Anchorage to Concrete: State-of-the-Art Report | ACI 355.1R-91

advertisement

ACI 355.1R-91

(Reapproved 1997)

STATE-OF-THE-ART REPORT ON

ANCHORAGE TO CONCRETE

Reported by ACI Committee 355

Harry A. Chambers

Secretary

Patrick J. Creegan

Chairman

Edwin A. Burdette

Robert W. Cannon

Peter J. Carrato

Peter D. Courtois

Rolf Eligehausen

Raymond R. Funk

C. Raymond Hays

Paul R. Hollenbach

Gerard B. Hassehvander

Harry B. Lancelot III*

Douglas D. Lee

Alexander Makitka, Jr.

Donald F. Meinheit

Richard S. Orr

Moorman L Scott

George A. Senkiw

Harry Wiewel

Jim L Williams

Richard E. Wollmershauser

*Committee Chairman during the formative years of this report.

For the first time concrete anchoring knowledge based on worldwide test programs is presented in a state-of-the-art document. Performance

of different anchor types, including cast-in-place, grouted, expansion, torque-controlled, chemical (adhesive), and undercut anchors is presented

in both uncracked and cracked concrete. Failure modes in tension and shear, spacing and edge distance, group performance, and load

displacements are offered. The effect of loading conditions for structural supports, column bases, and pipe supports as well as base plate

flexibility, how load is transferred to anchors, and ductility are discussed. Design criteria and existing code requirements, both domestic and

foreign, are presented.

KEYWORDS: Adhesive anchors; anchorages; anchors; anchor groups; base plates; bolts; cast-in-place anchors; chemical anchors; code

requirements; combined loads; compression zone; concrete; cracked concrete; creep; deformation; design criteria; drilling; ductility;

dynamic loads; edge distance; embedment; expansion anchors; failure modes; fatigue loads; fasteners; flexible base plates; grouting; loads;

load transfer; load-displacement; post-installed anchors; preload; pullout; seismic loads; shear loads; slip; spacing; spalling; static loads;

stiffness; studs; structural design; tensile strength; tension loads; tension zone; temperature; torque; torque-controlled anchors; ultimate

strength; undercut anchor, yield strength.

FORWARD

This state-of-the-art report on anchorage to concrete is the first of a two-volume project being undertaken

by ACI Committee 355. The second volume, currently being developed, is a design manual. This first

volume includes no design aids or procedures, per se, but with emphasis on behavior will serve as the guide

for preparation of the second volume.

Committee 355 is working with Committees 349 and 318 toward the objective of including the subject of

anchorage to concrete in ACI 318-95.

ACI Committee Reports, Guides, Standard Practices, and

Commentaries are intended for guidance in designing,

planning, executing, or inspecting construction, and in

preparing specifications. Reference to these documents shall

not be made in the Project Documents. If items found in

these documents are desired to be a part of the Project

Documents, they should be phrased in mandatory language

and incorporated into the Project Documents.

ACI 355.1R-91 became effective JuIy 1, 1991.

Copyright 0 1991, American Concrete Institute.

All rights reserved including rights of reproduction and use in any

form or by any means, including the making of copies by any photo

process, or by any electronic or mechanical device, printed or written or

oral, or recording for sound or visual reproduction or for use in any

knowledge or retrieval system or device, unless permission in writing is

obtained from the copyright proprietors.

--`,``,````,,,`,``,``,,,,,```,`-`-`,,`,,`,`,,`---

Copyright American Concrete Institute

Provided by IHS under license with ACI

No reproduction or networking permitted without license from IHS

355.1 R-l

Licensee=Jacobs Engineering ( new WAN ) /3219500102, User=Schoolmeyer, Scott

Not for Resale, 02/05/2007 07:29:17 MSTs/org1

355.1R-2

MANUAL OF CONCRETE PRACTICE

TABLE OF CONTENTS

Chapter 1-Introduction, p 355.1R-2

1.1 Purpose

1.2 Significance of the subject

1.3 Scope

--`,``,````,,,`,``,``,,,,,```,`-`-`,,`,,`,`,,`---

Chapter 2-Types of anchoring devices,

p 355.1R-2

2.1

2.2

2.3

2.4

2.5

Introduction

Scope

Anchor systems

Cast-in-place systems

Post-installed systems

Chapter 3-Behavior of anchors, p 355.1R-9

3.1

3.2

3.3

3.4

Introduction

Behavior of anchors in uncracked concrete

Behavior of anchors in cracked concrete

Behavior of cast-in-place anchor bolts in

uncracked concrete piers

3.5 References

Chapter 4-Design considerations,

p 355.1R-53

4.1 Introduction

4.2 Functional requirements

4.3 Materials

4.4 Design basis

4.5 Construction practices

4.6 References

Chapter 5-Construction considerations,

p 355.1R-60

5.1 Introduction

5.2 Shop drawings/submittals

5.3 Tolerances

5.4 Installation of anchors

5.5 Inspection

5.6 Grouting

5.7 Field problems

Chapter 6-Requirements in existing codes

and specifications, p 355.1R-66

6.1 Introduction

6.2 Existing codes and specifications

6.3 Application and development of codes

6.4 References

Appendix A-Conversion factors, p 355.1R-71

Appendix B-Notations, p 355.1R-71

Copyright American Concrete Institute

Provided by IHS under license with ACI

No reproduction or networking permitted without license from IHS

CHAPTER 1 -INTRODUCTION

1.1-Purpose

The purpose of this document is to summarize

the current state of the art in anchorage to

concrete.

1.2-Significance of the subject

To date, anchorage to concrete has received

little attention in structural codes. Emphasis has

been primarily on the tensile and shear capacities

of anchorage devices. As designs became more

sophisticated and analyses more exacting, more

emphasis was placed on the transfer of loads

through single anchors and anchor systems. It was

recognized that performance of anchors controlled

these load transfers, and that generally, failure

modes at ultimate anchor capacities were

important. There were no definitive design codes

or anchorage performance criteria on which

designers and installers could rely. Subsequently,

a myriad of approaches were developed.

1.3-Scope

This state-of-the-art report summarizes anchor

types and provides an overview of anchor performance and failure modes under various loading

conditions in both uncracked and cracked concrete.

It covers design and construction

considerations and summarizes existing requirements in codes and specifications. References are

given for further review.

CHAPTER 2 -TYPES OF ANCHORING

DEVICES

2.1-Introduction

There are many types of devices used for

anchoring structures or structural members to

concrete. The design of anchorages, involving the

selection and positioning of these devices has been

based on the Engineer’s experience and judgment,

private test data, manufacturers’ data, and existing

(sometimes obsolete) code requirements. It is

proposed to promote a design of anchorages that

more consistently reflects the performance

potential of each type of anchor.

2.2-Scope

This report relates to the most widely used

types of anchor, in sizes ranging from 1/4 in. (6.35

mm) to 2 l/2 in. (63.5 mm) in diameter. Included

for consideration are only those devices which can

generally be considered bolt and insert-type

Licensee=Jacobs Engineering ( new WAN ) /3219500102, User=Schoolmeyer, Scott

Not for Resale, 02/05/2007 07:29:17 MSTs/org1

ANCHORAGE TO CONCRETE

anchors. Excluded from consideration are shear

lugs, structural shapes, powder actuated fasteners,

light plastic or lead inserts, hammer driven

concrete nails, screw driven systems, and cables.

These are excluded because there is a paucity of

test data regarding their performance. The

anchors included in this report are either

commercially available or may be fabricated.

2.3-Anchor Systems

According to present practice, there are two

broad groups of anchoring systems: cast-in-place

systems (anchors installed before the concrete is

cast) and post-installed systems (anchors installed

in holes drilled after the concrete has been cast

and cured). Table 2.1 identifies these two groups

of anchors.

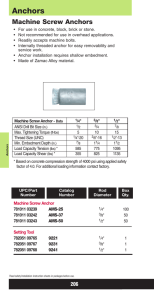

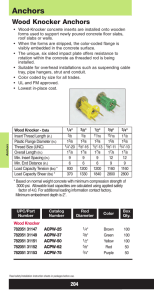

Table 2.1 -Types of anchors in concrete

Cast-in-place systems

Embedded, nonadjustable

Common bolts

Hooked "J" & "L" bolts

Threaded rod

Reinforcing steel

Threaded inserts

Stud-welded plates

Bolted connections

Adjustable anchors

Fig. 2.1

Fig. 2.2

Fig. 2.3

Fig. 2.4

Fig. 2.5

Fig. 2.6

Fig. 2.7

Fig. 2.8

Post-installed systems

Bonded anchors

Grouted anchors

Headed bolts or anchor

Fig. 2.9

Chemical anchors

With threaded rod

With reinforcing steel

Fig. 2.10

Fig. 2.11

Expansion anchors

Torque-controlled

Heavy-duty sleeve anchor

Sleeve anchor

Shell expansion anchor

Wedge anchor

Rock/concrete expansion

anchor

Fig. 2.12

Fig. 2.13

Fig. 2.14

Fig. 2.15

Deformation controlled

Drop-in anchor

Self-drilling anchor

Stud anchor

Fig. 2.17

Fig. 2.18

Fig. 2.19

Undercut

With predrilled under-cut

hole

Self undercutting

2.4-Cast-in-place systems

2 . 4 . 1 - Embedded Anchors, Non Adjustable - These anchors may have an end

attachment, such as a coil loop, head, nut, or

plate, which will enhance anchorage properties

and develop full potential strength by means of

bond, and/or bearing, or both. Typical examples

of these anchors are:

Common bolts

- structural steel bolts

placed with the head into

the concrete. (Fig. 2.1)

Hooked

"J" or "L" bolts

-bent, smooth or deformed

threaded bars. Have been

known to straighten out in

pull-out tests. (Fig. 2.2)

Threaded rod

- straight threaded rod,

usually with coarse

threads. (Fig. 2.3)

Reinforcing steel - Stock or trade-name reinforcing bar (Fig. 2.4)

wire form or internally

Threaded inserts

threaded ferrule inserts,

or coils, usually manufactured with internal or

external threads, with wire

loop struts. Headed

anchors made from

smooth or reinforcing

steel bar also fall into this

category. (Fig. 2.5)

Stud welded plates - steel plates which have

smooth bent hooked bars,

deformed bars, or headed

stud anchors. (Fig. 2.6)

2.4.2 Bolted connections-These anchors consist

of headed bolts, as embedded or throughconnectors. (Fig. 2.7).

Plastic

Fig. 2.16

L Steel

plate

Fig. 2.20

Fig. 2.20

--`,``,````,,,`,``,``,,,,,```,`-`-`,,`,,`,`,,`---

Copyright American Concrete Institute

Provided by IHS under license with ACI

No reproduction or networking permitted without license from IHS

355.1R-3

Fig. 2.7-Bolted connections

Licensee=Jacobs Engineering ( new WAN ) /3219500102, User=Schoolmeyer, Scott

Not for Resale, 02/05/2007 07:29:17 MSTs/org1

MANUAL OF CONCRETE PRACTICE

355.1R4

--`,``,````,,,`,``,``,,,,,```,`-`-`,,`,,`,`,,`---

D

P

Washer tack welded

.

Note

Fig. 2.1- Common bolts

-

: E i t h e r ' J ' o r ' L ' ’ b o I ts c a n

be

made

from plain or threaded rod

Fig. 2.2-J- and L-bolts (not recommended)

.

b

v

*

Fig. 2.4 -Reinforcing steel

Fig. 2.3 - Threaded rod

Copyright American Concrete Institute

Provided by IHS under license with ACI

No reproduction or networking permitted without license from IHS

Licensee=Jacobs Engineering ( new WAN ) /3219500102, User=Schoolmeyer, Scott

Not for Resale, 02/05/2007 07:29:17 MSTs/org1

ANCHORAGE TO CONCRETE

--`,``,````,,,`,``,``,,,,,```,`-`-`,,`,,`,`,,`---

a

*

.

‘X

..

v

*

B

.

Fig. 2.5 - Threaded inserts

We I d

Fig. 2.6 - Stud- welded plates

Copyright American Concrete Institute

Provided by IHS under license with ACI

No reproduction or networking permitted without license from IHS

Licensee=Jacobs Engineering ( new WAN ) /3219500102, User=Schoolmeyer, Scott

Not for Resale, 02/05/2007 07:29:17 MSTs/org1

355.1R-6

MANUAL OF CONCRETE PRACTICE

2.4.3 Adjustable anchors-Adjustable anchors

can be adjusted for lateral position or depth (Fig.

2.8). They are normally used for attaching large

machines or equipment bases. On thin floor slabs,

the anchor bolt often goes through the concrete to

develop the required anchor capacity. When the

floor slab or foundation is very thick, the anchor

can develop full capacity and still be embedded in

the concrete. After the equipment or machine

base is installed and leveled, grout is used to fill

the void around the anchor. The anchor then acts

similar to a cast-in-place anchor.

--`,``,````,,,`,``,``,,,,,```,`-`-`,,`,,`,`,,`---

.

P

-

4

Fig. 2.8-Adjustable anchors

2.5-Post-installed s y s t e m s

These anchors are installed in a hole drilled in

the cured concrete. There are two basic groups of

post-installed systems: bonded and expansion.

2.5.1-Bonded anchors

2.5.1.1 Grouted anchors-Grouted anchors are

headed or headless bolts or threaded rods. They

are set in predrilled holes with portland cement

and sand grout or other commercially available

premixed grout. (Fig. 2.9)

2.5.1.2 Chemical anchors-Chemical anchors

are usually threaded rods (Fig. 2.10) or deformed

bars (Fig. 2.11) which are bonded in place with

two-part chemical compounds of polyesters,

vinylesters, or epoxies.

The chemicals are

available in four forms: glass capsules, plastic

cartridges, tubes, or bulk.

Glass capsules are inserted into the drilled hole,

and then broken by the anchor rod when it is rotated and hammered into place, thereby mixing

two components to cause a chemical reaction.

The plastic cartridges are used with a dispenser

and a mixing nozzle which mixes the two parts,

initiating a chemical reaction while installing the

compound into the drilled hole. The anchor rod

is then inserted into the hole completing the

installation. The setting time is dependent on

temperature, varying from a few minutes at 90o F

up to several hours at 30o F.

The tube or “sausage” type contains two

components which are mixed by kneading the

tube, placing the mixture into the hole, and finally,

inserting the anchor rod into the hole.

The bulk systems predominantly use epoxies,

which are either premixed in a pot and used

immediately, or pumped through a mixer and

injected into the hole. The anchor is installed

immediately afterward. Epoxies can be formulated to set up quickly or slowly (up to 36 hr

curing time).

*

in

.v

chemical

or

from capsule

Fig. 2.10-Chemical anchor with threaded rod

n

Copyright American Concrete Institute

Provided by IHS under license with ACI

No reproduction or networking permitted without license from IHS

Licensee=Jacobs Engineering ( new WAN ) /3219500102, User=Schoolmeyer, Scott

Not for Resale, 02/05/2007 07:29:17 MSTs/org1

ANCHORAGE TO CONCRETE

--`,``,````,,,`,``,``,,,,,```,`-`-`,,`,,`,`,,`---

2.5.2 Expansion anchors-Expansion anchors

are designed to be inserted into predrilled holes

and then expanded by either tightening the nut

(torque controlled expansion anchor, Sections

2.5.2.1 to 2.5.2.5), hammering the anchor

(deformation controlled expansion anchor,

Sections 2.5.2.6 to 2.5.2.8), or expanding into an

undercut in the concrete (undercut anchors,

Section 2.5.2.9). These anchors transfer the

tension load from the bolt to the concrete by

expansion pressures or forces through friction

and/or keying against the side of the drilled hole.

They often are supplied with a bolt, nut, and

The following sections describe the

washer.

various types of expansion anchors.

2.5.2.1 Heavy duty, torque controlled sleeve

anchor-This type of anchor consists of a bolt or

threaded rod with nut and washer on one end and

a cone on the embedded end, (Fig. 2.12). Around

the cone is a heavy expansion sleeve. Above the

sleeve is a collapsible mechanism, sometimes made

of plastic. A spacer sleeve extends to the surface

of the drilled hole. The anchor is set by tightening the bolt head or nut which draws the cone

up through the expansion sleeve, expanding it

against the side of the drilled hole. The anchor

develops its tensile capacity by means of a combination of keying into the concrete and high

friction between the sleeve and concrete. The

spacer sleeve aids in increasing the shear capacity.

Tensile capacity depends on the strength of the

bolt and its depth of embedment.

BEFORE

TORQUING

AFTER

TORQUING

355.1R-7

2.5.2.2 Sleeve anchors- The sleeve anchor

consists of a steel stud, an expansion sleeve usually

made of sheet metal, and a nut and washer (Fig.

2.13). The bottom of the steel stud has a

uniformly tapered mandrel which has the same

diameter at the end as the expansion sleeve. The

entire length of the bolt below the washer is

enclosed in a section or sections of the steel

tubing. The bottom of the expansion sleeve is slit

longitudinally to provide for expansion. When the

nut is tightened, the tapered mandrel moves into

and expands the sleeve which in turn bears against

the wall of the hole. This anchor is used for

medium and light holding requirements.

.

.

Fig. 2.13 - Sleeve anchor

2.5.2.3 Shell expansion anchors - The shell

expansion anchor, (Fig. 2.14) is available in two

types. One type consists of a two-piece shell held

together by steel tabs with a tapered, internally

threaded end plug. The second type consists of a

two-piece shell section with two tapered steel

cones, one at the top end and one at the bottom,

which are held together by a steel spring at the

center. The bottom cone is internally threaded to

accept a bolt or stud. By torquing the fastener

into the anchor, the steel cones expand the shell

to bear against the wall of the hole.

by

Single-acting

(shell

expanded

single wedge nut)

Double acting

expanded

(shel

by opposing wedge)

Fig. 2.14 - Shell expansion anchor

Fig. 2.12 - Heavy-duty, torque-controlled sleeve

anchor

Copyright American Concrete Institute

Provided by IHS under license with ACI

No reproduction or networking permitted without license from IHS

2.5.2.4 Wedge anchors-The wedge anchor,

(Fig. 2.15) consists of a steel stud bolt with a nut

Licensee=Jacobs Engineering ( new WAN ) /3219500102, User=Schoolmeyer, Scott

Not for Resale, 02/05/2007 07:29:17 MSTs/org1

355.1R-8

MANUAL OF CONCRETE PRACTICE

and washer. The bottom of the steel stud has a

uniform tapered mandrel around which is positioned an expandable steel clip or separate steel

When the nut is

wedges with protrusions.

tightened, the clip or steel wedges ride up on the

tapered mandrel, wedging between the mandrel

and the wall of the hole.

AFTER

TORQUING

BEFORE

TORQUING

2.5.2.6 Drop-in anchors-The drop-in anchor

consists of a steel shell and an internal steel

expander plug (Fig. 2.17). The anchor is internally

threaded at the top end while the internal end is

machined to a uniform taper, matching the shape

of the steel plug inside the anchor. The lower

portion of the shell is slit longitudinally into equal

segments to allow the anchor to expand when the

internal plug is hammered with a setting tool. By

hammering the plug into the shell, the lower

portion of the shell expands to bear against the

wall of the hole.

BEFORE

AFTER

Fig. 2.15- Wedge anchor

2.5.2.5 Rock/concrete expansion anchor-The

rock/concrete expansion anchor, (Fig. 2.16) consists of a stud bolt that is threaded on the top end

for a hex nut. The bottom end consists of a large

mechanical expansion anchor. To set the expansion anchor, the stud bolt is rotated in a clockwise

direction. Grouting is optional down the center of

the bolt to fill the annular space between the rod

and the drilled hole for corrosion protection.

Grout hole

Threaded rob

Nut

Air tube

Plate

Fig. 2.17-Drop-in anchor

2.5.2.7 Self-drilling anchors-The self-drilling

anchor, (Fig. 2.18) consists of a steel shell and a

tapered steel end plug. The bottom of the shell

has teeth for cutting its own hole in the concrete.

The top of the shell is internally threaded to

accept a bolt or stud. The bottom of the shell is

expanded by hammer drilling the anchor over the

steel plug. The plug expands the bottom of the

shell which bears against the wall of the drilled

hole.

BEFORE

AFTER

Hollow bar

Grout hole

Thrust rl

Mal leable

e shell

Fig. 2. I6 - Rock/concrete expansion anchor

(grouted)

b

0.

Fig. 2.18 -Self-drilling anchor

--`,``,````,,,`,``,``,,,,,```,`-`-`,,`,,`,`,,`---

Copyright American Concrete Institute

Provided by IHS under license with ACI

No reproduction or networking permitted without license from IHS

Licensee=Jacobs Engineering ( new WAN ) /3219500102, User=Schoolmeyer, Scott

Not for Resale, 02/05/2007 07:29:17 MSTs/org1

355.1R-9

2.5.2.8 Stud anchors -The stud anchor consists of a steel stud, threaded at the top end, and

has a drilled hole with longitudinal slits at the

bottom end, which accepts a tapered steel plug

(Fig. 2.19). The top of the threaded section is

raised to provide a surface for hammering. By

hammering the top of the stud, the tapered plug

expands the bottom end of the bolt causing it to

bear against the wall of the hole.

BEFORE

b

.

v

-

’ .

.

t

.

.v

Q

AFTER

V

*

.

BEFORE

.

4

.

.

n

.

D

V

v

v-

4

Q

A

AFTER

.

.

bolt and tapered cone are drawn up into the

expansion sleeve, keeping the bottom of the

expansion sleeve in the undercut.

A .b

I

.

V’

Fig. 2.19 - Stud anchor

2.5.2.9 Undercut anchors-There are two

primary designs of undercut anchors available

(Fig. 2.20). They all operate by keying and

bearing against an undercut in the concrete at the

bottom of the drilled hole. They cause little or no

expansion force in the concrete, but generate high

tensile-loading capacities.

The first type requires a second drilling

operation to create an undercut at the bottom of

the first drilled hole. The anchor is installed with

the bottom of the expansion sleeve at the undercut. When the nut is tightened, the tapered

expander plug expands the bottom of the steel

expansion sleeve into the undercut.

The second type cuts its own undercut at the

bottom of the drilled hole. A sleeve is hammered

by a rotary hammer drill with a special setting

tool. The bottom of the expansion sleeve is driven

over a cone at the bottom of the hole. The

bottom of the expansion sleeve has a sharp edge

which, on expansion, cuts its own undercut into

the wall of the hole. By tightening the nut, the

Fig. 2.20 - Undercut anchor

CHAPTER 3-BEHAVIOR

3.1 - Introduction

Understanding anchor behavior is necessary in

specifying the appropriate anchorage for a given

application. This includes an understanding of

failure modes and strengths as well as loaddisplacement and relaxation characteristics of

various anchor types. This chapter covers anchor

behavior in uncracked concrete and in cracked

concrete.

Anchors are primarily loaded through

attachments to the embedded anchor. The

loading can be in tension and shear or

combinations of tension and shear (Fig. 3.1).

They may also be subjected to bending depending

on the details of shear transfer through the

attachment. The behavior of anchors in tension is

of primary importance and will be discussed first.

--`,``,````,,,`,``,``,,,,,```,`-`-`,,`,,`,`,,`---

Copyright American Concrete Institute

Provided by IHS under license with ACI

No reproduction or networking permitted without license from IHS

OF ANCHORS

Licensee=Jacobs Engineering ( new WAN ) /3219500102, User=Schoolmeyer, Scott

Not for Resale, 02/05/2007 07:29:17 MSTs/org1

355.1R-10

MANUAL OF CONCRETE PRACTICE

combined tension

and shear loading

tension loading

[ shear

loading

bending

Fig. 3.1 -Possible loadings of anchors

By far, most anchor testing to date has been

performed in uncracked concrete. While cracking

occurs in almost all concrete, testing in uncracked

concrete provides the basis for understanding

anchor behavior.

The various types of anchors have different displacement characteristics depending on preload,

load transfer mechanism, and failure mode. Fig.

3.3(a)-3.3(c) present three load-displacement

graphs. Fig. 3.3(a) gives the characteristic curves

for headed and undercut anchors while Fig. 3.3(b)

presents curves for torque-controlled, drop-in, and

self-drilling expansion anchors. Fig. 3.3(c) gives

load displacement curves for adhesive anchors.

The displacements shown represent the displacement (slip) of the embedded anchor and the deformation of the concrete as well as the deformation of the anchor.

When a preload is applied to an anchor,

typically by tightening the nut to a prescribed

moment torque, the displacement caused by an

externally applied load is affected. The preloaded

3.2-Behavior of anchors in uncracked

concrete

3.2.1 Load-displacement behavior and failure

modes under tension loading- The five primary

failure modes of anchors in tension are (Fig. 3.2):

(a) Steel failure

(b) Pull-out failure

(c) Concrete splitting failure

(d) Concrete cone failure

(e) Spacing and edge cone failure

a) steel failure

d) concrete cone failure

b) pull-out failure

c) concrete splitting failure

e) spacing and edge cone failure

--`,``,````,,,`,``,``,,,,,```,`-`-`,,`,,`,`,,`---

Fig. 3.2 - Typical failure modes of anchors loaded in tension

Copyright American Concrete Institute

Provided by IHS under license with ACI

No reproduction or networking permitted without license from IHS

Licensee=Jacobs Engineering ( new WAN ) /3219500102, User=Schoolmeyer, Scott

Not for Resale, 02/05/2007 07:29:17 MSTs/org1

355.1R-11

--`,``,````,,,`,``,``,,,,,```,`-`-`,,`,,`,`,,`---

ANCHORAGE TO CONCRETE

load F [kN]

l o a d F [kN]

0

4

6

8

10

Displacement s [mm]

Fig. 3.3(a) - Typical load-displacement relationships

of headed and undercut anchors (from Rehm,

Eligehausen, and Mallee 1988)

2

I I

Iine

anchor type

6

8

4

d i s p l a c e m e n t s [mm]

bolt diameter anchorage depth

mm

mm

I

Fig. 3.3(b) - Typical load-displacement relationships

of expansion anchors under tension loading (from

Eligehausen and Pusill-Wachtsmuth 1982)

d i s p l a c e m e n t [mm]

Fig. 3.3(c)- Typical load-displacement behavior of chemical anchors under tension and shear loading (from

Eligehausen and Pusill- Wachtsmuth 1982)

Copyright American Concrete Institute

Provided by IHS under license with ACI

No reproduction or networking permitted without license from IHS

Licensee=Jacobs Engineering ( new WAN ) /3219500102, User=Schoolmeyer, Scott

Not for Resale, 02/05/2007 07:29:17 MSTs/org1

355.1R-12

MANUAL OF CONCRETE PRACTICE

--`,``,````,,,`,``,``,,,,,```,`-`-`,,`,,`,`,,`---

anchor shows little displacement with increasing

external loading until the preload in the anchor

(and resulting clamping force on the concrete) is

overcome. The preload has no effect on the ultimate static tensile capacity of the anchorage, but

significantly reduces the anchor total displacement.

In the case of steel failure (Fig. 3.3(a), Line 3)

the ductility depends on the relationship between

tensile strength and yield strength of the steel and

the anchor length. Inelastic displacements of

headed anchors due to concrete deformations

under the head may be expected at relatively low

loads unless preloaded. Increasing the bearing

area under the head may reduce inelastic displacements but will have little influence on the failure

load [compare Lines 1 and 2 in Fig. 3.3(a)].

Headed anchors that fail due to fracture of the

concrete will exhibit a brittle failure (Fig. 3.3(b),

line 2).

The behavior of drop-in anchors is dependent

on the magnitude of the expansion force created

in setting the anchor. When expanded properly

during installation, high expansion forces are

induced and the load displacement curve may

remain almost linear up to failure [Fig. 3.3(b),

Line 2).

The expansion force, at installation, of torquecontrolled expansion anchors is smaller than that

of drop-in anchors and, therefore, the displacements are larger for equal loads. If the external

load exceeds the preloading force in the bolt

generated by the torquing during installation, the

spreading cone is pulled further into the sleeve,

leading to increased displacement. At failure the

deformations are much larger than for comparable

drop-in anchors [Fig. 3.3(b)].

Self-drilling anchors show larger displacements

in the total load range than torque-controlled

expansion and drop-in anchors [Fig. 3.3(b)]. This

happens because load transfer is mainly by

mechanical interlock which causes high pressure

on the concrete and large concrete deformations.

The displacement behavior of undercut anchors

depends primarily on the bearing area (undercut

area) and the installation torque. Therefore

relatively large deformations may be expected with

some undercut anchors while others exhibit elastic

behavior well above service load [Fig. 3.3(a)].

Adhesive anchors exhibit elastic behavior up to

nearly maximum load [Fig. 3.3(c)]. While the

load-displacement curves of adhesive anchors

exhibit relatively low coefficients of variation in

Copyright American Concrete Institute

Provided by IHS under license with ACI

No reproduction or networking permitted without license from IHS

comparison to torque-controlled expansion and

drop-in anchors, the bond strengths vary considerably depending on the adhesive component

mix used and the installation procedure.

Under working loads all categories of anchors

should behave elastically with little additional

displacement after installation.

However, at

ultimate load a plastic behavior and in the case of

cyclic loading only a limited strength degradation

is desired. Fig. 3.3(a)-3.3(c) show that the actual

load-displacement behavior of the currently

available expansion, undercut, adhesive, and

headed anchors differs somewhat from this plastic

behavior.

Under sustained loads displacements will

increase with time due to creep of concrete in the

highly stressed load transfer area (bearing area in

the case of headed or undercut anchors, contact

area in the case of expansion anchors, bonded

area in the case of adhesive or grouted anchors).

As an example, in Fig. 3.4 (see Seghezzi and

Vollmer, 1982) the displacements of a torquecontrolled expansion anchor loaded with a

constant tensile force corresponding to approximately 70 percent of the static ultimate strength,

are plotted as a function of load duration on a

double logarithmic scale. It can be seen that the

displacement velocity (tangent to the

displacement-time curve) decreases with increasing

time and, therefore, the displacements approach a

limiting final value. The increase in displacements

is smaller for lower sustained loads. If the load is

increased after a sustained load test, the displacement curve is rather steep until it reaches the

static envelope which is followed thereafter. Failure load and displacement at maximum load are

not negatively influenced by a previous sustained

load smaller than about 70 to 80 percent of the

static failure load.

10*

10

10 2

Duration [Days]

Fig. 3.4 -Increase of displacement during sustained

loading

Licensee=Jacobs Engineering ( new WAN ) /3219500102, User=Schoolmeyer, Scott

Not for Resale, 02/05/2007 07:29:17 MSTs/org1

ANCHORAGE TO CONCRETE

In principle, the same behavior is valid for

cyclic loadings with up to 1 x lo6 load repetitions

and an upper load (where the cyclic load ranges

between an upper and lower value, both of which

are tension) smaller than about 50 percent of the

static failure load (provided no fatigue failure of

the bolt occurs). For higher upper loads the displacements may increase significantly and a fatigue

failure of the concrete might occur (Rehm,

Eligehausen, and Mallee 1988).

Sustained and cyclic loadings in the workingload range have the same influence on displacements and ultimate loads of headed anchors

as for expansion and undercut anchors.

3.2.2 Relaxation -If headed anchors are preloaded, the initial force induced in the anchor is

reduced with time due to creep of the highly

stressed concrete under the anchor head. The

final value of the tension force in the anchor

depends primarily on the value of bearing stresses

under the head, the concrete deformation and the

anchorage depth. In typical cases the value of

that final force will approach 40 to 80 percent of

the initial preload (40 percent for short anchors,

80 percent for long anchors).

Torque-controlled expansion anchors are

usually preloaded by tightening the nut during

installation. This preload is essential for the

proper performance of such anchors. In a typical

installation, locally high concrete stresses are

created around the embedded anchor wedges or

expansion devices as the anchor is preloaded.

Creep of concrete under these high stresses results

in a slight movement of the embedded anchor,

and in turn, in a reduction in the load in the bolt.

Fig. 3.5 shows a typical load-relaxation test

(Burdette, Perry, and Funk 1987). Preload is

plotted as a function of time. The shape of the

curve is essentially the same for all anchors

(including headed anchors).

There is an

exponential drop-off of load immediately after the

applied tension is released, followed by a

continued gradual diminishing of the load over an

indefinite period. It is estimated that the final

preload will be about 40 to 60 percent of the

initial value. This is confirmed by other test data

(Seghezzi and Vollmer 1982, and Wagner-Grey

1976). After retorquing the anchors, the process

of load relaxation starts again, however, the final

value of the preload is increased (Fig. 3.6).

Retorquing even a short time after anchor installation can be effective (Wagner-Grey 1976).

355.1R-13

I

0

0

20

30

40

50

60

70

Time [Days]

Fig. 3.5 -Reduction of preload as a function of time

(after Burdette, Perry, and Funk 1987)

1

i

I

.I

Torque Controlled Expansion Anchor M12

0

0

2,5

I

I

5,0

7,5

I

10

12,5

Time [h]

Fig. 3.6 -Influence of retorquing on the final value

of preload (from Seghezzi and Vollmer 1982)

Chemical anchors are usually preloaded by

applying a predefined torque. Because of the high

stresses in the adhesive bond, the preload force in

the anchor declines faster and the final value is

less than for torque-controlled expansion and

headed anchors.

Long-term relaxation and creep has been

Four Ml6

investigated in several studies.

diameter polyester anchors tested at loads of 25,

30, 38, and 40 kN (6, 7, 8.5, and 9 kips), showed

displacements still increasing after 5 years, but

ranging from 0.090 to 0.140 mm (0.0036 to 0.056

in.)(Elfgren, Anneling, Eriksson, and Granlund

1988). Creep tests were also performed on 26

Ml6 anchors for 3 years at various loads and

--`,``,````,,,`,``,``,,,,,```,`-`-`,,`,,`,`,,`---

Copyright American Concrete Institute

Provided by IHS under license with ACI

No reproduction or networking permitted without license from IHS

I

I

I

10

Licensee=Jacobs Engineering ( new WAN ) /3219500102, User=Schoolmeyer, Scott

Not for Resale, 02/05/2007 07:29:17 MSTs/org1

MANUAL OF CONCRETE PRACTICE

environmental conditions. At allowable working

loads of 15 kN (3.4 kips), anchors tested indoors

showed small creep, 0.10 to 0.40 mm (0.004 to

0.016 in.). However, anchors tested outdoors

exhibited continually increasing creep. Those

tested indoors at 30- and 45- kN (7 and 10 kips),

loads exhibited continually increasing creep. A 4

month test on epoxy anchors showed creep less

than 0.009 in. (0.2 mm) (Wiewel 1989).

The U.S. Army Corps of Engineers performed

creep tests on polyester and epoxy anchors,

subjecting the anchors to 60 percent of the anchor

steel yield strength for 6 months. Cement and

epoxy grouted specimens exhibited low slippage,

0.0013 to 0.0008 in. (0.03 to 0.02 mm), while

polyester anchors exhibited approximately 30 times

as much movement, 0.008 to 0.024 in. (0.2 to 0.6

mm) (Best, Floyd, and McDonald 1989).

3.2.3 Ultimate strength in tension

3.2.3.1 Steel failure -The strength of anchor

steel controls failure when the embedment of the

anchor is sufficient to preclude concrete failure

and when the spreading forces are sufficiently high

(expansion anchors) or the bearing area is sufficiently large (headed and undercut anchors) to

preclude an anchor slip failure. The failure mode

[Fig. 3.2(a)] is rupture of the anchor steel with

ductility dependent on the type of anchor steel

and embedment length. The ultimate strength can

be determined from Eq. 3.1.

F u = 4 x f,,, lb

(3 .1)

where

As = tensile stress area, in.*

f ut = ultimate tensile strength of steel, psi

For given material properties and anchor

dimensions this case defines the upper limit for

the tensile-load-carrying capacity.

Fig. 3.7 shows a comparison of the failure loads

of headed anchors measured in tests to the values

predicted by Eq. 3.1. Because the theoretical

failure load was calculated with the nominal steel

strength, the ratios of actual to predicted tensile

capacity are larger than one.

number

of

specimens

10 STEEL FAILURE

5-

Fig. 3.7-Ratio of actual to predicted tensile capacity

according to Eq. (3.1) for steel failure (after Klingner

and Mendonca 1982)

3.2.3.2 Concrete cone failure -When the

embedment of an anchor or group of anchors is

insufficient to develop the tensile strength of the

anchor steel, a pullout cone failure of the concrete

[see Fig. 3.2(d)] is the principal failure mode.

When the spacing of anchors or location of an

edge [Fig. 3.2(e)] interferes with the development

of the full cone strength of an anchor, its capacity

will be reduced.

The angle of the failure cone, measured from

the axis of the anchor, varies along the failure

surface and shows considerable scatter. In ACI

349, Appendix B, ACI Committee 349,1985) the

angle of the failure cone of headed and expansion

anchors is assumed as 45’. According to Cannon*,

in the case of expansion anchors the angle varies

from about 60’ for short embedments (Id ( 2 in)

to 45O for 1, 2 6 in. According to Rehm,

Eligehausen, and Mallee 1988, the angle varies

between approximately 50° and 60”, (mean value

5S”) and tends to decrease with increasing

anchorage depth.

The following formulas have been developed to

describe behavior of headed studs, expansion, and

undercut anchors.

*Cannon, Robert W., correspondence to ACI

Committee 355, Nov.

1986.

Cannon, Robert W., correspondence to ACI Committee 355, Sept.

1988.

This correspondence is filed at ACI

ACI headquarters and is available

at cost of reproduction and handling at time of request.

Copyright American Concrete Institute

Provided by IHS under license with ACI

No reproduction or networking permitted without license from IHS

Licensee=Jacobs Engineering ( new WAN ) /3219500102, User=Schoolmeyer, Scott

Not for Resale, 02/05/2007 07:29:17 MSTs/org1

--`,``,````,,,`,``,``,,,,,```,`-`-`,,`,,`,`,,`---

355.1R-14

ANCHORAGE TO CONCRETE

ACI 349, Appendix B, limits the tensile capacity

of

of the cone failure of an anchor, or wup

.

anchors, to a uniform stress of 4 +d$ (psi) on

the stress cone surface of the anchors.

(3.2)

--`,``,````,,,`,``,``,,,,,```,`-`-`,,`,,`,`,,`---

strength reduction factor

0.85 for uncracked concrete

= 0.65 in zone of potential

cracking

A = the summation of the projected

areas (in.2) of individual stress

cones minus the areas of overlap and of any area, or areas,

cut off by intersecting edges.

Note: Other reductions are made based on

member thickness relative to embedment and the

area of fabricated anchor heads (see Fig. 3.8).

ACI 349 has no requirements for minimum

center-to-center spacing of single anchors or

anchors belonging to a group.

Fig. 3.9 shows the frequency diagram of the

ratio of actual to Predicted tensile capacity of

headed anchors.

Theoretical capacity was

calculated according to Eq. (3.2). The tests were

described by Klingner and Mendonca (1982a), and

were evaluated by Cannon*.

Tested were

individual anchors with large and small edge

distances and anchor groups.

In all tests a

concrete cone failure occurred.

If an anchor is installed too close to an edge,

the anchor will fail before developing the concrete

cone strength. Therefore, for headed anchors,

ACI 349 requires that the minimum edge distance

m to the center of the anchor be sufficient to

prevent a side cone failure.

The following

equation is suggested in the ACI 349 Commentary

for determining this minimum value.

m

, in.

(3.3)

where

D = anchor diameter, in.

F = ultimate tensile strength of anchor, psi

f 'c = compressive strength of concrete, psi

If this requirement cannot be satisfied, stirrup

or tie reinforcement should be provided.

Cannon+ found that for embedments less than

6 in., ACI 349 becomes increasingly conservative

with decreasing embedment. He has proposed a

modification to Eq. (3.3) to provide a better fit to

test data. For embedments less than 6 in., this

modification would increase the angle of the

failure cone, measured from the axis of the

anchor.

(3 3

For 1, c 3 in.: cy = 62 - 1.1 (l#, deg

For ld 2 3 in. but < 6 in.: (Y = 45 + 0.79 (6-ld) ,

(3 . 5)

deg

With respect to the minimum edge distance he

reported the results of tests which indicated a

direct relationship between anchor load and side

cone failure.** He suggested Eq. (3.6) instead of

Eq. (3.3) as a more correct lower bound for the

edge distance for headed anchors:

-A Frequency [%]

n = 45 tests

5i = 1,14

v = 26 O/o

20

355.1

R-1 5

m

10

F ut = ASTM-specified tensile strength of the

anchor bolt, kips

1,5

2,0

2,5

Fu,test /Fu,pred

Fig. 3.9 -Ratio of actual to predicted tensile capacity

of headed anchors according to Eq. (3.2) (from

Cannon, 1984 **)

Copyright American Concrete Institute

Provided by IHS under license with ACI

No reproduction or networking permitted without license from IHS

*Cannon, private correspondence, 1988, previously cited (see

footnote p 14).

+Cannon, private correspondence, 1986, previously cited (see

footnote p 14).

**Cannon, Robert W., Letter to ACI 355, “Comparison of Testing

Edge Conditions and Anchor Spacing with Predictions”, Dec. 1984.

Licensee=Jacobs Engineering ( new WAN ) /3219500102, User=Schoolmeyer, Scott

Not for Resale, 02/05/2007 07:29:17 MSTs/org1

*EFFECTIVE STRESS AREA,

Ld

I41

B

*EFFECTIVE STRESS

AREA

A t

L

\L DEDUCT AREA

OF ANCHOR HEADS

EFFECTIVE STRESS

AREA

P L A N

--`,``,````,,,`,``,``,,,,,```,`-`-`,,`,,`,`,,`---

*REDUCE BY THE TOTAL BEARING AREA OF THE ANCHOR STEEL.

Pd

Pd

t

t

L

J

(a+2Ld-2h)

. A) Effective stress area for anchorage pullout

EFFECTIVE

STRESS

AREA

.

STRESS AREA REDUCTION FOR LIMITED DEPTH (Ar)

Ar= (a+2Ld-2h)(b+2Ld-2h)

*REDUCE BY THE TOTAL BEARING AREA OF THE ANCHOR STEEL

B) Stress area reduction for I imited depth A

Copyright American Concrete Institute

Provided by IHS under license with ACI

No reproduction or networking permitted without license from IHS

Fig. 3.8-ACI 349 method for determining effective stress areas

Licensee=Jacobs Engineering ( new WAN ) /3219500102, User=Schoolmeyer, Scott

Not for Resale, 02/05/2007 07:29:17 MSTs/org1

ANCHORAGE TO CONCRETE

The average failure load for a side cone

(bursting) failure is given as:

where

F,

= 15m

f

- kips

(3.7)

35cCo’

m = actual edge distance, in.

For expansion

and undercut anchors,

Eligehausen, Fuchs, and Mayer (1987 and 1988),

derived Eq. (3.8a) from 287 test series with single

anchors with large edge distances showing

concrete cone failure.

(3.8a)

mm (1 9/16 to 20 l/2 in.) and concrete strengths

f’, = 20 to 50 N/mm2 (2900 psi to 7150 psi). Fig.

3.11 shows a histogram of the ratio of measured to

predicted failure load.

The average failure loads given in Eq. (3.8) can

only be obtained if the distances between anchors

are large enough so that concrete cones do not

overlap each other. Assuming an angle of the

failure cone cy = 55o the critical distance is

approximately three times the embedment depth.

The failure load of a two-point fastening results

in:

F ul

‘d

f’,

= average ultimate load, N

depth (see Fig. 3.10), mm

= average compressive strength of concrete cylinders (6 by 12 in.) at time of

testing, N/mm2

(3.9)

G = xcr x F,,

where

where

Fu

355.1R-17

= embedment

ultimate failure load, single

anchor, from Eq. (3.8)

=

& = 1 +a/a,,it I 2

(3.10)

where

a

= distance between center of

anchors

a crit = critical distance between center

of anchors

= 31,, where 1d is the depth of

embedment.

Results of an additional 196 tests on headed

studs showed a similar relationship (from Rehm,

Eligehausen, and Mallee 1988).

FIA4

xai

(3.8b)

= %a1

x Xd

=

ai(acd 5

1 +

x Fur

2

where

In the original equation the concrete strength

was measured on cubes with a side length of 200

mm (8 in.). Eq. (3.8a) and (3.8b) assume f 'c

(cylinder) = 0.82 f 'cc (cube).

The tests with expansion, undercut and headed

studs included anchorage depths from 40 to 525

Copyright American Concrete Institute

Provided by IHS under license with ACI

No reproduction or networking permitted without license from IHS

a.I = spacing in direction i

Licensee=Jacobs Engineering ( new WAN ) /3219500102, User=Schoolmeyer, Scott

Not for Resale, 02/05/2007 07:29:17 MSTs/org1

(3.11)

(3.12)

--`,``,````,,,`,``,``,,,,,```,`-`-`,,`,,`,`,,`---

Fig. 3.10 -Illustration of embedment depth as used

in Eq. (3.8a) and (3.86)

Eq. (3.9) leads to the x-method for calculating

the ultimate capacity of multiple anchor fastenings. For the calculation of the ultimate load of

quadruple fastenings the xa factors can be derived

separately for both directions and combined in

product form as follows.

355.1R-18

MANUAL OF CONCRETE PRACTICE

40

Frequency [%]

n = 196 individual tests

si= 1 0 0

v= 1 4 %

30

I

20

10

0.5

1.0

$,

1.5

2.0

0.5

1.0

Fu, test

test ’ %,pred

1.5

/Fu, pred

Fig. 3.11 (a) -Ratio of acutual to predicted tensile

capacity for concrete cone failure of individual

expansion and undercut anchors away from edges

according to Eq. (3.8a). (from Rehm, Eligehausen,

and Mallee 1988, and Eligehausen, Fuchs, and

Mayer 1987 and 1988)

Fig. 3.11(b) -Ratio of actual to predicted tensile

capacity for concrete cone failure of individual

headed anchors away from edges according to Eq.

(3.86). (from Rehm, Eligehausen, and Mallee 1988)

Fig. 3.12 shows the capacity of quadruple

fastenings for headed studs, expansion and

undercut anchors as a function of the ratio of

anchor spacing to embedment depth as measured

in tests and calculated according to Eq. (3.11).

Eq. (3.9) and (3.11) can also be extended for

multiple anchorages with any number of anchors

in any spacing by setting the value of ai as the

distance atot between the outer anchors, and the

x0- value is limited to xa I n with n = number of

anchors in one direction. This is provided that the

spacings between the individual anchors are

smaller than acrit = 31, and the anchor plate is

sufficiently stiff to assure an even distribution of

tension forces to all anchors (see Rehm,

Eligehausen, and Mallee 1988). The X-method

can also be extended to take account of load

eccentricities (Riemann 1985).

Fig. 3.13 shows the ratio of actual to predicted

tensile capacity of groups of headed studs. In the

tests the number of anchors was varied between 4

and 36, the spacing of the outer anchors between

100 and 875 mm and the spacing of the individual

anchors between 0.541, and 2.2&. The groups

were loaded by a concentric tension load which

was equally distributed to all anchors.

Eq. (3.13) covers the influence of edge distances, a,, smaller than critical:

Copyright American Concrete Institute

Provided by IHS under license with ACI

No reproduction or networking permitted without license from IHS

Fu* = a& * Fy

(3.13)

Xa?n = 0.3 + 0.7 am/a,crit S 1

(3.14)

a m,crit

Fu

=

=

critical distance from free edge

1.5 1d

--`,``,````,,,`,``,``,,,,,```,`-`-`,,`,,`,`,,`---

where

=

‘ actual embedment length

= ultimate failure load, single anchor

to be taken from Eq. (3.8)

Licensee=Jacobs Engineering ( new WAN ) /3219500102, User=Schoolmeyer, Scott

Not for Resale, 02/05/2007 07:29:17 MSTs/org1

355.1R-19

5.0

0

I

I

FE according to eqn. ( 3.8 )

4.0

O

I

8

0

3.0

2.0

1.0

--`,``,````,,,`,``,``,,,,,```,`-`-`,,`,,`,`,,`---

Fig. 3.12-Ratio of actual failure load of a group of anchors to the predicted value for an individual anchor as

a function of the ratio of anchor spacing to embedment depth (from Rehm, Eligehausen, and Mallee 1988)

Copyright American Concrete Institute

Provided by IHS under license with ACI

No reproduction or networking permitted without license from IHS

Licensee=Jacobs Engineering ( new WAN ) /3219500102, User=Schoolmeyer, Scott

Not for Resale, 02/05/2007 07:29:17 MSTs/org1

MANUAL OF CONCRETE PRACTICE

I

_.

l-

,

L

--`,``,````,,,`,``,``,,,,,```,`-`-`,,`,,`,`,,`---

Copyright American Concrete Institute

Provided by IHS under license with ACI

No reproduction or networking permitted without license from IHS

Licensee=Jacobs Engineering ( new WAN ) /3219500102, User=Schoolmeyer, Scott

Not for Resale, 02/05/2007 07:29:17 MSTs/org1

ANCHORAGE TO CONCRETE

Fig. 3.14 shows a comparison of test results with

the theoretical values according to Eq. (3.13). It

should be noted, however, that minimum distances

from the free edge are necessary for headed studs

in order to allow proper concreting and avoid

local spalling of concrete.

Minimum edge

distances for expansion and undercut anchors are

necessary to avoid splitting of concrete during

installation and expansion of the anchors.

If anchors are located in a corner [see Fig.

3.15(b,)], the factors xarn are calculated separately

for each direction and then the two x-factors are

multiplied.

355.1R-21

Bode and Roik (1987), evaluated data of 106

tests with headed studs to arrive at Eq. (3.15).

F” = 12r,3/2(1 + d&,) 8, N

(3.15)

where

F,

1d

d,

f’,

=

=

=

=

average failure load, N

embedment length, mm

head diameter, mm

concrete cylinder strength

at time of testing, N/mm2

Fig. 3.16 compares the measured failure loads

of headed studs with the values according to Eq.

Roik (1987), assume the critical

spacing of neighboring headed

a cl+ = 41,

(3.16)

Fig. 3.15 - Typical failure modes of anchors Loaded

in shear (from Rehm, Eligehausen, and Mallee

1988)

kN

TU’k lN/mmz I

--`,``,````,,,`,``,``,,,,,```,`-`-`,,`,,`,`,,`---

mean value

50

75 100 125 150

h [mm]

Fig. 3.16 - Measured failure loads compared to Eq. 3.15 (where p, = concrete splitting strength) (from Bode and

Roik 1987)

Licensee=Jacobs Engineering ( new WAN ) /3219500102, User=Schoolmeyer, Scott

Copyright American Concrete Institute

Provided by IHS under license with ACI

No reproduction or networking permitted without license from IHS

Not for Resale, 02/05/2007 07:29:17 MSTs/org1

--`,``,````,,,`,``,``,,,,,```,`-`-`,,`,,`,`,,`---

.50

o Anchor

0

.00

/

. 00

studs,

concrete break-out

l Headed studs,

local concrete failure

( blow -out)

I

/

L

.50

1.00

1.50

Fig. 3.14-Ratio of actual failure load of an individual anchor close to the edge to the predicted value for an

anchor with large edge distance (from Rehm,

Eligehausen, and Mallee 1988)

Licensee=Jacobs Engineering ( new WAN ) /3219500102, User=Schoolmeyer, Scott

Copyright American Concrete Institute

Provided by IHS under license with ACI

No reproduction or networking permitted without license from IHS

Not for Resale, 02/05/2007 07:29:17 MSTs/org1

1.75

--`,``,````,,,`,``,``,,,,,```,`-`-`,,`,,`,`,,`---

355.1R-23

With respect to the influence of free edges (see

Fig, 3.15) they consider the critical distance

beyond which there is no significant influence on

load as being in the case of one free

ati1 IJ 1.21,

and in the case of two or more free edges:

acit.2

5 21,

For distances from center of headed stud to the

free edge(s) which are smaller than the critical

distance according to Eq. (3.17) and (3.18), they

fou d that the assumption of a linear decrease of

ulti ate failure load in proportion to the ratio of

act”al distance/critical distance gives a lower

bound of their test results, in much the same

ner as shown in Fig. 3.14.

raestrup, Nielson, Jense, and Bach (1976), give

the predicted failure load as:

FM

= 0.21 x 2; (1 + d,ll&f$ N (3.19)

Eq. (3.19) was deduced by applying the theory

of plasticity to headed studs embedded in

co rrete. The failure load is assumed to be

pronI ortional to the concrete compressive strength.

3.2.3.3 Pullout (slip) of the anchor- Slip

failure occurs [Fig. 3.2(b)] with expansion anchors

when the expansion force is too small to develop

either the strength of the anchor steel or a shear

cone failure of the concrete. This is a typical

failure mode for wedge anchors at moderate to

deep embedments in lower strength concrete

where the crushing of the concrete at the wedges

allows the bolt to “pull through”. The cause may

also be due to an oversize hole. Slip failure may

also occur in low strength concrete due to

deformation of the wall of the hole.

The testing of wedge bolt expansion anchors by

Hanks (1973), clearly demonstrated that the

primary failure mode for individual anchor tests

(uninhibited by edge conditions) was either cone

failure of the concrete or anchor slip depending

on the depth of anchor for a given size. Only 10

of 464 tension tests indicated any cracking

associated with a cone failure. The line of

demarcation between shear cone failure and slip

Copyright American Concrete Institute

Provided by IHS under license with ACI

No reproduction or networking permitted without license from IHS

failure was approximately six bolt diameters.

Under conditions of poor workmanship in the

field (e.g., oversize holes) slip failure may occur at

a much smaller embedment depth than ld = 6D.

Slip failure may also occur with bonded and

adhesive anchors of insufficient embedment to

develop the strength of the anchor steel or to

cause a concrete cone failure.

Torque-controlled wedge anchors, which fail by

slip, generally fail by slipping the expansion cone

past the wedges. This failure mode may also

occur with sleeve anchors. However, in some case

anchors may fail by pulling the whole anchor

(including expansion sleeve) out of the hole.

Torque-controlled expansion anchors may also slip

to a critical depth and fail the concrete.

Deformation-controlled expansion anchors (e.g.,

drop-in anchors) have a fixed expansion and may

slip to a critical depth and then fail the concrete.

The slip failure load is dependent on the

coefficient of friction between the sliding surfaces

and on the spreading force at failure which is a

function of the critical expansion force producing

failure and the deformability of the concrete which

varies with hole depth and concrete properties.

All of these factors may vary with anchor type,

manufacturer, and installation. The spreading

force and thus the slip load of drop-in anchors

decreases significantly with increasing diameter of

the drilled hole with respect to the diameter of the

anchor.

Theoretically the slip failure load F, could be

calculated from Eq. (3.20).

Fit = ps

(3.20)

where

I, = coefficient of friction

S = spreading force

The coefficient of friction depends mainly on

the roughness and cleanliness of the drilled hole

and of the surface of the expansion sleeve or

wedge as well as on the spreading pressure. From

Wagner-Grey (1976), the factor p for torque

controlled expansion anchors is in the range of 0.2

to 0.3 and for drop-in anchors is approximately

0.35. The difficulty in using Eq. (3.20) lies in

properly estimating the spreading force, since

complex mechanics are involved. For this reason

Licensee=Jacobs Engineering ( new WAN ) /3219500102, User=Schoolmeyer, Scott

Not for Resale, 02/05/2007 07:29:17 MSTs/org1

MANUAL OF CONCRETE PRACTICE

the profession relies on test data. However,

equations for estimating of the spreading force are

given by Wagner-Grey (1976).

Because of the large variability of the spreading

forces and the coefficient of friction, Eq. (3.20)

gives only an approximate estimate of the pullout

load (see Eligehausen, and Pusill-Wachtsmuth

1982). Furthermore, in important applications it

is advisable to test expansion anchors, which

typically fail by slip at specified embedments, in

design strength job concrete to confirm slip

characteristics.

For pullout failures of a chemical anchor, the

bond between the wall of the drilled hole and the

mortar is critical (see Sell 1973). Assuming a

uniform bond stress distribution along the

anchorage length, the bond strength is in the order

of 1300 psi (9 MPa) with a coefficient of variation

of 10 to 15 percent for polyester and vinylester

chemical anchors. This value is for a concrete

compressive strength of 3000 psi (21 MPa) and an

embedment of about nine anchor diameters. The

bond strength increases approximately with the

square root of the concrete strength.

The pullout capacity of chemical anchors

increases with increasing embedment depth:

however, after about nine anchor diameters the

increase is not proportional to embedment. This

is due to the high bonding effect resulting in high

load transfer to the concrete at the top of the

anchorage. The bond stress is no longer uniform,

and if the tensile load is sufficiently high, the

failure initiates with a concrete failure in the

upper portion of the concrete and then the bond

fails in the remainder of the embedment.

For headed anchors local failure in front of the

head will occur when the pressure on the concrete

is larger than about 12f’, to 15f’, (Rehm, Eligehausen, and Mallee, 1988). This type of failure is

somewhat similar to a pullout failure.

3.2.3.4 Splitting failure of concrete -This

failure mode will occur only if the dimensions of

the concrete are too small, the anchors are placed

too close to an edge or too close to each other

[Fig. 3.2(c)], or the expansion forces are too high.

The failure load is usually smaller than for a

concrete cone failure.

Torque-controlled expansion and deformationcontrolled anchors (e.g., drop-in and self-drill

anchors are the type anchor most likely to

experience splitting failure due to the high lateral

thrust required to resist sliding by friction on the

Copyright American Concrete Institute

Provided by IHS under license with ACI

No reproduction or networking permitted without license from IHS

steel wedges. Deformation-controlled expansion

anchors generate higher spreading forces and

require larger edge distances than torquecontrolled expansion and undercut anchors.

The capacity of expansion anchors which fail by

splitting of the concrete has been evaluated by

Pusill-Wachtsmuth (1982), using theoretical

considerations. It was assumed that splitting

occurs when the tensile stresses averaged over a

critical area reach the concrete tensile strength.

The size of this area was found by evaluating the

results of tests with concentrated loads and of

tests with thick concrete rings subjected to a

constant inner pressure. According to this theory,

the necessary side cover or spacing to preclude a

splitting failure before reaching the concrete cone

failure load must be about 1.751d or 3.51,, respectively. For drop-in anchors a side cover m I 31d

was recommended. The validity of this evaluation

was checked by relatively few test results.

With respect to the minimum edge distance

Cannon* has proposed the following criteria to

preclude a splitting failure occuring at a load

lower than the capacity for concrete cone failure

or pullout failure:

m = D(11.4 - 0.92& in.

where

(3.21)

--`,``,````,,,`,``,``,,,,,```,`-`-`,,`,,`,`,,`---

355.1R-24

= minimum edge distance

= anchor bolt diameter, in.

= embedment depth to the bottom of the

ld

anchor, in

Eq. (3.21) is valid for anchor spacings s L 2 in.

:

If side cover or spacings of anchors are too

small, splitting cracks may occur during installation

of anchors. This possibility is greater for drop-in

anchors and for self-drilling anchors than for

torque-controlled expansion anchors because of

the higher initial spreading forces. The minimum

edge distance and the minimum spacing to avoid

splitting during installation, as recommended by

Rehm, Eligehausen, and Mallee (1988), are based

on many tests and are given in Table 3.1 for the

different types of anchors.

*Cannon, Private correspondence previously cited Dec. 1984

(see footnote p 14).

Licensee=Jacobs Engineering ( new WAN ) /3219500102, User=Schoolmeyer, Scott

Not for Resale, 02/05/2007 07:29:17 MSTs/org1

ANCHORAGE TO CONCRETE

355.1R-25

Table 3.1 -Minimum edge distance and minimum spacing to avoid splitting failure

Torque-controlled expansion anchors

with one cone (recent design)

Mihimum edge distance m / 1d to avoid

splitting during installation

1.0

2.0

Minimum center-to-center spacing a / 1d

to avoid splitting during installation

1.0

1.0

3.2.4 Load-displacement behavior and failure

modes in shear-For anchors with an applied

preload, the initial friction forces between the

baseplate and the concrete have to be overcome

by the shear load before there is initial anchor

movement (Fig. 3.17). The baseplate slides and

the anchor moves to the side of the hole in the

second stage of behavior. The third stage of loaddisplacement behavior is a pressure loading

against the top surface of the concrete and a

surface spa1l of the concrete at the edge of the

hole. Depending on edge distance and anchor

embedment, the failure may be by shearing of the

anchor (for deep embedments) with or without a

concrete spa11 preceding the steel failure [Fig.

3.15(a)] or by shearing of the concrete (concrete

failure) in the case of anchors loaded near an

edge [Fig. 3.15(b1), (b2), (b3)].

Shear loading generally produces larger

displacements than tension loading [see Fig.

3.3(c)]. This can be attributed to the bending of

the anchor rod and the deformation of the

concrete in the direction of loading. This is

especially true if the anchor is not flush with the

concrete at the hole opening (e.g., when the

concrete is spalled during drilling). For cast-inplace anchors, the behavior will depend on the

type of anchorage used, the embedment and the

steel strength.

The distribution of shear from the attachment

to anchors of a group depends on the details of

the anchors to the attachment connection and on

overcoming the frictional resistance of the

attachment. The frictional resistance depends on

surface conditions, the existing preload (if any) in

the anchors and the compressive forces applied

Copyright American Concrete Institute

Provided by IHS under license with ACI

No reproduction or networking permitted without license from IHS

Drop-in anchors

I

3.0

I

through the attachment as a result of direct loads

or applied moments. The connection details

concern the treatment of connecting surfaces and

the fit and manner of connecting the anchors to

the attachment.

--`,``,````,,,`,``,``,,,,,```,`-`-`,,`,,`,`,,`---

Undercut anchors

Onset of bearing

crushing in the concrete

lip of loading plate into

bearing on anchor stud

Load transfered by

friction to embedment

. ~~~

0

.50

r

10

r

1.5 0

Deformatlon

Fig. 3.17- Typical load-displacement curve for

wedge anchor in shear from Meinheit and

Heidbrink 1985)

Licensee=Jacobs Engineering ( new WAN ) /3219500102, User=Schoolmeyer, Scott

Not for Resale, 02/05/2007 07:29:17 MSTs/org1

-7

20

355.1R-26

MANUAL OF CONCRETE PRACTICE

3.2.5 Ultimate strength in shear

3.2.5.1 Steel failure - Steel failure usually occurs

after relatively large displacements and is most

common for deep embedments, lower strength

steels and large edge distances. The failure load

depends on the steel area and the steel strength

and is given by Eq. (3.22).

number

of specimens

x

I

”

0,: 0.65-4

I

= N A,f,, lb

(3.22)

where the factor N takes account of the steel

“shear” strength and has the range 0.6 to 0.7

[Klingner and Mendonca, (1982b)], A, is the tensile stress area (as defined in Eq. (3.1)) and f,t is

the ultimate tensile strength.

Eligehausen and Fuchs (1988), propose the

value N = 0.6 on the basis of an evaluation of

230 tests.

3.2.5.2 Concrete failure -Concrete failures will

exhibit two modes; (1) blow out cones due to edge

proximity (Fig. 3.15) and (2) concrete spa11

followed by a possible anchor pullout or steel

failure away from an edge.

3.2.5.2.1 Edge failure- For all types of

anchors loaded in shear toward an adjacent, free

edge and exhibiting a concrete failure (Fig. 3.15),

the failure load is influenced by the concrete

tensile strength, the edge distance m and the

stiffness of the anchor. Another influencing factor

is the embedment depth. The failure surface has

a conical shape that may radiate from the embedded end of the anchor for shallow embedments

or from the upper part of the anchorage for deep

embedments.

In the following paragraphs, several formulas

for calculating the failure load for an edge failure

are reviewed.

ACI 349, Appendix B, Commentary gives a

design shear strength of

vu = 24$$n2, lb

(3.23)

RATIO OF ACTUAL TO

F’FQICTED CAPACITY

Fig. 3.18 -Histogram of actual to predicted capacity

ACI 349, Appendix B further recommends a

minimum side cover or edge distance m required

to preclude edge failures: be calculated by Eq.

(3.24).

m=

D = anchor diameter, in.

F t = anchor ultimate tensile load, lb

fr”, = concrete compressive strength, psi

Eligehausen and Fuchs (1988), have suggested,

based on the evaluation of some 80 test results

with headed and expansion anchors (anchorage

depth ld > 4D), the average ultimate failure load

of the concrete of a single fastener in shear be

calculated by:

F,, = 1.4@$n1.s~~, N

where

D

f’,

m

(3.25)

shank diameter (mm) of headed

studs or drill-hole diameter for

anchors, D < 25mm

average concrete compressive

strength (cylinders) at time of testing,

N/mm2

distance from anchor to free edge,

mm

Fig. 3.18, taken from Klingner and Mendonca

(1982b) gives the ratio of actual to predicted shear

capacities for this approach.

Copyright American Concrete Institute

Provided by IHS under license with ACI

No reproduction or networking permitted without license from IHS

(3.24)

where

where

= 0.85

cb

f’, = compressive strength of concrete

m = distance from anchor to free edge

(see Fig. 3.15)

, in.

Licensee=Jacobs Engineering ( new WAN ) /3219500102, User=Schoolmeyer, Scott

Not for Resale, 02/05/2007 07:29:17 MSTs/org1

--`,``,````,,,`,``,``,,,,,```,`-`-`,,`,,`,`,,`---

F8l

ANCHORAGE TO CONCRETE

355.1R-27

h

Xh =-sl

1.4m

where

h = member thickness, mm

Eq. (3.25) is valid for 1,/D = 4 to 6.

Fig. 3.19 shows a comparison between failure

loads according to Eq. (3.25) and test results. The

thickness of the test specimens was h 1 1.4m.

The tests were performed in concretes with

different strengths and anchors ranging in

diameter between 12 and 22 mm. The test results

were normalized to a concrete strength f 'c =

20N/mm2 and D = 18 mm.

If an anchor group is loaded in shear toward an

edge, a common failure cone may occur [see Fig.

3.15(b2)]. T he corresponding failure load may

also be calculated as described in Section 3.2.3.2

for tension loading [Eq. (3.9), (3.11), and (3.12)]

according to the x-method. The x-values for

shear loads, however, depend on the distance from

the free edge measured in load direction.

The critical (minimum) distance between two or

more anchors beyond which no intersection of

failure cone will happen is given by Eligehausen

and Fuchs (1988), as:

a Wit = 3.5m

Similar expressions are proposed for calculating

the failure load of single fastenings or anchor

groups situated in a corner or in narrow members.

The influence of load eccentricity on the failure

load of an anchor group can also be taken into

account by the x-method (Rehm, Eligehausen,

and Mallee 1988). The method has been extended

to anchor groups with an arbitrary number of

anchors.

Klingner, Mendonca, and Malik (1982),

recommend a critical (minimum) edge spacing of:

(3.27)

mkD

For a I a,,i, Eligehausen and Fuchs (1988),

have proposed the calculation of the average

failure load of a group of anchors (see Fig. 3.20)

subjected to shear load by:

Fut in.

-,

(3.29)

%@

where

#C = 0.90 and the other terms are as given

the ACI 349 [Eq. (3.24)].

for

(3.28)

For anchors with small embedment depth

situated away from an edge and loaded in shear,

the failure mode may be a tensile cone failure as

the anchor bends under load and induces a tensile

loading into the concrete. Because of ductility

requirements and reversible load conditions

associated with seismic design, ACI 349 does not

distinguish between embedment requirements for

shear and tension. This is very conservative if only

shear is considered (see Shaikh and Yi, 1985).

where

= 1 + a/a,,i,

&

F, is from Eq. (3.25)

Fig. 3.20 (Eligehausen and Fuchs, 1988) shows

the ratio of the failure load of a group loaded in

shear towards the edge to the failure load of an

individual anchor calculated according Eq. (3.25).

The failure load ratio is plotted against the ratio

of spacing to edge distance.