî - Glue and ïîâ-òè roller temperature. áàðàáàíà - Running temperature. = Ðàáî÷óþ òåìïåðàòóðó êëåÿ - Adhesive in tank. = Óðîâåíü êëåÿ level â ðåçåðâóàðå Êëåé Honeycomb èìååò ôîðìó film ñîò ñ ìåäîì Ïðîâåðüòå: Check: = Òåìïåðàòóðó êëååâîãî - Glue andïîâåðõíîñòè roller temperature. áàðàáàíà - Level of adhesive in the tank. = Óðîâåíü êëåÿ in â ðåçåðâóàðå - Moisture the cover or book stock. = Âëàæíîñòü îáëîæêè è áëîêà Îáëîæêà â âèäå øëÿïêè ãâîçäÿ Nail head Adhesive and/or Òåìïåðàòóðà êëåÿroller ñëèøêîì temperature too low. íèçêàÿ Ïðîâåðüòå: Check: = Ïðèæèì - Cover îáëîæêè press tooñëèøêîì tight. ñèëüíûé - Height of back pressure. = Ïðèæèìíîé ñòîë ïîäíÿò ñëèøêîì âûñîêî Íåîäíîðîäíûé ñëîé Uneven glueêëååâîé line Çàêðóãëåííûé êîðåøîê Cavity spine Íà êîðåøîê adhesive ïîäàåòñÿapplied. Insufficient íåäîñòàòî÷íîå êîëè÷åñòâî êëåÿ. Ïðîâåðüòå ïîëîæåíèå ëåçâèÿ äëÿ ñíÿòèÿ èçëèøêîâ êëåÿ. Ñëèøêîì Coverñèëüíûé press tooïðèæèì tight. îáëîæêè Sharpen the knife. Çàòóïèëàñü ôðåçà Îáëîæêà íåCover ñîâìåùàåòñÿ registerñ áëîêîì Îáëîæêà íåïðàâèëüíî Cover feed is ïîçèöèîíèðîâàíà not square íà ñòîëå ïîäà÷è with theîáëîæåê. cover clamp. Ðóêîâîäñòâî ïîëüçîâàòåëÿ Ñòðàíèöà 38 Ïåðåâåäåíî: Ñ. Ëàçóòêèí. ÇÀÎ “Êîìëàéí Òðåéä” Ìîñêâà, 2003 ã. c.p. bourg C.P. Bourg S.A. rue des Technologies, 22 B-1340 Ottignies (Belgium) Tel.: +32 (0) 10 / 62 22 11 Fax: +32 (0) 10 / 61 69 03 E-mail: export.be@cpbourg.com contactus@cpbourg.com C.P. Bourg GmbH Schweizerstrasse 70/1 D-72336 Balingen (Germany) Tel.: +49 7433 998 16 80 Fax: +49 7433 998 16 86 C.P. Bourg S.A. 14 rue Millewee, B.P. 85 L-7201 Walferdange (Luxembourg) Tel.: +352 33 24 47 Fax: +352 33 19 99 C.P. Bourg S.A. SILIC 410 32, rue des Gémeaux F-94573 Rungis (France) Tel.: +33 1 46 87 32 14 Fax: +33 1 46 87 52 17 C.P. Bourg Inc 50 Samuel Barnet Blvd. New Bedford MA 02745 USA Tel.:+1 508 998 6200 Fax:+1 508 998 2391 E-mail: cpbourg@worldnet.att.net http: //www.cpbourg.com C y er t i f i e d b ISO 9001 Ðóêîâîäñòâî ïîëüçîâàòåëÿ Ñòðàíèöà 39 Ïåðåâåäåíî: Ñ. Ëàçóòêèí. ÇÀÎ “Êîìëàéí Òðåéä” Ìîñêâà, 2003 ã. Çàìåòêè NOTES Ðóêîâîäñòâî ïîëüçîâàòåëÿ Ñòðàíèöà 40 Ïåðåâåäåíî: Ñ. Ëàçóòêèí. ÇÀÎ “Êîìëàéí Òðåéä” Ìîñêâà, 2003 ã. Çàìåòêè NOTES Ðóêîâîäñòâî ïîëüçîâàòåëÿ Ñòðàíèöà 41 Ïåðåâåäåíî: Ñ. Ëàçóòêèí. ÇÀÎ “Êîìëàéí Òðåéä” Ìîñêâà, 2003 ã. Çàìåòêè NOTES Ðóêîâîäñòâî ïîëüçîâàòåëÿ Ñòðàíèöà 42 Ïåðåâåäåíî: Ñ. Ëàçóòêèí. ÇÀÎ “Êîìëàéí Òðåéä” Ìîñêâà, 2003 ã.