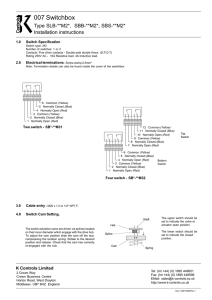

1771 A novel method for the dynamic synthesis of cam mechanisms with an imposed driving force profile H Erdelyi∗ and D Talaba Transilvania University of Brasov, bdul. Eroilor, Brasov, Romania The manuscript was received on 30 March 2009 and was accepted after revision for publication on 11 November 2009. DOI: 10.1243/09544062JMES1649 Abstract: In the car industry, the ergonomic and haptic properties of controls are gaining high priority. The cam mechanisms of switches and knobs, such as those of car turn switches, are usually required to comply with a certain user force profile, according to human physical limitations and ergonomic requirements. In order to fine-tune the force input and the function performed by the mechanism, the cam profile is normally subjected to a detailed synthesis having as input the desired user force profile. Nevertheless, conventional cam synthesis and analysis methods do not provide an adequate tool for designing the cam profile based on the required driving effort. In this article, an energy-based method is proposed for designing a cam mechanism able to accurately replicate the desired profile of the driving effort. According to the proposed method, the cam profile is determined as a finite series of points and takes into consideration all contact forces between the cam and the follower, including friction. The method is non-linear, considering a combined Stribeck–Therfall friction model as well as the damping of the system. Numerical validation is provided considering the case of the cam mechanism of a conventional car turn switch. Keywords: cam design, cam mechanism, cam profile, driving force profile, energy-based calculation, finite series 1 INTRODUCTION Cam mechanisms provide a wide variety of motion generation methods, due to their different geometrical configurations and different combinations of cams and followers. Because of their versatility and ease of adaptability, cam mechanisms are widely spread in all types of mechanical devices and machines, like agricultural machines, the textile industry, packaging machines, machine tools, printing presses, the automotive industry, switches, or control systems [1, 2]. Cam mechanisms, being a kind of mechanical program carrier, are also used in robotic design when it is not possible to satisfy a desired position function by means of other systems [3]. Usually, the industrial design of cam mechanisms considers primary guidelines such as [1, 4, 5] (a) transfer function; (b) design speed; ∗ Corresponding author: Product Design and Robotics, Transilvania University of Brasov, bdul. Eroilor nr.29, Brasov 500036, Romania. email: erdelyi@unitbv.ro JMES1649 (c) (d) (e) (f ) (g) (h) (i) (j) kinematic constraints; cam–follower acceleration curve; maximum follower acceleration; maximum pressure angle; manufacturing considerations; surface wear; torque on the camshaft; cost and space requirements. However, there is a special area of application where the above-mentioned guidelines are only of secondary importance, namely those cam mechanisms that are actuated manually, such as switches for example. These mechanisms operate usually at low speeds and involve relatively low forces. In these mechanisms, also the user force feedback properties (haptic properties) are considered, and sometimes they constitute the primary design parameter. A good example of such human-operated mechanisms is switches in general and, in particular, the switches used in the automotive industry. In the last few years, the major car manufacturers have been conducting research on the issue of deliberately shaping the haptic sensation of knobs and switches in terms of ergonomics, comfort, and pleasure in manipulating them [6, 7]. Proc. IMechE Vol. 224 Part C: J. Mechanical Engineering Science Downloaded from pic.sagepub.com at WEST VIRGINA UNIV on June 20, 2015 1772 H Erdelyi and D Talaba By manufacturing a switch that looks pleasant, a positive impression is created in the customer and this provides a competitive advantage in the market. Therefore, in addition to the purely functional requirements, designers now face the challenge of having to design the ‘user feel’ of the controls as well. To solve this problem in the best possible way, the designer would need straightforward methods for determining the mechanism’s characteristics based on a desired force feedback (haptic) property. Previous work on the haptic design of such switches proposed mainly tools for aiding the analysis of the user feel; investigating, for example, the characterization of the haptic parameters [8, 9] or focusing on developing haptic systems [10–12], but not considering the design of the user feel itself through a specific cam mechanism design. The usual kinematic approach of cam mechanism synthesis deals with the establishment of geometrical parameters and transmission functions, velocities, accelerations, and pulses [2, 5, 13]. In the dynamic analysis of cam mechanisms, the system is generally treated from the point of view of vibration [2, 13] considering rigid and elastic camshafts, and one or several degrees of freedom spring and damper models. The motion of the equivalent mass of the follower is described by differential equations. Lederer [14] proposes a two-degree-of-freedom spring and damper model to analyse the influence of the adopted transfer function on the dynamics of the cam mechanism. He first solves the differential equations in order to determine the transfer function and then an optimization procedure is applied, in case of inadequate stiffness and damping parameters. Although the cam design and manufacturing methods presented in the available literature are well established, they do not provide an adequate tool for designing a cam profile based on a required driving effort. Therefore, this article proposes a new method devoted specifically to designing a cam mechanism according to a desired profile of the driving force or driving torque. Using energy-based calculations, the cam profile is determined as a finite series of points in polar coordinates and takes into consideration all contact forces between the cam and the follower, including friction. The method is non-linear, considering a combined Stribeck–Therfall friction model as well as the damping of the system. Numerical validation is provided considering the case of a cam mechanism from a conventional car turn indicator switch. 2 or torque’s profile contains all the necessary information about the cam geometry. Considering the driving torque’s profile as a function of the cam rotation angle (as a design input), with the method presented in this article it is possible to accurately design the cam geometry corresponding to the required force profile. The method has two main stages: first, an idealized model is considered, neglecting any type of losses, for which a so-called ‘preliminary cam profile’ is determined. At the second stage, an iterative method is implemented, considering losses due to friction and damping, by which one can correct the preliminary cam profile determined previously. For the method presented below, the time evolution of the driving force’s profile, the cam rotation angle, and the angular velocity are considered as known and the goal is to determine the cam profile. 2.1 Determining the preliminary cam profile For the preliminary design stage, a simplified model of a typical cam mechanism is presented in Fig. 1, where K indicates the spring of the follower, C is the damper, and Tr stands for the translational joint that guides the follower. As the driving torque T acts on the cam, the follower–cam point of contact moves along the cam profile (Po Pa Po ) displacing the follower and simultaneously compressing the spring of the follower. Since the follower displacement and the spring compression are equal in this case, one can determine the cam profile using the spring compression data as a function of the cam rotation angle. The cam displacement can be represented using polar coordinates as a function of the rotation angle of the cam α and the polar radius ρ: the distance between the follower and cam pivot axes (Fig. 1). A CAM DESIGN METHOD BASED ON THE DRIVING TORQUE’S PROFILE The method presented in this article relies on the idea that for a cam mechanism, the driving force’s Fig. 1 Schematic model of the cam mechanism Proc. IMechE Vol. 224 Part C: J. Mechanical Engineering Science Downloaded from pic.sagepub.com at WEST VIRGINA UNIV on June 20, 2015 JMES1649 A novel method for the dynamic synthesis of cam mechanisms According to the proposed method, for the preliminary stage, the joint compliances and losses due to friction and damping are neglected. In this case the energy balance of the system is dW T = dE P + dE K (1) where dW T is the work done by the driving torque T , dE P is the potential energy of the system, and dE K is the kinetic energy. At this point, considering low speeds and low masses, the kinetic energy term dE K ≈ 0 will also be preliminarily neglected, leaving a simple form of the energy balance dW T = dE P (2) The potential energy term dE P in the above equation (equation (2)) is the potential energy stored in the spring of the follower and therefore it can be expressed as dE P = F el dx = kx dx (3) where F el is the elastic force of the spring, k is the stiffness coefficient, and x is the compression of the spring. Using the trapezoidal formula, one can numerically approximate the potential energy between two consecutive values of spring compression (x0 and x1 ) as follows x1 k F el dx ≈ (x12 − x02 ) (4) 2 x0 From the above equation (equation (4)), the spring compression x1 can be determined as x1 ≈ 2 k x1 x0 F el dx + x02 (5) Following the above algorithm, the potential energy stored in the spring for the next compression cycle (x1 to x2 ) can be written as x1 x2 k k 2 2 x2 − F el dx ≈ (x22 − x12 ) = F el dx + x02 2 2 k x0 x1 (6) From equation (6), x2 can be determined as shown below x2 x1 2 el el x2 ≈ F dx + F dx + x02 (7) k x0 x1 1773 of spring compression with the formula x2 xn 2 x1 el el el F dx + F dx + · · · + F dx + x02 xn ≈ k x0 x1 xn−1 n xi 2 = F el dx + x02 (8) k i=1 xi−1 On the other hand, according to equation (2), the work done by the driving torque is equal to the potential energy of the spring. Furthermore, by considering that any α interval of rotation has a corresponding x compression of the spring, the energy balance is xn αn F el dx = dW T (9) xn−1 αn−1 In the above equation (equation (9)), the work of the driving torque T can be determined as dW T = T dα (10) where T is the driving torque and α is the rotation angle of the cam. Over a small interval of rotation the work done by the driving torque will be α0 +α α0 +α T dW = T dα (11) α0 α0 For a finite sequence of rotation intervals of the cam, the above equation can be approximated with the trapezoidal formula determining the generic term as follows αn α WnT ≈ (12) (Tn−1 + Tn ) 2 αn−1 Considering equation (2), the potential energy term from equation (8) can be replaced with the driving torque work determined in equation (12). Considering the above-mentioned algorithm, one can determine a finite series of spring compression data as a function of the cam rotation and the driving torque 2 n α (13) xn ≈ (Ti−1 + Ti ) + x02 k i=1 2 Finally, one can compute a series of follower displacement ρn based on the compression data of the spring – provided by equation (13) ρn = r0 + rr + xn ≈ r + R 2 n α + (Ti−1 + Ti ) + x02 k i=1 2 (14) Using the same algorithm, one can determine for a finite series of compression intervals the generic term where r0 is the minimum radius and rr is the roller radius as presented in Fig. 1. JMES1649 Proc. IMechE Vol. 224 Part C: J. Mechanical Engineering Science Downloaded from pic.sagepub.com at WEST VIRGINA UNIV on June 20, 2015 1774 H Erdelyi and D Talaba Equation (14) determines the cam profile as a series of points in polar coordinates, having the generic term ρn , being a function of the driving torque and cam rotation angle α. Nevertheless, this cam profile is just a preliminary approximation needed in the next stage of the method, since the friction, damping, and kinetic energy of the system have not yet been considered. 2.2 Actual cam profile calculus After determining the preliminary cam profile for the simplified model, losses due to friction and damping as well as kinetic energy of the system can be introduced. This is done in an iterative manner based on the preliminary results provided by the simplified model. First, the mechanical work of the friction and damping forces will be determined as well as the kinetic energy of the cam mechanism. The next step is to implement them into an iterative method to determine the actual cam profile. 2.2.1 Damping force F d = c ẋ (15) where F d is the damping force, c the coefficient of damping, and ẋ the displacement velocity of the follower. Considering a series of displacements xn , the displacement velocity ẋ can be approximated as xn xn xn+1 − xn = n = n tn αn αn+1 − αn (16) where n is the mean angular velocity of the cam, between αn and αn+1 . Equations (15) and (16) give the generic term of the damping force Fnd ≈ c xn xn xn+1 − xn =c n = c n tn αn αn+1 − αn The work of the damping force is given by x x dW D = −F d dx x0 Friction model Friction forces should be considered for all kinematic joints as well as the cam–tappet contact. Figure 2 presents friction types which are typical for kinematic joints and which are discussed in this article. In the method presented in this article, the usual formulae known from the literature were adopted for the calculus of the friction forces in the kinematic joints. Their effect will be taken into consideration by a separate energy term cumulating the friction energy in all the joints of the actual mechanism. In the case of the cam mechanisms used in switches and knobs, the sliding friction at the contact between the cam and the follower has a greater overall effect than journal or circular crown type friction encountered at the revolute joints of the rotating parts. However, for the sake of completeness, also the rotary friction term will be discussed. In the case of a journal type contact [15, 16], the friction torque will be determined with the formula TnfrJ = µQn rj The damping force in the follower spring unit can be determined as ẋ ≈ 2.2.2 (17) (20) where TnfrJ is the friction torque, µ is the friction coefficient, Qn is the radial load, and rj is the journal radius. The work of the journal type friction torque is given as follows (based on equation (20)) αn αn−1 dWnfrJ = −µQn rj αn (21) For a circular crown contact, the friction torque will be determined as [15, 16] TnfrC = r 3 − ri3 2 µPn e2 3 re − ri2 (22) where TnfrC is the friction torque in the case of the circular crown contact, Pn is the axial load, re is the outer radius, and ri is the inner radius. The generic term for the work WnfrC corresponding to the friction torque in the circular crown is given below αn (18) r 3 − ri3 2 dWnfrC = − µPn e2 αn 3 re − ri2 αn−1 (23) x0 D where W represents the work of the damping force over a portion of the displacement (x0 . . . x) of the follower. Furthermore, using the trapezoidal approximation method, one can write the work equation as xn x d dWnD ≈ − Fn−1 + Fnd 2 xn−1 (xn − xn−1 ) xn+1 − xn c n 2 αn+1 − αn (19) Fig. 2 Typical types of friction encountered in kinematic joints Proc. IMechE Vol. 224 Part C: J. Mechanical Engineering Science JMES1649 =− Downloaded from pic.sagepub.com at WEST VIRGINA UNIV on June 20, 2015 A novel method for the dynamic synthesis of cam mechanisms To model the sliding friction of the cam–follower contact, numerous methods are available in the literature ranging from simple – like the basic Coulomb friction model – to more complex ones like the Rooney and Deravi friction model [17] or the Threlfall model [18]. Considering that cam mechanisms are usually lubricated, a viscous friction model is adopted within the proposed method, namely the Stribeck friction model [19] that considers the variation of friction force with the sliding speed as i vn Fnfr = FnC + (FnS − FnC ) e−(|vn |/vS ) + µvisc vn |vn | Fnfr FnC = µstat FnN tan σ = vn (1 − e−(3vn /vr ) ) if |vn | |vn | < vr (26) where µ is the sliding friction coefficient, FnN is the normal contact force, and vr is a small characteristic velocity. In the above equation (equation (26)), 1 − e−(3v/vr ) is the regulation factor that smoothes out the discontinuity of the friction force. Figure 3 presents the Threlfall friction, the Stribeck friction, and the combined friction model, which tan σn ≈ JMES1649 Different friction models (27) yn yn+1 − yn = xn xn+1 − xn (28) Turning to polar coordinates in equation (28), one will arrive at the following σn ≈ arctan ρn+1 cos αn+1 − ρn cos αn ρn+1 sin αn+1 − ρn sin αn (29) On the other hand, it can be proved that a relation exists between the pressure angle, the cam rotation angle and σn as follows σ n = αn − β n (30) where βn is the pressure angle. Fig. 4 Fig. 3 dy dx For discrete values of a finite series, equation (27) can be approximated as (25) where µstat is the static friction coefficient. In order to avoid discontinuity at zero relative tangential velocity and to obtain a continuous friction force for the Coulomb friction force term FnC , the Threlfall friction model [18] is used FnC = µFnN eliminates the discontinuity at zero of the standard Stribeck model. Before writing the equation for the normal contact force, first the pressure angle will be determined. In Fig. 4, the pressure angle is denoted by βn and the tangent to the pitch curve is denoted by σn . FnN is the contact force and its two orthogonal components are denoted by Fnl and Fnt . Considering a coordinate system attached to the cam – as shown in Fig. 4 – the tangent to the pitch curve in the contact point can be defined as (24) where is the friction force, is the Coulomb sliding friction, FnS represents the maximum static friction force, vn is the sliding speed, vS is the sliding speed coefficient, µvisc is the viscous friction coefficient, and i is an exponent. The generic term of the maximum static friction force series FnS can be written as FnS 1775 Schematic representation of the contact force and important angles Proc. IMechE Vol. 224 Part C: J. Mechanical Engineering Science Downloaded from pic.sagepub.com at WEST VIRGINA UNIV on June 20, 2015 1776 H Erdelyi and D Talaba From equations (29) and (30) the pressure angle βn can be determined as ρn+1 cos αn+1 − ρn cos αn (31) βn ≈ αn − arctan ρn+1 sin αn+1 − ρn sin αn FnN can be determined as a funcThe normal force tion of the pressure angle βn and the follower spring and damper forces FnN = (Fnel + Fnd ) cos βn (32) where Fnel is the elastic force of the follower’s spring, having the generic term Fnel = kxn = k(xn+1 − xn ) (33) Finally, considering equations (17) and (33), the normal force will be xn+1 − xn N n cos βn (34) Fn = k(xn+1 − xn ) + c αn+1 − αn The sliding speed v, tangent to the cam profile, can be determined as a function of the displacement velocity of the follower and the pressure angle v = ẋ sin β The total work of friction forces, considering sliding friction of the follower, circular crown and journal type of contacts, is given below xn xn−1 dWnTFr = xn+1 − xn n sin βn αn+1 − αn (36) The work done by the sliding friction force over a portion of displacement (S0 . . . S) can be determined as S dW fr = S0 −F fr ds (37) Sn−1 αn−1 dWnfrJ + αn αn−1 dWnfrC where WnTFr is the total work of friction forces. 2.2.3 Kinetic energy Cam mechanisms used in human-operated controls are usually driven at a low speed and are lightweight. As such, the kinetic energy term is considerably lower than the potential energy of the spring. However, for the completeness of the method, also the kinetic energy term will be considered. Assuming that the cam mechanism is composed of k elements with translation movements (with masses mi and velocities ẋi ) and p elements with fixed axis rotation movements (with moments of inertia Jl and angular velocities α̇l ), the total kinetic energy can be determined as [15] EK = i=1 mi (ẋi )2 + 2 p l=1 Jl (α̇l )2 2 (42) For the particular case presented in Fig. 4, considering a constant angular velocity of the cam, the series of the kinetic energy will have the generic form EnK = mf [(xn+1 − xn /αn+1 − αn )n ]2 Jc (n )2 + 2 2 (43) S0 Using the trapezoidal formula, one can integrate the above equation in an approximated form as Sn αn (41) k S xn−1 dWnfr + (35) Given equations (16) and (35), the generic term of the sliding speed is vn = xn dWnfr ≈ − s fr (F + Fnfr ) 2 n−1 (38) The displacement S = S − S0 can be determined as a function of spring compression x s = x sin β (39) Taking into account the above, one will get xn xn sin βn fr Fn−1 + Fnfr dWnfr ≈ − 2 xn−1 =− (xn − xn−1 ) sin βn fr Fn−1 + Fnfr 2 (40) where the friction force Fnfr is given in equation (24). where mf is the mass of the follower, Jc is the moment of inertia of the cam, and n is the angular velocity of the cam. 2.2.4 Numerical integration and cam profile iterative calculation The iterative method presented below implies that the preliminary cam profile is known. In the first iteration, with equations (43), (19), and (41), the kinetic energy, the work of the damping force and that of the friction force, respectively, will be determined for the preliminary cam profile, determined by equation (14) for the idealized model. A new energy balance equation will subsequently be written, considering all the losses and the kinetic energy determined for the preliminary cam profile dWnT = dEnP + dEnK − dWnTFr − dWnD Proc. IMechE Vol. 224 Part C: J. Mechanical Engineering Science Downloaded from pic.sagepub.com at WEST VIRGINA UNIV on June 20, 2015 (44) JMES1649 A novel method for the dynamic synthesis of cam mechanisms From the above equation, the potential energy term will be determined xn xn xn xn dEnP = dWnT − dEnK + dWnTFr xn−1 xn−1 xn + xn−1 xn−1 xn−1 dWnD (45) Using equations (45) and (14), the cam profile equation resulting within the first iteration is xi n 2 α + T ) − dEiK0 (T i−1 i k 2 xi−1 ρn1 = r0 + rr + xi xi i=0 TFr0 D0 + x02 + dWi + dWi xi−1 xi−1 (46) where the terms of the kinetic energy E K0 of the work of the friction force W TFr0 and of the damping force W D0 are determined for the preliminary cam profile with equations (43), (41), and (19), respectively. Note that since this article deals with a synthesis problem, all parameters from equation (43) (mf , Jc , and ωn ) are known as input data. After having obtained the new cam profile ρn1 for the first iteration, the method goes on with the next iterations by determining the kinetic energy, the work of the friction force and that of the damping forces for the newly determined cam profile. The terms E K1 , W TFr1 , and W D1 will thus be obtained using equations (43), (41), and (19) for ρn1 . E K1 , W TFr1 , and W D1 will be substituted into equation (14), while the cam profile ρn2 will be obtained as xi n 2 α (T + T ) − dEiK1 i−1 i k 2 x i−1 ρn2 = r0 + rr + xi xi i=0 TFr1 D1 + x02 + dWi + dWi xi−1 xi−1 are the kinetic energy, the work of the friction force, and the work of the damping force, determined for the cam profile ρnm−1 , obtained in the preceding (m − 1)th step of the iterative process, respectively. After some steps the process stabilizes, and the cam profile, determined with the iterative process, falls within a margin of error that suits the application, and the calculation can therefore be stopped. The number of steps required for stabilization is application dependent, but for a large set of torque data the process usually stabilizes after just a few steps. 3 NUMERICAL EXAMPLE AND EXPERIMENTAL VALIDATION For the experimental validation, the turn switch of a car was considered. The switch has a cam mechanism with a fixed cam and a moving follower, as shown in Fig. 5. The contact between the follower and the cam is ensured by a spring. The follower is connected to the lever of the switch via a translational joint. Between the lever and the cam, there is a revolute joint, ensuring the rotation of the lever around the lever pivot axis as one turns the blinkers on. For the experimental study, the electrical contacts have been removed, leaving just the cam mechanism to be considered. The objective of the experimental research was to determine the driving force profile of the switch and the real cam profile, using a three-dimensional (3D) digitizer. Finally, the dynamic synthesis method presented before was applied to compute the cam profile based on the measured driving force. The results were compared to the original cam profile to see if the proposed method delivered back the cam mechanism that experimentally provided the input user force profile. 3.1 (47) 1777 Driving force profile measurement and reference cam profile determination where ρnm is the cam profile determined for the mth step of the iterative process, E Km−1 , W Frm−1 , and W Dm−1 The driving force profile needed for the cam profile calculus was measured with a Series 244 hydraulic actuator. The switch was rigidly fixed on a workbench, and it was driven by the piston of the actuator at a constant speed of 0.044 rad/s, while the force and position were recorded and processed to obtain the driving force profile. The layout of the measurement is presented in Fig. 6. The recorded dataset contained 3797 data pairs of force value as a function of lever rotation angle, for a period of 3.5 s. The data were smoothened to obtain a continuous evolution of the force profile (as presented in Fig. 7), which constituted the input for the calculation. The cam profile was carefully digitized with a 3D digitizer. The resulting dataset was interpolated to JMES1649 Proc. IMechE Vol. 224 Part C: J. Mechanical Engineering Science This algorithm is carried out for a number of steps, always determining the terms of the friction and damping force’s work W TFr and W D and the kinetic energy E K for the cam profile obtained in the previous step of the iterative process ρnm = r0 + rr xi n 2 α (T + T ) − dEiKm−1 i−1 i k 2 x i−1 + i=0 xi xi TFrm−1 Dm−1 + x02 + dWi + dWi xi−1 xi−1 (48) Downloaded from pic.sagepub.com at WEST VIRGINA UNIV on June 20, 2015 1778 H Erdelyi and D Talaba Fig. 5 Car turn switch and its cam mechanism obtain the real cam profile that was used as a reference profile for the validation of the method. 3.2 Cam profile calculus The schematic representation of the cam system of the turn switch is given in Fig. 8. For the numerical calculus, the following parameters were used. Fig. 6 Fig. 7 Driving force profile measurement Measured driving force profile k = 1.857 (N/mm) c = 0.1 (Ns/mm) x0 = 5 mm ri = 2.5 mm re = 3.5 mm rj = 2.5 mm µstat = 0.2 µ = 0.13 n = 0.044 (1/s) mf = 2.137 × 10−3 kg Jlever = 39.374 kg mm2 Spring stiffness coefficient Damping coefficient Spring initial compression Inner radius of the revolute joint Outer radius of the revolute joint Radius of the revolute joint Static friction coefficient Sliding friction coefficient Mean angular velocity Follower mass Lever moment of inertia The mass of the follower and the moment of inertia of the lever were used to compute the kinetic energy with equation (42). With the computation method presented in section 2 using the measured driving force profile (Fig. 7), the preliminary cam profile was determined in polar coordinates. In Fig. 9, the preliminary cam profile is shown with a continuous line and the reference cam profile is shown with a dashed line. The preliminary cam profile differs considerably from the reference profile, since in its calculation the mechanical losses and the kinetic energy are not included. At the next step, the mechanical losses and the kinetic energy of the system were computed for the preliminary cam profile. Proc. IMechE Vol. 224 Part C: J. Mechanical Engineering Science Downloaded from pic.sagepub.com at WEST VIRGINA UNIV on June 20, 2015 JMES1649 A novel method for the dynamic synthesis of cam mechanisms Fig. 8 Schematic representation of the turn switch Fig. 10 Fig. 9 Preliminary cam profile versus reference cam profile The friction force in the revolute joint was computed using the method presented in section 2. The revolute joint had two pairs of surfaces in contact, as presented in Fig. 10. The contact between the lever and the cam is realized by a compression spring, while the contact inside the revolute joint was maintained by the resultant of the external forces acting in the plane perpendicular to the lever pivot axis. For the circular crown contact, the friction torque TnfrC was determined using equation (22) in which, for the present case, the axial load Pn is the preload of the spring as seen in Fig. 10. The generic term for the journal type friction torque TnfrJ in the revolute joint was determined based on equation (20). Furthermore, Qn (as presented in Fig. 10) is the resultant of the external forces, which act in the plane perpendicular to the lever pivot JMES1649 1779 Revolute joint of the turn switch axis. These forces are as follows: the driving force of the lever Fndrv and the friction and normal forces at the cam–follower contact Fnfr and FnN , respectively. The friction and normal forces are orthogonal; thus their resultant is Rn = (Fnfr )2 + (FnN )2 (49) The generic term of the angle θn between the first resultant Rn and the driving force Fndrv can be determined as θn = π − (αn + βn + σn ) 2 (50) where σn is the angle between the normal force FnN and the first resultant Rn , determined with equation (49) F fr σn = arctan nN Fn (51) Proc. IMechE Vol. 224 Part C: J. Mechanical Engineering Science Downloaded from pic.sagepub.com at WEST VIRGINA UNIV on June 20, 2015 1780 H Erdelyi and D Talaba Finally, the resultant of the driving force and the first resultant can be determined with the relation 2 2 (52) Qn = Fndrv + Rn1 + 2Fndrv Rn1 cos(σn ) The generic term of the cam profile ρnm at the step m of the iterative process will be determined using equation (48). 3.3 Results and discussion The cam profile was determined based on the iterative method presented in section 2 using the measured driving force data. The first cam profile in the iterative process (presented in Fig. 11), determined with equation (48), shows considerable deviation from the reference cam profile. As the iterative process is carried out, the computed cam geometry approaches the reference cam profile. In Fig. 11 the preliminary cam profile is shown with a continuous line and the reference cam profile is shown with dashed line. Furthermore, two cam profiles are also shown, determined at the first and at the third iteration step. Figure 11 reveals that the cam profile determined at the third iteration step falls close to the reference cam geometry. The relative error of the cam geometry to the reference cam geometry was determined as Error = ρcomp − ρref ρref (53) Computed cam geometry (iteration 01 and iteration 03) versus preliminary and reference cam geometries Relative error of the first four cam profiles with the iterative method, one can monitor and stop the evolution of the process when the relative error between two consecutive profiles is small enough. The relative error between the cam profiles can be given as EnIT = where ρcomp is the computed cam profile and ρref is the reference cam profile. Expressed in percentage, the relative error for the first four computed cam profiles is presented in Fig. 12. As can be seen in Fig. 12, an error margin of ±2.5 per cent is obtained after only four iterations. Defining the relative error between the cam profiles EnIT , obtained Fig. 11 Fig. 12 ρn − ρn−1 ρn−1 (54) In Fig. 13, the relative error between the consecutive cam profiles is presented for the first four profiles. As can be seen in Fig. 13, the relative error between the third and fourth cam profiles, determined with the iterative method, falls into the error margin of Fig. 13 Relative error between the consecutive cam profiles Proc. IMechE Vol. 224 Part C: J. Mechanical Engineering Science Downloaded from pic.sagepub.com at WEST VIRGINA UNIV on June 20, 2015 JMES1649 A novel method for the dynamic synthesis of cam mechanisms ±1 per cent, and thus the iterative process could be stopped. The results prove that by using the computation method presented in section 2, it is possible to determine the cam geometry corresponding to a desired driving force profile with a very good error margin. 4 CONCLUSIONS In this article, a new approach to cam mechanism dynamic synthesis is presented, based on the driving effort imposed on the cam mechanism. The problem is treated using an energy-based algorithm, in which the calculations involve the driving work of the cam mechanism, the work of friction and damping forces, as well as the potential and kinetic energy of the system. The computation is carried out iteratively, starting with a preliminary synthesis considering an idealized model, and continuing with a number of iterations that take into consideration the mechanical losses and kinetic energy. To model the friction between the cam and the follower of the mechanism, an alternative friction model is proposed that combines the Threllfall and the Stribeck friction models. The method is numerically and experimentally validated for the cam mechanism of a conventional car turn indicator switch. In the validation process, the driving force profile of the switch is recorded with experimental measurements, using a hydraulic actuator. The cam profile of the turn switch is digitized, and is used as the reference profile in the validation. Based on the measured force profile, the cam geometry is determined and compared to the reference cam profile. Results show that with the method presented in this article, after only a few iterative steps, the computed cam profile approaches the cam profile of the real switch with a relative error of <2.5 per cent. ACKNOWLEDGEMENTS This work was supported by the research grant titled IREAL – Haptic Interface for Virtual Prototyping in an Immersive Environment – 132/2007, funded by the Romanian National Council for Higher Education and Research. © Authors 2010 REFERENCES 1 Rothbart, H. A. Cam design handbook, 2004 (McGrawHill, New York). 2 Shigley, J. E., Mischke, C. R., and Brown, T. H. Standard handbook of machine design, 2004 (McGraw-Hill, New York). JMES1649 1781 3 Sandler, B. Z. Robotics – designing the mechanisms for automated machinery, 2nd edition, 1999 (Academic Press, San Diego, California). 4 Alexandru, P., Talaba, D., and Alexandru, C. Functional design of mechanisms (in Romanian), vol. 2, 2000 (Lux Libris Press, Brasov). 5 Norton, R. Design of machinery. Introduction to the synthesis and analysis of mechanisms and machines, 1992 (McGraw-Hill, New York). 6 Burnett, G. E. and Porter, J. M. Ubiquitous computing within cars: designing controls for non-visual use. Int. J. Hum. Comput. Stud., 2001, 55(4), 521–531. 7 Moreau, G., Fuchs, P., and Stergiopoulos, P. Applications of virtual reality in the manufacturing industry: from design review to ergonomic studies. Mecanique Ind., 2004, 5(2), 171–179. 8 Weir, D. W., Peshkin, M., and Colgate, J. E. The haptic profile: capturing the feel of switches. In Proceedings of the IEEE 12th International Symposium on Haptic interfaces for virtual environment and teleoperator systems (HAPTICS 2004), Chicago, IL, 27–28 March 2004, pp. 186–193. 9 MacLean, K. E. Haptic camera: a technique for characterizing and playing back haptic properties of real environments. In Proceedings of the ASME Dynamic Systems and Control Devision, Atlanta, GA, 1996, pp. 245–252. 10 Colton, M. B. and Hollerbach, J. M. Reality-based haptic force models of buttons and switches. In Proceedings of the IEEE International Conference on Robotics and automation (ICRA ’07 ), Rome, Italy, 10–14 April 2007, pp. 497–502. 11 Colton, M. B. and Hollerbach, J. M. Haptic models of an automotive turn-signal switch: identification and playback results. In Proceedings of the WorldHaptics 2007: Second Joint EuroHaptics Conference and IEEE Symposium on Haptic interfaces for virtual environments and teleoperator systems, Tsukuba, Japan, 22–24 March 2007, pp. 243–248. 12 Erdelyi, H., Antonya, Cs., and Talaba, D. Haptic feedback generation for a car direction indicator switch. In ASI on: product engineering: tools and methods based on virtual reality (series: intelligent systems, control and automation: science and engineering), vol. 35, 2007, pp. 257–273 (Springer, Berlin). 13 Mathew, G. K. and Tesar, D. Cam system design: the dynamic synthesis and analysis of the one degree of freedom model. Mech. Mach. Theory, 1976, 11, 247–257. 14 Lederer, P. Dynamische synthese der übertagungsfunktion eines kurvengetriebes. Mech. Mach. Theory, 1993, 28, 23–29. 15 Kreith, F. Mechanical engineering handbook, 1999 (CRC Press, Boca Raton, Florida). 16 Talaba, D. Articulated mechanisms. Computer aided design (in Romanian), 2001 (Transilvania University Publisher, Brasov). 17 Rooney, G. T. and Deravi, P. Coulomb friction in mechanism sliding joints. Mech. Mach. Theory, 1982, 17, 207–211. 18 Threlfall, D. C. The inclusion of coulomb friction in mechanisms programs with particular reference to DRAM. Mech. Mach. Theory, 1978, 13, 475–483. Proc. IMechE Vol. 224 Part C: J. Mechanical Engineering Science Downloaded from pic.sagepub.com at WEST VIRGINA UNIV on June 20, 2015 1782 H Erdelyi and D Talaba 19 Andersson, S., Söderberg, A., and Björklund, S. Friction models for sliding dry, boundary and mixed lubricated contacts. Tribol. Int., 2006, 40(4), 580–587. APPENDIX Notation In this article, subscripts are used to represent a generic term of a series. For example, xn represents the generic term of a finite series of spring compression data. c E IT EK EP FC Fd F drv F el F fr F l and F t FN FS Jc Jl Jlever k mf mi P damping coefficient relative error between the cam profiles kinetic energy potential energy Coulomb sliding friction damping force driving force elastic force sliding friction force of a cam–follower contact orthogonal components of F N normal contact force maximum static friction force moment of inertia of the cam moment of inertia of an element with rotational motion moment of inertia of the lever stiffness coefficient mass of the follower mass of an element with translational motion axial load Q re ri rj rr r0 R s W frJ WT W TFr radial load outer radius inner radius journal radius roller radius minimum radius resultant of F fr and F N displacement of the follower along the pitch curve driving torque friction torque of a circular crown type contact friction torque of a journal type contact sliding speed compression of the spring initial compression of the spring work of the damping force work done by the sliding friction force work of the circular crown type friction torque work of the journal type friction torque work done by the driving torque total work of the friction forces α β θ µ µstat µvisc ρ ρcomp ρref σ cam or lever rotation angle pressure angle angle between R and F drv sliding friction coefficient static friction coefficient viscous friction coefficient cam profile computed cam profile reference cam profile tangent to the pitch curve angular velocity of the cam or lever T T frC T frJ v x x0 WD W fr W frC Proc. IMechE Vol. 224 Part C: J. Mechanical Engineering Science Downloaded from pic.sagepub.com at WEST VIRGINA UNIV on June 20, 2015 JMES1649