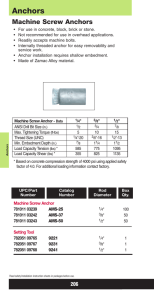

Project: BASE PLATE CONECTION DESIGN Project no: Author: Project data Project name BASE PLATE CONECTION DESIGN Project number Author Description Date 6/4/2023 Design code AISC 360-16 Material Steel A36, A572 Gr.55 Concrete 4000 psi 1 / 38 Project: BASE PLATE CONECTION DESIGN Project no: Author: Project item CON1 Design Name CON1 Description Analysis Stress, strain/ simplified loading Design code AISC - LRFD 2016 Beams and columns Name Cross-section β – Direction [°] γ - Pitch [°] α - Rotation [°] Offset ex [mm] Offset ey [mm] Offset ez [mm] Forces in M3 4 - HSS(Imp)8X2X1/8 0.0 -20.0 0.0 0 0 0 Node M4 5 - HSS(Imp)8X2X1/8 0.0 20.0 0.0 0 0 0 Node 2 / 38 Project: BASE PLATE CONECTION DESIGN Project no: Author: 3 / 38 Project: BASE PLATE CONECTION DESIGN Project no: Author: Cross-sections Name Material 4 - HSS(Imp)8X2X1/8 A36 5 - HSS(Imp)8X2X1/8 A36 4 / 38 Project: BASE PLATE CONECTION DESIGN Project no: Author: Cross-sections Name Material 4 - HSS(Imp)8X2X1/8 A36 5 - HSS(Imp)8X2X1/8 A36 Drawing Anchors Name Diameter [mm] Bolt assembly 20 A325M 20 A325M Gross area [mm2] fu [MPa] 20 830.0 314 Load effects (equilibrium not required) Name LE1 Member N [kN] Vy [kN] Vz [kN] Mx [kNm] My [kNm] Mz [kNm] M3 -1.0 3.5 0.0 -4.0 0.6 0.6 M4 0.0 0.0 0.0 0.0 0.0 0.0 M4 1.0 3.5 0.0 -4.0 0.6 0.6 Foundation block Item Value Unit CB 1 Dimensions 751 x 1219 mm Depth 400 mm Anchor 20 A325M Anchoring length 300 Shear force transfer Anchors mm 5 / 38 Project: BASE PLATE CONECTION DESIGN Project no: Author: Check Summary Name Value Check status Analysis 100.0% OK Plates 0.3 < 5.0% OK Anchors 32.1 < 100% OK Welds 75.7 < 100% OK Concrete block 1.5 < 100% OK Buckling Not calculated Plates Name Material fy [MPa] Thickness [mm] Loads σEd [MPa] εPl [%] σcEd [MPa] Check status M3 A36 248.2 3.2 LE1 223.9 0.3 0.0 OK M4 A36 248.2 3.2 LE1 223.9 0.3 0.0 OK BP1 A572 Gr.55 379.2 15.0 LE1 81.8 0.0 0.0 OK Design data fy [MPa] Material εlim [%] A36 248.2 5.0 A572 Gr.55 379.2 5.0 Symbol explanation εPl Plastic strain σcEd Contact stress σEd Eq. stress fy Yield strength εlim Limit of plastic strain 6 / 38 Project: BASE PLATE CONECTION DESIGN Project no: Author: Overall check, LE1 Strain check, LE1 7 / 38 Project: BASE PLATE CONECTION DESIGN Project no: Author: Equivalent stress, LE1 Anchors Shape Item Loads Nf [kN] V [kN] ϕNcbg [kN] ϕVcbg [kN] ϕVcp [kN] Utt [%] Uts [%] Utts [%] Status A1 LE1 0.0 0.7 - 77.3 475.1 0.0 9.1 1.8 OK A2 LE1 6.3 0.7 167.0 - 475.1 32.1 1.5 15.1 OK A3 LE1 0.0 1.1 - 77.3 475.1 0.0 9.1 1.8 OK A4 LE1 13.7 1.1 167.0 - 475.1 32.1 1.5 15.1 OK A5 LE1 0.0 1.5 - 77.3 475.1 0.0 9.1 1.8 OK A6 LE1 15.8 1.4 167.0 - 475.1 32.1 1.8 15.2 OK A7 LE1 0.0 1.2 - 77.3 475.1 0.0 9.1 1.8 OK A8 LE1 11.2 1.2 167.0 - 475.1 32.1 1.5 15.1 OK A9 LE1 0.0 0.5 - 77.3 475.1 0.0 9.1 1.8 OK A10 LE1 6.6 0.6 167.0 - 475.1 32.1 1.5 15.1 OK Design data Grade 20 A325M - 1 ϕNsa [kN] ϕVsa [kN] 142.3 79.3 8 / 38 Project: BASE PLATE CONECTION DESIGN Project no: Author: Symbol explanation Nf Tension force V Resultant of shear forces Vy, Vz in bolt ϕNcbg Concrete breakout strength in tension – ACI 318-14 – 17.4.2 ϕVcbg Concrete breakout strength in shear – ACI 318-14 – 17.5.2 ϕVcp Concrete pryout strength in shear – ACI 318-14 – 17.5.3 Utt Utilization in tension Uts Utilization in shear Utts Utilization in tension and shear ϕNsa Steel strength of anchor in tension - ACI 318-14 – 17.4.1 ϕVsa Steel strength of anchor in shear - ACI 318-14 – 17.5.1 Detailed result for A1 Anchor tensile resistance (ACI 318-14 – 17.4.1) ϕNsa = ϕ ⋅ Ase,N ⋅ futa = 142.3 kN Nf = ≥ 0.0 kN Where: ϕ = 0.70 – resistance factor Ase,N = 245 mm2 – tensile stress area futa = 830.0 MPa – specified tensile strength of anchor steel: futa = min(860 MPa, 1.9 ⋅ fya , fu ) , where: fya = 660.0 MPa – specified yield strength of anchor steel fu = 830.0 MPa – specified ultimate strength of anchor steel Shear resistance (ACI 318-14 – 17.5.1) ϕVsa = ϕ ⋅ 0.6 ⋅ Ase,V ⋅ futa = 79.3 kN ≥ V = 0.7 kN Where: ϕ = 0.65 – resistance factor Ase,V = 245 mm2 – tensile stress area futa = 830.0 MPa – specified tensile strength of anchor steel: futa = min(860 MPa, 1.9 ⋅ fya , fu ) , where: fya = 660.0 MPa – specified yield strength of anchor steel fu = 830.0 MPa – specified ultimate strength of anchor steel 9 / 38 Project: BASE PLATE CONECTION DESIGN Project no: Author: Concrete shear breakout check (ACI 318-14 – 17.5.2) The check is performed for group of anchors that form common shear breakout cone: A1, A3, A5, A7, A9 ϕVcbg = ϕ ⋅ AV c AV c0 ⋅ Ψec,V ⋅ Ψed,V ⋅ Ψc,V ⋅ Ψh,V ⋅ Ψα,V ⋅ Vbr = 77.3 kN ≥ Vg = 7.0 kN Where: Vg = 7.0 kN – sum of shear forces of anchors on common base plate ϕ = 0.65 – resistance factor AV c = 487600 mm2 – projected concrete failure area of an anchor or group of anchors AV c0 = 320000 mm2 – projected concrete failure area of one anchor when not limited by corner influences, spacing or member thickness Ψec,V = 1.00 – modification factor for anchor groups loaded eccentrically in shear: Ψec,V = 1 2⋅e′ 1+ 3⋅c V , where: a1 e′V = 1 mm – shear load eccentricity ha ca2,max s ca1 = 267 mm ≤ max ( 1.5 , 1.5 , 3 ) – edge distance in direction of the load ha ca2,max s ca1 = 267 mm ≤ max ( 1.5 , 1.5 , 3 ) – edge distance in direction of the load ca2,max = 325 mm – larger of the two distances to the edges parallel to the direction of loading s = 150 mm – maximum spacing in direction 2 between fasteners within a group Ψed,V = 0.93 – modification factor for edge effect: ca2 Ψed,V = 0.7 + 0.3 ⋅ 1.5⋅c ≤ 1 , where: a1 ha , ca2,max , s ) – edge distance in direction of the load ca1 = 267 mm ≤ max ( 1.5 1.5 3 ha ca2,max s ca1 = 267 mm ≤ max ( 1.5 , 1.5 , 3 ) – edge distance in direction of the load ca2,max = 325 mm – larger of the two distances to the edges parallel to the direction of loading s = 150 mm – maximum spacing in direction 2 between fasteners within a group ca2 = 300 mm – edge distance in direction perpendicular to the load Ψc,V = 1.00 – modification factor for concrete conditions Ψh,V = 1.00 – modification factor for anchors located in a shallow concrete member: 1.5⋅ca1 ha Ψh,V = ≥ 1 , where: ha = 400 mm – thickness of member in which an anchor is anchored measured parallel to anchor axis Ψα,V = 1.00 – modification factor for anchors loaded at an angle with the concrete edge 1 (cos αV )2 +(0.5⋅sin αV )2 Ψα,V = , where: αV = 1.7 ° – angle between direction of shear force and direction perpendicular to concrete edge Vb = 84.6 kN – basic concrete breakout strength of a single anchor in shear: 10 / 38 Project: BASE PLATE CONECTION DESIGN Project no: Author: Vb = min(0.6 ⋅ ( dlea )0.2 ⋅ λa ⋅ da ⋅ fc′ ⋅ c1.5 fc′ ⋅ c1.5 a1 , 3.7 ⋅ λa ⋅ a1 ) , where: le = 160 mm – effective length da = 20 mm – anchor diameter λa = 1.00 – modification factor for lightweight concrete fc′ = 27.6 MPa – concrete compressive strength ha ca2,max s ca1 = 267 mm ≤ max ( 1.5 , 1.5 , 3 ) – edge distance in direction of the load ha ca2,max s ca1 = 267 mm ≤ max ( 1.5 , 1.5 , 3 ) – edge distance in direction of the load ca2,max = 325 mm – larger of the two distances to the edges parallel to the direction of loading s = 150 mm – maximum spacing in direction 2 between fasteners within a group Concrete pryout resistance (ACI 318-14 – 17.5.3) The check is performed for group of anchors on common base plate ϕVcp = ϕ ⋅ kcp ⋅ Ncp = 475.1 kN ≥ Vg = 7.0 kN Where: ϕ = 0.65 – resistance factor kcp = 2.00 – concrete pry-out factor Ncp = 365.5 kN – concrete cone tension break-out resistance in case all anchors are in tension Vg = 7.0 kN – sum of shear forces of anchors on common base plate Interaction of tensile and shear forces (ACI 318-14 – R17.6) Utt 5/3 + Uts 5/3 = 0.02 ≤ 1.0 Where: Utt = 0.00 – maximum ratio of factored tensile force and tensile resistance determined from all appropriate failure modes Uts = 0.09 – maximum ratio of factored shear force and shear resistance determined from all appropriate failure modes Detailed result for A2 Anchor tensile resistance (ACI 318-14 – 17.4.1) ϕNsa = ϕ ⋅ Ase,N ⋅ futa = 142.3 kN Nf = ≥ 6.3 kN Where: ϕ = 0.70 – resistance factor Ase,N = 245 mm2 – tensile stress area futa = 830.0 MPa – specified tensile strength of anchor steel: futa = min(860 MPa, 1.9 ⋅ fya , fu ) , where: fya = 660.0 MPa – specified yield strength of anchor steel fu = 830.0 MPa – specified ultimate strength of anchor steel 11 / 38 Project: BASE PLATE CONECTION DESIGN Project no: Author: Concrete breakout resistance of anchor in tension (ACI 318-14 – 17.4.2) The check is performed for group of anchors that form common tension breakout cone: A2, A4, A6, A8, A10 ϕNcbg = ϕ ⋅ AN c AN c0 ⋅ Ψed,N ⋅ Ψec,N ⋅ Ψc,N ⋅ Nb = 167.0 kN ≥ Nf g = 53.6 kN Where: Nf g = 53.6 kN – sum of tension forces of anchors with common concrete breakout cone area ϕ = 0.70 – resistance factor AN c = 749070 mm2 – concrete breakout cone area for group of anchors AN c0 = 422500 mm2 – concrete breakout cone area for single anchor not influenced by edges Ψed,N = 0.97 – modification factor for edge distance: a,min Ψed,N = min(0.7 + 0.3⋅c 1.5⋅hef , 1) , where: ca,min = 290 mm – minimum distance from the anchor to the edge s hef = min(hemb , max( ca,max 1.5 , 3 )) = 217 mm – depth of embedment, where: hemb = 300 mm – anchor length ca,max = 325 mm – maximum distance from the anchor to one of the three closest edges s = 144 mm – maximum spacing between anchors Ψec,N = 0.83 – modification factor for eccentrically loaded group of anchors Ψec,N = Ψecx,N ⋅ Ψecy,N , where: Ψecx,N = 2⋅e1 x,N = 0.83 – modification factor that depends on eccentricity in x-direction 1+ 3⋅hef ex,N = 66 mm – tension load eccentricity in x-direction Ψecy,N = 2⋅e1 y,N = 1.00 – modification factor that depends on eccentricity in y-direction 1+ 3⋅hef ey,N = 0 mm – tension load eccentricity in y-direction hef = 217 mm – depth of embedment Ψc,N = 1.00 – modification factor for concrete conditions Nb = 167.5 kN – basic concrete breakout strength of a single anchor in tension: Nb = kc ⋅ λa ⋅ fc′ ⋅ h1.5 ef , where: kc = 10.0 – coefficient for cast-in anchors λa = 1.00 – modification factor for lightweight concrete fc′ = 27.6 MPa – concrete compressive strength hef = 217 mm – depth of embedment 12 / 38 Project: BASE PLATE CONECTION DESIGN Project no: Author: Shear resistance (ACI 318-14 – 17.5.1) ϕVsa = ϕ ⋅ 0.6 ⋅ Ase,V ⋅ futa = 79.3 kN ≥ V = 0.7 kN Where: ϕ = 0.65 – resistance factor Ase,V = 245 mm2 – tensile stress area futa = 830.0 MPa – specified tensile strength of anchor steel: futa = min(860 MPa, 1.9 ⋅ fya , fu ) , where: fya = 660.0 MPa – specified yield strength of anchor steel fu = 830.0 MPa – specified ultimate strength of anchor steel Concrete pryout resistance (ACI 318-14 – 17.5.3) The check is performed for group of anchors on common base plate ϕVcp = ϕ ⋅ kcp ⋅ Ncp = 475.1 kN ≥ Vg = 7.0 kN Where: ϕ = 0.65 – resistance factor kcp = 2.00 – concrete pry-out factor Ncp = 365.5 kN – concrete cone tension break-out resistance in case all anchors are in tension Vg = 7.0 kN – sum of shear forces of anchors on common base plate Interaction of tensile and shear forces (ACI 318-14 – R17.6) Utt 5/3 + Uts 5/3 = 0.15 ≤ 1.0 Where: Utt = 0.32 – maximum ratio of factored tensile force and tensile resistance determined from all appropriate failure modes Uts = 0.01 – maximum ratio of factored shear force and shear resistance determined from all appropriate failure modes Detailed result for A3 Anchor tensile resistance (ACI 318-14 – 17.4.1) ϕNsa = ϕ ⋅ Ase,N ⋅ futa = 142.3 kN Nf = ≥ 0.0 kN Where: ϕ = 0.70 – resistance factor Ase,N = 245 mm2 – tensile stress area futa = 830.0 MPa – specified tensile strength of anchor steel: futa = min(860 MPa, 1.9 ⋅ fya , fu ) , where: fya = 660.0 MPa – specified yield strength of anchor steel fu = 830.0 MPa – specified ultimate strength of anchor steel 13 / 38 Project: BASE PLATE CONECTION DESIGN Project no: Author: Shear resistance (ACI 318-14 – 17.5.1) ϕVsa = ϕ ⋅ 0.6 ⋅ Ase,V ⋅ futa = 79.3 kN ≥ V = 1.1 kN Where: ϕ = 0.65 – resistance factor Ase,V = 245 mm2 – tensile stress area futa = 830.0 MPa – specified tensile strength of anchor steel: futa = min(860 MPa, 1.9 ⋅ fya , fu ) , where: fya = 660.0 MPa – specified yield strength of anchor steel fu = 830.0 MPa – specified ultimate strength of anchor steel 14 / 38 Project: BASE PLATE CONECTION DESIGN Project no: Author: Concrete shear breakout check (ACI 318-14 – 17.5.2) The check is performed for group of anchors that form common shear breakout cone: A1, A3, A5, A7, A9 ϕVcbg = ϕ ⋅ AV c AV c0 ⋅ Ψec,V ⋅ Ψed,V ⋅ Ψc,V ⋅ Ψh,V ⋅ Ψα,V ⋅ Vbr = 77.3 kN ≥ Vg = 7.0 kN Where: Vg = 7.0 kN – sum of shear forces of anchors on common base plate ϕ = 0.65 – resistance factor AV c = 487600 mm2 – projected concrete failure area of an anchor or group of anchors AV c0 = 320000 mm2 – projected concrete failure area of one anchor when not limited by corner influences, spacing or member thickness Ψec,V = 1.00 – modification factor for anchor groups loaded eccentrically in shear: Ψec,V = 1 2⋅e′ 1+ 3⋅c V , where: a1 e′V = 1 mm – shear load eccentricity ha ca2,max s ca1 = 267 mm ≤ max ( 1.5 , 1.5 , 3 ) – edge distance in direction of the load ha ca2,max s ca1 = 267 mm ≤ max ( 1.5 , 1.5 , 3 ) – edge distance in direction of the load ca2,max = 325 mm – larger of the two distances to the edges parallel to the direction of loading s = 150 mm – maximum spacing in direction 2 between fasteners within a group Ψed,V = 0.93 – modification factor for edge effect: ca2 Ψed,V = 0.7 + 0.3 ⋅ 1.5⋅c ≤ 1 , where: a1 ha , ca2,max , s ) – edge distance in direction of the load ca1 = 267 mm ≤ max ( 1.5 1.5 3 ha ca2,max s ca1 = 267 mm ≤ max ( 1.5 , 1.5 , 3 ) – edge distance in direction of the load ca2,max = 325 mm – larger of the two distances to the edges parallel to the direction of loading s = 150 mm – maximum spacing in direction 2 between fasteners within a group ca2 = 300 mm – edge distance in direction perpendicular to the load Ψc,V = 1.00 – modification factor for concrete conditions Ψh,V = 1.00 – modification factor for anchors located in a shallow concrete member: 1.5⋅ca1 ha Ψh,V = ≥ 1 , where: ha = 400 mm – thickness of member in which an anchor is anchored measured parallel to anchor axis Ψα,V = 1.00 – modification factor for anchors loaded at an angle with the concrete edge 1 (cos αV )2 +(0.5⋅sin αV )2 Ψα,V = , where: αV = 1.7 ° – angle between direction of shear force and direction perpendicular to concrete edge Vb = 84.6 kN – basic concrete breakout strength of a single anchor in shear: 15 / 38 Project: BASE PLATE CONECTION DESIGN Project no: Author: Vb = min(0.6 ⋅ ( dlea )0.2 ⋅ λa ⋅ da ⋅ fc′ ⋅ c1.5 fc′ ⋅ c1.5 a1 , 3.7 ⋅ λa ⋅ a1 ) , where: le = 160 mm – effective length da = 20 mm – anchor diameter λa = 1.00 – modification factor for lightweight concrete fc′ = 27.6 MPa – concrete compressive strength ha ca2,max s ca1 = 267 mm ≤ max ( 1.5 , 1.5 , 3 ) – edge distance in direction of the load ha ca2,max s ca1 = 267 mm ≤ max ( 1.5 , 1.5 , 3 ) – edge distance in direction of the load ca2,max = 325 mm – larger of the two distances to the edges parallel to the direction of loading s = 150 mm – maximum spacing in direction 2 between fasteners within a group Concrete pryout resistance (ACI 318-14 – 17.5.3) The check is performed for group of anchors on common base plate ϕVcp = ϕ ⋅ kcp ⋅ Ncp = 475.1 kN ≥ Vg = 7.0 kN Where: ϕ = 0.65 – resistance factor kcp = 2.00 – concrete pry-out factor Ncp = 365.5 kN – concrete cone tension break-out resistance in case all anchors are in tension Vg = 7.0 kN – sum of shear forces of anchors on common base plate Interaction of tensile and shear forces (ACI 318-14 – R17.6) Utt 5/3 + Uts 5/3 = 0.02 ≤ 1.0 Where: Utt = 0.00 – maximum ratio of factored tensile force and tensile resistance determined from all appropriate failure modes Uts = 0.09 – maximum ratio of factored shear force and shear resistance determined from all appropriate failure modes Detailed result for A4 Anchor tensile resistance (ACI 318-14 – 17.4.1) ϕNsa = ϕ ⋅ Ase,N ⋅ futa = 142.3 kN Nf = ≥ 13.7 kN Where: ϕ = 0.70 Ase,N = – resistance factor 245 mm2 – tensile stress area futa = 830.0 MPa – specified tensile strength of anchor steel: futa = min(860 MPa, 1.9 ⋅ fya , fu ) , where: fya = 660.0 MPa – specified yield strength of anchor steel fu = 830.0 MPa – specified ultimate strength of anchor steel 16 / 38 Project: BASE PLATE CONECTION DESIGN Project no: Author: Concrete breakout resistance of anchor in tension (ACI 318-14 – 17.4.2) The check is performed for group of anchors that form common tension breakout cone: A2, A4, A6, A8, A10 ϕNcbg = ϕ ⋅ AN c AN c0 ⋅ Ψed,N ⋅ Ψec,N ⋅ Ψc,N ⋅ Nb = 167.0 kN ≥ Nf g = 53.6 kN Where: Nf g = 53.6 kN – sum of tension forces of anchors with common concrete breakout cone area ϕ = 0.70 – resistance factor AN c = 749070 mm2 – concrete breakout cone area for group of anchors AN c0 = 422500 mm2 – concrete breakout cone area for single anchor not influenced by edges Ψed,N = 0.97 – modification factor for edge distance: a,min Ψed,N = min(0.7 + 0.3⋅c 1.5⋅hef , 1) , where: ca,min = 290 mm – minimum distance from the anchor to the edge s hef = min(hemb , max( ca,max 1.5 , 3 )) = 217 mm – depth of embedment, where: hemb = 300 mm – anchor length ca,max = 325 mm – maximum distance from the anchor to one of the three closest edges s = 144 mm – maximum spacing between anchors Ψec,N = 0.83 – modification factor for eccentrically loaded group of anchors Ψec,N = Ψecx,N ⋅ Ψecy,N , where: Ψecx,N = 2⋅e1 x,N = 0.83 – modification factor that depends on eccentricity in x-direction 1+ 3⋅hef ex,N = 66 mm – tension load eccentricity in x-direction Ψecy,N = 2⋅e1 y,N = 1.00 – modification factor that depends on eccentricity in y-direction 1+ 3⋅hef ey,N = 0 mm – tension load eccentricity in y-direction hef = 217 mm – depth of embedment Ψc,N = 1.00 – modification factor for concrete conditions Nb = 167.5 kN – basic concrete breakout strength of a single anchor in tension: Nb = kc ⋅ λa ⋅ fc′ ⋅ h1.5 ef , where: kc = 10.0 – coefficient for cast-in anchors λa = 1.00 – modification factor for lightweight concrete fc′ = 27.6 MPa – concrete compressive strength hef = 217 mm – depth of embedment 17 / 38 Project: BASE PLATE CONECTION DESIGN Project no: Author: Shear resistance (ACI 318-14 – 17.5.1) ϕVsa = ϕ ⋅ 0.6 ⋅ Ase,V ⋅ futa = 79.3 kN ≥ V = 1.1 kN Where: ϕ = 0.65 – resistance factor Ase,V = 245 mm2 – tensile stress area futa = 830.0 MPa – specified tensile strength of anchor steel: futa = min(860 MPa, 1.9 ⋅ fya , fu ) , where: fya = 660.0 MPa – specified yield strength of anchor steel fu = 830.0 MPa – specified ultimate strength of anchor steel Concrete pryout resistance (ACI 318-14 – 17.5.3) The check is performed for group of anchors on common base plate ϕVcp = ϕ ⋅ kcp ⋅ Ncp = 475.1 kN ≥ Vg = 7.0 kN Where: ϕ = 0.65 – resistance factor kcp = 2.00 – concrete pry-out factor Ncp = 365.5 kN – concrete cone tension break-out resistance in case all anchors are in tension Vg = 7.0 kN – sum of shear forces of anchors on common base plate Interaction of tensile and shear forces (ACI 318-14 – R17.6) Utt 5/3 + Uts 5/3 = 0.15 ≤ 1.0 Where: Utt = 0.32 – maximum ratio of factored tensile force and tensile resistance determined from all appropriate failure modes Uts = 0.01 – maximum ratio of factored shear force and shear resistance determined from all appropriate failure modes Detailed result for A5 Anchor tensile resistance (ACI 318-14 – 17.4.1) ϕNsa = ϕ ⋅ Ase,N ⋅ futa = 142.3 kN Nf = ≥ 0.0 kN Where: ϕ = 0.70 – resistance factor Ase,N = 245 mm2 – tensile stress area futa = 830.0 MPa – specified tensile strength of anchor steel: futa = min(860 MPa, 1.9 ⋅ fya , fu ) , where: fya = 660.0 MPa – specified yield strength of anchor steel fu = 830.0 MPa – specified ultimate strength of anchor steel 18 / 38 Project: BASE PLATE CONECTION DESIGN Project no: Author: Shear resistance (ACI 318-14 – 17.5.1) ϕVsa = ϕ ⋅ 0.6 ⋅ Ase,V ⋅ futa = 79.3 kN ≥ V = 1.5 kN Where: ϕ = 0.65 – resistance factor Ase,V = 245 mm2 – tensile stress area futa = 830.0 MPa – specified tensile strength of anchor steel: futa = min(860 MPa, 1.9 ⋅ fya , fu ) , where: fya = 660.0 MPa – specified yield strength of anchor steel fu = 830.0 MPa – specified ultimate strength of anchor steel 19 / 38 Project: BASE PLATE CONECTION DESIGN Project no: Author: Concrete shear breakout check (ACI 318-14 – 17.5.2) The check is performed for group of anchors that form common shear breakout cone: A1, A3, A5, A7, A9 ϕVcbg = ϕ ⋅ AV c AV c0 ⋅ Ψec,V ⋅ Ψed,V ⋅ Ψc,V ⋅ Ψh,V ⋅ Ψα,V ⋅ Vbr = 77.3 kN ≥ Vg = 7.0 kN Where: Vg = 7.0 kN – sum of shear forces of anchors on common base plate ϕ = 0.65 – resistance factor AV c = 487600 mm2 – projected concrete failure area of an anchor or group of anchors AV c0 = 320000 mm2 – projected concrete failure area of one anchor when not limited by corner influences, spacing or member thickness Ψec,V = 1.00 – modification factor for anchor groups loaded eccentrically in shear: Ψec,V = 1 2⋅e′ 1+ 3⋅c V , where: a1 e′V = 1 mm – shear load eccentricity ha ca2,max s ca1 = 267 mm ≤ max ( 1.5 , 1.5 , 3 ) – edge distance in direction of the load ha ca2,max s ca1 = 267 mm ≤ max ( 1.5 , 1.5 , 3 ) – edge distance in direction of the load ca2,max = 325 mm – larger of the two distances to the edges parallel to the direction of loading s = 150 mm – maximum spacing in direction 2 between fasteners within a group Ψed,V = 0.93 – modification factor for edge effect: ca2 Ψed,V = 0.7 + 0.3 ⋅ 1.5⋅c ≤ 1 , where: a1 ha , ca2,max , s ) – edge distance in direction of the load ca1 = 267 mm ≤ max ( 1.5 1.5 3 ha ca2,max s ca1 = 267 mm ≤ max ( 1.5 , 1.5 , 3 ) – edge distance in direction of the load ca2,max = 325 mm – larger of the two distances to the edges parallel to the direction of loading s = 150 mm – maximum spacing in direction 2 between fasteners within a group ca2 = 300 mm – edge distance in direction perpendicular to the load Ψc,V = 1.00 – modification factor for concrete conditions Ψh,V = 1.00 – modification factor for anchors located in a shallow concrete member: 1.5⋅ca1 ha Ψh,V = ≥ 1 , where: ha = 400 mm – thickness of member in which an anchor is anchored measured parallel to anchor axis Ψα,V = 1.00 – modification factor for anchors loaded at an angle with the concrete edge 1 (cos αV )2 +(0.5⋅sin αV )2 Ψα,V = , where: αV = 1.7 ° – angle between direction of shear force and direction perpendicular to concrete edge Vb = 84.6 kN – basic concrete breakout strength of a single anchor in shear: 20 / 38 Project: BASE PLATE CONECTION DESIGN Project no: Author: Vb = min(0.6 ⋅ ( dlea )0.2 ⋅ λa ⋅ da ⋅ fc′ ⋅ c1.5 fc′ ⋅ c1.5 a1 , 3.7 ⋅ λa ⋅ a1 ) , where: le = 160 mm – effective length da = 20 mm – anchor diameter λa = 1.00 – modification factor for lightweight concrete fc′ = 27.6 MPa – concrete compressive strength ha ca2,max s ca1 = 267 mm ≤ max ( 1.5 , 1.5 , 3 ) – edge distance in direction of the load ha ca2,max s ca1 = 267 mm ≤ max ( 1.5 , 1.5 , 3 ) – edge distance in direction of the load ca2,max = 325 mm – larger of the two distances to the edges parallel to the direction of loading s = 150 mm – maximum spacing in direction 2 between fasteners within a group Concrete pryout resistance (ACI 318-14 – 17.5.3) The check is performed for group of anchors on common base plate ϕVcp = ϕ ⋅ kcp ⋅ Ncp = 475.1 kN ≥ Vg = 7.0 kN Where: ϕ = 0.65 – resistance factor kcp = 2.00 – concrete pry-out factor Ncp = 365.5 kN – concrete cone tension break-out resistance in case all anchors are in tension Vg = 7.0 kN – sum of shear forces of anchors on common base plate Interaction of tensile and shear forces (ACI 318-14 – R17.6) Utt 5/3 + Uts 5/3 = 0.02 ≤ 1.0 Where: Utt = 0.00 – maximum ratio of factored tensile force and tensile resistance determined from all appropriate failure modes Uts = 0.09 – maximum ratio of factored shear force and shear resistance determined from all appropriate failure modes Detailed result for A6 Anchor tensile resistance (ACI 318-14 – 17.4.1) ϕNsa = ϕ ⋅ Ase,N ⋅ futa = 142.3 kN Nf = ≥ 15.8 kN Where: ϕ = 0.70 – resistance factor Ase,N = 245 mm2 – tensile stress area futa = 830.0 MPa – specified tensile strength of anchor steel: futa = min(860 MPa, 1.9 ⋅ fya , fu ) , where: fya = 660.0 MPa – specified yield strength of anchor steel fu = 830.0 MPa – specified ultimate strength of anchor steel 21 / 38 Project: BASE PLATE CONECTION DESIGN Project no: Author: Concrete breakout resistance of anchor in tension (ACI 318-14 – 17.4.2) The check is performed for group of anchors that form common tension breakout cone: A2, A4, A6, A8, A10 ϕNcbg = ϕ ⋅ AN c AN c0 ⋅ Ψed,N ⋅ Ψec,N ⋅ Ψc,N ⋅ Nb = 167.0 kN ≥ Nf g = 53.6 kN Where: Nf g = 53.6 kN – sum of tension forces of anchors with common concrete breakout cone area ϕ = 0.70 – resistance factor AN c = 749070 mm2 – concrete breakout cone area for group of anchors AN c0 = 422500 mm2 – concrete breakout cone area for single anchor not influenced by edges Ψed,N = 0.97 – modification factor for edge distance: a,min Ψed,N = min(0.7 + 0.3⋅c 1.5⋅hef , 1) , where: ca,min = 290 mm – minimum distance from the anchor to the edge s hef = min(hemb , max( ca,max 1.5 , 3 )) = 217 mm – depth of embedment, where: hemb = 300 mm – anchor length ca,max = 325 mm – maximum distance from the anchor to one of the three closest edges s = 144 mm – maximum spacing between anchors Ψec,N = 0.83 – modification factor for eccentrically loaded group of anchors Ψec,N = Ψecx,N ⋅ Ψecy,N , where: Ψecx,N = 2⋅e1 x,N = 0.83 – modification factor that depends on eccentricity in x-direction 1+ 3⋅hef ex,N = 66 mm – tension load eccentricity in x-direction Ψecy,N = 2⋅e1 y,N = 1.00 – modification factor that depends on eccentricity in y-direction 1+ 3⋅hef ey,N = 0 mm – tension load eccentricity in y-direction hef = 217 mm – depth of embedment Ψc,N = 1.00 – modification factor for concrete conditions Nb = 167.5 kN – basic concrete breakout strength of a single anchor in tension: Nb = kc ⋅ λa ⋅ fc′ ⋅ h1.5 ef , where: kc = 10.0 – coefficient for cast-in anchors λa = 1.00 – modification factor for lightweight concrete fc′ = 27.6 MPa – concrete compressive strength hef = 217 mm – depth of embedment 22 / 38 Project: BASE PLATE CONECTION DESIGN Project no: Author: Shear resistance (ACI 318-14 – 17.5.1) ϕVsa = ϕ ⋅ 0.6 ⋅ Ase,V ⋅ futa = 79.3 kN ≥ V = 1.4 kN Where: ϕ = 0.65 – resistance factor Ase,V = 245 mm2 – tensile stress area futa = 830.0 MPa – specified tensile strength of anchor steel: futa = min(860 MPa, 1.9 ⋅ fya , fu ) , where: fya = 660.0 MPa – specified yield strength of anchor steel fu = 830.0 MPa – specified ultimate strength of anchor steel Concrete pryout resistance (ACI 318-14 – 17.5.3) The check is performed for group of anchors on common base plate ϕVcp = ϕ ⋅ kcp ⋅ Ncp = 475.1 kN ≥ Vg = 7.0 kN Where: ϕ = 0.65 – resistance factor kcp = 2.00 – concrete pry-out factor Ncp = 365.5 kN – concrete cone tension break-out resistance in case all anchors are in tension Vg = 7.0 kN – sum of shear forces of anchors on common base plate Interaction of tensile and shear forces (ACI 318-14 – R17.6) Utt 5/3 + Uts 5/3 = 0.15 ≤ 1.0 Where: Utt = 0.32 – maximum ratio of factored tensile force and tensile resistance determined from all appropriate failure modes Uts = 0.02 – maximum ratio of factored shear force and shear resistance determined from all appropriate failure modes Detailed result for A7 Anchor tensile resistance (ACI 318-14 – 17.4.1) ϕNsa = ϕ ⋅ Ase,N ⋅ futa = 142.3 kN Nf = ≥ 0.0 kN Where: ϕ = 0.70 – resistance factor Ase,N = 245 mm2 – tensile stress area futa = 830.0 MPa – specified tensile strength of anchor steel: futa = min(860 MPa, 1.9 ⋅ fya , fu ) , where: fya = 660.0 MPa – specified yield strength of anchor steel fu = 830.0 MPa – specified ultimate strength of anchor steel 23 / 38 Project: BASE PLATE CONECTION DESIGN Project no: Author: Shear resistance (ACI 318-14 – 17.5.1) ϕVsa = ϕ ⋅ 0.6 ⋅ Ase,V ⋅ futa = 79.3 kN ≥ V = 1.2 kN Where: ϕ = 0.65 – resistance factor Ase,V = 245 mm2 – tensile stress area futa = 830.0 MPa – specified tensile strength of anchor steel: futa = min(860 MPa, 1.9 ⋅ fya , fu ) , where: fya = 660.0 MPa – specified yield strength of anchor steel fu = 830.0 MPa – specified ultimate strength of anchor steel 24 / 38 Project: BASE PLATE CONECTION DESIGN Project no: Author: Concrete shear breakout check (ACI 318-14 – 17.5.2) The check is performed for group of anchors that form common shear breakout cone: A1, A3, A5, A7, A9 ϕVcbg = ϕ ⋅ AV c AV c0 ⋅ Ψec,V ⋅ Ψed,V ⋅ Ψc,V ⋅ Ψh,V ⋅ Ψα,V ⋅ Vbr = 77.3 kN ≥ Vg = 7.0 kN Where: Vg = 7.0 kN – sum of shear forces of anchors on common base plate ϕ = 0.65 – resistance factor AV c = 487600 mm2 – projected concrete failure area of an anchor or group of anchors AV c0 = 320000 mm2 – projected concrete failure area of one anchor when not limited by corner influences, spacing or member thickness Ψec,V = 1.00 – modification factor for anchor groups loaded eccentrically in shear: Ψec,V = 1 2⋅e′ 1+ 3⋅c V , where: a1 e′V = 1 mm – shear load eccentricity ha ca2,max s ca1 = 267 mm ≤ max ( 1.5 , 1.5 , 3 ) – edge distance in direction of the load ha ca2,max s ca1 = 267 mm ≤ max ( 1.5 , 1.5 , 3 ) – edge distance in direction of the load ca2,max = 325 mm – larger of the two distances to the edges parallel to the direction of loading s = 150 mm – maximum spacing in direction 2 between fasteners within a group Ψed,V = 0.93 – modification factor for edge effect: ca2 Ψed,V = 0.7 + 0.3 ⋅ 1.5⋅c ≤ 1 , where: a1 ha , ca2,max , s ) – edge distance in direction of the load ca1 = 267 mm ≤ max ( 1.5 1.5 3 ha ca2,max s ca1 = 267 mm ≤ max ( 1.5 , 1.5 , 3 ) – edge distance in direction of the load ca2,max = 325 mm – larger of the two distances to the edges parallel to the direction of loading s = 150 mm – maximum spacing in direction 2 between fasteners within a group ca2 = 300 mm – edge distance in direction perpendicular to the load Ψc,V = 1.00 – modification factor for concrete conditions Ψh,V = 1.00 – modification factor for anchors located in a shallow concrete member: 1.5⋅ca1 ha Ψh,V = ≥ 1 , where: ha = 400 mm – thickness of member in which an anchor is anchored measured parallel to anchor axis Ψα,V = 1.00 – modification factor for anchors loaded at an angle with the concrete edge 1 (cos αV )2 +(0.5⋅sin αV )2 Ψα,V = , where: αV = 1.7 ° – angle between direction of shear force and direction perpendicular to concrete edge Vb = 84.6 kN – basic concrete breakout strength of a single anchor in shear: 25 / 38 Project: BASE PLATE CONECTION DESIGN Project no: Author: Vb = min(0.6 ⋅ ( dlea )0.2 ⋅ λa ⋅ da ⋅ fc′ ⋅ c1.5 fc′ ⋅ c1.5 a1 , 3.7 ⋅ λa ⋅ a1 ) , where: le = 160 mm – effective length da = 20 mm – anchor diameter λa = 1.00 – modification factor for lightweight concrete fc′ = 27.6 MPa – concrete compressive strength ha ca2,max s ca1 = 267 mm ≤ max ( 1.5 , 1.5 , 3 ) – edge distance in direction of the load ha ca2,max s ca1 = 267 mm ≤ max ( 1.5 , 1.5 , 3 ) – edge distance in direction of the load ca2,max = 325 mm – larger of the two distances to the edges parallel to the direction of loading s = 150 mm – maximum spacing in direction 2 between fasteners within a group Concrete pryout resistance (ACI 318-14 – 17.5.3) The check is performed for group of anchors on common base plate ϕVcp = ϕ ⋅ kcp ⋅ Ncp = 475.1 kN ≥ Vg = 7.0 kN Where: ϕ = 0.65 – resistance factor kcp = 2.00 – concrete pry-out factor Ncp = 365.5 kN – concrete cone tension break-out resistance in case all anchors are in tension Vg = 7.0 kN – sum of shear forces of anchors on common base plate Interaction of tensile and shear forces (ACI 318-14 – R17.6) Utt 5/3 + Uts 5/3 = 0.02 ≤ 1.0 Where: Utt = 0.00 – maximum ratio of factored tensile force and tensile resistance determined from all appropriate failure modes Uts = 0.09 – maximum ratio of factored shear force and shear resistance determined from all appropriate failure modes Detailed result for A8 Anchor tensile resistance (ACI 318-14 – 17.4.1) ϕNsa = ϕ ⋅ Ase,N ⋅ futa = 142.3 kN Nf = ≥ 11.2 kN Where: ϕ = 0.70 – resistance factor Ase,N = 245 mm2 – tensile stress area futa = 830.0 MPa – specified tensile strength of anchor steel: futa = min(860 MPa, 1.9 ⋅ fya , fu ) , where: fya = 660.0 MPa – specified yield strength of anchor steel fu = 830.0 MPa – specified ultimate strength of anchor steel 26 / 38 Project: BASE PLATE CONECTION DESIGN Project no: Author: Concrete breakout resistance of anchor in tension (ACI 318-14 – 17.4.2) The check is performed for group of anchors that form common tension breakout cone: A2, A4, A6, A8, A10 ϕNcbg = ϕ ⋅ AN c AN c0 ⋅ Ψed,N ⋅ Ψec,N ⋅ Ψc,N ⋅ Nb = 167.0 kN ≥ Nf g = 53.6 kN Where: Nf g = 53.6 kN – sum of tension forces of anchors with common concrete breakout cone area ϕ = 0.70 – resistance factor AN c = 749070 mm2 – concrete breakout cone area for group of anchors AN c0 = 422500 mm2 – concrete breakout cone area for single anchor not influenced by edges Ψed,N = 0.97 – modification factor for edge distance: a,min Ψed,N = min(0.7 + 0.3⋅c 1.5⋅hef , 1) , where: ca,min = 290 mm – minimum distance from the anchor to the edge s hef = min(hemb , max( ca,max 1.5 , 3 )) = 217 mm – depth of embedment, where: hemb = 300 mm – anchor length ca,max = 325 mm – maximum distance from the anchor to one of the three closest edges s = 144 mm – maximum spacing between anchors Ψec,N = 0.83 – modification factor for eccentrically loaded group of anchors Ψec,N = Ψecx,N ⋅ Ψecy,N , where: Ψecx,N = 2⋅e1 x,N = 0.83 – modification factor that depends on eccentricity in x-direction 1+ 3⋅hef ex,N = 66 mm – tension load eccentricity in x-direction Ψecy,N = 2⋅e1 y,N = 1.00 – modification factor that depends on eccentricity in y-direction 1+ 3⋅hef ey,N = 0 mm – tension load eccentricity in y-direction hef = 217 mm – depth of embedment Ψc,N = 1.00 – modification factor for concrete conditions Nb = 167.5 kN – basic concrete breakout strength of a single anchor in tension: Nb = kc ⋅ λa ⋅ fc′ ⋅ h1.5 ef , where: kc = 10.0 – coefficient for cast-in anchors λa = 1.00 – modification factor for lightweight concrete fc′ = 27.6 MPa – concrete compressive strength hef = 217 mm – depth of embedment 27 / 38 Project: BASE PLATE CONECTION DESIGN Project no: Author: Shear resistance (ACI 318-14 – 17.5.1) ϕVsa = ϕ ⋅ 0.6 ⋅ Ase,V ⋅ futa = 79.3 kN ≥ V = 1.2 kN Where: ϕ = 0.65 – resistance factor Ase,V = 245 mm2 – tensile stress area futa = 830.0 MPa – specified tensile strength of anchor steel: futa = min(860 MPa, 1.9 ⋅ fya , fu ) , where: fya = 660.0 MPa – specified yield strength of anchor steel fu = 830.0 MPa – specified ultimate strength of anchor steel Concrete pryout resistance (ACI 318-14 – 17.5.3) The check is performed for group of anchors on common base plate ϕVcp = ϕ ⋅ kcp ⋅ Ncp = 475.1 kN ≥ Vg = 7.0 kN Where: ϕ = 0.65 – resistance factor kcp = 2.00 – concrete pry-out factor Ncp = 365.5 kN – concrete cone tension break-out resistance in case all anchors are in tension Vg = 7.0 kN – sum of shear forces of anchors on common base plate Interaction of tensile and shear forces (ACI 318-14 – R17.6) Utt 5/3 + Uts 5/3 = 0.15 ≤ 1.0 Where: Utt = 0.32 – maximum ratio of factored tensile force and tensile resistance determined from all appropriate failure modes Uts = 0.01 – maximum ratio of factored shear force and shear resistance determined from all appropriate failure modes Detailed result for A9 Anchor tensile resistance (ACI 318-14 – 17.4.1) ϕNsa = ϕ ⋅ Ase,N ⋅ futa = 142.3 kN Nf = ≥ 0.0 kN Where: ϕ = 0.70 – resistance factor Ase,N = 245 mm2 – tensile stress area futa = 830.0 MPa – specified tensile strength of anchor steel: futa = min(860 MPa, 1.9 ⋅ fya , fu ) , where: fya = 660.0 MPa – specified yield strength of anchor steel fu = 830.0 MPa – specified ultimate strength of anchor steel 28 / 38 Project: BASE PLATE CONECTION DESIGN Project no: Author: Shear resistance (ACI 318-14 – 17.5.1) ϕVsa = ϕ ⋅ 0.6 ⋅ Ase,V ⋅ futa = 79.3 kN ≥ V = 0.5 kN Where: ϕ = 0.65 – resistance factor Ase,V = 245 mm2 – tensile stress area futa = 830.0 MPa – specified tensile strength of anchor steel: futa = min(860 MPa, 1.9 ⋅ fya , fu ) , where: fya = 660.0 MPa – specified yield strength of anchor steel fu = 830.0 MPa – specified ultimate strength of anchor steel 29 / 38 Project: BASE PLATE CONECTION DESIGN Project no: Author: Concrete shear breakout check (ACI 318-14 – 17.5.2) The check is performed for group of anchors that form common shear breakout cone: A1, A3, A5, A7, A9 ϕVcbg = ϕ ⋅ AV c AV c0 ⋅ Ψec,V ⋅ Ψed,V ⋅ Ψc,V ⋅ Ψh,V ⋅ Ψα,V ⋅ Vbr = 77.3 kN ≥ Vg = 7.0 kN Where: Vg = 7.0 kN – sum of shear forces of anchors on common base plate ϕ = 0.65 – resistance factor AV c = 487600 mm2 – projected concrete failure area of an anchor or group of anchors AV c0 = 320000 mm2 – projected concrete failure area of one anchor when not limited by corner influences, spacing or member thickness Ψec,V = 1.00 – modification factor for anchor groups loaded eccentrically in shear: Ψec,V = 1 2⋅e′ 1+ 3⋅c V , where: a1 e′V = 1 mm – shear load eccentricity ha ca2,max s ca1 = 267 mm ≤ max ( 1.5 , 1.5 , 3 ) – edge distance in direction of the load ha ca2,max s ca1 = 267 mm ≤ max ( 1.5 , 1.5 , 3 ) – edge distance in direction of the load ca2,max = 325 mm – larger of the two distances to the edges parallel to the direction of loading s = 150 mm – maximum spacing in direction 2 between fasteners within a group Ψed,V = 0.93 – modification factor for edge effect: ca2 Ψed,V = 0.7 + 0.3 ⋅ 1.5⋅c ≤ 1 , where: a1 ha , ca2,max , s ) – edge distance in direction of the load ca1 = 267 mm ≤ max ( 1.5 1.5 3 ha ca2,max s ca1 = 267 mm ≤ max ( 1.5 , 1.5 , 3 ) – edge distance in direction of the load ca2,max = 325 mm – larger of the two distances to the edges parallel to the direction of loading s = 150 mm – maximum spacing in direction 2 between fasteners within a group ca2 = 300 mm – edge distance in direction perpendicular to the load Ψc,V = 1.00 – modification factor for concrete conditions Ψh,V = 1.00 – modification factor for anchors located in a shallow concrete member: 1.5⋅ca1 ha Ψh,V = ≥ 1 , where: ha = 400 mm – thickness of member in which an anchor is anchored measured parallel to anchor axis Ψα,V = 1.00 – modification factor for anchors loaded at an angle with the concrete edge 1 (cos αV )2 +(0.5⋅sin αV )2 Ψα,V = , where: αV = 1.7 ° – angle between direction of shear force and direction perpendicular to concrete edge Vb = 84.6 kN – basic concrete breakout strength of a single anchor in shear: 30 / 38 Project: BASE PLATE CONECTION DESIGN Project no: Author: Vb = min(0.6 ⋅ ( dlea )0.2 ⋅ λa ⋅ da ⋅ fc′ ⋅ c1.5 fc′ ⋅ c1.5 a1 , 3.7 ⋅ λa ⋅ a1 ) , where: le = 160 mm – effective length da = 20 mm – anchor diameter λa = 1.00 – modification factor for lightweight concrete fc′ = 27.6 MPa – concrete compressive strength ha ca2,max s ca1 = 267 mm ≤ max ( 1.5 , 1.5 , 3 ) – edge distance in direction of the load ha ca2,max s ca1 = 267 mm ≤ max ( 1.5 , 1.5 , 3 ) – edge distance in direction of the load ca2,max = 325 mm – larger of the two distances to the edges parallel to the direction of loading s = 150 mm – maximum spacing in direction 2 between fasteners within a group Concrete pryout resistance (ACI 318-14 – 17.5.3) The check is performed for group of anchors on common base plate ϕVcp = ϕ ⋅ kcp ⋅ Ncp = 475.1 kN ≥ Vg = 7.0 kN Where: ϕ = 0.65 – resistance factor kcp = 2.00 – concrete pry-out factor Ncp = 365.5 kN – concrete cone tension break-out resistance in case all anchors are in tension Vg = 7.0 kN – sum of shear forces of anchors on common base plate Interaction of tensile and shear forces (ACI 318-14 – R17.6) Utt 5/3 + Uts 5/3 = 0.02 ≤ 1.0 Where: Utt = 0.00 – maximum ratio of factored tensile force and tensile resistance determined from all appropriate failure modes Uts = 0.09 – maximum ratio of factored shear force and shear resistance determined from all appropriate failure modes Detailed result for A10 Anchor tensile resistance (ACI 318-14 – 17.4.1) ϕNsa = ϕ ⋅ Ase,N ⋅ futa = 142.3 kN Nf = ≥ 6.6 kN Where: ϕ = 0.70 – resistance factor Ase,N = 245 mm2 – tensile stress area futa = 830.0 MPa – specified tensile strength of anchor steel: futa = min(860 MPa, 1.9 ⋅ fya , fu ) , where: fya = 660.0 MPa – specified yield strength of anchor steel fu = 830.0 MPa – specified ultimate strength of anchor steel 31 / 38 Project: BASE PLATE CONECTION DESIGN Project no: Author: Concrete breakout resistance of anchor in tension (ACI 318-14 – 17.4.2) The check is performed for group of anchors that form common tension breakout cone: A2, A4, A6, A8, A10 ϕNcbg = ϕ ⋅ AN c AN c0 ⋅ Ψed,N ⋅ Ψec,N ⋅ Ψc,N ⋅ Nb = 167.0 kN ≥ Nf g = 53.6 kN Where: Nf g = 53.6 kN – sum of tension forces of anchors with common concrete breakout cone area ϕ = 0.70 – resistance factor AN c = 749070 mm2 – concrete breakout cone area for group of anchors AN c0 = 422500 mm2 – concrete breakout cone area for single anchor not influenced by edges Ψed,N = 0.97 – modification factor for edge distance: a,min Ψed,N = min(0.7 + 0.3⋅c 1.5⋅hef , 1) , where: ca,min = 290 mm – minimum distance from the anchor to the edge s hef = min(hemb , max( ca,max 1.5 , 3 )) = 217 mm – depth of embedment, where: hemb = 300 mm – anchor length ca,max = 325 mm – maximum distance from the anchor to one of the three closest edges s = 144 mm – maximum spacing between anchors Ψec,N = 0.83 – modification factor for eccentrically loaded group of anchors Ψec,N = Ψecx,N ⋅ Ψecy,N , where: Ψecx,N = 2⋅e1 x,N = 0.83 – modification factor that depends on eccentricity in x-direction 1+ 3⋅hef ex,N = 66 mm – tension load eccentricity in x-direction Ψecy,N = 2⋅e1 y,N = 1.00 – modification factor that depends on eccentricity in y-direction 1+ 3⋅hef ey,N = 0 mm – tension load eccentricity in y-direction hef = 217 mm – depth of embedment Ψc,N = 1.00 – modification factor for concrete conditions Nb = 167.5 kN – basic concrete breakout strength of a single anchor in tension: Nb = kc ⋅ λa ⋅ fc′ ⋅ h1.5 ef , where: kc = 10.0 – coefficient for cast-in anchors λa = 1.00 – modification factor for lightweight concrete fc′ = 27.6 MPa – concrete compressive strength hef = 217 mm – depth of embedment 32 / 38 Project: BASE PLATE CONECTION DESIGN Project no: Author: Shear resistance (ACI 318-14 – 17.5.1) ϕVsa = ϕ ⋅ 0.6 ⋅ Ase,V ⋅ futa = 79.3 kN ≥ V = 0.6 kN Where: ϕ = 0.65 – resistance factor Ase,V = 245 mm2 – tensile stress area futa = 830.0 MPa – specified tensile strength of anchor steel: futa = min(860 MPa, 1.9 ⋅ fya , fu ) , where: fya = 660.0 MPa – specified yield strength of anchor steel fu = 830.0 MPa – specified ultimate strength of anchor steel Concrete pryout resistance (ACI 318-14 – 17.5.3) The check is performed for group of anchors on common base plate ϕVcp = ϕ ⋅ kcp ⋅ Ncp = 475.1 kN ≥ Vg = 7.0 kN Where: ϕ = 0.65 – resistance factor kcp = 2.00 – concrete pry-out factor Ncp = 365.5 kN – concrete cone tension break-out resistance in case all anchors are in tension Vg = 7.0 kN – sum of shear forces of anchors on common base plate Interaction of tensile and shear forces (ACI 318-14 – R17.6) Utt 5/3 + Uts 5/3 = 0.15 ≤ 1.0 Where: Utt = 0.32 – maximum ratio of factored tensile force and tensile resistance determined from all appropriate failure modes Uts = 0.01 – maximum ratio of factored shear force and shear resistance determined from all appropriate failure modes Weld sections Item Edge Xu Th [mm] Ls [mm] L [mm] Lc [mm] Loads Fn [kN] ϕRn [kN] Ut [%] Status BP1 M3 E70xx ◢4.0 ◢5.7 107 5 LE1 4.1 5.4 75.7 OK M4-arc 8 M3 E70xx ◢2.8◣ ◢4.0◣ 613 3 LE1 1.7 2.3 75.6 OK BP1 M4 E70xx ◢2.8◣ ◢4.0◣ 1237 5 LE1 3.4 4.5 75.7 OK E70xx ◢2.8◣ ◢4.0◣ 613 3 LE1 1.5 2.0 74.9 OK E70xx ◢2.8◣ ◢4.0◣ 1233 5 LE1 3.0 4.0 75.3 OK 33 / 38 Project: BASE PLATE CONECTION DESIGN Project no: Author: Symbol explanation Th Throat thickness of weld Ls Leg size of weld L Length of weld Lc Length of weld critical element Fn Force in weld critical element ϕRn Weld resistance AISC 360-16 J2.4 Ut Utilization Detailed result for BP1 / M3 - 1 Weld resistance check (AISC 360-16: J2-4) ϕRn = ϕ ⋅ Fnw ⋅ Awe = 5.4 kN ≥ Fn = 4.1 kN Where: Fnw = 353.9 MPa – nominal stress of weld material: Fnw = 0.6 ⋅ FEXX ⋅ (1 + 0.5 ⋅ sin1.5 θ) , where: FEXX = 482.6 MPa – electrode classification number, i.e. minimum specified tensile strength θ = 35.6° – angle of loading measured from the weld longitudinal axis Awe = 20 mm2 – effective area of weld critical element ϕ = 0.75 – resistance factor for welded connections Detailed result for M4-arc 8 / M3 - 1 Weld resistance check (AISC 360-16: J2-4) ϕRn = ϕ ⋅ Fnw ⋅ Awe = 2.3 kN ≥ Fn = 1.7 kN Where: Fnw = 412.4 MPa – nominal stress of weld material: Fnw = 0.6 ⋅ FEXX ⋅ (1 + 0.5 ⋅ sin1.5 θ) , where: FEXX = 482.6 MPa – electrode classification number, i.e. minimum specified tensile strength θ = 63.6° – angle of loading measured from the weld longitudinal axis Awe = 7 mm2 – effective area of weld critical element ϕ = 0.75 – resistance factor for welded connections 34 / 38 Project: BASE PLATE CONECTION DESIGN Project no: Author: Detailed result for BP1 / M4 - 1 Weld resistance check (AISC 360-16: J2-4) ϕRn = ϕ ⋅ Fnw ⋅ Awe = 4.5 kN ≥ Fn = 3.4 kN Where: Fnw = 414.3 MPa – nominal stress of weld material: Fnw = 0.6 ⋅ FEXX ⋅ (1 + 0.5 ⋅ sin1.5 θ) , where: FEXX = 482.6 MPa – electrode classification number, i.e. minimum specified tensile strength θ = 64.9° – angle of loading measured from the weld longitudinal axis Awe = 14 mm2 – effective area of weld critical element ϕ = 0.75 – resistance factor for welded connections Detailed result for BP1 / M4 - 2 Weld resistance check (AISC 360-16: J2-4) ϕRn = ϕ ⋅ Fnw ⋅ Awe = 2.0 kN ≥ Fn = 1.5 kN Where: Fnw = 368.1 MPa – nominal stress of weld material: Fnw = 0.6 ⋅ FEXX ⋅ (1 + 0.5 ⋅ sin1.5 θ) , where: FEXX = 482.6 MPa – electrode classification number, i.e. minimum specified tensile strength θ = 41.7° – angle of loading measured from the weld longitudinal axis Awe = 7 mm2 – effective area of weld critical element ϕ = 0.75 – resistance factor for welded connections Detailed result for / - 2 Weld resistance check (AISC 360-16: J2-4) ϕRn = ϕ ⋅ Fnw ⋅ Awe = 4.0 kN ≥ Fn = 3.0 kN Where: Fnw = 372.2 MPa – nominal stress of weld material: Fnw = 0.6 ⋅ FEXX ⋅ (1 + 0.5 ⋅ sin1.5 θ) , where: FEXX = 482.6 MPa – electrode classification number, i.e. minimum specified tensile strength θ = 43.5° – angle of loading measured from the weld longitudinal axis Awe = 14 mm2 – effective area of weld critical element ϕ = 0.75 – resistance factor for welded connections Concrete block Item CB 1 Loads LE1 A1 [mm2] 148164 A2 [mm2] 706009 σ [MPa] Ut [%] 0.5 Status 1.5 OK 35 / 38 Project: BASE PLATE CONECTION DESIGN Project no: Author: Symbol explanation A1 Loaded area A2 Supporting area σ Average stress in concrete Ut Utilization Detailed result for CB 1 Concrete block compressive resistance check (AISC 360-16 Section J8) ϕc fp,max = 30.5 MPa ≥ σ= 0.5 MPa Where: fp,max = 46.9 MPa – concrete block design bearing strength: fp,max = 0.85 ⋅ fc′ ⋅ fc′ A2 A1 ≤ 1.7 ⋅ fc′ , where: = 27.6 MPa – concrete compressive strength A1 = 148164 mm2 – base plate area in contact with concrete surface A2 = 706009 mm2 – concrete supporting surface ϕc = 0.65 – resistance factor for concrete Buckling Buckling analysis was not calculated. Cost estimation Steel Steel grade Total weight [kg] Unit cost [US$/kg] Cost [US$] 27.22 2.50 68.05 Total weight [kg] Unit cost [US$/kg] Cost [US$] 4.54 6.00 27.24 A572 Gr.55 Bolts Bolt assembly 20 A325M Welds Throat thickness [mm] Leg size [mm] Total weight [kg] Unit cost [US$/kg] Cost [US$] Fillet rear 4.0 5.7 0.01 45.00 0.61 Double fillet 2.8 4.0 0.23 45.00 10.49 Weld type Hole drilling Bolt assembly cost [US$] 27.24 Percentage of bolt assembly cost [%] Cost [US$] 30.0 8.17 36 / 38 Project: BASE PLATE CONECTION DESIGN Project no: Author: Cost summary Cost [US$] Cost estimation summary Total estimated cost 114.56 Bill of material Manufacturing operations Plates [mm] Name BP1 Shape P15.0x300.8-768.5 (A572 Gr.55) Welds [mm] Nr. 1 Length [mm] Fillet: a = 4.0 107.2 CUT1 Double fillet: a = 2.8 615.2 CUT2 Double fillet: a = 2.8 1241.5 Bolts Nr. 20 A325M 10 Welds Type Throat thickness [mm] Material Leg size [mm] Length [mm] Fillet E70xx 4.0 5.7 107.2 Double fillet E70xx 2.8 4.0 1856.7 Anchors Name 20 A325M Length [mm] Drill length [mm] Count 315 300 10 Drawing BP1 37 / 38 Project: BASE PLATE CONECTION DESIGN Project no: Author: P15.0x769-301 (A572 Gr.55) Code settings Item Value Unit Reference Friction coefficient - concrete 0.40 - ACI 349 – B.6.1.4 Friction coefficient in slip-resistance 0.30 - AISC 360-16 J3.8 Limit plastic strain 0.05 - Weld stress evaluation Plastic redistribution Detailing No Distance between bolts [d] 2.66 - AISC 360-16 – J3.3 Distance between bolts and edge [d] 1.25 - AISC 360-16 – J.3.4 Concrete breakout resistance check Both Base metal capacity check at weld fusion face No AISC 360-16: J2-2 Cracked concrete Yes ACI 318-14 – Chapter 17 Local deformation check No Local deformation limit 0.03 Geometrical nonlinearity (GMNA) Yes - CIDECT DG 1, 3 - 1.1 Analysis with large deformations for hollow section joints 38 / 38