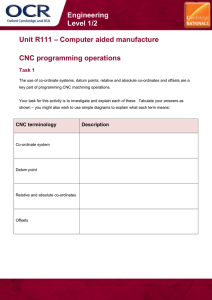

CRITERIA FOR ASSESSMENT OF TRAINEES Qualification Document: Machine Operator & Programmer – CNC Milling Sector: Petrochemical Assessment Guidelines: 1. Criteria for assessment for each Qualification Document will be created by CIPET. 2. Each Performance Criteria (PC) will be assigned marks proportional to its importance in Learning Outcome and few performance criteria may be allotted marks in combine. 3. Each Learning Outcome will be assessed both for theoretical knowledge and practical which is being proportionately demonstrated in the table below. 4. The assessment for the theory part will be based on knowledge bank of questions created by CIPET which will contain multiple choice theory questions and Practical question database with mark allotment criteria. 5. To pass the Qualification Pack, every trainee should score a minimum of 50 % in Functional and all Generic Learning Outcome’s. 6. In case of successfully passing only certain number of Learning Outcome’s, the trainee is eligible to take Subsequent assessment on the balance Learning Outcome’s to pass the Qualification Document. Title of the Component: Machine Operator & Programmer – CNC Milling Assessable Outcome LO CPC/ N 7119 Perform machining operations on metal or plastic material using Conventional Centre Milling machine Performance Criterion Description PC1. understand and comply with safety, environmental & other relevant regulations and guidelines PC2. wear personal protective equipment (PPE) like safety glasses, apron, no loose cloths/ hair, safety shoes while performing milling operations regulations while performing CNC turning operations PC3. ensure work area is clean and safe PC4. ensure that machine safety guards are in place and are in correctly working condition PC5. ensure that all tools, equipments are in a safe and usable conditions PC6. ensure availability of job specification i.e. approved drawings, sketches, instructions from the supervisor, job instruction sheet/ job card. PC7. read and understand the Job Assessment Criteria for the outcome Theory Practical Total 0.5 2 2.5 0.5 2 2.5 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 requirements from the job specifications and attention shall be given to the geometric tolerances PC8. check the work piece material for the dimensions and ensure that it is free from foreign objects, dirt or other contamination and is within the required size PC9. plan to perform the turning or other machining operations and sequence of operations as per required job specifications PC10. obtain all the appropriate tools and measuring instruments/ gauges required for the job PC11. check the milling machine for its functioning and ensure that it is ready for operation PC12. prepare the Milling machine for the operations by mounting and setting the required work holding devices and cutting tools PC13. clarify any doubt, if any and see necessary instruction /training on the operation of the machine whenever required PC14. hold the work piece securely and correctly, without distortion PC15. adjust the machine settings as per job requirement to maintain desired accuracy PC16. adjust and set the speed and feed of the Milling machine to achieve the job specifications PC17. Operate the machine tool controls safely & correctly, in line with operational procedures both in manual & power modes. PC18. stop the Milling machine, both in normal and emergency situations correctly by following the right procedure and should be able to restart the machine after and emergency PC19. should be able to use the Milling machine accessories and attachments such as steady and follower rests, tail stock, taper turning attachments, profile attachments etc. PC20. perform various Milling operations using different tools to produce components with various features. Tool: H.S.S, tools, brazed carbide tip tools, interchangeable carbide insert tools, drills, 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 reamers, boring tool, threading tool. Component Feature: flat faces, outer diameter parallel, stepped, eccentric and taper, chambers, grooves, undercuts, holes – drilled, reamed, bored, tapered, internal and external threads, internal and external threads, parting off, knurling or special profiles PC21. produce components as per required quality standards and free from burrs & sharp edges PC22. shall achieve given production targets PC23. shall be able to apply roughing and finishing cuts, considering the effect on tool life, surface finish and dimensional accuracy PC24. shall be able to use coolants/ cutting fluids for different combinations of work piece and tool as per different locations PC25. shall be able to observe and report any difficulties/ discrepancies that may arise during the machine operation and carry out the corrective actions as per instructions PC26. correctly shutting down the machine on completion of the machining operations, removing and disposing of the chips/ waste and critical parameters different locations PC27. use of measuring instruments/ gauges to check the critical parameters Range of checking equipment: e.g external micrometers, vernier/digital/dial calipers, dial test indicators (DTI), surface finish equipment (eg. comparison plates), steel rules, micrometers (internal, depth), depth verniers, gauges (slip, bore/hole), thread gauges (eg. ring, plug, profile), gauges (plug, ring, radius/profile), protractors, etc Critical parameters: diameters (external, internal, eccentricity), parallelism, bore/hole size/fit, angle/taper, surface finish, linear dimensions (eg. lengths, depths), grooves/undercuts (eg. position, width, depth), concentricity, ovality, thread fit, straightness, squareness PC28. shall be able to carry out the corrective action, in the case of deviation from the required specifications PC29. report the problem to the supervisor, if 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 LO CPC/ N 7120 Perform machining operations on metal or plastic work pieces using Computer Numerically Controlled Milling machines it cannot be resolved PC30. seek guidance from the supervisor/ specialist of the problem is outside his/her area of competence Sub total Performance Criterion Description PC1. understand and comply with safety, environmental & other relevant regulations and guidelines PC2. wear personal protective equipment (PPE) like safety glasses, apron, no loose cloths/ hair, safety shoes while performing milling operations PC3. ensure work area is clean and safe PC4. ensure that machine safety guards are in place and are in correctly working condition PC5. ensure that all tools, equipments are in a safe and usable conditions PC6. ensure availability of job specification i.e. approved drawings, sketches, instructions from the supervisor, job instruction sheet/ job card. PC7. read and understand the Job requirements from the job specifications and attention shall be given to the geometric tolerances PC8. check the work piece material for the dimensions and ensure that it is free from foreign objects, dirt or other contamination &is within the required size PC9. plan to perform the turning or other Millilng operations and the sequence of operations as per required job specifications on CNC Milling machine PC10. obtain all the appropriate tools and measuring instruments/ gauges required for the job PC11. check the CNC Milling machine for its functioning and ensure that it is ready for operation PC12. prepare the CNC Milling machine for the operations by mounting and setting the required workholding devices and cutting tools PC13. clarify any doubt, if any & see necessary instruction / training on operation of CNC Milling machine whenever required PC14. hold the work piece securely and 1 2 3 29 Theory 60 Practical 89 Total 1 3 4 1 3 4 1 1 3 3 4 4 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 correctly, without distortion PC15. adjust the CNC Milling machine settings as per job requirement to maintain desired accuracy PC16. perform daily maintenance of machine according to defined checklist, at the beginning of day's shifts. Basic maintenance activities: replenish coolant; ensure all parts are clean; perform housekeeping tasks on the machine; remove and dispose swarf PC17. use and extract information from engineering drawings, dimensioning and tolerances Drawings, dimensioning and tolerances: projections (orthographic [first angle, third angle]; isometric [including exploded], sectional view); reference points, lines, edges and surfaces PC18. use and extract information from reference charts, tables, graphs and Engineering standards Information pertaining to: e.g. thread sizes; feeds and speeds; machining symbols and tolerances; surface finish symbols; etc. PC19. load and unload component(s) using pre-determined fixtures or work holding devices as per work instructions Work-holding devices to position and secure work-pieces: chucks with hard jaws, chucks with soft jaws, fixtures, drive centres, collet chucks, faceplates, magnetic/pneumatic devices and other work-holding devices PC20. make basic program and check correctness of program through dry run and single block check PC21. adjust and set the speed and feed of the CNC Milling machine to achieve the job specifications PC22. operate the machine tool controls safely and correctly, in line with operational procedures. PC23. stop the CNC Milling machine, both in normal and emergency situations correctly by following the right procedure and should be able to restart the machine after the 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 emergency PC24. do first part cutting trial by setting tool offsets to get oversize part PC25. measure the critical parameters of the machined component on the machine (without removing from the machine ), after the trial run Critical parameters: linear dimensions (such as lengths, depths), slots (position, width, depth), flatness, surface finish, squareness, parallelism, hole size/fit, angles, recesses, thread fit, runout and roundness PC26. correct the offsets based on the measurements by accessing program edit facility in order to enter tooling data Tooling data: offset compensation, radius compensation PC27. measure the component after unloading to check for accuracy in the critical parameters as per job specifications PC28. produce machined components that combine different turning operations and have a range of features Features of machined components: facing, slotting, pocket milling, circular pocket, drilling, reaming, boring, counter boring, profile milling keyways, grooves, slots, gear cutting, helical milling or special profiles etc. PC29. follow the specified machining sequence and procedure as per job specifications PC30. interpret in-built machine alarms & respond to same as per operating manual or specified instructions PC31. observe for inconsistency in dimensions due to tool wear and correct the offsets accordingly PC32. ensure that machine settings are adjusted as and when required, either by self or the setter, to maintain the required accuracy PC33. identify when tools need replacement and replace worn tool with new tool PC34. produce components as per required standards Produce component standards: components 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 LO CPC/ N 7121 Programming of Computer Numerically Controlled (CNC) Milling Machines to be free from false tool cuts, burrs and sharp edges; general dimensional tolerance +/- 0.02mm; specific dimensional tolerances within +/- 0.1mm; surface finish within 1.6μm; reamed holes within H8; screw threads 6G/6H; angles/tapers within +/- 15 sec; flatness and squareness 0.025mm PC35. report problems and seek appropriate assistance in a timely manner PC36. complete documentation during and post operations as per organizational procedures and applicable quality management system PC37. return the machine and all tools and equipment to the correct location on completion of activities PC38. leave the work area in a safe and tidy condition on completion of job activities as per 5S practices Safe conditions: correctly isolated; operating programs closed or removed; cleaning the machine; ensuring that any spilt cutting fluids are correctly dealt with; disposing of metal and other waste PC39. report the problem to the supervisor, if it cannot be resolved PC40. seek guidance from the supervisor/ specialist of the problem is outside his/her area of competence Sub total Performance Criterion Description PC1. comply with health and safety, environmental and other relevant regulations and guidelines at work PC2. adhere to procedures and guidelines for personal protective equipment (PPE) and other relevant safety regulations while programming CNC Milling machines PC3. work following laid down procedures and instructions PC4. ensure that machine guards are in place and are correctly adjusted PC5. read and understand safety instructions, warning signs on the machine PC6. ensure work area is clean and safe from hazards 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 40 Theory 120 Practical 160 Total 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 PC7. ensure that all tools, equipment, power tool cables, extension leads are in a safe and usable condition PC8. ensure availability of job specification i.e. approved drawings, sketches, instructions from the supervisor, job instruction sheet/ job card. PC9. read and establish job requirements from the job specification documentaccurately Job specification documents: detailed component drawings; approved sketches/illustrations; national, international and organizational standards; reference tables and charts; fabrication/casting drawings; operational diagrams; contractual specifications Job requirements: raw materials or components required (type, quality, quantity); dimensions; limits & tolerances; surface finish requirements; profiles to be generated; instruments & tools to be used; form tolerances (flatness, concentricity, etc.); cycle time, production rate; projections orthographic (first angle, third angle), isometric (including exploded, oblique); reference points, lines, edges & surfaces; dimensions (baseline, continuous); workholding devices. PC10. follow job instructions, assembly drawings and laid down procedures at all times PC11.report and rectify incorrect and inconsistent information in job specification documents as per organization procedures PC12. use and extract information from reference charts, tables, graphs and standards Information pertaining to: tapping sizes and threads; cutting parameters – feeds, speed, depth of cut; machining symbols and tolerances PC13. prepare the work area as per procedure or operational specification PC14. conduct a preliminary check of the readiness of the program so that the CNC machine operates correctly CNC machines: 2-axis CNC machine, 3-axis machining centers (VMC, HMC), > 3 axes machining centers(3.5/4/5 axes) Checks: ensure that all tool tool length / wear 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 / radius offsets are correctly entered; for finishing operations, adjust offsets to get slightly oversize/undersize dimensions to ensure that the part does not get rejected; run the program in dry run mode to ensure that there are no collisions between the tool and workpiece / work holding devices; check tool change positions are safe and clear of the workpiece and work holding devices; ensure that correct tools are selected at the appropriate points in the program; check if the tool paths are executed safely and correctly; ensure that the auxiliary functions operate at the correct point in the program(spindle start/stop, coolant flow, program optional stop); run the program, in single block mode wherever necessary; measure the dimensions of the component on the machine and make necessary corrections in tool offsets; inspect the component for all dimensions and record findings in specified formats; make necessary changes in tool length / wear / radius offsets to correct dimension errors; run the next component; ensure that all dimensions are within specifications; if dimensions are not within specifications, correct using appropriate actions; repeat this till parts come within specifications without any correction requirement PC15. determine what operational objectives and targets need to be achieved and how best the machine needs to be programmed to achieve this CNC programming operations: preparing, loading, storing in appropriate format, proving the part program, trial runs PC16. extract and use information from engineering drawings and related specifications in relation to work undertaken PC17. identify tool requirements from tooling layout and assess their suitability PC18. identify suitable workholding or fixturing device as per the job requirement PC19. ensure the correct and latest partprogram is uploaded onto the CNC system PC20. make CNC program with commands for tool motions, spindle motions, 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 miscellaneous functions & tool change, in syntax corresponding to machine and control system on which the component will be machined. PC21. various ways to make CNC program are by writing it on paper or in computer's text editor, or using CAM software or controllers on machine Ways: written, directly entered into machine controller, using computer software- CAM software PC22. ensure that part program is efficient & results in minimal cycle time, with optimal cutting parameters and no unnecessary tool motions PC23. use subprograms and canned cycles, to reduce program size and input time and avoid memory overflow on the machine PC24. transfer the program to the machine by entering it at the console or transmitting it through a wired link or through a data transfer device PC25. follow the correct procedures for calling up the program and dealing with any error messages or faults PC26. handle the typical problems that can occur with the programming, loading and editing activities effectively using approved procedures PC27. save the proven program in the appropriate storage medium – paper, computer hard disk, etc. and location PC28. complete relevant documentation as per organizational procedure PC29. leave the work area in a safe and tidy condition on completion of the activities PC30. obtain appropriate equipment or tools needed as per job requirements PC31. ensure that all measuring equipment is calibrated and approved for usage PC32. ensure that the tools and fixtures are in usable condition(eg. free from breakage, damage, calibration, etc.) PC33. pre-set tooling appropriately using setting jigs/ fixtures PC34. seek any necessary instruction/training on operation of the 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 machine where required PC35. mount tools in the correct positions in the tool turret or magazine PC36. check that the tools have been mounted in positions corresponding to tool numbers in the part program PC37. mount the part on machine firmly in the specified work holding devices, with the appropriate clamping forces. PC38. enter work offset and tool data on the machine – X and Z offsets, tool orientation and LOe radius for lathes; length offsets and tool radius for machining centers. PC39. ensure that tool data has been entered in offset number corresponding to tool offset numbers in part program PC40. deal with error messages and faults on the program or equipment PC41. cut a trial part using single block run, dry run and feed and speed override controls PC42. edit the program and adjust tool and wear offsets to correct any dimensional errors on the part PC43. ensure that trial part conforms to drawing specifi-cations in terms of dimensions, surface finishes & geometrical parameters like concentricity, parallelism, runout, etc. PC44 correct the tool wear offsets whenever required, based on the results of the period inspection PC45. change worn out tools and indexable inserts whenever required PC46. after every change of a worn out tool or insert, cut a trial part and correct any dimensional inaccuracies by adjusting the tool offsets or wear offsets PC47. return worn out cutting tools, workholding device / fixtures / instruments / drawings to store PC48. ensure that there is no damage to the tool/fixture while doing the prove-out PC49. shut down the equipment to a safe condition on conclusion of the activities PC50. deal promptly and effectively with 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 1 3 4 LO CPC/ N 7122 Maintain healthy and safe work practices problems within span of responsibility and control and report those that cannot be solved Sub total Performance Criterion Description PC1. understand potential dangers/ risks and their causes at the workplace Dangers: Heated & sharp metal chips, sharp edged objects, heavy tools, loose rotating parts, loud noise, welding radiations, gas cylinders, fume, dust, chemical coolant, hazardous surfaces – slippery, broken, uneven etc., working at heights, intense light, electrical hazards- loose & naked cables, power supply and points, loose contacts etc. Causes: physical actions, inattention, mental sickness, drumpedness, health issues, other peoples mistake, faulty equipment, natural disaster. PC2. use protective clothing/equipment for specific tasks and work conditions as per work environment Protective clothing: leather or asbestos gloves, flame proof aprons, flame proof overalls buttoned to neck, cuffless (without folds), trousers, industrial footwear, safety helmets, cap & shoulder covers, ear defenders/plugs, knee pads, glasses/ goggles/visors Equipment: hand shields, machine guards, residual current devices, dust sheets, respirator PC3. know the location of general health & safety equipments at the workplace PC4. shall know the name and location of people responsible for health and safety in the workplace PC5. shall have complete knowledge of the names and location of documents that refer to health and safety in the workplace Documents: fire notices, accident reports, safety instructions for equipment and procedures, company notices and documents, legal documents (eg government notices) PC6. carry out safe working practices to ensure the safety of self and others Safe working practices: using protective clothing and equipment; putting up and 50 Theory 150 Practical 200 Total 0.5 2 2.5 0.5 2 2.5 0.5 2 2.5 0.5 2 2.5 0.5 2 2.5 0.5 2 2.5 reading safety signs; handle tools in correct manner and store and maintain them properly; keep work area clear of clutter, spillage and unsafe object lying casually; while working with electricity take all electrical precautions like insulated clothing, adequate equipment insulation, use of control equipment, dry work area, switch off the power supply when not required, etc.; safe lifting and carrying practices; use equipment that is working properly and is well maintained PC7. understand methods of accident prevention at the workplace Methods of accident prevention: training in health and safety procedures; using health and safety procedures; use of equipment and working practices (such as safe carrying procedures); safety notices, advice; instruction from colleagues and supervisors PC8. identify common danger signs displayed in various areas Various areas: on chemical containers; equipment; packages; inside buildings; in open areas and public spaces, machine, electrical panels etc PC9. apply good housekeeping practices at all times Good housekeeping practices: clean/tidy work areas, removal/ disposal of waste products, protect surfaces, 5S practices PC10. understand the application and use the various appropriate fire extinguishers on different types of fires correctly Types of fires: Class A: eg. ordinary solid combustibles, such as wood, paper, cloth, plastic, charcoal, etc.; Class B: flammable liquids and gases, such as gasoline, propane, diesel fuel, tar, cooking oil, and similar substances; Class C: eg. electrical equipment such as appliances, wiring, breaker panels, etc.; Class D: combustible metals such as magnesium, titanium, and sodium (These fires burn at extremely high temperatures and require special suppression agents) PC11. understand and follow rescue techniques practices during fire hazard PC12. follow good housekeeping in order to 0.5 2 2.5 0.5 2 2.5 0.5 2 2.5 0.5 2 2.5 0.5 2 2.5 0.5 2 2.5 LO CPC/ N 7123 Effective working with others prevent fire hazards PC13. participate in emergency procedures Emergency procedures: raising alarm, notifying authorities, contacting emergency numbers, safe/efficient, evacuation, correct means of escape, correct assembly point, roll call, correct return to work PC14. respond promptly and appropriately to an accident situation or medical emergency PC15. demonstrate correct method to move injured people and others during an emergency PC16. Provide appropriate first aid to victims where required eg. in case of bleeding, burns, choking, electric shock, poisoning etc. PC17. demonstrate how to free a person from electrocution PC18. complete a written accident/incident report or dictate a report to another person, and send report to person responsible Incident Report includes details of: name, date/time of incident, date/time of report, location, environment conditions, persons involved, sequence of events, injuries sustained, damage sustained, actions taken, witnesses, supervisor/manager notified Sub total Performance Criterion Description PC1. display appropriate communication etiquette while working Communication etiquette: use appropriate tone, pitch and language to convey politeness, assertiveness, care and professionalism, use appropriate titles and terms of respect; do not use abusive language PC2. display active listening skills while interacting with others at work PC3. demonstrate responsible and disciplined behaviors at the workplace Disciplined behaviors: e.g. punctuality; completing tasks as per given time and standards; not gossiping and idling time; eliminating waste, observing honesty, etc General health and safety equipment: fire extinguishers; first aid equipment; safety instruments and clothing; safety installations(eg fire exits, emergency door) 0.5 2 2.5 0.5 2 2.5 0.5 2 2.5 0.5 2 2.5 0.5 2 2.5 0.5 2 2.5 9 Theory 36 Practical 45 Total 0.5 2 2.5 0.5 2 2.5 0.5 2 2.5 LO CPC/ N 7124 Basics of computer and data entry LO CPC/ N 7125 Soft Skills PC4. accurately receive information and instructions from the supervisor and fellow workers, getting clarification where required PC5. accurately pass on information to authorized persons who require it and within agreed timescale & confirm its receipt PC6. display helpful behavior by assisting others in performing tasks in a positive manner, where required and possible PC7. Consult with & assist others to maximize effectiveness and efficiency in carrying out tasks PC8. escalate grievances and problems to appropriate authority as per procedure to resolve them & avoid conflict. Sub total Performance Criterion Description PC1. Fill and process mandated forms for receiving, processing, or tracking data, enter data from source documents in to Computer application having MS OFFICE software PC2. Verify data entered with source documents, checks for compliance and corrects all typographical errors and missing or repeated data. PC3. Maintain files of source documents or other information related to data entered. PC4. Update database information to reflect most current source information PC5. Assist in the filing and storage of security and back up data files PC6. Respond to requests for information and access relevant files Sub total Performance Criterion Description PC1. Able to effectively understand the verbal instructions in English or any vernacular language PC2. Able to communicate effectively with the supervisor and fellow colleagues to carry out day to day activities. Able to read the reports either in PC3. English or any vernacular language PC4. Understand the meaning of these 0.5 2 2.5 0.5 2 2.5 0.5 2 2.5 0.5 2 2.5 0.5 2 2.5 4 Theory 16 Practical 20 Total 0.5 2 2.5 0.5 2 2.5 0.5 2 2.5 0.5 2 2.5 0.5 2 2.5 0.5 2 2.5 3 Theory 12 Practical 15 Total 0.5 2 2.5 0.5 2 2.5 0.5 2 2.5 0.5 1 1.5 LO CPC/ N 7126 Understanding and Implementation of 5S reports and its importance. PC5. Filing of the reports and formats in proper location. PC6. Retrieval and producing the specific reports/files to the supervisor as and when required. PC7. Numbering and orderliness maintenance of files in safe locations Sub total Performance Criterion Description PC1. Follow the sorting process and check that the tools, fixtures & jigs that are lying on workstations are the ones in use and unnecessary items are not cluttering the workbenches or work surfaces. PC2. Ensure segregation of waste in hazardous/ non Hazardous waste as per the sorting work instructions PC3. Follow the technique of waste disposal and waste storage in the proper bins as per SOP PC4. Segregate the items which are labelled as red tag items for the process area and keep them in the correct places PC5. Sort the tools/ equipment/ fasteners/ spare parts as per specifications/ utility into proper trays, 8 cabinets, lockers as mentioned in the 5S guidelines/ work instructions PC6. Ensure that areas of material storage areas are not overflowing PC7. Properly stack the various types of boxes and containers as per the size/ utility to avoid any fall of items/ breakage and also enable easy sorting when required PC8. Return the extra material and tools to the designated sections and make sure that no additional material/ tool is lying near the work area PC9. Follow the floor markings/ area markings used for demarcating the various sections in the plant as per the prescribed instructions and standards PC10. Follow proper labeling mechanism of instruments/ boxes/ containers and maintaining reference files/ documents with 0.5 1 1.5 0.5 1 1.5 0.5 1 1.5 3.5 Theory 10 Practical 13.5 Total 0.5 2 2.5 0.5 2 2.5 0.5 2 2.5 0.5 2 2.5 0.5 2 2.5 0.5 2 2.5 0.5 2 2.5 0.5 2 2.5 0.5 2 2.5 the codes and the lists PC11. Check that the items in the respective areas have been identified as broken or damaged PC12. Follow the given instructions and check for labeling of fluids, oils. Lubricants, solvents, chemicals etc. and proper storage of the same to avoid spillage, leakage, fire etc. PC13. Make sure that all material and tools are stored in the designated places and in manner indicated in 5S instructions PC14. Check whether safety glasses are clean and in good condition PC15. Keep all outside surfaces of recycling containers are clean PC16. Ensure that the area has floors swept, machinery clean and Generally clean. In case of cleaning, ensure that proper displays are maintained on the floor which indicate potential safety hazards PC17. Check whether all hoses, cabling & wires are clean, in good condition and clamped to avoid any mishap or mix up PC18. Ensure workbenches and work surfaces are clean and in good condition PC19. Follow the daily cleaning standards and schedules to create a clean working environment PC20. Attend all training programs for employees on 5 S PC21. Support the team during the audit of 5 S PC22. Participate actively in employee work groups on 5S and encourage team members for active participation PC23. Follow the guidelines for What to do and What not to do to build sustainability in 5S as mentioned in the 5S check lists/ work instructions Sub total Total Means of Assessment 1: The assessment comprise of : Theory Viva-voce Practical assessment 0.5 2 2.5 0.5 2 2.5 0.5 2 2.5 0.5 2 2.5 0.5 2 2.5 0.5 2 2.5 0.5 2 2.5 0.5 2 2.5 0.5 2 2.5 0.5 2 2.5 0.5 2 2.5 0.5 2 2.5 0.5 2 2.5 11.5 150 46 450 57.5 600 Means of Assessment 2: Pass/Fail – The Pass mark of theory written assessment is 40% and for viva and practical assessment is 50%. The candidate has to pass separately in Theory and Practical.