AI in Distillation Processes: Applications & Optimization

advertisement

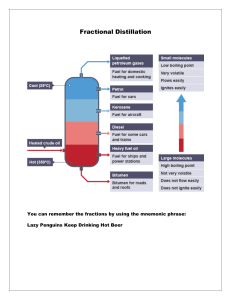

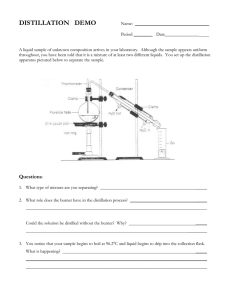

Applications of Artificial Intelligence in Distillation Processes Abstract: Artificial Intelligence (AI) has revolutionized various industries, and the field of chemical engineering is no exception. In recent years, AI technologies have shown great promise in enhancing the efficiency, safety, and optimization of distillation processes. This document explores the applications of AI in distillation, discussing how machine learning, neural networks, and other AI techniques are leveraged to improve distillation operations, reduce energy consumption, and optimize product purity. Furthermore, we examine the challenges and opportunities associated with the integration of AI in distillation processes. 1. Introduction: Distillation is a fundamental separation process widely used in the chemical and petrochemical industries to purify substances based on their boiling points. Traditionally, distillation process design and optimization relied heavily on empirical methods and heuristics. However, the advent of AI technologies has presented new opportunities for enhancing the efficiency and sustainability of distillation operations. 2. AI-Based Process Optimization: AI-driven process optimization has emerged as a powerful tool for improving the performance of distillation units. Machine learning algorithms can analyze vast datasets from distillation operations to identify optimal operating conditions, leading to increased energy efficiency and reduced production costs. Additionally, neural networks can predict critical parameters such as distillation column temperature, pressure, and flow rates, enabling real-time process adjustments for enhanced performance. 3. Fault Detection and Diagnostics: AI techniques have proven effective in detecting and diagnosing faults in distillation units. By analyzing sensor data and historical performance, AI algorithms can quickly identify anomalies and deviations from expected behavior. Early detection of issues allows for timely maintenance and avoids costly downtime, contributing to improved plant reliability. 4. Intelligent Control Systems: AI-based control systems offer sophisticated solutions for optimizing distillation processes. Reinforcement learning algorithms can learn from the system's behavior and adjust control parameters to achieve desired outcomes. Such intelligent control systems have demonstrated the ability to achieve tighter product specifications, higher product yields, and reduced energy consumption compared to conventional control methods. 5. Predictive Maintenance: The integration of AI in distillation processes enables predictive maintenance strategies. By analyzing sensor data and performance trends, AI algorithms can predict equipment failure before it occurs, allowing for proactive maintenance and minimizing unplanned shutdowns. 6. Optimization of Heat Integration: AI techniques play a crucial role in optimizing heat integration within distillation units. Genetic algorithms and neural networks can identify the most efficient heat exchanger configurations, minimizing energy consumption and overall operating costs. 7. Advanced Data Analytics for Process Insights: AI-driven data analytics provides valuable insights into process behavior and performance. By analyzing data from multiple sources, AI algorithms can identify hidden correlations and patterns, facilitating better decision-making and process improvements. 8. Challenges and Future Directions: Despite the numerous advantages AI brings to distillation processes, certain challenges must be addressed. Data quality, availability, and privacy concerns can limit the effective implementation of AI technologies. Additionally, there is a need for robust AI models that can handle process uncertainties and dynamic conditions. Continued research and development in AI for distillation will lead to smarter and more adaptive distillation units in the future. Conclusion: The integration of AI in distillation processes has the potential to revolutionize the chemical industry, leading to enhanced efficiency, reduced environmental impact, and improved product quality. By leveraging AI technologies for process optimization, fault detection, control, and predictive maintenance, distillation units can achieve higher performance levels and contribute to sustainable and efficient chemical production.