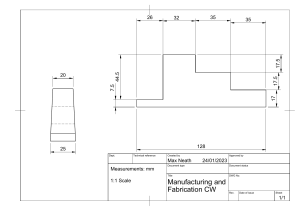

Inspection Body of NCNDT Standard Operating Procedure Doc Ref: NCNDT/IB/SOP 28/VT 01/ DVT QM Chapter: Date:19/06/2023 Page: 1/6 5.1.3 Title: Visual Testing - Direct visual testing Rev: 00 RELEASE AUTHORIZATION This Standard Operating Procedure is released under the authority of Director – NCNDT and is a property of the National Centre for Non-Destructive Testing, Sri Lanka Atomic Energy Board. Prepared by: Reviewed by: Name : Name : Position : OIC – VT Laboratory Position : OIC – Inspection Signature : Signature : Date : Date : Authorized by: Issued by: Name : M.A.K.Jayathilaka Name : Sisara Sanjeewani Position : Director – NCNDT Position : CQM – SLAEB Signature : Signature : Date : Date : DISTRIBUTION LIST The followings are the authorized holders of the controlled copy of the Standard Operating Procedure. Designation of the holder of controlled copy: 1. Corporate Quality Manager – SLAEB 2. Director – NCNDT 3. Deputy Quality Manager of IB of NCNDT 4. Officer In Charge – NDT Inspection 5. Officer In Charge – VT Laboratory Authorized by: Issued by: Inspection Body of NCNDT Standard Operating Procedure Doc Ref: NCNDT/IB/SOP 28/VT 01/ DVT QM Chapter: Date:19/06/2023 Page: 2/6 5.1.3 Title: Visual Testing - Direct visual testing Rev: 00 Contents 1) Amendment Sheet 2 2) Scope 3 3) References 3 4) Personnel Qualifications 3 5) Apparatus 3 6) Purpose of the Test 3 7) Test conditions and Calibration 3 8) Application of the Test 4 9) Recording and Reporting of Results 4 10) Safety 4 Authorized by: Issued by: Inspection Body of NCNDT Standard Operating Procedure Doc Ref: NCNDT/IB/SOP 28/VT 01/ DVT QM Chapter: Date:19/06/2023 Page: 3/6 5.1.3 Title: Visual Testing - Direct visual testing Rev: 00 1. Amendment Sheet IN Page No Authorized by: Clause No Date Amendment Issued by: Authorizing Issuing Inspection Body of NCNDT Standard Operating Procedure Doc Ref: NCNDT/IB/SOP 28/VT 01/ DVT QM Chapter: Date:19/06/2023 Page: 4/6 5.1.3 Title: Visual Testing - Direct visual testing Rev: 00 2. Scope This procedure provides the guidelines for performing Visual Testing (VT) technique, Direct Visual Examination. In particular, this procedure is followed to perform a visual testing of materials including non-metals, metals and their alloys such as carbon steel, stainless steel, aluminium etc. 3. References - ASME Boiler and Pressure Vessel Code, Section V, Article 9: Curent Edition – Visual Examination EN 13018 : Non-destructive Testing - Visual Testing - General Principles EN ISO 5817 : EN ISO 17637 : Non-destructive testing of welds – Visual testing of fusion-welded joints ISO 9712 : Current Edition – Non-destructive Testing – Qualification and Certification of NDT Personnel or any standard/code agreed upon between the NDT group and the client 4. Personnel Qualification Personnel performing examinations per this guide shall be qualified and certified per ISO 9712, or as specified in the contract or purchase order. 5. Equipment and Accessories 5.1 Visual Testing Tool Kit The visual testing tool kit composes of tools including a ruler, micrometre screw gauge, V-WAC gauge 5.2 Illumination source A torch is used to improve the light intensity Magnifying Glass Mirror 6. Purpose of the Test The visual testing method is used for the examination of the Weld materials and surface quality of materials. (to determine the surface condition of the part, alignment of mating surfaces, shape, or evidence of leaking) 7. Test Conditions 7.1 Surface Condition of the Weld and Heat-Affected Zone The surface of the area to be inspected comprises of weld bead plus heat affected zone (HAZ) on each side. The surface of the area to be examined shall be clean and free from rust and foreign material/spatters on both the inside (where accessible) and outside. Authorized by: Issued by: Inspection Body of NCNDT Standard Operating Procedure Doc Ref: NCNDT/IB/SOP 28/VT 01/ DVT QM Chapter: Date:19/06/2023 Page: 5/6 5.1.3 Title: Visual Testing - Direct visual testing Rev: 00 7.2 Visible Light Intensity The intensity of the visible light at the surface of the part/workpiece undergoing examination should be a minimum of 100 fc (1076 lux) unless provided by the code. 7.3 Calibration of Equipment The equipment (micrometre screw gauge, V-WAC gauge) which are used for visual inspection, examination and testing shall be calibrated annually. 8. Application of the Test 8.1 Direct visual testing The direct visual is performed when placing the eye within 24 in. (600 mm) of the surface to be examined. The angle between the plane of the eye placement and the object shall be beyond not less than 30°. Mirrors can be used to improve the visual angle and magnification aids such as lenses can be used. 8.2 Accept/Reject Criteria Defects revealed in the radiographs will be evaluated according to relevant accept/reject criteria of applicable code or any other document provided by the client. 8.3 Post-Examination Requirements When the testing activities are ended, all examined areas will be as clean as that before testing. 8.4 Limitations of Visual Testing Method Only the surface discontinuities can be examined. Smaller flaws are difficult to detect. 9. Recording and Reporting of Results 9.1 When specified, a procedure should be written for all visual examinations and should include as a minimum the following information. A sketch is usually used for illustrating part geometry, techniques, and areas for examination. This sketch may also be used for recording the location of discontinuities. Visual testing reports are prepared for the official record. Results of the VT inspection are reported in a proper format. A typical Report Form may include the following as a minimum: Unique report number Test specimen characteristics such as material, dimensions, wall thickness, and sketch. VT equipment. VT technique/s followed. Eye placement Light meter identification (Manufacturer, model, serial number) Light source and intensity on the test specimen Results obtained. Signing personnel. Authorized by: Issued by: Inspection Body of NCNDT Standard Operating Procedure Doc Ref: NCNDT/IB/SOP 28/VT 01/ DVT QM Chapter: Date:19/06/2023 Page: 6/6 5.1.3 Title: Visual Testing - Direct visual testing Rev: 00 Report distribution. 9.2 Written Reports —written reports shall be prepared as agreed upon between the testing agency and the purchaser/user. 9.3 The standard report format is recorded in NCNDT/IB/File No 03/FM 10. Safety 10.1 General Safety Precautions Before testing in industrial areas, always wear safety helmets and safety shoes if necessary. Observe the necessary precautions against electrical shock. Always ensure that there are no “live wires” (exposed or without insulation) present in the area where the testing is being conducted. Electrical hazards by ignition of combustible materials may be kept in view. Be careful in pulling long electrical cords used for electrical extensions, especially in cutting corners. The cord might accidentally come in contact with sharp objects that might uncover the cord and thus expose the wires. Avoid working on wet grounds or floors. If such areas cannot be avoided, place pieces of plywood over the wet surfaces before doing the testing. Authorized by: Issued by: