Wind Turbine Deterioration: Probability Evaluation Method

advertisement

Mechanical Systems and Signal Processing 76-77 (2016) 729–741

Contents lists available at ScienceDirect

Mechanical Systems and Signal Processing

journal homepage: www.elsevier.com/locate/ymssp

A probability evaluation method of early deterioration

condition for the critical components of wind turbine

generator systems

Yaogang Hu a,n, Hui Li a, Xinglin Liao a, Erbing Song a, Haitao Liu a, Z. Chen b

a

State Key Laboratory of Equipment and System Safety of Power Transmission and Distribution & New Technology, Chongqing University,

Chongqing 400044, China

b

Department of Energy Technology, Aalborg University, Aalborg East DK-9220, Denmark

a r t i c l e i n f o

abstract

Article history:

Received 6 July 2015

Received in revised form

18 January 2016

Accepted 3 February 2016

Available online 18 February 2016

This study determines the early deterioration condition of critical components for a wind

turbine generator system (WTGS). Due to the uncertainty nature of the fluctuation and

intermittence of wind, early deterioration condition evaluation poses a challenge to the

traditional vibration-based condition monitoring methods. Considering the its thermal

inertia and strong anti-interference capacity, temperature characteristic parameters as a

deterioration indication cannot be adequately disturbed by the uncontrollable noise and

uncertainty nature of wind. This paper provides a probability evaluation method of early

deterioration condition for critical components based only on temperature characteristic

parameters. First, the dynamic threshold of deterioration degree function was proposed

by analyzing the operational data between temperature and rotor speed. Second, a

probability evaluation method of early deterioration condition was presented. Finally, two

cases showed the validity of the proposed probability evaluation method in detecting

early deterioration condition and in tracking their further deterioration for the critical

components.

& 2016 Elsevier Ltd. All rights reserved.

Keywords:

Wind turbine

Condition monitoring

Dynamic threshold

Probability evaluation

Degradation degree

1. Introduction

Wind turbine generator systems (WTGSs) are unmanned, remote power plants. Unlike conventional power stations,

WTGS is exposed to highly variable and harsh weather conditions, including calm to severe winds, tropical heat, lightning,

arctic cold, hail, and snow. WTGSs undergo constantly changing loads because of these external variations, thereby resulting

in gradual changes of critical component performance. Today, premature failure rates, restoration times, and operation and

maintenance (O&M) costs of wind power are higher than desirable [1,2]. The operational unavailability of WTGS reaches 3%

of WTGS lifetime. Moreover, O&M costs can account for 10–20% of the total energy cost for a wind turbine project, and this

percentage can reach 35% for a WTGS at the end of its lifetime. Therefore, reducing O&M costs and improving reliability have

become top priorities in wind turbine maintenance strategies [2]. Early deterioration conditions of every critical component

must be effectively identified by monitoring deterioration degree and the trend of gradual deterioration changes to ensure a

n

Corresponding author.

E-mail address: huyaogang345@163.com (Y. Hu).

http://dx.doi.org/10.1016/j.ymssp.2016.02.001

0888-3270/& 2016 Elsevier Ltd. All rights reserved.

730

Y. Hu et al. / Mechanical Systems and Signal Processing 76-77 (2016) 729–741

satisfactory level of real-time operational reliability and to arrange suitably the optimal maintenance strategies throughout

WTGS lifetime.

Several condition monitoring techniques have been recently applied to WTGS through vibration-based methods, such as

blades [3], gearbox [4,5], and electrical systems [6]. However, these techniques are typically focused on vibration detection,

thereby making early deterioration conditions impossible to obtain comprehensively because of the uncertainty nature of

the fluctuation and intermittence of wind. Furthermore, these mentioned vibration-based techniques typically require

additional sensors or equipment, which directly increase costs [7]. An unexpected increase in component temperature may

indicate overload, poor lubrication, or possibly ineffective passive or active cooling, for example, when a generator cooling

system becomes partially blocked or defective for some reason or another [8,9]. Possessing the characteristic of thermal

inertia and strong anti-interference capacity, temperature can be used to indicate a critical component deterioration. In

addition, large amounts of temperature data available as the research foundation were easily acquired by the supervisory

control and data acquisition (SCADA) system. Therefore, this system may be a feasible way to acquire deterioration degree

and the evaluation result of gradual deterioration changes by analyzing the relationship between deterioration degree and

temperature characteristic parameters of the critical components. Previous works [10,11] constructed the normal operating

temperature models of gearbox, generator, and bearing through artificial neural network (ANN) based on SCADA data. A

potential fault is identified when the residual between model prediction and the measured value expands. In [12], the

authors proposed a method that used multiple layer perception to build a temperature model of the gearbox. A fault is

registered when the measured temperature value is outside the confidence range of the value predicted by the model. In [9],

an improved memory matrix construction method was adopted to achieve the coverage of the normal operational space of a

generator by constructing normal behavior model. A condition-monitoring method based on nonlinear state estimate

technique (NSET) for a WTGS was then proposed. These papers used ANN or NSET to construct normal operating model

based on SCADA data; however, ANN and NSET have demerits of requiring a time-consuming training process, and local

minima problems that may limit the improvement of model accuracy can occur [9]. Other works [13,14] used deterioration

degree concept to reflect the relationship between temperature characteristic parameters and deterioration conditions of

critical components. However, the values of temperature data from SCADA system change within wide ranges in varying

operational conditions, and a deterioration condition of critical components cannot be detected adequately through deterioration degree function with fixed threshold. In [14], although the authors proposed a threshold set method of deterioration degree function through massive history temperature data, the proposed method may be not be able to apply

effectively the actual WTGS. In addition, few studies pay close attention to content about the evaluation result of gradual

deterioration changes of critical components based on real-time temperature data from SCADA system. This paper presents

a probability evaluation method of early deterioration condition for critical components based on the temperature data by

considering the operational conditions of variable speed and uncertainty. First, dynamic threshold was proposed for

deterioration degree function through data fitting and cluster classification method based on SCADA data of temperature

characteristic parameters and rotor speed. Second, a probability evaluation method of early deterioration condition was

presented by combining the concepts of deterioration degree, dynamic thresholds, and nonparametric estimation method.

Finally, the validity of the proposed method is verified based on the temperature data of an actual 1.5 MW WTGS through

two cases of generator bearing fault and main bearing fault.

The contributions of this paper include presenting a probability evaluation method of early deterioration condition for

critical components of WTGS based on the SCADA data of temperature characteristic parameters. In Section 2, the process of

determined dynamic threshold for deterioration degree function is introduced. In Section 3, the probability evaluation

method of early deterioration condition is described, including the established probability density function of deterioration

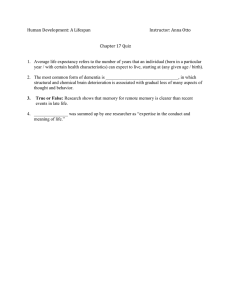

Fig. 1. Temperature characteristic parameter distribution of critical components in a WTGS.

Y. Hu et al. / Mechanical Systems and Signal Processing 76-77 (2016) 729–741

731

degree and the trend analysis of gradual deterioration changes for critical component under varying operational conditions.

In Section 4, two cases are investigated to validate the proposed method. In Section 5, the conclusion is presented.

2. Deterioration degrees with dynamic threshold for critical components of WTGS

2.1. Temperature characteristic parameters of critical components

Drive chain is core part of a WTGS, which transforms mechanical energy into electric energy through the wind energy

captured at a different rotor speed. Fig. 1 illustrates critical components of drive chain, such as main bearing, gearbox front

bearing, and generator winding, and the main monitoring temperature characteristic parameters are shown.

This online temperature monitoring information from critical WTGS subassemblies can be obtained from SCADA system,

such as main bearing temperature, gearbox bearing temperature, gearbox oil temperature, and generator winding temperature, which can be used as the basis for the gradual deterioration change process of critical components.

The concept of deterioration degree is initially introduced to evaluate the deterioration level between the normal

condition and the fault condition [14]. Deterioration degree is set in the range [0, 1], and small value usually denotes good

condition of the component. The deterioration degree function of critical component can be shown as

gðxÞ ¼

x β1

;

β2 β1

ð1Þ

where g is deterioration degree; β1 and β2 are lower and upper limit values, respectively; and x denotes monitoring

temperature.

The performance degradation trend of increases with operational time, whereas the temperature trend of these critical

components increases with degradation trend. However, changes in temperature monitoring value reflect a wide range of

performance degradation trends with varying rotor speeds because of the uncertain nature of the fluctuation and intermittence of wind. Moreover, temperature trend data fluctuate increasingly. Therefore, the effective thresholds play a key

role in obtaining the actual deterioration degree and in analyzing the process of gradual deterioration changes of critical

components. Both dynamic upper threshold and dynamic lower threshold are obtained as follows.

1) Dynamic upper threshold. Given the strong affinity between rotor speed and temperature characteristics, a function

between rotor speed and temperature characteristics is established by extracting failure data from SCADA system through

data fitting method to acquire the temperature upper threshold under varying rotor speed.

2) Dynamic lower threshold. The temperature value of the superior component is smaller than that of the deteriorated

component in the same rotor speed; thus, all WTGSs can be classified to different group in a wind farm through cluster

classification method according to the principle of approximately equal rotor speed [15]. Moreover, the minimum value of

the same temperature characteristics at a same group can be determined as dynamic lower threshold.

2.2. Dynamic upper threshold of deterioration degree function

The temperature value of the deteriorated component is larger than that of the superior component when a component

deteriorated heavily. Given that temperature characteristic parameters are positively proportional to the rotor speed, the

extracted failure data can be analyzed with bin method [16]. In this paper, rotor speed range was divided into d bins ranging

from the minimum and maximum rotor speeds, and all history temperature values of the destroyed component for each bin

were averaged. The function of all the presented temperature variables with the change of rotor speed can be obtained with

data fitting method, and the determination process is described as follows.

Step 1: SCADA data of interest are defined.

Step 2: Those data collected about rotor speed and temperature characteristic parameters when WTGS is in standby

mode are extracted.

Step 3: Given that rotor speed is divided into d bins ranging from the minimum and maximum rotor speeds by using rotor

speed as a reference, d can be estimated with the following equation:

d¼

nmax nmin

;

0:5

ð2Þ

where nmax and nmin are the minimum rotor speed and maximum rotor speed of a WTGS, respectively.

Step 4: All temperature values and rotor speed values for each bin are averaged in the abnormal operational data. The

expected value of the rotor speed in j-th bin can be calculated.

nj ¼

k

1X

nij ði ¼ 1; 2; …; k

ki¼1

j ¼ 1; 2; …; dÞ;

ð3Þ

where nj is an average value of rotor speed in j-th bin; k is the number of rotor speed data located in j-th bin; and ni is the

732

Y. Hu et al. / Mechanical Systems and Signal Processing 76-77 (2016) 729–741

rotor speed corresponding to j-th bin.

Similarly, the aforementioned method is used by analyzing the data of temperature characteristic parameters, and the

expected value is obtained as follows:

xj ¼

k

1X

xij ði ¼ 1; 2; …; k

ki¼1

j ¼ 1; 2; …; dÞ;

ð4Þ

where xj stands for the average value of temperature characteristic parameters; and xi is the temperature characteristic

parameters corresponding to the j-th bin. Then, the expected value ðx1 ; n1 Þ; ðx2 ; n2 Þ; ⋯; ðxd ; nd Þ can be obtained through the

process of average value for all temperature values and rotor speed every bin.

Step 5: Based on the set of the expected value, the function x ¼ f ðnÞ of all the presented temperature variables with the

change of rotor speed can be obtained through data fitting method. The dynamic upper threshold β2 with rotor speed can

be calculated as

β2 ¼ f ðnÞ:

ð5Þ

2.3. Dynamic lower threshold of deterioration degree function

Compared with wind speed, rotor speed can efficiently reflect the operational condition of a WTGS in a wind farm, and

rotor speed data are monitored and stored through SCADA system online. All WTGSs are divided into different groups with

similar or same rotor speed based on rotor speed values of all WTGSs at the same time, and the minimum value of temperature characteristic parameters in every group can be deemed as the dynamic lower threshold. By reflecting the same

degree of the operational condition, the rotor speed difference Δn between two rotor speeds of WTGSs can be calculated as

Δn ¼ nmax ðtÞ nmin ðtÞ oε;

ð6Þ

where nmax and nmin are the maximum and minimum rotor speeds of some WTGSs at t time, respectively; and ε is check

value and defined as ε ¼1 rpm [15]. When Δn oε, all WTGSs of the group at t time are assumed to work at same operational

condition, namely, all of them are in same group.

Start

The SCADA

monitoring data

Extract rotor speed

values of k WTGSs

(n1,n2,...nk)

Set the parameters and

the first classification c

Normalization

Fuzzy C-means

algorithm

c=c+1

No

Check the results of cluster

classification by

ε<1rpm

Yes

The results of cluster

classification

the dynamic lower

threshold β1

End

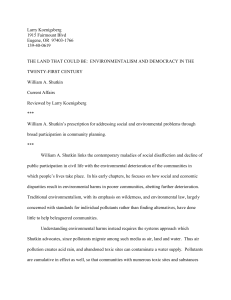

Fig. 2. Flow of cluster classification for grouping.

Y. Hu et al. / Mechanical Systems and Signal Processing 76-77 (2016) 729–741

733

With cluster analysis method, determining the dynamic lower threshold from SCADA data of a wind farm is possible

through fuzzy C-means algorithm. The flow of cluster classification for grouping is shown in Fig. 2.

The SCADA data of k WTGSs are the samples of cluster analysis, and the process of cluster classification has four steps:

Step 1: The rotor speed values of k WTGSs (n1, n2,…,nk) are extracted from SCADA data. In addition, the parameters of

fuzzy C-means algorithm, power exponent, maximum iterations, and number of first classification c ¼2 are set.

Step 2: The rotor speed values of k WTGSs (n1, n2,…, nk) are normalized for fuzzy C-means algorithm, and the group

results of cluster classification are acquired through iterative computations of fuzzy C-means algorithm.

Step 3: Every group is checked whether Δn oε or not. If “No,” let c¼c þ1, and step 2 is iterated until Δn oε. Otherwise,

the expected group D(i) (i ¼1, 2,…, c) result is obtained.

Step 4: The dynamic lower threshold is β1 ¼min(x(i)), where x(ij) stands for the monitoring data of temperature characteristic parameters that correspond to the component about j-th WTGS in group D(i). The small value denotes a good

condition of the component.

2.4. Deterioration degree with dynamic threshold and deterioration level for critical components

From the preceding dynamic upper and lower threshold, deterioration degree is related to both rotor speed n and

temperature characteristic parameters x in this paper. The deterioration degree of j-th WTGS in group D(i) can be calculated

as

g ðijÞ ðxðijÞ Þ ¼

xðijÞ minðxðiÞ Þ

;

f ðnðijÞ Þ minðxðiÞ Þ

ð7Þ

where f(n(ij)) and min(x(i)) are dynamic upper and dynamic lower thresholds, respectively; g(ij)(x(ij)) is the deterioration

degree of j-th WTGS in group D(i).

Deterioration degree is divided into four categories according to [13,14], namely, L¼ {Excellent, Good, Alert, Danger} ¼{l1,

l2, l3, l4.} to obtain the qualitative deterioration level of the critical component. “Excellent” indicates that the operational

component is in a good and generating condition at high efficiency, and all temperature data are functioning in a normal

operational range. “Good” indicates that the operational component is in the normal operating condition, yet a few temperature data may be abnormal. “Alert” indicates that the operational component generates electric energy condition at low

efficiency, numerous temperature data are beyond its normal operating range, and the operator must determine whether

any special action is warranted. “Danger” indicates that all temperature data are beyond the acceptable operating limits and

that continued operation at such levels can lead to imminent component damage and/or power system failure. The relationship between the deterioration level and the deterioration degree is defined as follows: l1 A [0,0.30), l2 A[0.30,0.55), l3 A

[0.55,0.80), l4 A [0.80,1).

3. Probability evaluation method of gradual deterioration changes

As the deterioration degree of a critical component worsens, the discrepancy of probability density distribution of the

deterioration degree appear obviously among different monitoring periods, and it can be used to reveal the trend of gradual

deterioration changes. In this section, from the direction of probability statistics, the probability density distribution of

deterioration degree is established through nonparametric estimation method. Both the corresponding maximum deterioration degrees of probability density function and the values of the conditional probability among different monitoring

periods are on behalf of the trend of gradual deterioration changes of a critical component.

3.1. Probability density function based on nonparametric estimation method

In general, probability density function includes parameter estimation and nonparametric estimation. Compared with

parametric estimation, nonparametric estimation is used widely, which does not need any preknowledge hypothesis for

variable distribution [17]. Hence, in this paper, the probability density function of deterioration degree can be established

through nonparametric estimation.

A time series of deterioration degrees of a critical component is {g(1), g(2), …, g(N)} in a monitoring period, and the

probability density function F can be obtained as follows [17]:

N

1 X

g gðiÞ

F ¼ f ðgÞ ¼

;

ð8Þ

K

hN i ¼ 1

h

where K denotes Gaussian kernel function; h40 is smoothing bandwidth parameter [18]; and N is the sample number of

a monitoring period.

If the significance level α(0 oαo1)can meet the cumulative probability Pc (gmin og ogmax)¼1 α, the interval [gmin,

gmax] is the bilateral confidence interval of the deterioration degree g, and 1 α stands for the confidence level of bilateral

734

Y. Hu et al. / Mechanical Systems and Signal Processing 76-77 (2016) 729–741

confidence interval. In addition, given that a monitoring period is shorter than whole lifetime, every deterioration degree

that is calculated in a monitoring period can be deemed a stationary stochastic process. N can be determined by the method

of mathematical statistics. At any time, deterioration degrees are independent of each other, and the deterioration degree g

must meet this law as presented [17]:

(

EðgÞ μ; DðgÞ σ 2

2 :

ð9Þ

EðgÞ ¼ μ; DðgÞ ¼ σN

According to Chebyshev inequality P c ðjg μj ZλÞ r σ 2 =ðNλ2 Þ, with any given significance level α, N for meeting the

relationship σ2/(Nλ2)r α exists, where μ is the mean of g, g is the average value of the sum of g(1), g(2), …, g(N), λ is a

deviation value from data to mean, α¼ 0.05, σ is the maximum value of standard deviation from the history g data, and λ is

three times the standard deviation of history g data.

Based on the previous statistics analysis work about the SCADA data from a wind farm through the aforementioned

method, the value N Z1000 can satisfy the need of establishing the probability density function.

3.2. Deterioration conditional probability of the critical component

In the process of gradual deterioration changes of a critical component, the curve of probability density function changes

with the condition of deterioration from f1 to f2, as shown in Fig. 3.

In Fig. 3, g1 and g2 are the corresponding maximum deterioration degree of f1 and f2, respectively, and δ is the absolute

difference value between g1 and g2. The larger the δ is, the smaller the overlapping area from f1 to f2 becomes. In this paper,

the conditional probability is used to indicate the deterioration probability of a critical component. The confidence interval

of f1 is assumed as [gmin, gmax] with the confidence level 1 α, and the cumulative probability P cðwÞ of fw can be calculated as

follows:

Z gmax

P ðwÞ

f w ðgÞdg;

ð10Þ

c ¼

gmin

f(g)

f1

Probability

f2

g1

g

g2

Deterioration degree

Fig. 3. Schematic of probability density function of deterioration degree for critical component.

g1

the 1st time series of

deterioration degree

f1(g)

the 2nd time series of

deterioration degree

f2(g)

[gmin, gmax]

g2

the 3rd time series of

deterioration degree

The method of

non-parametric

estimation

P2

g3

f3(g)

P3

...

...

...

the w-th time series of

deterioration degree

fw(g)

cumulative

probability

conditional

probability

...

gw

Fig. 4. Flowchart of gradual deterioration changes analysis for critical components.

Pw

Y. Hu et al. / Mechanical Systems and Signal Processing 76-77 (2016) 729–741

735

where w denote w-th time series of deterioration degrees. Therefore, the conditional probability P(w) can be calculated as

follows:

Pw ¼ 1 P ðwÞ

c

;

1α

ð11Þ

in which the larger the Pw is, the severer the component deteriorates. The conditional probability Pw represents increasing

deterioration possibility of gradual deterioration changes.

3.3. Gradual deterioration change flow of critical components

The difference of probability characteristic between the first and another monitoring period must be analyzed to acquire

the trend of gradual deterioration changes of a critical component. The corresponding maximum deterioration degree of

probability density function gw and conditional probability Pw from w-th time series of deterioration degrees {g(N*(w 1) þ

1), g(N*(w 1) þ2), …,g(N*(w 1) þN)} with N samples can be obtained through the flowchart in Fig. 4 based on the first

monitoring period. The flowchart is introduced by three steps.

Step 1: f1(g), g1, and [gmin, gmax] of the first monitoring period are calculated with nonparametric estimation method.

Step 2: Similarly, f2(g) and g2 about the second monitoring period are calculated, and the conditional probability P2 is

acquired according to Eqs. (10) and (11). The smaller the P2 is, the smaller the deterioration possibility of a critical

component is.

Step 3: Based on the first monitoring period, {g3, g4, …, gw} and {P3, P4, …, Pw} are calculated from third to w-th monitoring period repeatedly. Two data series, namely, {g3, g4, …, gw} and {P3, P4, …, Pw}, present the trend of gradual

deterioration changes of a critical component.

4. Case study

Two cases are investigated by using SCADA monitoring data of a wind farm with 33*1.5 MW WTGSs to validate the

effectiveness of this proposed method. The first case is about the generator rear bearing fault of WTGS 10, and the second

case is about the No. 1 main bearing fault of WTGS 23. The calculation results obtained at each step are graphically

introduced as follows to understand the proposed method.

4.1. Case I

In 01:42 29/03/2012, WTGS 10 stopped working. The generator rear bearing fault was found by checking the operational

records, and the incident was due to high temperature beyond maximum allowable value of 95 °C. Based on the operational

data of WTGS 10 from 10:00 15/06/2011 to 01:42 29/03/2012, the trend of gradual deterioration changes of generator rear

bearing was presented through the proposed method. To introduce the analysis process in detail, case I is shown with three

parts. 1) The acquired process of dynamic threshold and deterioration degree is introduced with an example of generator

rear bearing at practical WTGS 10 applications in 07:30 11/02/2012. 2) Dynamic threshold is compared with fixed threshold

through the operational data from 10:00 15/06/2011 to 15:00 15/06/2011. 3) Both deterioration levels of operational stages

and the gradual deterioration trend of generator rear bearing are obtained through the proposed method from 10:00 15/06/

2011 to 01:42 29/03/2012. The detailed contents of three parts are given as follows.

Part 1: The acquired process of deterioration degree through the dynamic threshold method

According to the dynamic threshold method, the dynamic upper threshold and the dynamic lower threshold are obtained

based on the operational data in 07:30 11/02/2012, so that the deterioration degree of this moment can be calculated.

Deterioration degree of

generator rear bearing ( )

95

90

85

80

75

actrual temperature data

fitting curve

70

65

60

10

11

12

13

14

15

16

17

18

Rotor speed (rpm)

Fig. 5. Data fitting curve of the generator rear bearing temperature upper threshold.

736

Y. Hu et al. / Mechanical Systems and Signal Processing 76-77 (2016) 729–741

1) Upper threshold β2 determination.

The relevant operational data of both rotor speed and generator rear bearing temperature are extracted before the

generator rear bearing fault occurred, and then the rotor speed range from minimum value (nmin ¼10 rpm) to maximum

value (nmax ¼18 rpm) is used to determine each bin through Eq. (2). The function of generator rear bearing temperature

variables with the change of rotor speed can be obtained through data fitting method according to all steps in Section 2.2.

The dynamic upper threshold can be obtained with

β2 ¼ f ðnÞ ¼ 0:2964n2 4:8551n þ 85:4187:

ð12Þ

The actual value and the fitting value are shown in Fig. 5, and the actual value fluctuates with the fitting curve on a small

scale.

2) Lower threshold β1 determination.

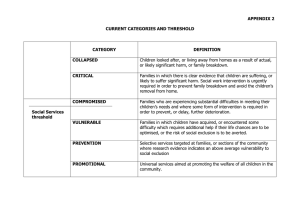

According to the flowchart of cluster classification in Fig. 2, except for WTGS 30, which has stopped working, the other

operational 32 WTGSs are used to join in the process of cluster classification, and the cluster results are as listed in Table 1.

Group 3 D(3) with WTGS 10 and WTGS 19 is composed of 18 WTGSs, and the minimum temperature value among 18 WTGSs

1

ð3Þ

belongs to WTGS 19, namely, the dynamic lower threshold is βð3Þ

1 ¼ minðx Þ ¼ 43:8 C in 07:30 11/02/2012.

3) Deterioration degree of generator rear bearing based on dynamic threshold.

Table1

Cluster classification results for a practical wind farm on 07:30 11/02/2012.

Group 1

Group 2

Group 3

Generator rear bearing

temperature (°C)

WTGS Rotor speed

(rpm)

Generator rear bearing

temperature (°C)

WTGS Rotor speed

(rpm)

Generator rear bearing

temperature (°C)

23

31

24

21

28

25

22

32

33

52.8

44.7

43.0

38.7

43.0

42.6

61.6

77.7

41.6

26

2

3

27

29

42.6

40.3

49.1

50.0

51.6

9

15

7

14

18

20

13

16

12

10

5

17

1

19

8

11

4

6

59.1

46.0

47.6

56.7

48.6

49.1

55.8

45.4

54.5

71.3

45.6

54.1

48.3

43.8

44.5

46.4

53.5

54.3

Generator rear bearing temperature(

/Rotor speed (rpm)

16.18

16.20

16.37

16.41

16.42

16.51

16.63

16.64

16.64

)

WTGS Rotor speed

(rpm)

16.83

16.88

16.94

16.96

17.07

17.17

17.26

17.26

17.29

17.31

17.31

17.36

17.36

7.37

7.39

17.40

17.42

17.42

17.42

17.51

17.53

17.55

17.58

100

80

60

40

20

0

0

200

400

600

800

1000

1200

1400

1600

Sampling time (min)

Fig. 6. Distribution of deterioration degree of generator rear bearing under sampling interval of 1 min.

Y. Hu et al. / Mechanical Systems and Signal Processing 76-77 (2016) 729–741

737

Deterioration degree

/Rotor speed 0.1*rpm

2

1.5

1

Rotor speed

Curve 1

Curve 2

0.5

0

0

200

400

600

800

1000

1200

1400

1600

Sampling time (min)

Interval number of deterioration degree

Fig. 7. Two curves of deterioration degree through fixed threshold and dynamic threshold.

200

frequency histogram

curve of Gaussian

distribution

150

100

50

0

0

0.1

0.2

0.3

0.4

0.5

Deterioration degree of generator rear bearing

Fig. 8. Frequency histogram and Gaussian distribution density function of generator rear bearing.

After obtaining the upper threshold and the lower threshold, the deterioration degree of generator rear bearing in 07:30

11/02/2012 can be calculated according to Eq. (7), as follows:

gð71:3Þ ¼

71:3 minðxð3Þ Þ

71:3 43:8

¼ 0:59:

¼

f ð17:39Þ minðxð3Þ Þ 90:6 43:8

The deterioration degrees of other monitoring periods can be obtained in a way similar to the preceding process.

Part 2: Comparison between the method of the dynamic threshold and the method of the fixed threshold

The part of operational data with the sampling time interval of 1 min, from 10:00 15/06/2011 to 15:00 15/06/2011, is

about the “Excellent” generator rear bearing, which was checked and repaired at 10:00 15/06/2011 [19]. Two time series of

deterioration degree can be obtained with the proposed dynamic threshold and the fixed threshold in Ref. [14]. Fig. 6

presents the comparison and analysis process. The fixed upper threshold and the fixed lower threshold are the maximum

temperature trigger value of 95 °C and minimum temperature value of 5 °C, respectively, according to the operational

requirement of WTGS. Compared with fixed threshold, dynamic thresholds change with rotor speed.

Two curves of deterioration degree, namely, curve 1 with fixed threshold and curve 2 with dynamic threshold, present

the difference in Fig. 7. Curve 1 obviously changes with rotor speed, and the fluctuant range of curve 1 is very wide from

0.25 to 0.48. Thus, identifying the real deterioration degree of generator rear bearing is difficult. However, in view of the

change of rotor speed, curve 2 seldom fluctuates near 0.23 greatly, and it can effectively reflect the real deterioration degree

of generator rear bearing.

Given that the value of deterioration degree is 0.23Al1 A[0,0.30), the deterioration level of generator rear bearing is

“Excellent” and consistent with the real operational condition. In addition, the frequency histogram and the Gaussian distribution

density function in Fig. 8 are obtained with the data of curve 2, which are nearly in accordance with Gaussian distribution.

Part 3: Probability evaluation of gradual deterioration changes of generator rear bearing

The operational SCADA data of generator rear bearing with the sampling time interval of 10 min, from normal condition

to faulted condition between 10:00 15/06/2011 and 01:42 29/03/2012, are used to calculate the deterioration degrees based

738

Y. Hu et al. / Mechanical Systems and Signal Processing 76-77 (2016) 729–741

Deterioration degree of

generator rear bearing

1.5

1

0.5

0

0

2000

4000

6000

8000

10000 12000 14000 16000 18000

Sampling time (10 min)

Corresponding deterioration degrees

/Conditional probability

Fig. 9. Distribution of deterioration degree of generator rear bearing under the sampling interval of 10 min.

65500 min

1

28000 min

95000 min

67000 min

Danger

0.8

Alert

0.6

0.4 Excellent

Good

0.2

0

0

44

100

conditional probability

corresponding deterioration degrees curve

175 200

231

300

350

Number of monitoring cycle

Fig. 10. Probability analysis result of gradual deterioration changes of generator rear bearing.

on the dynamic threshold, and the distribution of deterioration degrees of generator rear bearing is shown in Fig. 9. The

overall trend of deterioration degrees is rising sharply.

According the Section 3.1, the number of sample is N ¼1000, and the time interval among monitoring periods is 500 min.

With the proposed flow in Section 3.3, the distribution of corresponding maximum deterioration degrees of probability

density function and the distribution of conditional probability are shown in Fig. 10 for all monitoring periods. The analysis

process is presented by the following four stages to understand the trend of gradual deterioration changes in depth.

Stage 1: The deterioration level is “Excellent.” From 1 to 40, the deterioration degree and conditional probability are

constant nearly at 0.26 and 0.05, respectively. From 41 to 44, the deterioration degree and conditional probability rise

sharply and reach the value at 0.29 and 0.22 in 44. The trend of gradual deterioration changes of generator rear bearing

may change the deterioration level from “Excellent” to “Good.”

Stage 2: The deterioration level is “Good.” From 45 to 175, although two curves have fluctuation within a narrow range,

deterioration degree and conditional probability rise and reach nearly at 0.55 and 0.75 after 65,500 min for approximately

45.5 days. The trend of gradual deterioration changes of generator rear bearing may change the deterioration level from

“Good” to “Alert.”

Stage 3: The deterioration level is “Alert.” From 176 to 231, deterioration degree and conditional probability rise and reach

nearly at 0.79 and 0.99 after 28,000 min for approximately 19.4 days. The trend of gradual deterioration changes of

generator rear bearing may change the deterioration level from “Alert” to “Danger.”

Stage 4: The deterioration level is “Danger.” From 232 to 357, the deterioration degree rises and reaches nearly at 0.94

after 28,000 min for approximately 19.4 days, and the conditional probability is constant nearly at 0.99. In this stage, the

generator rear bearing runs in the state of serious deterioration until the monitoring temperature of generator rear

bearing is beyond 95 °C, and then the WTGS 10 is forced to stop.

In addition, the preceding steps indicate that “Alert” condition can be acquired before 95,000 min for approximately 66

days through the proposed method. Moreover, in the transient process among the deterioration levels, the conditional

probability P represents increasing deterioration possibility of gradual deterioration changes. The larger the P is, the severer

the component deteriorates. Moreover, the proposed method can reveal the gradual deterioration change process of generator rear bearing, which undergoes severe environment and alternating load in a long time, from quantitative change to

qualitative change.

Y. Hu et al. / Mechanical Systems and Signal Processing 76-77 (2016) 729–741

739

1.4

Deterioration degree of

No.1 main bearing

1.2

1

0.8

0.6

0.4

0.2

0

0

1

2

3

4

5

6

7

x 10

Sampling time (10 min)

Fig. 11. Distribution of deterioration degree of No.1 main bearing in WTGS 23 under sampling interval of 10 min.

500

Gaussian distribution curve of group 1

Gaussian distribution curve of group 2

Gaussian distribution curve of group 3

Interval number of

deterioration degree

400

Frequency histogram of group 1

Frequency histogram of group 2

Frequency histogram of group 3

300

200

100

0

0

0.2

0.4

0.6

0.8

1

Deterioration degree of No.1 main bearing

Fig. 12. Frequency histogram and Gaussian distribution density function of No. 1 main bearing.

4.2. Case II

In this case, the proposed assessment method was also applied to detect the early deterioration condition about the No.1

main bearing of WTGS 23. In 09:00 24/06/2012, the No.1 main bearing of WTGS 23 was seriously damaged with large noise

and high temperature of 61 °C, which is near the maximum allowable value of 65 °C, because of poor lubrication and

powder pollution. The operational SCADA data of the No.1 main bearing, with the sampling time interval of 10 min from

7:00 15/04/2009 to 09:00 24/10/2012, are used to calculate the deterioration degrees based on the dynamic threshold

method. The distribution of deterioration degrees of No.1 main bearing is shown in Fig. 11. In addition, frequency histogram

and the Gaussian distribution density function are made from the three groups of data in Fig. 11. Three groups of data are

from 1 to 10,000, 30,000 to 40,000 and 60,000 to 70,000, and the frequency histogram and the Gaussian distribution density

function are shown in Fig. 12.

Figs. 11 and 12 indicate the following:

1) The overall trend of deterioration degrees rises steadily with the deterioration of the No. 1 main bearing.

2) Gaussian density function translates with operational time, which presents the deterioration symptom of the No.1 main bearing at

early stages. Every group of Gaussian distribution density function is nearly consistent with the theoretical Gaussian distribution.

The whole trend of gradual deterioration changes is analyzed, and the result is shown in Fig. 13. Fig. 13 illustrates that a

clear result has been achieved: 1) Both the occurrence and further development of the deterioration conditions have been

clearly exhibited from “Excellent” to “Danger.” 2) The proposed method can reveal the gradual deterioration change process

of the No.1 main bearing, and “Alert” can be acquired before 3,555,000 min for approximately 247 days. 3) The conditional

probability P can represent the increasing deterioration possibility of gradual deterioration changes. Despite fluctuation over

a wide range, conditional probability P rise with the deterioration degrees.

5. Conclusions

Based on the operational temperature data from the SCADA system, the dynamic threshold method is proposed with the

data fitting and cluster classification method. The probability density functions of degradation degree are derived through

nonparametric estimation method, and the probability evaluation method of early deterioration condition for different

Y. Hu et al. / Mechanical Systems and Signal Processing 76-77 (2016) 729–741

Corresponding deterioration degrees

/Conditional probability

740

355500 min

251500 min

1

230500 min

125000 min

Danger

0.8

Alert

0.6

0.4

Good

0.2

0

conditional probability

corresponding deterioration degrees curve

Excellent

0

251

400

754 800

1000

1215

1400

Number of monitoring cycle

Fig. 13. Probability analysis result of progressive change of No.1 main bearing.

monitoring periods is presented. By using the online temperature data of an actual 1.5 MW WTGS, two cases are used to

validate the effectiveness of the proposed method. The major conclusions can be given as follows: (1) Compared with fixed

threshold, dynamic threshold can reflect the actual deterioration degree of critical component. (2) The trend of gradual

deterioration changes for critical component can be emerged by using the proposed method. (3) The proposed method can

evaluate the deterioration level of critical components early, which is helpful in improving O&M strategies and can further

increase the operational reliability for WTGSs. Besides, this idea is different from the traditional evaluation method used by

the much more kinds of information from the SCADA system, and the proposed method is also more practical and valuable

for the real WTGS.

Acknowledgments

This study is supported by the National Natural Science Foundation of China (51377184), the International Science and

Technology Cooperation Program of China (2013DFG61520), the Fundamental Research Funds for the Central Universities

(CDJXS10151152), the Fundamental Research Funds for the Central Universities (CDJZR12150074), the Integration and

Demonstration Program of Chongqing (CSTC2013JCSF70003), and Chongqing Graduate Student Research Innovation Project

(CYB14014). The authors are grateful for the supports.

References

[1] Wenxian Yang, Richard Court, Jiesheng Jiang, Wind turbine condition monitoring by the approach of SCADA data analysis, Renew. Energy 53 (2013)

365–376.

[2] Pierre Tchakoua, René Wamkeue, Mohand Ouhrouche, Fouad Slaoui-Hasnaoui, Tommy Andy Tameghe, Gabriel Ekemb, Wind turbine condition

monitoring: state-of-the-art review, new trends, and future challenges, Energies 7 (4) (2014) 2595–2630.

[3] Simon Hoell, Piotr Omenzetter, Optimal selection of autoregressive model coefficients for early damage detectability with an application to wind

turbine blades, Mech. Syst. Signal Process. 70 (2016) 557–577.

[4] I. Antoniadou, G. Manson, W.J. Staszewski, T. Barszcz, K. Worden, A time-frequency analysis approach for condition monitoring of a wind turbine

gearbox under varying load conditions, Mech. Syst. Signal Process. 64 (2015) 188–216.

[5] Zhang Zijun, Anoop Verma, Andrew Kusiak, Fault analysis and condition monitoring of the wind turbine gearbox, Energy Convers. IEEE Trans. 27 (2)

(2012) 526–535.

[6] Ahmed M. Kassem, Robust voltage control of a standalone wind energy conversion system based on functional model predictive approach, Int. J. Electr.

Power Energy Syst. 41 (1) (2012) 124–132.

[7] Wenxian Yang, Peter J. Tavner, Christopher J. Crabtree, Michael Wilkinson, Cost-effective condition monitoring for wind turbines, Ind. Electron. IEEE

Trans. 57 (1) (2010) 263–271.

[8] P.J. Tavner, Review of condition monitoring of rotating electrical machines, Electr. Power Appl. IET 2 (4) (2008) 215–247.

[9] Guo Peng, David Infield, Xiyun Yang, Wind turbine generator condition-monitoring using temperature trend analysis, Sustain. Energy IEEE Trans. 3 (1)

(2012) 124–133.

[10] A. Zaher, S.D.J. McArthur, David Infield, Y. Patel, Online wind turbine fault detection through automated SCADA data analysis, Wind Energy 12 (6)

(2009) 574–593.

[11] Andrew Kusiak, Anoop Verma, Analyzing bearing faults in wind turbines: a data-mining approach, Renew. Energy 48 (2012) 110–116.

[12] Mari Cruz Garcia, Miguel A. Sanz-Bobi, Javier del Pico, SIMAP: Intelligent system for predictive maintenance: application to the health condition

monitoring of a wind turbine gearbox, Comput. Ind. 57 (6) (2006) 552–568.

[13] Li Hui, Hu Yaogang, Yang Chao, Li Xuewei, Tang Xianhu, A matter-element assessment method of a grid-connected wind turbine drivern generator

system under on-line operating conditions, Autom. Electr. Power Syst. 35 (6) (2011) 81–85.

[14] Li Hui, Hu Yaogang, Tang Xianhu, Liu Zhixiang, Method for on-line operating conditions assessment for a grid- connected wind turbine generator

system, Proc. CSEE 30 (33) (2010) 103–109.

[15] Zhang Baohui, Li Guanghui, Wang Jin, Hao Zhiguo, Zhang Jinhua, Impact of wind farm integration on relay protection (2): DFIG-based wind farm

electromagnetic transient equivalent model, Electr. Power Autom. Equip. 33 (2) (2013) 1–7.

[16] Brandon Mauch, Jay Apt, Pedro M.S. Carvalho, Mitchell J. Small, An effective method for modeling wind power forecast uncertainty, Energy Syst. 4 (4)

(2013) 393–417.

Y. Hu et al. / Mechanical Systems and Signal Processing 76-77 (2016) 729–741

741

[17] Li Jiansheng, Liang Jun, Yun Zhihao, Han Xueshan, Zhong Feng, Probability analysis of gradual changes of equipment state based on electrical

information, Trans. China Electrotech. Soc. 28 (10) (2013) 355–363.

[18] A. Delaigle, Nonparametric kernel methods with errors-in-variables: constructing estimators, computing them, and avoiding common mistakes, Aust.

N.Z. J. Stat. 56 (2) (2014) 105–124.

[19] Xiao Yunqi, Wang Kunpeng, He Guanju, Sun Yanping, Yang Xiyun, Real-time health condition evaluation on wind turbines based on operational

condition recognition, Proc. CSEE 11 (2013) 88–95. þ15.

Yaogang Hu received the B.S. and M.S. degrees in electrical engineering from the Yanshan University and Chongqing University, China, in 2008 and 2011.

Currently, he is working toward the Ph.D. degree in electrical engineering at the Chongqing University, Chongqing, China. His research interests include

condition monitoring, fault diagnosis, lifetime prediction and performance assessment for wind turbine.