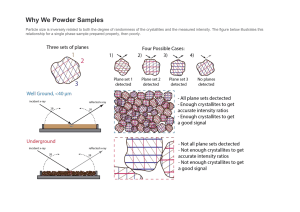

BORED TUNNELS DESIGN AND CONSTRUCTION Slides and notes courtesy of Dr WEN Dazhi Some slides originate from Mr Nick Shirlaw 1 BORED TUNNELS DESIGN AND CONSTRUCTION • Tunnel Face Pressure Control • Planning Face Pressure – Clay • Planning Face Pressure – Sand • Maximum Face Pressure • Method Statements for Tunnelling Works 2 TUNNEL FACE PRESSURE CONTROL • A critical parameter in driving EPB or slurry TBMs through soft ground • Inadequate face pressure or inability to control face pressure will cause excessive ground movement or collapse of tunnel face 3 TUNNEL FACE PRESSURE CONTROL Exceptional Settlement / Sinkholes High Risk Areas – Results of inadequate or inability to control face pressure • • • • • • Launching the shield - particularly into cohesionless soils below the water table Breaking out into shafts or excavations Interfaces between strong, stable soils and weak soils (Kallang Formation marine clay) Mixed faces of rock and soil (including soil grades of weathered rock) Head access for maintenance Long drives in abrasive ground 4 TUNNEL FACE PRESSURE CONTROL EPBM Ideally spoils in the excavation chamber should have the following properties: Good plastic ductility and pasty to soft consistency: to ensure that the support pressure acts on the face as uniformly as possible and the flow into the screw conveyor is continuous Low internal friction to ensure the drive torque of the cutting wheel and the screw conveyor remains within economic limits Low permeability to maintain face pressure to prevent over excavation (<10-5 m/s according to Thewes, 2014) 5 TUNNEL FACE PRESSURE CONTROL EPBM No plug, material saturated and flowing “Plastic” nature allowing plug and control 6 TUNNEL FACE PRESSURE CONTROL Foams / soil conditioning agents are often used to condition the spoil Soil conditioning needs of EPBM in different ground types (EFNARC, 2005) 7 TUNNEL FACE PRESSURE CONTROL Foam product type for EPBM relative to different soils (FIR values indicative), EFNARC (2005) Form Injection Ratio (FIR) Sandy clay - silt Sandy clayey silt Clayey gravels FIR = 100 x Vfoam / Vsoil (%) Vfoam : Volume of foam at working pressure Vsoil : Volume of in-situ soil to be excavated Sandy gravels Foam Type A: high dispersing capacity (breaking clay bonds) and / or good coating capacity to reduce swelling effects Foam Type B: general purpose, with medium stability Foam Type C: high stability and anti-segregation properties to develop and maintain a cohesive soil as impermeable as possible 8 TUNNEL FACE PRESSURE CONTROL Slurry Shields • For slurry TBMs, tunnel face pressure is maintained by controlling the volume difference of the bentonite suspension supplied to the chamber and the suspension combined with excavated material removed from it or by the provision of a compressed air reservoir or bubble. • The primary function of the slurry is to stabilise the face. It is also required to suspend and transport the cuttings, to lubricate and cool the cutter head and to reduce abrasive wear of the cutting tools. • Formation of filter cake (membrane) is critical in maintaining the face pressure. 9 TUNNEL FACE PRESSURE CONTROL Slurry Shields – Membrane Model Membrane Model slurry soil Filter cake formed If the permeability of the ground is relatively low (fine or medium sands) and the bentonite content is sufficient the suspension will enter the ground under the differential pressure and seal the tunnel face with the solid matter particles contained in it, thus creating a thin but impermeable film (filter cake) through which the support pressure can be applied. This process takes place in a short time of 1 to 2 seconds. Maidl, et al (2012) 10 TUNNEL FACE PRESSURE CONTROL Slurry Shields – Penetration Model Penetration Model In coarse-grained more permeable ground, a filter cake cannot always be formed, even with a high bentonite content. The bentonite suspension penetrates into the face and, due to its thixotropic properties, transfers shear forces into the grain skeleton. slurry P soil Pure penetration Maidl, et al (2012) 11 TUNNEL FACE PRESSURE CONTROL Slurry Shields – Penetration Model The penetration distance smax can be calculated from smax = p d10 2f where p is the pressure difference between supporting fluid and the ground water; d10 is diameter corresponding to 10% passing or finer in sieve analysis and f is the yield strength of the slurry The extent of slurry penetration does not depend on the complete particle size distribution; but rather is governed by the finer particle fraction. 12 TUNNEL FACE PRESSURE CONTROL Slurry Shields – Penetration Model • The greater the penetration the lower the factor of safety • Below a d10 of about 0.6mm treat as membrane • Above a d10 of about 0.6mm, slurry penetrates into ground and factor of safety reduces Anagnostou & Kovari, 1996 13 TUNNEL FACE PRESSURE CONTROL Slurry Shields – Slurry Treatment Plant • Slurry shields require slurry treatment plants to separate excavated materials, prepare and control the quality of slurry before feeding into the TBM. • Space will be required for the plants – something not required for EPB tunneling. • Shaker or vibrating screens - to separate coarse particles (grain size > 3 • • to 6mm). Desander & desilter – one or more stages of cyclones to separate sands and silts (Single stage – medium sand, 70 to 150 m; 2-stage plants – coarse silt, 35 m). Centrifuge or press filters – to separate clay / silt particles. 14 PLANNING OF FACE PRESSURE - CLAY • For tunnelling in clays, face pressure is related to Stability Number • There is a relationship between face pressure and ground settlement 15 PLANNING OF FACE PRESSURE - CLAY Stability Number, N Overburden Pressure – Tunnel Support Pressure N= Undrained Shear Strength Surcharge q (zO + q – t) N= cu zo C D t P 16 PLANNING OF FACE PRESSURE - CLAY Stability Number at Collapse, Nc o = zo = (6 to 8)cu cu N = o / cu < 6 Failure surface 17 PLANNING OF FACE PRESSURE - CLAY Stability Number at Collapse, Nc For deep tunnels (C/D > 3), Nc = 9 when P/D = 0 9.0 8.6 Heading Geometry and Depth vs. Stability Number at Collapse, Nc 2.5 18 PLANNING OF FACE PRESSURE - CLAY Load Factor Load Factor = Stability Number (Working Condition) Stability Number at Collapse LF = N/NC LF is the inverse of the factor of safety 19 PLANNING OF FACE PRESSURE - CLAY Load Factor vs. Volume Loss Load Factor = 0.49 1 = N (Working Condition) F 0.42 N (At Collapse) Load Factor = 0.67 (F = 1.5) at Volume Loss = 4% 1.5 CIRIA Report 30, March 1996 20 PLANNING OF FACE PRESSURE - CLAY Load Factor vs Volume Loss Vl = 0.23e 4.4(LF) For LF>0.2 Vl in percentage LF = 0.49, Vl = 0.23 * e (4.4*0.49) = 1.98 (approx. 2%) Dimmock & Mair (2007) 21 PLANNING OF FACE PRESSURE - CLAY Example • Tunnel D = 6m @ 20m below ground, C = • • 17m, driven by EPBM, P = 0 cu = 50 kPa, q = 10 kPa, = 18 kN/m3 P/D = 0, C/D = 2.83, Nc = 9 from Chart 22 PLANNING OF FACE PRESSURE - CLAY Example cu 50 kPa density 18 kN/m^3 surcharge 10 kPa depth 20 m Nc overburden Face Pressure (% of overburden) 9 370 kN/m^2 10% 20% 30% 40% 50% 60% 70% 80% 90% 100% 37 74 111 148 185 222 259 296 333 370 N 6.66 5.92 5.18 4.44 3.70 2.96 2.22 1.48 0.74 0.00 1/F 0.74 0.66 0.58 0.49 0.41 0.33 0.25 0.16 0.08 0.00 Volume Loss (%) 6.0 4.0 3.0 2.0 1.3 1.0 0.5 0.2 0.1 0 Face Pressure Volume loss due to stress change 23 PLANNING OF FACE PRESSURE - CLAY • Need to carry out an Ultimate Limit State (ULS) calculation. ULS is instability leading to major loss of ground or collapse at the tunnel face. ULS calculation requires a partial factor of safety applied to cu: divide cu by 1.5; then calculate face pressure for LF of 1. • Tunnelling in urban environment requires stringent settlement control. It is necessary to carry out a Serviceability Limit State (SLS) calculation. First, assess Load Factor to achieve the allowable settlement, then calculate face pressure to achieve that LF, using partial factor of safety of 1. • To control Volume Loss to less than 2%, load factor should not be greater than of 0.4 (corresponding F = 2.5). • In settlement sensitive areas, need to apply face pressure close to full overburden pressure (LF = 0 to 0.25) 24 PLANNING OF FACE PRESSURE - CLAY The calculated pressure is the average pressure at the tunnel face, which can be taken as the pressure at the axis level. The target pressure at sensor 1 is: P1 = t – (zo – zs1)* + v Pressure Target Pressure v v where v is the max variation of face pressure due to control accuracy (+/20 kPa or 0.2 bar) and is the unit weight of the spoil in the chamber v v Time 25 PLANNING OF FACE PRESSURE - CLAY Example of poor control of face pressure for a EPB shield 26 PLANNING OF FACE PRESSURE – CLAY Heading Geometry Over cut (typically 10mm) t L P = 0 or P = Length of shield, L zo C D t P 27 PLANNING OF FACE PRESSURE – CLAY Heading Geometry • Cut diameter is bigger than the shield skin • Until the overcut gap closes, the area around the shield is unsupported • Once the over-cut closes, the ground is supported on the shield skin • For EPB shields the face pressure is not transmitted around the skin – but bentonite can be injected around skin using special ports • For slurry shields the slurry pressure is transmitted around the skin 28 PLANNING OF FACE PRESSURE – CLAY Heading Geometry Ports for bentonite injection (16 No total) After Shirlaw, J. N. 29 PLANNING OF FACE PRESSURE – CLAY Loss at Tail Void • With good grouting typically about 15% to 20% of theoretical volume of the tail void will close in soft or loose soils • Figure may reduce with improved technology and construction control After Shirlaw, J. N. 30 PLANNING OF FACE PRESSURE - SAND • Assumed failure surface for tunnels in sand, based on limit equilibrium methods developed by Anagnostu and Kovari (1996) Anagnostou and Kovari (1996) 31 PLANNING OF FACE PRESSURE - SAND For fully saturated, homogeneous and isotropic sands under drained condition, the effective pressure required to maintain equilibrium of the tunnel face is: ’ = F0’D – F1c’ +F2’Dh – F3c’ Dh/D ’ = Effective pressure required to maintain equilibrium of tunnel face; ’ = Submerged unit weight of soil; D = Diameter of tunnel; c’ = Drained cohesion of soil; Dh = Water head difference between the ground water table level, h0 and the piezometric head in the excavation chamber, hf ; F0, F1, F2 & F3 – Dimensionless coefficients that depend on the drained friction angle, ’ and geometrical parameter, H/D and (h0-D)/D; and H = Overburden to crown of tunnel. 32 PLANNING OF FACE PRESSURE - SAND If the piezometric head in the excavation chamber is maintained to balance the water pressure due to the ground water, i.e. Dh = 0 (membrane model), then the minimum face pressure, at the tunnel crown that is required to prevent a face collapse (maintaining equilibrium) can be calculated : = F0’D – F1c’ + P where P is the water pressure at the crown of tunnel based on the original ground water level. 33 PLANNING OF FACE PRESSURE - SAND 0.3 27.5 Anagnostou, G. and Kovari, K. (1996). Chart based assumption of d / ’ = 1.6. Since d / ’ = Gs/(Gs – 1), the assumption is that Gs = 2.67, which is reasonable within practical limits. 34 PLANNING OF FACE PRESSURE - SAND 2.54 27.5 Anagnostou, G. and Kovari, K. (1996). 35 PLANNING OF FACE PRESSURE – SAND Water Pressure • For EPBM: Unless the sand has significant cementation, additives have to be used to reduce the permeability of the sand, such that the piezometric head at crown is close to that based on the original ground water level. • For slurry TBM: The process of TBM tunnelling increases the groundwater pressure in the face, and the initial water pressure has to be increased to compensate for this 36 PLANNING OF FACE PRESSURE – SAND Water Pressure • Documented results from slurry shield tunnelling show an increase of up to 50kPa (5m head) of pressure just ahead of the face • Effects on stability are both adverse (increased water pressure) and beneficial (outward seepage from face) • Net effect shown to be equivalent to an increase of water pressure of 20 to 30 kPa in sand. This effect should be added to the initial piezometric pressure in deriving P in = F0’D – F1c’ + P After Shirlaw, J. N. 37 PLANNING OF FACE PRESSURE – SAND • Need to carry out an Ultimate Limit State (ULS) calculation • Partial factors: divide by tan ’ by 1.2, c’ by 1.2 (but c’ often taken as 0). Factoring tan ’ affects FO and F1 • Water pressure: use the most onerous (highest) likely pressure. Need to allow for the tunnelling effect on the water pressure. Need to consider the change of water pressure when tunnelling through changes in ground level. • If settlement is an issue, need to carry out a Serviceability Limit State (SLS) calculation. Use partial factors of 1 for SLS calculation 38 PLANNING OF FACE PRESSURE – SAND • Limit equilibrium methods give pressure required to avoid failure, not to control settlement. Need higher pressure to control settlement. • Limited theoretical basis: To target 1% Volume Loss = F’D + P where: F = 0.25 for Dense Sand (SPT >30) F = 0.4 for Medium Sand (SPT 10-30) F = 0.55 for Loose Sand (SPT <10) HK GEO Report No. 249 – Ground Control for Slurry TBM Tunnelling . Dec 2009. 39 PLANNING OF FACE PRESSURE – SAND Pressure at Control Sensor • The pressure at the control sensor required to achieve the target pressure at the crown (S1) = + SL(ZS1-C) + v Where SL is the unit weight of the slurry and C is the cover to tunnel crown (expressed as H in Anagnostou and Kovari Chart) 40 PLANNING OF FACE PRESSURE - SAND Tunnel excavated diameter: 6 m Depth of tunnel to tunnel crown: 15 m Water table: 2 m below ground level c’ = 5 kPa (factored c’ = 4.27) ’ = 32o (factored ’ = 27.5o ) (unit weight of soil) = 20 kN/m3 F0 = 0.3, F1 = 2.5 = 0.3 x 10 x 6 – 2.5 x 4.17 + (130+20) = 158 kPa (ULS at tunnel crown) 2m 15m D = 6m = F’D + P (where F = 0.4 for medium sands) = 0.4 x 10 x 6 + (130+20) = 174 kPa (SLS at tunnel crown for approx. 1% volume loss) Target pressure at crown, considering a variation of 20 kPa: 194 kPa, or 2 bars. 41 MAXIMUM FACE PRESSURE • To avoid excessive ground heave, need to define maximum face pressure • Two cases: If undisturbed ground, pressure required to heave the ground = Total overburden pressure + a factor based on shear strength of ground. If there is an old borehole or other open zone, slurry can escape to surface (Slurry Shields). 42 MAXIMUM FACE PRESSURE Slurry blowing out through an old borehole. Grouting of boreholes using cement grout important. 43 MAXIMUM FACE PRESSURE • Practically if the pressure is kept at or below the total vertical overburden pressure, there should be no risk of excessive heave or loss of slurry to the surface in intact ground. • In special cases, such as relatively shallow tunnels it may be found that the maximum design face pressure exceeds the overburden pressure. In this case a more detailed calculation can be carried out, allowing the resistance provided by the shear strength of the ground. 44 MAXIMUM FACE PRESSURE • If there is an old borehole or other open zone, slurry can escape to surface under a pressure of slZS1 , where sl is the unit weight of the slurry (typically 1.1 t/m3 for slurry shields and ZS1 is the depth of the reference sensor). • Identify as far as practicable any likely open paths and grout them in advance of tunneling. • Maintain continuous surface watch during slurry TBM tunnelling and implement control measures if a loss of slurry is observed. 45 FACE PRESSURE Kallang Formation • In Kallang Formation (marine clay), maintain between 0.9 and 1.2 x total overburden for <2% Volume Loss. • Need to apply this pressure when cover to Kallang formation is less than about 3m careful consideration needed in build-up of pressure entering Kallang filled valleys, also in reducing pressure when leaving such valleys. 46 FACE PRESSURE Stiff / Hard Soils • The Fort Canning Boulder Bed and the residual soil of Bukit Timah Granite Formation and Jurong Formation can generally be tunnelled without a face pressure, but some face pressure will be necessary to minimise settlements, particularly in the lower strength (low SPT) residual soils. 47 FACE PRESSURE Variable Strata • Bukit Timah Granite Formation, Jurong Formation and Old Alluvium contain zones, beds or lenses of material which act like a sand. • In these areas a face pressure of about one half of overburden pressure is required for stability. • The strata are variable and it can be difficult to identify these conditions in advance, so it is necessary to tunnel on the assumption the conditions are the most adverse. 48 FACE PRESSURE Variable Strata • Face pressure needed to control the ground is almost identical to that which would allow slurry to escape up a disturbed zone / opening to the ground surface • All known open piezometers and boreholes must be sealed by grouting • A close watch on slurry escape and a contingency plan to contain escape now common in urban tunnelling 49 EXCAVATION MANAGEMENT CONTROL • • • • Establish net dry weight of soil removed and compare with theoretical dry weight Accuracy typically +/- 5 to 10% Not accurate enough to control SLS case, but gives warning of possible ULS (very large settlement or sinkhole) Face pressure is the primary control, EMC is a valuable back-up control Flow meter Slurry TBM – flow and density, in and out Belt weigher for EPB – use two, for crosschecking 50 LASER BELT SCANNER – FOR EPBM 51 METHOD STATEMENTS • Method statements have to give assurance that tunnelling will be carried out in a way that minimises the risk to the structures / the public. • The method statements must cover the major areas of risk, and provide realistic contingency measures. 52 METHOD STATEMENTS Areas to be Covered • Ground interpretation, particularly identification of interfaces, ground behaviour • Machine configuration • Lining method • Face stability (pressure and volume control) • Additives • Grouting - mixes, pressure and volume control • Break-in (launch) 53 METHOD STATEMENTS Areas to be Covered • • • • • • • • Break-out (docking) Head access Maintenance Personnel Site organisation and levels of authority Monitoring - layout and review levels Risk Assessment Contingency planning 54 METHOD STATEMENTS Ground Interpretation • Enough information is required to make a sensible interpretation. It is easy to miss a valley of soft ground or an area of rock if the boreholes are widely spaced. • Rock/soil interfaces do not work in simple straight lines • Permeability is the key to soil behaviour during tunnelling. There is no correlation between SPT and permeability • Depending on the face pressure to be used, may need to be supplemented by probing 55 METHOD STATEMENTS Machine Configuration • A section through the actual machine to be used • Show the key features - head configuration (cutting tool type and locations, openings), pressure monitoring locations, conditioning ports, screw conveyor or slurry transport arrangement, manlocks, probing arrangements and possible locations, tail seals, grouting ports. 56 METHOD STATEMENTS Lining Type • The type of lining to be used i.e. segmental, sprayed concrete, pipe. • A GA for the lining showing jointing systems and grout ports. 57 METHOD STATEMENTS Face Stability • A detailed plan for the face pressures to be used, justified by calculation and previous experience. The plan must be for the whole drive, and prepared prior to starting tunnelling • A procedure for changing the target face pressure from that planned. • Method(s) for measuring the volume of material removed • Procedure for identifying over-excavation during advance, after taking into account the volume of conditioner used 58 METHOD STATEMENTS Conditioning Agent • Types of conditioning agents to be used • Typical mixes for conditioning agents proposed 59 METHOD STATEMENTS Grouting of Lining • How the lining is to be grouted, and when in the tunnelling process • Grout mixes to be used • Pressure AND volume controls (Min. Volume, Min. Pressure, Max. Pressure) 60 METHOD STATEMENTS TBM Break-in / Launching • Requirements for ground treatment and/or probing in the launching area • Sequence of ground treatment/probing/tunnel eye removal • Details of seal to be used at eye • Procedure for Break-in, particularly when the annulus around the lining can be grouted 61 METHOD STATEMENTS TBM Break-out / Docking • Requirements for ground treatment and/or probing in the break-out area • Sequence of ground treatment/probing/tunnel eye removal • Details of seal to be used at eye • Procedure for Break-out, particularly when the annulus around the lining can be grouted 62 METHOD STATEMENTS Head Access • If compressed air is to be used for head access, the planned air pressure if an intervention is required, for the whole drive • If compressed air is not proposed, how the stability of the ground will be verified prior to head access • Procedure for head access 63 METHOD STATEMENTS Maintenance • Statement as to how often the cutting tools, main bulkhead, screw conveyor/slurry pipes and tail seals will be checked for wear. 64 METHOD STATEMENTS Personnel / Organisation Chart • Organisation chart - Identify key personnel (Project Manager, QP, engineers, machine operators) • Give CVs for each of the key personnel • If the QP is providing representative(s) to supervise the work, name(s) and CV(s) of the representative(s) • Identify what levels of authority each key person has to vary the operating parameters and implement contingency measures. 65 METHOD STATEMENTS Monitoring • Provide location map for monitoring instruments. Tip levels for piezometers, inclinometers, extensometers • Reading frequency • Review levels, and actions on exceedance 66 METHOD STATEMENTS Risk Assessment • A statement that the use of an EPB or slurry shield, with experienced operator and pressure controls results in ‘negligible’ risk of damage will NOT be accepted • The risk assessment needs to consider, separately, all of the ‘high risk’ areas identified previously, as well as general tunnelling in each of the ground conditions present 67 METHOD STATEMENTS Contingency Measures • Accept that there is a need for contingency planning in case a sudden loss of ground is detected • Need contingency plans that ensure the safety of the public and minimise disruption to road users 68 BORED TUNNELS DESIGN AND CONSTRUCTION Summary • • • • • • Tunnel Face Pressure Control TBM Selection Planning Face Pressure – Clay Planning Face Pressure – Sand Maximum Face Pressure Method Statements for Tunnelling Works 69