Heat Transfer Equipment: Chemical Engineering Handbook Section

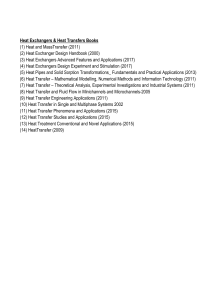

advertisement