Laser-Assisted Fabrication of Flexible Fiber Supercapacitors

advertisement

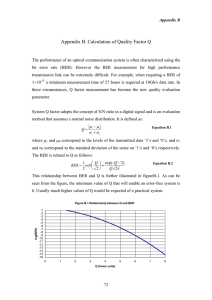

Journal of Materials Chemistry A View Article Online Published on 11 January 2021. Downloaded by University of California - Santa Barbara on 5/15/2021 7:20:38 PM. PAPER View Journal | View Issue Cite this: J. Mater. Chem. A, 2021, 9, 4841 Laser-assisted fabrication of flexible monofilament fiber supercapacitors† Phuong Thi Nguyen,a Jina Jang,a Yoonjae Lee,a Seung Tae Choib and Jung Bin In *ac Fiber supercapacitors (SCs) are potential and promising candidates for the development of wearable lightweight energy storage units. Thus, investigations have been conducted on various aspects such as electrode materials and device configuration to enhance their performance. The representative types of fiber SC configurations are characterized by certain limitations, including the imprecise assembling process and increased resistance of the SCs. To address these limitations, herein, we report a laserassisted fabrication method by which active electrodes, current collectors, electrolyte, and a flexible polymer support can be integrated into a monofilament fiber-type SC. Instead of combining two individual electrode fibers, two separate microscale current collectors and active electrodes were implemented on a polymeric monofilament surface by exploiting the micromachining capability of laser processing. Metallic current collectors were printed on a polyvinylidene fluoride fiber by selective laser sintering of Ag nanoparticles and nanowires. This highly conductive layer enabled reduction in the equivalent series resistance, leading to increased specific capacitance. The current collector was coated with a graphene layer, and a thin layer of pseudocapacitive MnO2 nanostructures was deposited onto the graphene layer to further improve the specific capacitance of the final fiber SC. The monofilament fiber SC exhibited a specific capacitance of 24.5 mF cm2 at 0.1 mA cm2 in a PVA–Na2SO4 electrolyte, along with excellent mechanical flexibility (94.3% capacitance retention in 3000 bending cycles at a bending radius of 7.5 mm). In particular, this laser-assisted electrode patterning method enabled the fabrication Received 21st October 2020 Accepted 8th January 2021 of serially connected SCs within a seamless monofilament unit, without post-fabrication assembly DOI: 10.1039/d0ta10283k This research suggests the development of an unconventional structure for fiber SCs, which is expected rsc.li/materials-a to be highly beneficial for promising flexible/wearable electronics applications. processing. Thus, the operation of a highly flexible fiber SC was demonstrated in a wide voltage window. 1. Introduction The rapid growth of the portable and wearable device market has spurred the development of wearable lightweight energy storage units, having high electrochemical performance, tiny volume, and high mechanical exibility. Fiber supercapacitors (SCs) are promising candidates to fulll this demand owing to their lamentous structure with diameters generally less than 1 mm. They can be woven into a wearable functional textile to power the embedded microdevices, such as the internet of things (IoT) wearable sensors for bio-signals.1,2 In an a So Energy Systems and Laser Applications Laboratory, School of Mechanical Engineering, Chung-Ang University, Seoul, 06974, Republic of Korea. E-mail: jbin@ cau.ac.kr b Functional Materials and Applied Mechanics Laboratory, School of Mechanical Engineering, Chung-Ang University, Seoul, 06974, Republic of Korea c Department of Intelligent Energy and Industry, Chung-Ang University, Seoul 06974, Republic of Korea † Electronic supplementary 10.1039/d0ta10283k information (ESI) available. This journal is © The Royal Society of Chemistry 2021 See DOI: application stage, this functional textile can be attached onto a human body tightly but comfortably, thus enabling the user to take care of his/her health efficiently with remote aid. Various studies have been conducted to improve the performance of ber SCs in terms of electrode materials, electrolyte, and device conguration.3 Among them, the development of novel electrode materials, with large surface area and reversible redox activity, has been mainly pursued. Recently, however, researchers have also realized the importance of electrical conductance of the ber SC electrode.4–6 They have reported that the performance of a ber SC can signicantly drop with increasing length because of its extremely high aspect ratio and the resulting large internal resistance.7 This problem can be mitigated either by developing an active electrode with high intrinsic conductivity, or by introducing a highly conductive current collector into the ber SC. Related to the former, allcarbon ber electrodes have been developed, consisting of carbon microlaments,8 carbon nanotubes (CNTs),9 graphene (Gr),10–12 or carbon-based composites.13,14 The fabricated allcarbon ber SCs exhibited excellent electrochemical J. Mater. Chem. A, 2021, 9, 4841–4850 | 4841 View Article Online Published on 11 January 2021. Downloaded by University of California - Santa Barbara on 5/15/2021 7:20:38 PM. Journal of Materials Chemistry A performance, but their electrical conductivities were not as high as those of metals. For the latter approach, ultrathin metal bers15,16 or metal-coated polymer bers17,18 can be adopted as brous current collectors. The successful incorporation of such metallic elements into ber SCs and the consequent high-power performance have recently been reported.6 In parallel with the above material issues, the device conguration to construct a ber SC is an important factor that affects not only the electrochemical performance but also the mechanical properties of the SC.19 Three representative types of ber SC congurations have been extensively investigated: parallel structure,15,17,20–25 twisted two-ply structure,8,26–28 and coaxial structure.29–32 The parallel- or twisted-type ber SC consists of two separate ber units, which correspond to the anode and cathode. Although these types are relatively well reported, they require the additional step of combining the individual anode and cathode bers, which critically complicates the assembling process. Moreover, under mechanical bending, the two electrodes can get separated due to uneven strain distribution between them. This can cause serious problems, such as signicant increase in internal resistance and even failure of the SC. In this respect, the coaxial structure is advantageous because in this, unlike the parallel or twisted type, all the SC components, including a core electrode, a gel electrolyte, and an outer electrode, are integrated into a single compact ber. However, its fabrication generally involves layerby-layer coating of the cylindrical ber with different materials, which is not easily controllable for microscale layers.3 To realize such all-in-one ber SCs in a precise manner, a laser-based electrode patterning technique can be a plausible approach. Hu et al. pioneered this method and developed an unconventional all-in-one ber SC, in which two separated electrodes are rationally integrated into a single graphene oxide (GO) ber.33 Reduced graphene oxide (rGO) electrode lines were patterned on the GO ber surface in the longitudinal direction by exploiting area-specic reduction of GO by a laser.34 However, despite their great exibility, these all-in-one ber SCs exhibited only moderate capacitance (1.2–2.4 mF cm2 at 80 mA cm2), possibly due to the low electrical conductance of the rGO electrode. As discussed above, this large internal resistance can cause serious performance deterioration for long-ber SCs. Fig. 1 Paper In this study, laser microfabrication has been extensively exploited to develop exible monolament ber SCs, in which two separate electrodes are patterned on a microscale. For active charge-storage materials, thin layers of Gr and MnO2 were coated on the surface of a core polymer ber. The relatively low conductivity of the electrode was overcome by introducing exible metallic current collectors beneath the electrode layer. This ber SC exhibited signicantly decreased internal resistance, high capacitance, and excellent exibility. Moreover, to the best of our knowledge, multiple SC units were seamlessly integrated into a single ber SC for the rst time, with no need for external terminal connection between individual ber SCs. This novel architecture enables a compact ber SC to power a microdevice operated at high voltages. 2. 2.1 Results and discussion Fabrication of monolament supercapacitors Fig. 1 depicts the fabrication process of the monolament ber SC. A polyvinylidene uoride (PVDF) monolament ber (diameter: 300 mm) was used as the core material. Laserinduced sintering of Ag nanoparticles (AgNPs) was adopted to produce highly conductive current collectors on the PVDF surface.35 The ber was coated with AgNPs and Ag nanowires (AgNWs) and irradiated with a continuous-wave laser beam along its centerline. The AgNWs were added to enhance the exibility of the Ag layer.36 This laser irradiation induced siteselective sintering of the AgNPs/AgNWs and increased adhesion of the Ag layer to the underlying ber surface. Thus, when the ber was rinsed in deionized (DI) water using a bath sonicator, the unaffected AgNPs/AgNWs were washed out to obtain the line-type AgNP/AgNW current collectors. Based on this printing method, two symmetric current collectors were prepared for the cathode and anode. Fig. 2a shows the optical microscopy image of the Ag current collector line (linewidth: 120 mm), as well as the eld-emission scanning electron microscopy (FE-SEM) image of the sintered AgNPs/AgNWs, which exhibits the structural connectivity between the nanomaterials. The PVDF ber was selected because of its excellent chemical resistance, high mechanical exibility, and compatibility with Schematic of the monofilament fiber SC fabrication process. 4842 | J. Mater. Chem. A, 2021, 9, 4841–4850 This journal is © The Royal Society of Chemistry 2021 View Article Online Published on 11 January 2021. Downloaded by University of California - Santa Barbara on 5/15/2021 7:20:38 PM. Paper Journal of Materials Chemistry A Fig. 2 Optical microscopy image and SEM image of a PVDF fiber with (a) a sintered AgNP/AgNW current collector line and (b) a AgNP/AgNW/Au line. (c) Cross-sectional TEM images and EDS elemental maps of the AgNP/AgNW/Au layers. (d) Resistance comparison of 1 cm samples with different current collector compositions (inset: a photograph showing the resistance measurement for the 1 cm-long AgNP/AgNW/Au line on the PVDF fiber). (e) Cyclic bending test setup. (f) Resistance changes of AgNP and AgNP/AgNW samples (inset: bent state of the sample; the yellow line represents the current collector line). the laser-induced sintering process. It especially enabled excellent adhesion of the sintered Ag layer to its surface. Even under strong bath sonication (power: 100 W, frequency: 40 kHz, tank size: 1.95 L), the sintered Ag layer remained almost the same (veried by electrical measurements and microscopy images). The laser-induced sintering method was adopted because PVDF is thermally unstable at the onset temperature for AgNP/AgNW sintering (150 C). The laser beam was swept over the ber surface, instantaneously increasing the surface temperature above the sintering point. However, the heataffected zone was limited near the surface, and thus, thermal damage to the bulk ber could be avoided. In contrast, annealing of the PVDF ber using a general electrical heater resulted in serious deformation (Fig. S1 in the ESI†). Other polymers can also be used as the core ber material, as demonstrated in studies on laser-based printed electronics.37–39 In the next step, a thin layer of Au was introduced to cover the AgNP/AgNW layer via electrodeposition because Ag is vulnerable to corrosion by water-based electrolytes in the voltage range for the SC operation, resulting in electrochemical (EC) instability and rapid deterioration of the SC performance.7,40 The Au deposition was conrmed by the change in color and micromorphology (Fig. 2b), and also by the energydispersive X-ray spectroscopy (EDS) elemental maps (Fig. S2†). Fig. 2c shows the cross-sectional transmission electron microscopy (TEM) images of the coated AgNP/AgNW/Au layers and the EDS elemental maps of the marked area. From the TEM This journal is © The Royal Society of Chemistry 2021 image, the total thickness of the metal layers was measured to be 595 nm. The EDS maps (Fig. 2c) reveal the Au deposition thickness to be 40 nm. The electrical conductance of the current collector was improved sequentially with addition of the metallic materials. Fig. 2d compares the electrical resistances of three samples, each of which contained a single current collector line (length: 1 cm), composed of different composite components: AgNP, AgNP/AgNW, and AgNP/AgNW/Au. The addition of AgNWs to the AgNP layer decreased the resistance from 30.1 to 16.0 U cm1, and the following electrodeposition of Au further reduced the resistance to 10.9 U cm1. The added AgNWs not only increased the electrical conductance but also improved the mechanical exibility of the current collector. This effect was conrmed by the results of a cyclic bending test. Fig. 2e shows that bending was repeatedly applied to a 5 cm-long ber with a radius of 7.5 mm for 10 000 cycles, and the change in the electrical resistance of the ber was measured in a at state to evaluate its structural integrity. Fig. 2f shows the resistance changes for a AgNP-coated ber and a AgNP/AgNW-coated ber. The resistance of the sintered AgNP layer increased rapidly by over 40% in the rst 2000 cycles. Aer that, the resistance changes asymptotically reached a plateau of 47%. This is attributable to the short-range connection between the AgNPs, which can result in crack generation when the AgNP layer is subjected to severe mechanical stress. In our bending test, the crack was indeed generated, as shown in J. Mater. Chem. A, 2021, 9, 4841–4850 | 4843 View Article Online Published on 11 January 2021. Downloaded by University of California - Santa Barbara on 5/15/2021 7:20:38 PM. Journal of Materials Chemistry A Fig. S3a (ESI†). On the other hand, the sintered AgNP/AgNW ber exhibited an insignicant change in resistance: only 5% change in the rst 2000 cycles. The SEM image (Fig. S3b in the ESI†) revealed that the crevice in the AgNP layer was bridged by the long AgNWs, which provided shorter electrical conduction paths and compensated for conductance loss by crack formation. Aer patterning of the metal current collector, the ber was entirely coated with the Gr dispersion via dip-coating and then dried at 60 C for 1 h. This Gr layer additionally decreased the electrical resistance of the ber and widened the electrode area. To split the carbon electrode into anodes and cathodes, the Grcoated ber was suspended horizontally and scanned with the nanosecond laser beam along its centerline. Fig. 3a and Movie S1† show that the high-intensity pulsed laser induced ablation of the irradiated Gr. For the selected laser scanning speed (0.2 mm s1) and laser uence (1.3 J cm2), this ablation occurred not only from the directly irradiated top surface but also from the bottom surface even by a single sweep with the laser beam, producing two laser cutting lines simultaneously due to the optical transparency of PVDF with respect to the laser wavelength (532 nm). The incident laser pulses rst removed the irradiated Gr at the top surface and then passed through the transparent PVDF layer,41 ablating the Gr at the bottom surface. Fig. 3b shows that the kerf widths of the laser cutting were 50 and 75 mm for the top and bottom surfaces, respectively. The inset of Fig. 3b shows an SEM image of the coated Gr layer. Notably, a low scanning speed (0.2 mm s1) was selected because of the low pulse repetition rate (20 Hz) of the nanosecond laser used herein. Thus, if a high-repetition pulse laser is adopted, the ablation process can be even faster than that reported here. Finally, a PVA-based solid-state electrolyte was applied to the ber via dip-coating to achieve an all-solid-state monolament ber SC. The cross-sectional SEM image captured at the interface area of the coated layers (Fig. 3c) shows that the thicknesses of the Gr and the PVA electrolyte layers were estimated to be 5 and 7 mm, respectively. Considering the density of a thick Gr layer (2.0 g cm3), the mass loading of the thin Gr layer was estimated to be 82 mg per unit ber length (cm). This ber SC is hereaer denoted as MG-SC, which is an abbreviation for the ber SC fabricated with the metallic (AgNP/AgNW/Au) current collector and Gr layer. Paper 2.2 Electrochemical performance of the monolament ber supercapacitor 2.2.1 Effect of metal current collectors. The effect of using the AgNP/AgNW/Au current collector on the SC performance was investigated by comparing the performances of the MG-SC and the SC built with the Gr layer only (denoted as G-SC). Four SCs with different lengths (1, 2, 3, and 4 cm) were prepared for each case, and a gel-type PVA–H3PO4 electrolyte was used. The dimensional characteristics of the Gr layer were the same for all SCs. Fig. 4a and b show the CV (scan rate: 50 mV s1), CC (current density: 0.05 mA cm2), and electrochemical impedance spectroscopy (EIS) data for the 1 and 4 cm long MG-SCs and G-SCs. The data for the other SCs, with lengths of 2 cm and 3 cm, are provided in Fig. S4 of the ESI.† The results indicate that the AgNP/AgNW/Au current collector effectively increased the capacitance of the ber SC. For the same length, MG-SCs exhibited a larger closed-loop area in CV (Fig. 4a) and slower discharge in CC (Fig. 4b) than G-SCs, suggesting capacitance increase. In particular, the EIS result suggests that the equivalent series resistance (ESR) dramatically decreased by almost three orders of magnitude (Fig. 4c). As the electrochemical contribution of the current collector itself to the total capacitance was negligible, the increased capacitance could be attributed to the decreased internal resistance of the electrode, which was enabled by the AgNP/ AgNW/Au current collector. Fig. 4d shows the change in the length-specic ESR (ESRL) value of the SCs with the increase in the SC length. The ESR value was calculated from IRdrop of the CC curve; it was observed that the ESR of the ber SC increased with the ber length; however, the ESRL showed different characteristics depending on the presence of the current collector. While the ESRL for G-SCs increased with the SC length, the ESRL for MG-SCs remained almost the same, indicating a linear increase in ESR with the ber length. The effective role of the printed current collector enabled consistent performance of the ber SC with respect to the varying ber lengths. Fig. 4e shows the length-specic capacitances (CL) of the ber SCs that were calculated from their CV data (scan rate: 50 mV s1). For G-SCs, the CL of G-SCs decreased signicantly with an increase in the length. For instance, the 4 cm long G-SC (or G-SC-4) retained only 34% of G-SC-1's CL. (a) Schematic of the laser cutting process. (b) Optical microscopy images of the laser cutting line on the top and bottom surfaces and SEM image of the Gr layer (inset). (c) Cross-sectional SEM image of the graphene-coated fiber captured at the interface corresponding to the marked area of the inset schematic. Fig. 3 4844 | J. Mater. Chem. A, 2021, 9, 4841–4850 This journal is © The Royal Society of Chemistry 2021 View Article Online Published on 11 January 2021. Downloaded by University of California - Santa Barbara on 5/15/2021 7:20:38 PM. Paper Journal of Materials Chemistry A (a) CV, (b) CC, and (c) EIS for G-1, G-4, MG-SC-1, and MG-SC-4 supercapacitors. (d) Length-specific ESR and (e) length-specific capacitance values of the G-SC and MG-SC samples with the length varying from 1 to 4 cm. Fig. 4 This performance deterioration with increased length is a critical issue of ber SCs recently reported by researchers.4–6,8 Although a planar SC was used, our group previously demonstrated the mitigation of this problem by incorporating a laserprinted metal grid layer into a Gr electrode.7 A similar approach was adopted for ber-type SCs in this study, and the result was in good agreement with the planar SC case. As shown in Fig. 4d, the CL for MG-SCs was well retained; compared with G-SC-4 (34%), MG-SC-4 maintained 93% CL of MG-SC-1. 2.2.2 Capacitance enhancement by MnO2 deposition. Despite the improved characteristics of the capacitance, the specic capacitance values were still low (for MG-SC-1, only 34 mF cm1 or 0.84 mF cm2), possibly due to the limited capacitance of stacked graphene akes.42 Thus, to further increase the capacitance, a thin layer of manganese oxide (MnO2) nanostructures was coated onto the Gr lm surface via electrodeposition. MnO2 has been extensively studied as a promising electrode material for pseudocapacitors owing to its nontoxicity, low cost, and excellent pseudocapacitive charge storage.43,44 The electrodeposition process was added to the fabrication sequence described in Section 2.1. Between the Gr coating and the laser ablation (cutting) processes. As the Ag layer was protected by the Au layer, possible corrosion of Ag could be avoided during the MnO2 deposition.7 Fig. 5 shows the SEM image of the deposited MnO2 layer that exhibits sea urchin-like nanostructures. The energy-dispersive X-ray spectroscopy and X-ray photoelectron spectroscopy spectra of the MnO2 layer are provided in Fig. S5 of the ESI.† For the MnO2coated ber SC (denoted as MGM-SC), a gel-type PVA–Na2SO4 electrolyte was used.44–46 This journal is © The Royal Society of Chemistry 2021 A 3.5 cm long MGM-SC was fabricated, and its specic capacitance was observed to be markedly higher than that of MG-SCs. Fig. 6a–c show the CV (scan rate: 10–200 mV s1), CC (current density: 0.1 to 1 mA cm2), and EIS data (frequency: 0.1 to 100 kHz) of the MGM-SC. The potential range was conned within 0–0.85 V. The CC curves exhibit nearly linear symmetrical shapes with the current density ranging from 0.1 to 1 mA cm2, indicating good reversibility of the device. The CA of this ber SC was calculated from the discharge line of the CC curves. Fig. 5 FE-SEM image of the MnO2 nanostructures deposited on the graphene layer. J. Mater. Chem. A, 2021, 9, 4841–4850 | 4845 View Article Online Published on 11 January 2021. Downloaded by University of California - Santa Barbara on 5/15/2021 7:20:38 PM. Journal of Materials Chemistry A Paper Fig. 6 Electrochemical and mechanical characteristics of a 3.5 cm long MGM-SC. (a) CV curves obtained at a range of scan rates (10–200 mV s1). (b) CC curves obtained at 0.1, 0.2, 0.5, and 1 mA cm2 (c) EIS curve for the frequency range from 0.1 to 100 kHz. (d) CA calculated from the CC curves at various current densities and cyclic charge/discharge stability at a galvanostatic current density of 2 mA cm2. (e) Capacitance retention obtained under bending at different curvatures. The photographs show the testing at bending diameters of 1 and 0.5 cm. (f) Capacitance retention for 3000 bending cycles at a bending radius of 7.5 mm. The inset shows the CV curves (scan rate: 50 mV s1) obtained at different cycle numbers. The CA value was 24.5 mF cm2 at 0.1 mA cm2, and it decreased to 20.8 mF cm2 at 1 mA cm2 (Fig. 6d). When the MGM-SC was tested as a working electrode in a 3-electrode conguration with an aqueous Na2SO4 electrolyte (0.5 M) for comparison, its capacitance was markedly increased to 30.2 mF cm2 at 0.1 mA cm2 (see Fig. S6†). This capacitance is significantly higher than that (1.2–2.4 mF cm2 at 80 mA cm2) of Hu et al.‘s all-in-one ber SC that has a similar electrode conguration.33 As the neutral PVA electrolyte was used, the capacitance retention was high (over 95%) during 3000 cycles of galvanostatic charging/discharging at 2 mA cm2 (Fig. 6d). However, aer 10 000 cycles, the retention was reduced to 77% (see Fig. S7 in the ESI†). Owing to the superior exibility of the current collector and the active electrode nanomaterials, the MGM-SC also exhibited excellent exibility; this characteristic of the MGM-SC was evaluated based on the capacitance change occurring when the ber was subjected to various bending conditions. The inset of Fig. 6e shows the capacitance retention ratio varying with bending curvature. The capacitance of the MGM-SC was decreased by only 7.5% at the bending curvature of 4 cm1. In addition, cyclic bending of the ber SC was performed 3000 times at a bending radius of 0.75 cm, which is identical to the testing conditions shown in Fig. 2e. The capacitance changes were negligible; as shown in Fig. 6f, the MGM-SC retained 98% of its initial capacitance aer 1000 bending cycles and 94% aer 3000 cycles. 4846 | J. Mater. Chem. A, 2021, 9, 4841–4850 Due to the lack of a common protocol for bendability evaluation, it is difficult to directly compare bendabilities of different ber SCs reported in the literature, based on the same metric. However, although the electrode material was placed on the outer surface of the ber with a relatively large diameter (300 mm), the bendability of our ber SC is comparable or potentially superior to those of other ber SCs.5,9,12,15–17,20,24,32,33,46–52 For instance, Hu et al. reported the capacitance decrease of their all-in-one ber SC (diameter: 50 mm) by almost 20% aer only 160 bending cycles at the same bending radius (0.75 cm).33 Yu et al. demonstrated that the parallel-type carbon nanotube–graphene ber SC (diameter of a single electrode ber: 50 mm) supported on a PET lm retained 97% of its initial capacitance aer 1000 bending cycles;24 however, the bending angle was only 90 . Many reports demonstrated bend testing up to 1000 cycles with good retention results (above 90%), but the information of the bending radius was not specied.5,9,12,20,28,47,48,50 The detailed comparison of the bendabilities is provided in Table S1 of the ESI.† The ber SC structure developed in this study presents the implementation of conventionally planar microsupercapacitors53–55 on a curved ber platform. For yarn-type ber SCs and all-carbon ber SCs, the ber core generally consists of porous active materials; thus, the electrolyte ions can possibly adsorb to the entire ber core. In contrast, for the ber SCs developed in our study, the active materials responsible for This journal is © The Royal Society of Chemistry 2021 View Article Online Published on 11 January 2021. Downloaded by University of California - Santa Barbara on 5/15/2021 7:20:38 PM. Paper Journal of Materials Chemistry A (a) Schematic comparison of the conventional method and the proposed method for serial connection of multiple SCs. (b) Schematic showing the laser-based fabrication process for MGM-3SC-1 and its electrode structure, and microscopy image captured in the laser ablation area. (c) CV curves obtained at 50 mV s1 and (d) CC curves obtained at 0.2 mA cm2 for MGM-SC-1 and MGM-3SC-1. (e) Photograph of MGM3SC-1 powering an LED. Fig. 7 charge storage are concentrated at the outer surface of the core polymer in a form of thin lm. Nevertheless, the area-specic energy density (EA) and power density (PA) of the MGM-SC, which are calculated based on the apparent surface area of the cylindrical ber, are comparable to those of various bershape SCs (see the Ragone plot of Fig. S8 and Table S2†).27,47,49,56,57 The EA of the MGM-SC was 0.28–0.63 mW h cm2 in a PA range of 10.6–334.5 mW cm2. However, in terms of Ragone plot metrics, the performance of the MGM-SC could not reach those of recently reported high-performance ber SCs,10,13,15,48 although their fabrication methods did not achieve the lament-level precise patterning of ber SC electrodes reported in our study. This limited performance can be ascribed to our distinguished electrode conguration, where the loss in potential eld can occur via the PVDF domain that spatially mediates between the anode and the cathode.58 In recent years, ber SCs with pure metallic ber cores have been developed. Their excellent power performance has been demonstrated in terms of the very high conductance of the core wire that is superior to that of carbon cores or our thin metallic current collector layer.6,15,16 However, our ber SC is distinct from them in terms of exibility. Due to the low yield strain (3Y ¼ sY/E) of metals (typically 0.1–0.2% for most of metals), general metal wires with comparable diameters can barely withstand repeated bending without plastic deformation at a high curvature. In contrast, polymeric bers (such as PVDF ber) can This journal is © The Royal Society of Chemistry 2021 deform elastically up to at least several percent of bending strain (3Y ¼ 3% for our thermally drawn PVDF ber (Fig. S9†)). The mechanical strengths of metal wires are superior to those of polymeric bers. However, the promising applications of berSCs are related to wearable devices, whose strengths can match those of general polymers. Moreover, compared with metals, ber SCs with a polymer core are light in weight because their densities are much smaller than those of general metal wires by about one order of magnitude.59 2.3. Serial integration of monolament supercapacitors PVA-based solid-state electrolytes are highly useful for ber SCs. They can conveniently be prepared and applied to ber SCs at a moderate level of device packaging. Moreover, they are robust to mechanical deformation. However, most of them have limited potential windows because of electrochemical instability of the absorbed water over 1 V. Organic electrolytes may enable a wider potential window up to 3 V;60 however, these should be tightly sealed for stable operation, which is another challenge for the ber SCs. Thus, to power a device at a high voltage, the ber SC with a PVA-based solid state electrolyte needs to be connected serially. The technical merit of the proposed laser-patterned ber SC is highlighted when it comes to the fabrication of the ber SCs that are seamlessly connected in series. That is, separate individual electrode lines can be precisely patterned in a single J. Mater. Chem. A, 2021, 9, 4841–4850 | 4847 View Article Online Published on 11 January 2021. Downloaded by University of California - Santa Barbara on 5/15/2021 7:20:38 PM. Journal of Materials Chemistry A monolament ber, whereas the conventional method requires a considerable effort to assemble individual ber SCs via terminal connections (Fig. 7a). Fig. 7b describes the laser-based fabrication process to implement the serial connection of three SC units in a single ber. Before electrolyte coating, an MGM-SC was irradiated with the nanosecond laser for the ablation of the electrode line at the selected areas. At a laser uence of 1.4 J cm2, the Ag/Au/Gr/MnO2 layers were completely removed, exposing the electrical isolating PVDF surface (microscopy image in Fig. 7b). Consequently, alternating placement of separate electrode lines was achieved, which is equivalent to 3 SCs that are serially connected. The active length of each SC was 1 cm. This serially integrated ber SC is denoted as MGM-3SC-1. A single ber SC of 1 cm length (MGM-SC-1) was also prepared for comparison. Aer coating with the PVA–Na2SO4 electrolyte, MGM-3SC-1 was characterized via CV and CC in a potential window of 2.55 V, which is three times larger than that of MGM-SC-1. Fig. 7c and d show the CV (scan rate: 50 mV s1) and CC (current density: 0.2 mA cm2) curves, respectively, of MGM-SC1 and MGM-3SC-1. Typical features of serially connected SCs such as reduced total capacitance in the widened V range were observed.5,13,14,16,24,31,48 Fig. 7e shows a demonstration where MGM-3SC-1 could indeed turn on the light-emitting diode (LED) whose minimum operating voltage is 1.7 V. 3. Conclusions In conclusion, a monolament ber SC was successfully developed based on laser processing. The laser microfabrication enabled precise patterning of SC electrodes in a monolament microber. The addition of AgNP/AgNW/Au current collectors signicantly enhanced the electrode conductance. As a result, not only increased capacitance but also consistent performance with different ber SC lengths was achieved. The electrochemical deposition of MnO2 nanostructures onto the Gr electrode further improved the capacitance of the ber SC from 0.84 to 24.5 mF cm2. The ber SC operated reliably under thousands of charge/discharge and bending cycles, and no signicant change in the EC performance was observed. Moreover, multiple SC units could be serially integrated into a single monolament ber SC, which widened the operating voltage. Our fabrication method offers a highly useful route to implement SCs in series at the lament level, thereby widening the operating voltage window. The results of this research put forth the developmental process and the characteristics of an unconventional structure for ber-type SCs that are expected to have a high potential in the fabrication of exible/wearable electronics applications. 4. Experimental section 4.1 Fabrication of PVDF bers Pellets of the PVDF homopolymer (Kynar 740, Arkema) were consolidated into a cylindrical preform (diameter: 25 mm, length: 300 mm) at 200 C. This preform was vertically installed in a high-temperature furnace (maximum temperature: 230 C) 4848 | J. Mater. Chem. A, 2021, 9, 4841–4850 Paper and then drawn into a monolament PVDF ber under gravity, continuously producing a microscale lament (diameter: 300 20 mm) in a starkly long dimension (100 m).51,61 The thermally drawn monolament ber was annealed at 130 C to improve its crystallinity. 4.2 Silver current collector patterning The PVDF ber was ultrasonically cleaned in an ethanol– acetone mixture (volume ratio: 1 : 1) for 10 min and then rinsed in DI water. Thin layers of AgNPs (average diameter: 50 nm, 10 wt% in isopropyl alcohol (IPA), Flexio) and AgNWs (average length: 20 mm, average diameter: 40 nm, 0.5 wt% in IPA, Flexio) were successively coated on the PVDF ber surface by the droplet-coating method (for details, see Fig. S10 in the ESI†). For sintering of the AgNP/AgNW layer, the coated ber was loaded in an X–Y motorized stage and scanned with a CW laser (wavelength: 532 nm, MGL-FN-532-400 mW, CNI). The laser beam was focused via a 2 objective lens (NA: 0.055, PAL-2, OptoSigma), and the focused beam size (1/e2) was approximately 90 mm in diameter. The laser scanning was performed 5 times at a speed of 40 mm s1 and a laser power of 125 mW. Aer laser sintering, the unsintered AgNPs/AgNWs were removed by rinsing in DI water using a bath sonicator. 4.3 Preparation of graphene dispersion Single-layer graphene powder (ake diameter: 0.4–5 mm, thickness: 0.6–1.2 nm, ACS Material) was dissolved in DI water to obtain a graphene solution (1.4 wt%). To improve the dispersion of graphene, a binder mixture (weight ratio ¼ 1 : 1) of carboxymethyl cellulose (CMC) powder (MTI Korea) and styrenebutadiene rubber (SBR) emulsion (EQ-Lib-SBR, MTI Korea) was added to the aqueous Gr solution.62,63 The weight ratio of the solid binders to graphene was set to 1 : 9. The solution was then thoroughly stirred for 8 h at room temperature (20 C). 4.4 MnO2 deposition The electrodeposition of Au or MnO2 was conducted using a potentiostat (SP-150, Bio-Logic Science Instruments) in a three-electrode conguration (reference electrode: Ag/AgCl (sat. KCl), counter electrode: Pt coil). For Au deposition, the precursor solution was prepared by dissolving potassium dicyanoaurate powder (KAu(CN)2, 298115, Sigma-Aldrich) in a phosphate buffer (0.1 M, pH: 6.8). The amount of KAu(CN)2 was maintained at 8 mg per deposition area (cm2). A constant potential of 0.5 V was applied to the working electrode (Agpatterned ber), and the deposition was continued until the delivered charge density reached 4 C cm2. For MnO2 deposition, a constant current density of 250 mA cm2 was applied to the electrode ber for 15 min in a mixture of 0.02 M manganese nitrate (Mn(NO3)2$4H2O, 19346, Acros Organics) and 0.1 M sodium nitrate (NaNO3, Reagent Plus, Sigma-Aldrich). 4.5 Fabrication of a monolament ber SC A nanosecond laser (wavelength: 532 nm, pulse duration: 6–9 ns, repetition rate: 20 Hz, Nano L200-20, Litron) was employed This journal is © The Royal Society of Chemistry 2021 View Article Online Published on 11 January 2021. Downloaded by University of California - Santa Barbara on 5/15/2021 7:20:38 PM. Paper Journal of Materials Chemistry A to ablate electrode layers. A 10 lens (NA: 0.3, PAL-10-A, OptoSigma) was used to focus the laser, and the beam size was approximately 26 mm. As an electrical terminal, a strip of Cu tape was attached to each end of the ber SC. A minute amount of Ag paste was applied to the Cu–electrode interface to enhance the electrical contact. Two kinds of PVA-based gel-type electrolytes were used in this study. A PVA–H3PO4 electrolyte was prepared by mixing 6.91 g of H3PO4 solution (85 wt%, SigmaAldrich), 6 g of PVA powder (molecular weight: 89 000–98 000, Sigma-Aldrich), and 60 mL of DI water. The mixture was stirred at 90 C until PVA was completely dissolved and visually transparent. For a PVA–Na2SO4 electrolyte, the abovementioned process was followed, replacing 0.06 mol of H3PO4 with 6 g of Na2SO4 (powder, 99.9 wt%, Sigma-Aldrich). Before every EC measurement, the electrolyte was dried under ambient conditions for 1 h.5 4.6 Characterization The morphologies of the current collector layers and the active electrode materials were investigated by FE-SEM (SIGMA, Carl Zeiss). The thicknesses of the Ag and Au layers were determined by TEM (JEM-2100F) and EDS. The cross-sectional TEM specimen (thickness: 70–80 nm) was prepared using focused ion beam milling (FIB, Quanta 3D FEG, FEI). A digital multimeter (Keysight 34450A) was employed to measure the resistances of the ber samples. The electrochemical performances of the ber SCs were investigated by cyclic voltammetry (CV), galvanostatic charge/discharge (CC) analysis, and electrochemical impedance spectroscopy (EIS), using a potentiostat (SP-150, BioLogic Science Instruments). The cell capacitance (Ccell), lengthspecic capacitance (CL), area-specic capacitance (CA), areaspecic energy density (EA), and area-specic power density (PA) of the SC were calculated using the following equations: Ccell ¼ I t ðFÞ V IRdrop CL ¼ 2 Ccell L F cm1 CA ¼ 2 Ccell A F cm2 1 1 EA ¼ CA V 2 8 3600 PA ¼ EA 3600 t (1) (2) (3) W h cm2 W cm2 (4) (5) where A is the footprint area of a single electrode (cm2), I is the discharge current (A), t is the discharge time (s), V is the operating voltage (V), IRdrop is the voltage drop at the beginning of the discharge curve (V), and L is the active length of the ber SC (cm).10,64 Conflicts of interest The authors have no competing nancial interest to declare. This journal is © The Royal Society of Chemistry 2021 Acknowledgements This research was supported by the Nano$Material Technology Development Program through the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) (NRF-2016M3A7B4910532); and also by the Ministry of Trade, Industry & Energy (MOTIE, Korea) under Industrial Technology Innovation Program. No. 10062636, ‘Development of Compact, Lightweight, High-Performance, Highly Durable, Safe Twisted String Actuation Module Using Reinforced Strings, Variable Radius Pulleys, and Hybrid Actuation Control’. References 1 C. Lethien, J. Le Bideau and T. Brousse, Energy Environ. Sci., 2019, 12, 96–115. 2 H. He, T. Zhao, H. Guan, T. Zhong, H. Zeng, L. Xing, Y. Zhang and X. Xue, Sci. Bull., 2019, 64, 1409–1417. 3 S. T. Senthilkumar, Y. Wang and H. Huang, J. Mater. Chem. A, 2015, 3, 20863–20879. 4 Y. Ma, P. Li, J. W. Sedloff, X. Zhang, H. Zhang and J. Liu, ACS Nano, 2015, 9, 1352–1359. 5 W. Jiang, S. Zhai, Q. Qian, Y. Yuan, H. E. Karahan, L. Wei, K. Goh, A. K. Ng, J. Wei and Y. Chen, Energy Environ. Sci., 2016, 9, 611–622. 6 N. F. He, J. Y. Liao, F. Zhao and W. Gao, ACS Appl. Mater. Interfaces, 2020, 12, 15211–15219. 7 H. Choi, P. T. Nguyen, C. V. Tran and J. B. In, Appl. Surf. Sci., 2020, 510, 145432. 8 S. Zhai, W. Jiang, L. Wei, H. E. Karahan, Y. Yuan, A. K. Ng and Y. Chen, Mater. Horiz., 2015, 2, 598–605. 9 J.-H. Liu, X.-Y. Xu, W. Lu, X. Xiong, X. Ouyang, C. Zhao, F. Wang, S.-y. Qin, J.-l. Hong, J.-N. Tang and D.-Z. Chen, Electrochim. Acta, 2018, 283, 366–373. 10 N. He, W. Shan, J. Wang, Q. Pan, J. Qu, G. Wang and W. Gao, J. Mater. Chem. A, 2019, 7, 6869–6876. 11 C. Lu, J. Meng, J. Zhang, X. Chen, M. Du, Y. Chen, C. Hou, J. Wang, A. Ju, X. Wang, Y. Qiu, S. Wang and K. Zhang, ACS Appl. Mater. Interfaces, 2019, 11, 25205–25217. 12 G. Qu, J. Cheng, X. Li, D. Yuan, P. Chen, X. Chen, B. Wang and H. Peng, Adv. Mater., 2016, 28, 3646–3652. 13 Z. Yang, Y. Jia, Y. Niu, Y. Zhang, C. Zhang, P. Li, M. Zhu and Q. Li, J. Energy Chem., 2020, 51, 434–441. 14 T. Xu, D. Yang, Z. Fan, X. Li, Y. Liu, C. Guo, M. Zhang and Z.-Z. Yu, Carbon, 2019, 152, 134–143. 15 M. Huang, L. Wang, S. Chen, L. Kang, Z. Lei, F. Shi, H. Xu and Z.-H. Liu, RSC Adv., 2017, 7, 10092–10099. 16 P. Li, J. Li, Z. Zhao, Z. Fang, M. Yang, Z. Yuan, Y. Zhang, Q. Zhang, W. Hong, X. Chen and D. Yu, Adv. Sci., 2017, 4, 1700003. 17 Y. Fu, X. Cai, H. Wu, Z. Lv, S. Hou, M. Peng, X. Yu and D. Zou, Adv. Mater., 2012, 24, 5713–5718. 18 L. B. Liu, Y. Yu, C. Yan, K. Li and Z. J. Zheng, Nat. Commun., 2015, 6, 7260. 19 D. Chen, K. Jiang, T. Huang and G. Shen, Adv. Mater., 2020, 32, 1901806. J. Mater. Chem. A, 2021, 9, 4841–4850 | 4849 View Article Online Published on 11 January 2021. Downloaded by University of California - Santa Barbara on 5/15/2021 7:20:38 PM. Journal of Materials Chemistry A 20 Y. Li, K. Sheng, W. Yuan and G. Shi, Chem. Commun., 2013, 49, 291–293. 21 C. Choi, S. H. Kim, H. J. Sim, J. A. Lee, A. Y. Choi, Y. T. Kim, X. Lepro, G. M. Spinks, R. H. Baughman and S. J. Kim, Sci. Rep., 2015, 5, 9387. 22 S. Huang, Y. Han, S. Lyu, W. Lin, P. Chen and S. Fang, Nanotechnology, 2017, 28, 435204. 23 Z. Niu, L. Zhang, L. Liu, B. Zhu, H. Dong and X. Chen, Adv. Mater., 2013, 25, 4035–4042. 24 D. Yu, K. Goh, H. Wang, L. Wei, W. Jiang, Q. Zhang, L. Dai and Y. Chen, Nat. Nanotechnol., 2014, 9, 555–562. 25 J. Tao, N. Liu, W. Ma, L. Ding, L. Li, J. Su and Y. Gao, Sci. Rep., 2013, 3, 2286. 26 J. A. Lee, M. K. Shin, S. H. Kim, H. U. Cho, G. M. Spinks, G. G. Wallace, M. D. Lima, X. Lepro, M. E. Kozlov, R. H. Baughman and S. J. Kim, Nat. Commun., 2013, 4, 1970. 27 Y. Meng, Y. Zhao, C. Hu, H. Cheng, Y. Hu, Z. Zhang, G. Shi and L. Qu, Adv. Mater., 2013, 25, 2326–2331. 28 Q. Chen, Y. Meng, C. Hu, Y. Zhao, H. Shao, N. Chen and L. Qu, J. Power Sources, 2014, 247, 32–39. 29 S. Stankovich, D. A. Dikin, R. D. Piner, K. A. Kohlhaas, A. Kleinhammes, Y. Jia, Y. Wu, S. T. Nguyen and R. S. Ruoff, Carbon, 2007, 45, 1558–1565. 30 D. Harrison, F. Qiu, J. Fyson, Y. Xu, P. Evans and D. Southee, Phys. Chem. Chem. Phys., 2013, 15, 12215–12219. 31 C. Shen, Y. Xie, M. Sanghadasa, Y. Tang, L. Lu and L. Lin, ACS Appl. Mater. Interfaces, 2017, 9, 39391–39398. 32 X. Zhao, B. Zheng, T. Huang and C. Gao, Nanoscale, 2015, 7, 9399–9404. 33 Y. Hu, H. Cheng, F. Zhao, N. Chen, L. Jiang, Z. Feng and L. Qu, Nanoscale, 2014, 6, 6448–6451. 34 T. X. Tran, H. Choi, C. H. Che, J. H. Sul, I. G. Kim, S. M. Lee, J. H. Kim and J. B. In, ACS Appl. Mater. Interfaces, 2018, 10, 39777–39784. 35 J. Yeo, S. Hong, D. Lee, N. Hotz, M. T. Lee, C. P. Grigoropoulos and S. H. Ko, PLoS One, 2012, 7(8), e42315. 36 Y. D. Suh, J. Jung, H. Lee, J. Yeo, S. Hong, P. Lee, D. Lee and S. H. Ko, J. Mater. Chem. C, 2017, 5, 791–798. 37 D. F. Fernandes, C. Majidi and M. Tavakoli, J. Mater. Chem. C, 2019, 7, 14035–14068. 38 H. Min, B. Lee, S. Jeong and M. Lee, Optics and Lasers in Engineering, 2016, 80, 12–16. 39 I. Theodorakos, F. Zacharatos, R. Geremia, D. Karnakis and I. Zergioti, Appl. Surf. Sci., 2015, 336, 157–162. 40 M. Giovanni and M. Pumera, Electroanal, 2012, 24, 615–617. 41 K. Sabira, P. Saheeda, M. C. Divyasree and S. Jayalekshmi, Opt. Laser Technol., 2017, 97, 77–83. 4850 | J. Mater. Chem. A, 2021, 9, 4841–4850 Paper 42 H. Choi, P. T. Nguyen and J. B. In, Appl. Surf. Sci., 2019, 483, 481–488. 43 V. Augustyn, P. Simon and B. Dunn, Energy Environ. Sci., 2014, 7(5), 1597–1614. 44 L. Xu, M. Jia, Y. Li, X. Jin and F. Zhang, Sci. Rep., 2017, 7, 12857. 45 T. Gu and B. Wei, J. Mater. Chem. A, 2016, 4, 12289–12295. 46 Y. Ko, M. Kwon, W. K. Bae, B. Lee, S. W. Lee and J. Cho, Nat. Commun., 2017, 8, 536. 47 J. Ren, W. Bai, G. Guan, Y. Zhang and H. Peng, Adv. Mater., 2013, 25, 5965–5970. 48 N. He, J. Liao, F. Zhao and W. Gao, ACS Appl. Mater. Interfaces, 2020, 12, 15211–15219. 49 Q. Meng, K. Wang, W. Guo, J. Fang, Z. Wei and X. She, Small, 2014, 10, 3187–3193. 50 Y. Meng, L. Jin, B. Cai and Z. Wang, RSC Adv., 2017, 7, 38187– 38192. 51 M. Kanik, O. Aktas, H. S. Sen, E. Durgun and M. Bayindir, ACS Nano, 2014, 8, 9311–9323. 52 Z. Lu, R. Raad, F. Safaei, J. Xi, Z. Liu and J. Foroughi, Front. Mater., 2019, 6, 138. 53 J. B. In, B. Hsia, J. H. Yoo, S. Hyun, C. Carraro, R. Maboudian and C. P. Grigoropoulos, Carbon, 2015, 83, 144–151. 54 N. A. Kyeremateng, T. Brousse and D. Pech, Nat. Nanotechnol., 2017, 12, 7–15. 55 K. Y. Kim, H. Choi, T. C. Van and J. B. In, J. Power Sources, 2019, 441, 227199. 56 J. Bae, M. K. Song, Y. J. Park, J. M. Kim, M. Liu and Z. L. Wang, Angew. Chem., Int. Ed. Engl., 2011, 50, 1683–1687. 57 P. Xu, T. Gu, Z. Cao, B. Wei, J. Yu, F. Li, J.-H. Byun, W. Lu, Q. Li and T.-W. Chou, Adv. Energy Mater., 2014, 4(3), 1300759. 58 L. Li, Z. Lou, D. Chen, W. Han and G. Z. Shen, Adv. Mater. Technol., 2018, 3, 1800115. 59 H. F. Brinson and L. C. Brinson, Characteristics, Applications and Properties of Polymers, Polymer Engineering Science and Viscoelasticity: An Introduction, Springer US, Boston, MA, 2008, pp. 55–97. 60 B. Pal, S. Yang, S. Ramesh, V. Thangadurai and R. Jose, Nanoscale Adv., 2019, 1, 3807–3835. 61 S. Egusa, Z. Wang, N. Chocat, Z. M. Ruff, A. M. Stolyarov, D. Shemuly, F. Sorin, P. T. Rakich, J. D. Joannopoulos and Y. Fink, Nat. Mater., 2010, 9, 643–648. 62 N. Aguilo-Aguayo, D. Hubmann, F. U. Khan, S. Arzbacher and T. Bechtold, Sci. Rep., 2020, 10, 5565. 63 N. Böckenfeld, S. S. Jeong, M. Winter, S. Passerini and A. Balducci, J. Power Sources, 2013, 221, 14–20. 64 D. Yu, Q. Qian, L. Wei, W. Jiang, K. Goh, J. Wei, J. Zhang and Y. Chen, Chem. Soc. Rev., 2015, 44, 647–662. This journal is © The Royal Society of Chemistry 2021